Height adjusting device using in mechanical unit for screening combustible material

A technology for height adjustment devices and flammable materials, applied in conveyors, transportation and packaging, etc., can solve the problems of narrow working space, economic loss, inconvenient replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

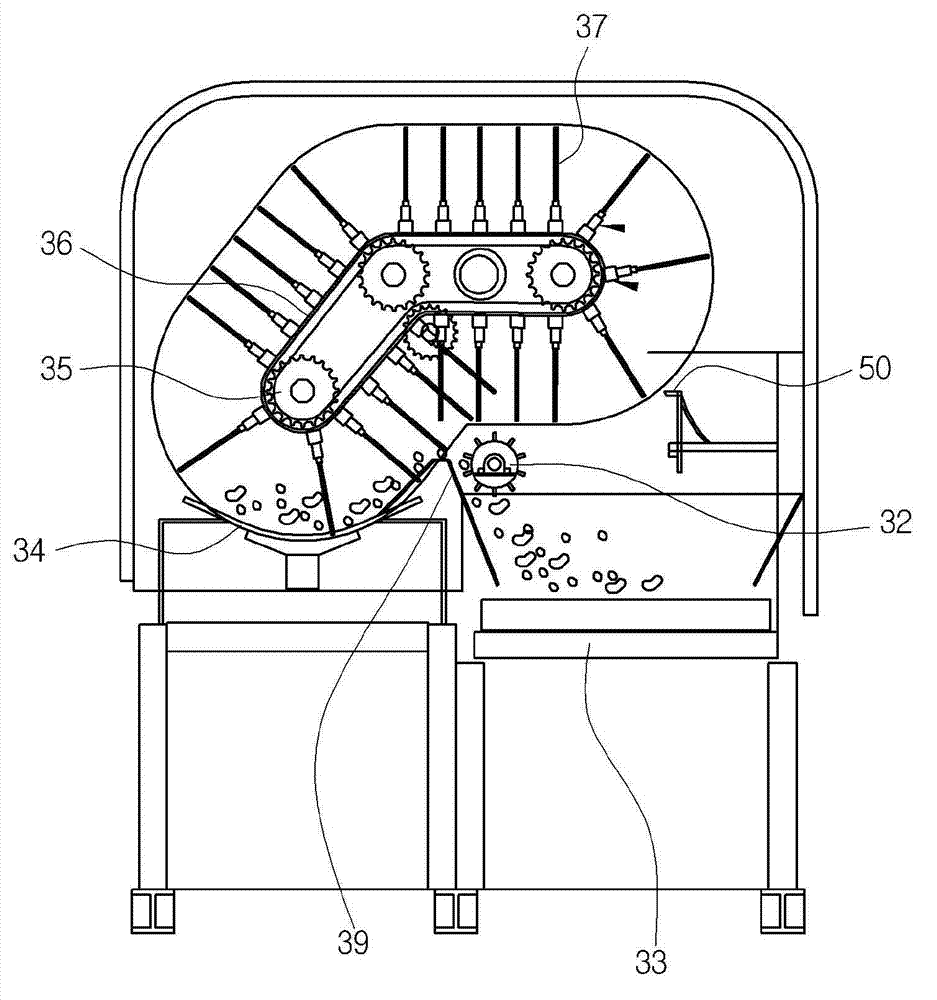

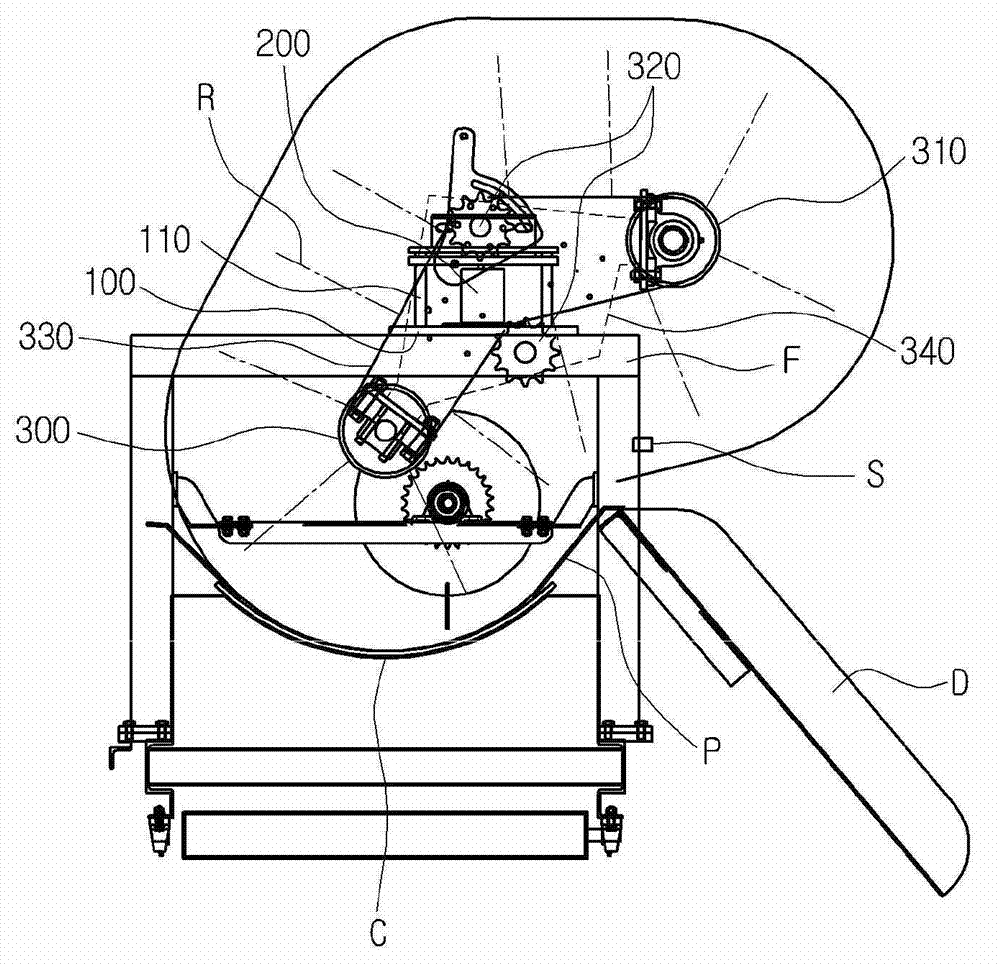

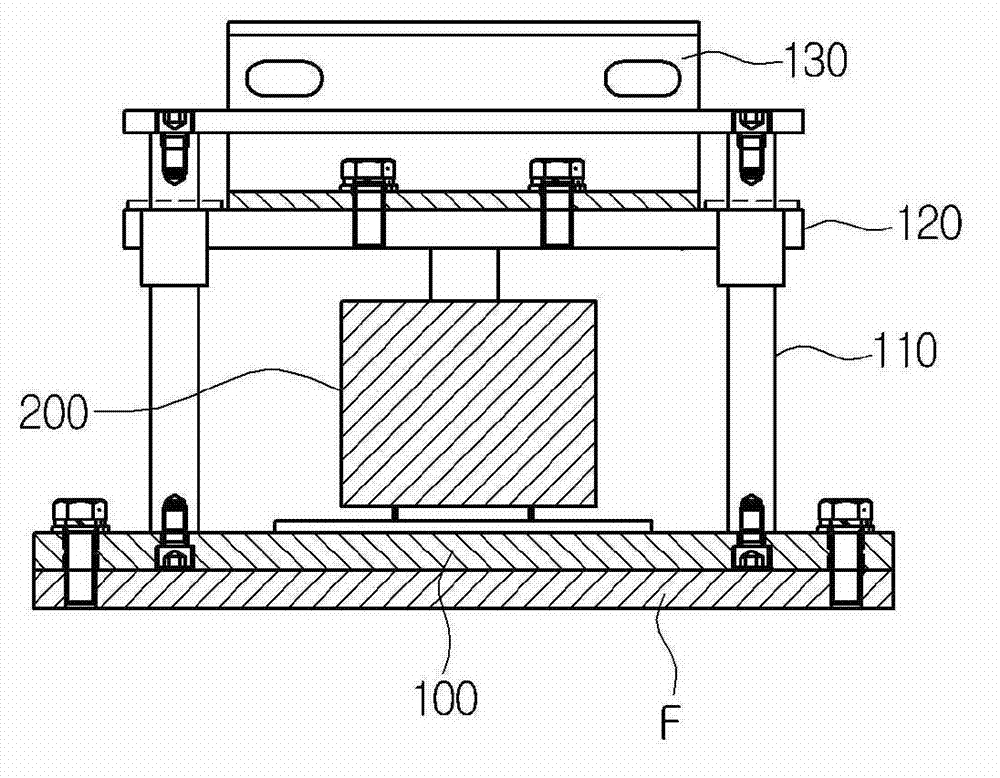

[0025] Hereinafter, a description will be given in detail about the height adjusting device for a mechanical combustible material sorter according to the present invention with reference to the accompanying drawings.

[0026] Such as figure 2 with image 3 As shown, the height adjustment device for a mechanical combustible material sorter according to the present invention mainly includes a base frame 100 .

[0027] The base frame 100 is rigidly fixed to the main frame F constituting the rake arrangement.

[0028] At this time, the main frame F has: a casing (not shown) formed therein; a mixed material conveyor C installed in the casing like a conventional machine; a discharge chute D along the A direction perpendicular to the longitudinal direction of the mixed material conveyor C is provided on one side; and a connecting plate P provided in a space between the mixed material conveyor C and the discharge chute D to pass through the steps to prevent the formation of empty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com