Floating finishing-machining grinding head with controllable grinding force

A technology of finishing and grinding force, used in grinding/polishing equipment, grinding heads, metal processing equipment, etc. Effect of finishing efficiency and machining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described by taking the most preferred example as an example, so as to better understand the present invention.

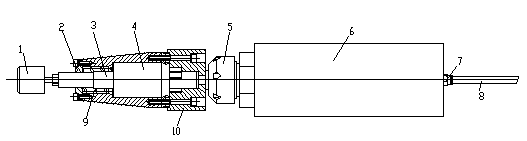

[0018] The controllable grinding force floating finishing grinding head of the present invention structurally includes a grinding head body, a high-speed rotating electric spindle 6 , a pressure control system and a floating finishing tool 1 .

[0019] The grinding head body is composed of a rolling spline shaft 3, a spline sleeve 4, a grinding head shell, a compensating spring 9, a connecting base 10 and an end cover 2. The rolling spline sleeve 4 is fixed in the shell of the grinding head, the rolling spline shaft 3 is arranged in the spline sleeve 4, and can move back and forth along the axis of the rolling spline sleeve 4, and the connecting base 10 is connected with the rolling spline sleeve 4 and the grinding head through bolts. The head shell is fixedly connected, and the compensation spring 9 is threaded on the stepped shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com