Main unit of numerical control notching press

A punching machine and host technology, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of difficult to control the indexing accuracy, can not meet the requirements of CNC punching machine, etc., to achieve convenient operation, maintain accuracy, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

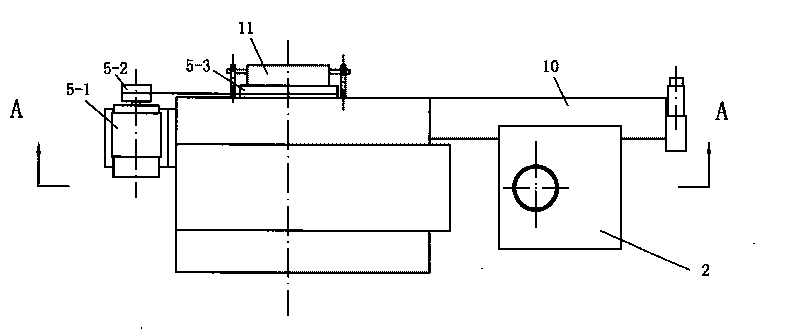

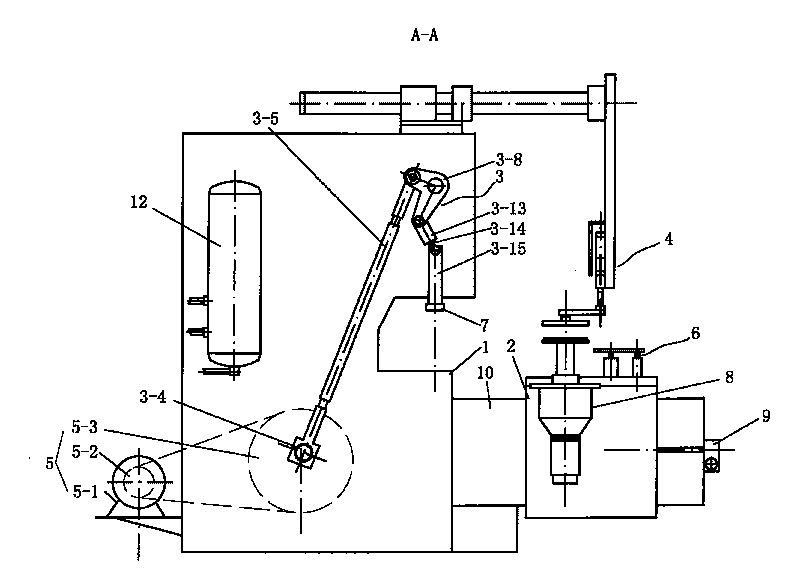

[0021] attached Figure 1~2 The illustrated embodiment comprises a frame 1, a workbench 2, a punch 7, an indexing device 8, a stamping device that drives the punch 7 to move up and down, and a radial feed device 9 that drives the workbench 2 to move. In addition, It includes an air pressure system 12, a tablet pressing device 4 and a tablet unloading device 6 controlled by air pressure.

[0022] A rail arm 10 is provided on one side of the frame 1 , and the workbench 2 is slidably connected to the rail arm 10 .

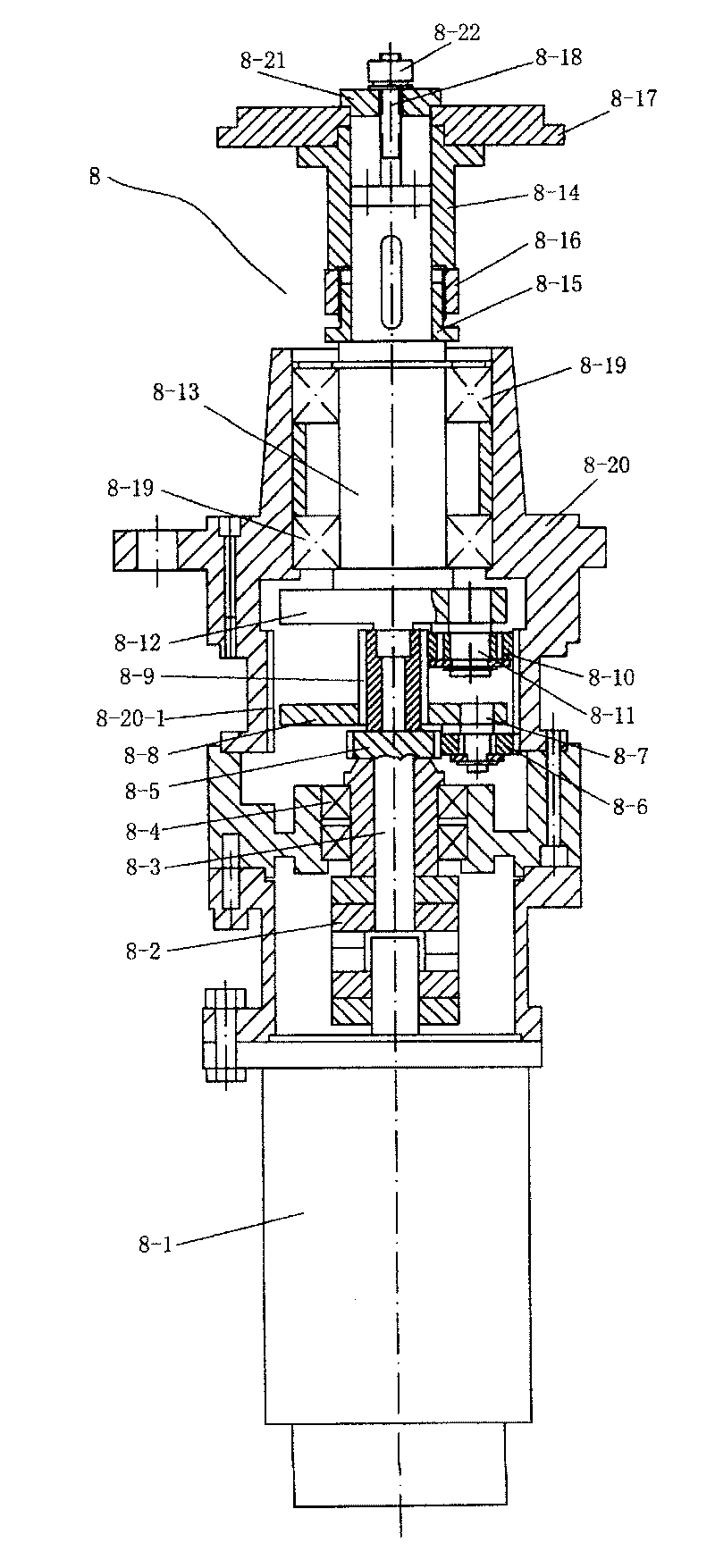

[0023] See image 3 , the above-mentioned indexing device 8 has an indexing servo motor 8-1 and a housing 8-20 fixed on the workbench, the housing 8-20 is provided with a planetary reduction mechanism for two-stage reduction, and the planetary reduction mechanism has an input shaft 8-3, the central gear 8-5 fixed on the input shaft 8-3, 3 to 4 evenly distributed primary planetary gears 8-6 meshed with the primary central gear 8-5, fixed on the primary planetary gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com