Low-wear rotary compensator

A rotary compensator, low-wear technology, used in pipeline expansion compensation devices, adjustable connections, pipes/pipe joints/pipe fittings, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

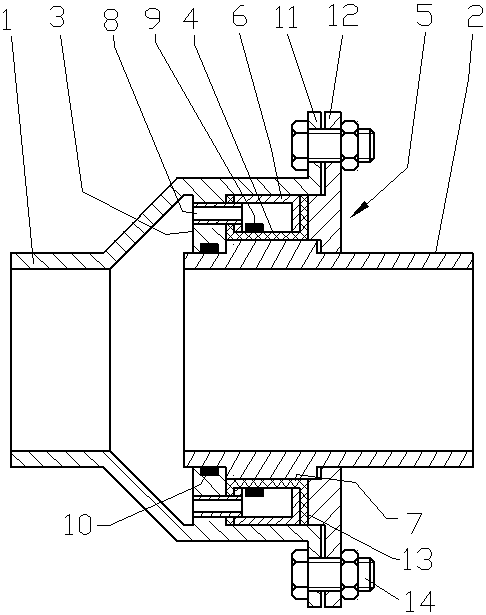

[0008] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

[0009] A low-wear rotary compensator, which includes an outer cylinder 1 and an inner cylinder 2. The outer cylinder has a variable diameter structure. The left section of the inner cylinder is located in the large diameter section of the outer cylinder. It is characterized in that the outer wall of the inner cylinder is covered with a rubber sleeve 4 , the outer wall of the rubber sleeve is covered with a pressure-bearing cylinder 5, and the left and right ends of the pressure-bearing cylinder extend radially inward respectively with a left annulus and a right annulus, and the inner circles of the left annulus and the right annulus are connected with the inner circle of the rubber sleeve. The outer wall is in contact, and the left and right ends of the rubber sleeve extend radially outward respectively to a left flange and a right flange, and the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com