An automatic tight packing polished rod sealer

A polished rod sealer and packing technology, used in sealing/packing, wellbore/well components, earth-moving drilling, etc. Achieve the effect of low manufacturing cost, avoid excessive wear and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

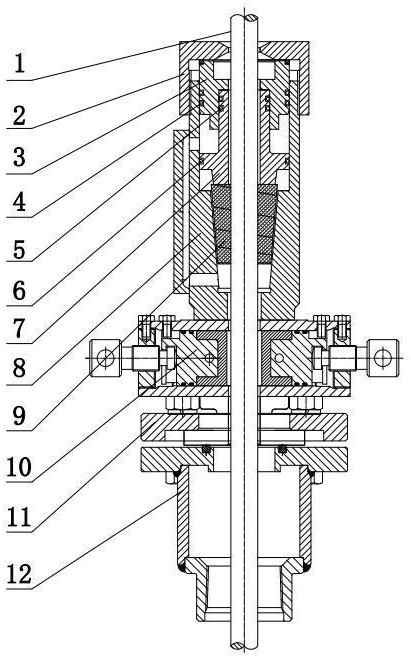

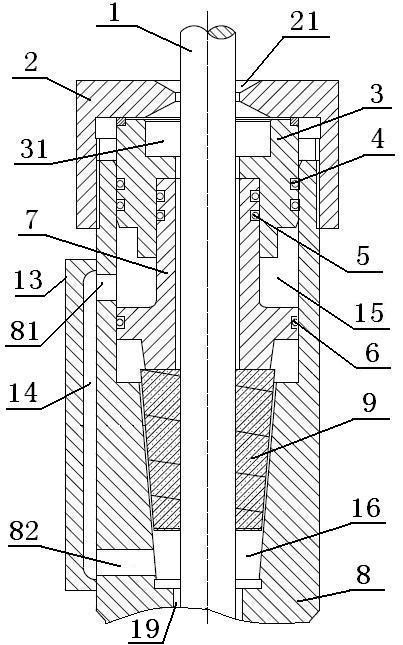

[0028] Such as figure 1 and figure 2 As shown, an automatic tight-packing polished rod sealer is mainly composed of a lower joint 12, a deflection adjustment mechanism 11, an auxiliary sealing mechanism 10, a packing box 8 and a packing pressing cap 2 which are sequentially set on the polished rod 1. The root box 8 and the packing pressing cap 2 are threadedly connected, wherein the auxiliary sealing mechanism 10, the deflection adjustment mechanism 11 and the lower joint 12 below the packing box 8 are all existing components. The auxiliary sealing mechanism 10 is mainly used to cut off the pressure oil under the packing 9 when the packing 9 needs to be replaced, and the deviation adjustment mechanism 11 is mainly used to prevent the polished rod 1 from eccentrically grinding the seal of the polished rod sealer, and the sealing of the polished rod sealer The component refers to the packing 9 in this embodiment, and the lower joint 12 is connected with the well head of the oi...

Embodiment 2

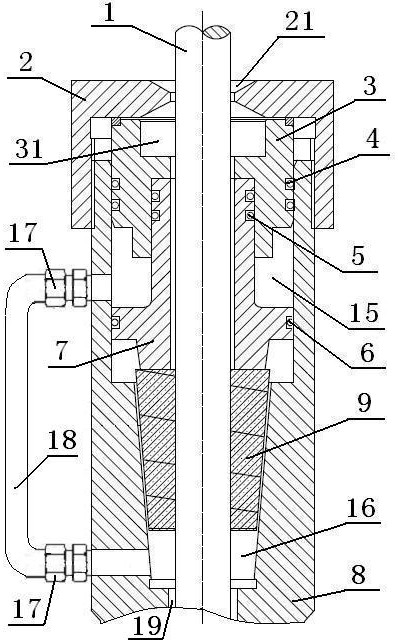

[0035] An automatic tight packing polished rod sealer. The difference between this embodiment and the first embodiment is that the lower through hole 82 and the upper through hole 81 are connected through the connecting pipe 18, and the connecting pipe 18 can be a hydraulic rubber hose, etc., and the connecting pipe 18 The two ends of each are respectively connected with the lower through hole 82 and the upper through hole 81 through joints. By adopting the above solution, the structure is simple, the manufacture is convenient, and the layout of the lower through hole 82 and the upper through hole 81 is not limited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com