High-pressure reaction kettle

A high-pressure reaction kettle and kettle body technology, which is applied in chemical/physical/physical-chemical stationary reactors, pressure vessel components, pressure vessels/vacuum vessels, etc. system, can not solve the problem of agitator wear and other problems, to achieve the effect of reducing volume, ensuring reaction conditions, and preventing fluid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

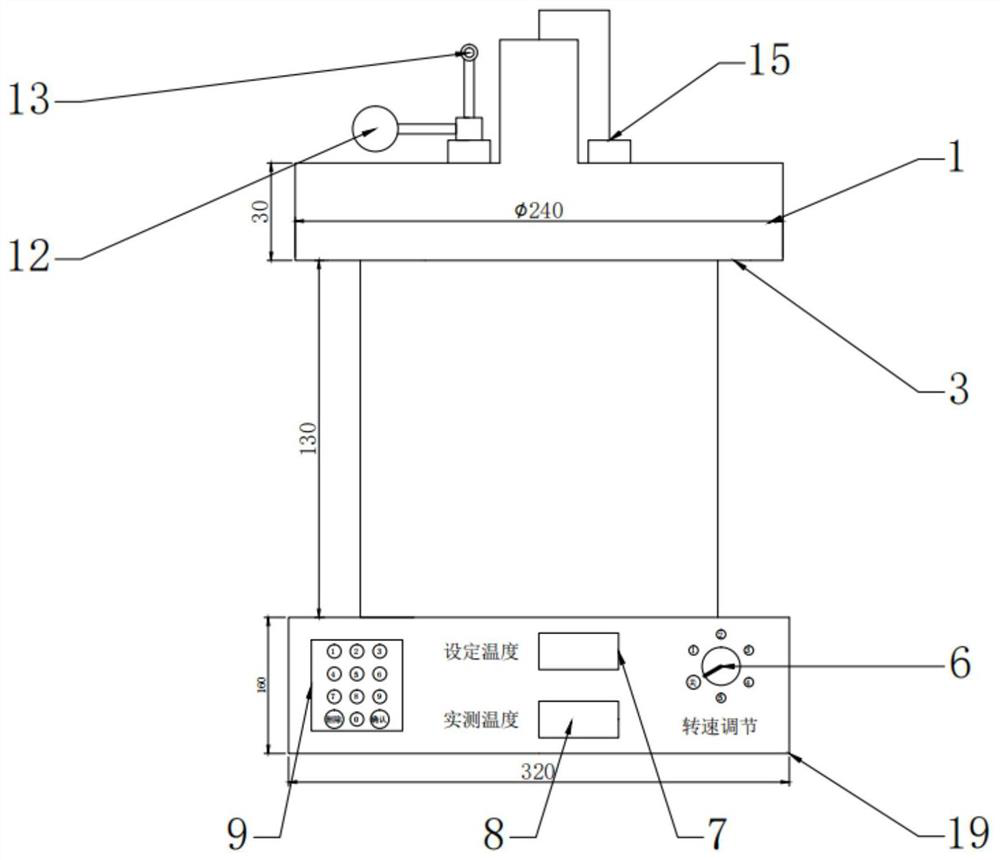

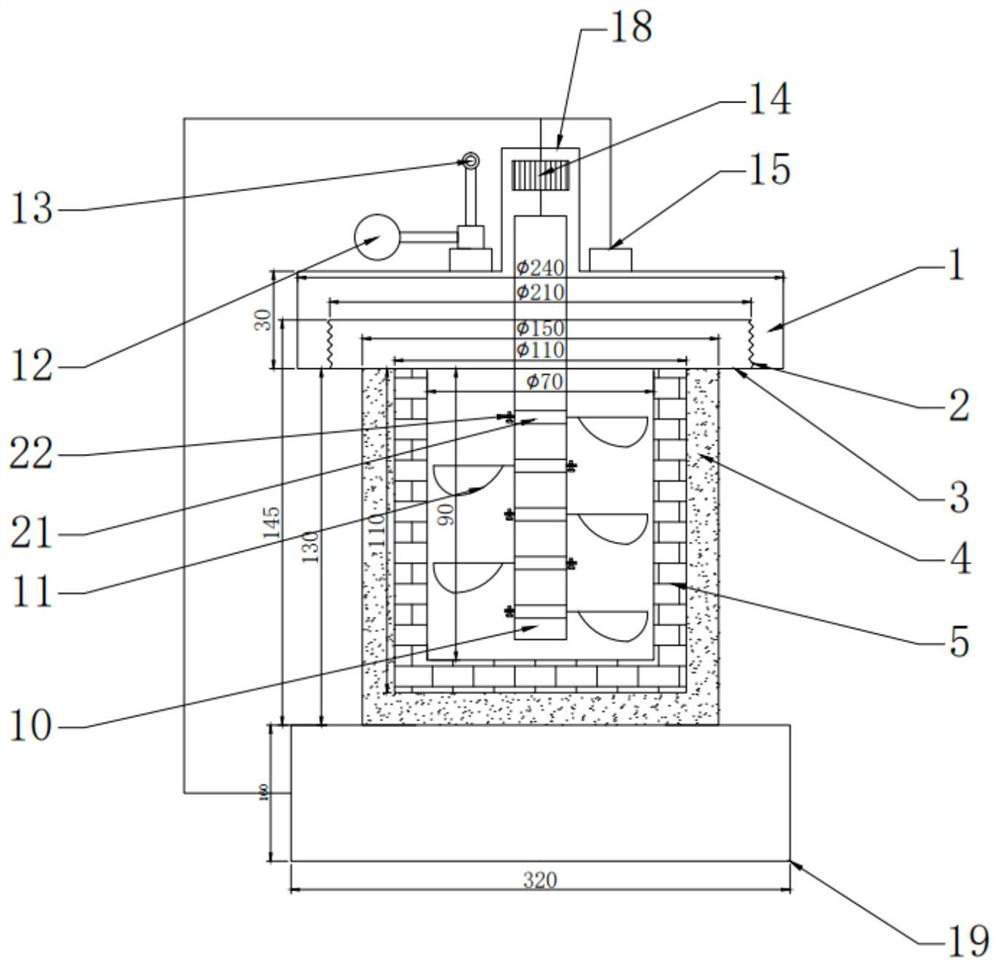

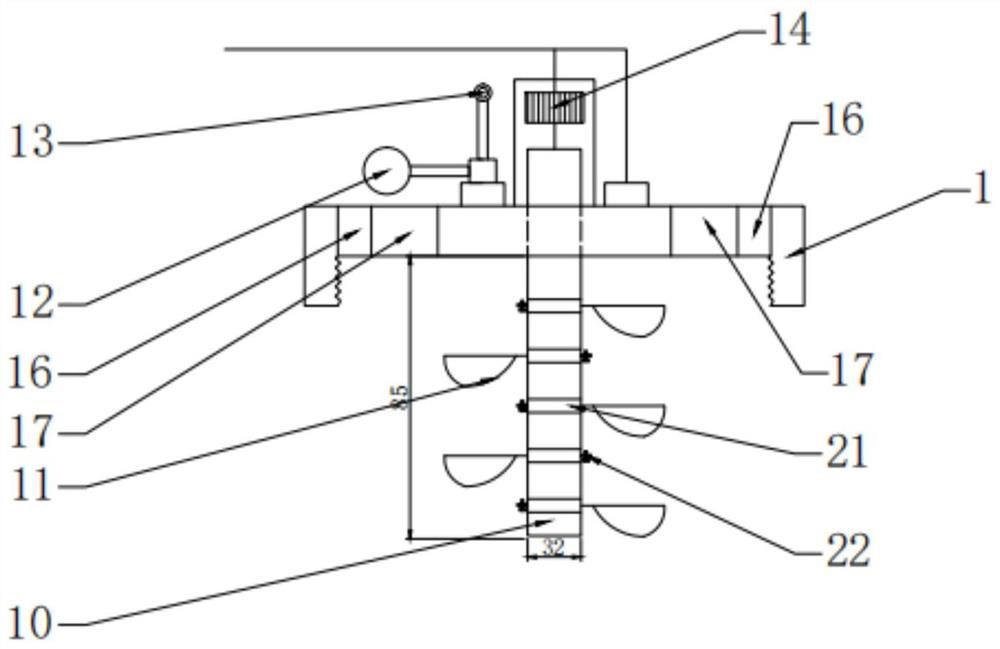

[0034] Embodiment 1: as Figure 1-5 As shown in one of them, a high-pressure reaction kettle of the present invention comprises a kettle body 3 and a kettle cover 1, and the kettle cover 1 is connected to the top of the kettle cover 1 by a thread 2, and a magnetic force is connected between the kettle cover 1 and the kettle body 3. The sealing assembly, the kettle body 3 includes an insulation layer 4, a heating layer 5 and an inner container in sequence from the outside to the inside, and the central axis inside the kettle body 3 is connected with a stirring shaft for rotation, and the stirring shaft is placed on the kettle cover 1 The driving system 14 drives the rotation, and the stirring blade 11 is fixed on the stirring shaft. The stirring shaft is an electric heating rod 10 , and the heating layer 5 , the electric heating rod 10 and the driving system 14 are respectively electrically connected to the control panel 19 .

[0035] The control panel 19 has a numeric keypad 9...

Embodiment 2

[0045] Embodiment 2: The structure is basically the same as that of Embodiment 1, the difference is that the stirring shaft in this embodiment is no longer an electric heating rod, that is, it only has a common stirring function. The liner of the kettle body is made of polytetrafluoroethylene material, and has four types of 150ml, 200ml, 250ml, and 300ml. In this embodiment, a 300ml liner is selected to be placed in the center of the reaction kettle, and the pressure inside the kettle body is designed as 8Mpa~12Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com