Spherical hinged support for opening and closure of door

A hinge seat and spherical technology, applied in the field of spherical hinge seat, can solve the problems of high processing and manufacturing costs, door leaf displacement, wear of pin shaft and pin hole, etc., achieve convenient processing and installation, maintain automatic centering, and compensate for spherical wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

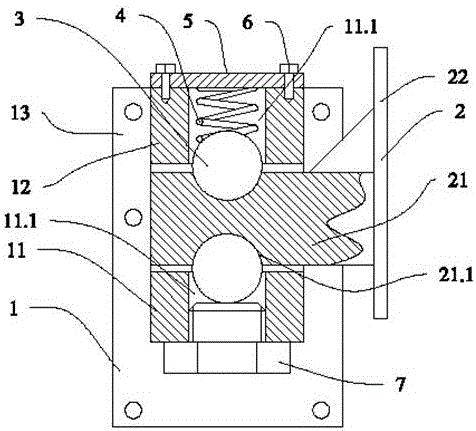

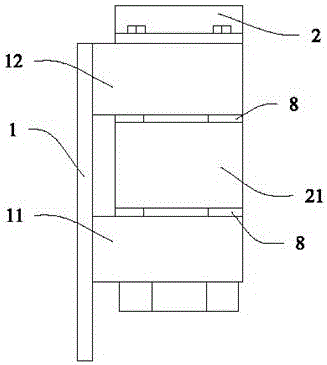

[0026] See attached figure 1 And attached figure 2 , A spherical hinge seat used for opening and closing the door body of the present invention consists of a fixed hinge seat 1, a movable hinge seat 2, a steel ball 3, a compression spring 4, a flange plate 5, a screw 6, and a plug bolt.

[0027] Wherein, the fixed hinge base 1 and the movable hinge base 2 form a conjoined structure. On the connecting base plate 13 of the fixed hinge seat 1, a hinge sleeve is fixedly connected. The sleeves 12, 11 have perforations 11.1 of the same diameter and the same axis.

[0028] On the connecting bottom plate 22 of the movable hinge seat 2, there is fixedly connected an intermediate hinge sleeve 21, which is located between the lower hinge sleeve 11 and the upper hinge sleeve 12, and at the upper and lower ends of the middle hinge sleeve 21, the coaxial The set has a hemispherical notch 21.1.

[0029] Two identical steel balls 3 are respectively placed in the upper and lower hemispher...

Embodiment 2

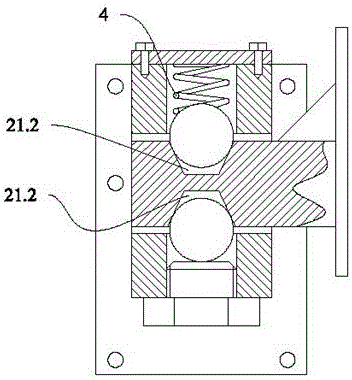

[0033] See attached image 3 , as a modification, the difference between this embodiment and the first embodiment is that: on the upper and lower ends of the middle hinge sleeve 21, a conical notch 21.1 with an outward opening is provided on the coaxial line.

Embodiment 3

[0035] See attached Figure 4 , as a modification, the difference between the present embodiment and the second embodiment is that the compression spring 4 is replaced by a rubber pad 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com