Planetary roller screw with clearance eliminating nut

A technology of anti-backlash nuts and planetary rollers, which is applied to belts/chains/gears, mechanical equipment, transmission devices, etc., to achieve the effects of wear compensation, convenient manufacture, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

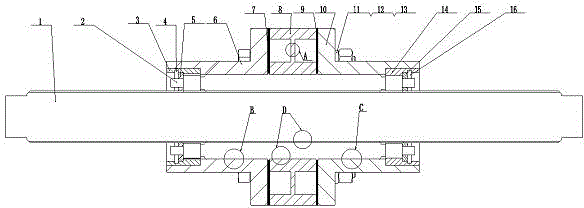

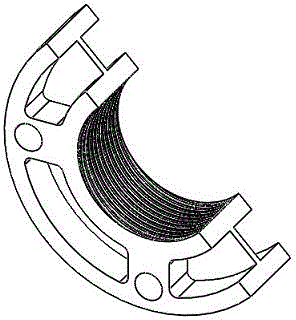

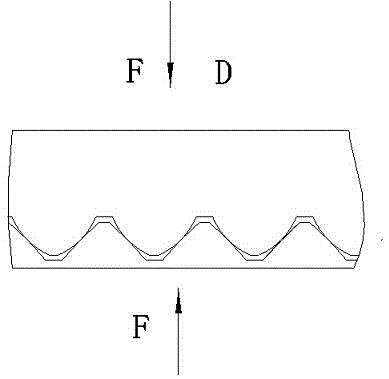

[0024] refer to figure 1 , figure 2 , a specific embodiment of the present invention is: in a planetary roller screw pair composed of a screw 1 and a nut assembly, several columnar helical rollers 2 are evenly distributed in the screw 1 and the nut assembly . Wherein the nut assembly is composed of a half nut 6, an elastic element 7, an anti-backlash nut 8, an elastic element 9, and a half nut 10 through bolt connectors 11, 12, 13. The nut assembly composed of the half nut 6, the anti-backlash nut 8 and the half nut 9 has a continuous helix, and has multi-thread threads, the tooth shape is triangular, and the tooth shape angle is 90°. The external thread of the screw has the same number of starts and profile as the internal thread of the nut assembly. Roller 2 is a single-line thread, and the tooth profile is a double-arc shape. The roller, lead screw, and nut assemblies have the same pitch. In order to eliminate the tilting moment of the roller caused by the helix angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com