Flexible fixture base capable of achieving quick changing of fixture

A quick-change fixture and fixture technology, applied in the direction of manufacturing tools, auxiliary devices, vehicle parts, etc., can solve the problems of inability to compensate for electrode wear, high production costs, and no movable mechanism, so as to quickly locate electrode wear and reduce production. The effect of input cost and automatic compensation of electrode wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

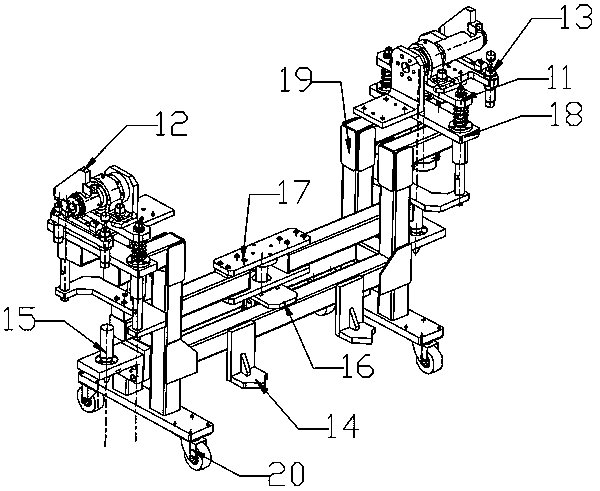

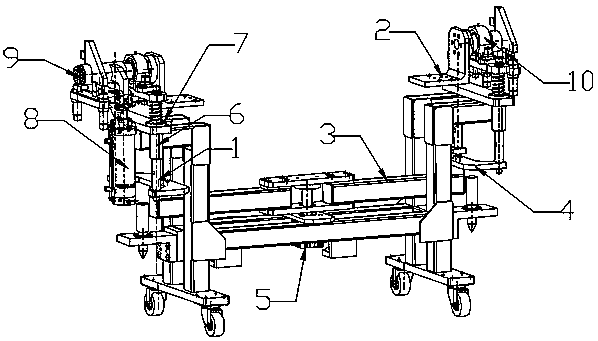

[0012] Such as figure 1 , figure 2 As shown, the fixture base 19 of the present invention mainly includes a floating mechanism, an overturning mechanism, and a quick positioning device.

[0013] The cylinder body of the floating mechanism jacking cylinder 5 is fixed on the lower end of the fixture base 19 and the middle position below the mounting plate 16, and the upper end of the piston rod is connected to the square tubes 3 on the left and right sides of the connecting plate 17 through the two ends of the connecting plate 17. , the lower connecting plate 4 located above the other end of the square tube 3 is respectively connected to the steps at the lower ends of the two guide posts 1, and the four guide rods 1 on the left and right sides of the square tube 3 slide and cooperate with the guide sleeve 6 to ensure that the floating device goes up and down. Smooth floating, the four springs 7 are installed on the four guide posts 1 respectively, between the upper connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com