Automatic compensation method of bottom dead center of turret punch press

A technology of automatic compensation and turret punching machine, which is applied in the direction of presses, metal processing equipment, forming tools, etc., can solve problems such as die edge collapse, workpiece size out of tolerance, and failure of accelerated punching machines, so as to ensure the depth of die entry, Effect of automatic compensation of wear amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

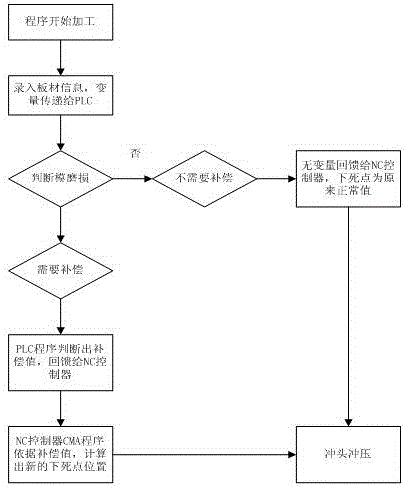

[0018] An automatic compensation method for the bottom dead point of a turret punch press, comprising the following steps:

[0019] C. When the turret punch program starts, the CMA program of the NC controller enters the information of different plates, and defines the wear amount Ⅰ of the mold core corresponding to the different plates, and transmits the wear amount Ⅰ as a variable Ⅰ to the PLC controller;

[0020] D. The PLC controller receives the variable Ⅰ, and the PLC controller judges the number of times the mold core is used, selects the wear amount II of the corresponding mold core, and judges whether automatic compensation of the bottom dead center position is required according to the wear amount II, and if compensation is not required When no variable is fed back to the NC controller, the bottom dead center is the original normal value; when compensation is required, the wear amount II is fed back to the NC controller as variable II, and the NC controller accepts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com