Magnetic seal

A magnetic and magnet technology, applied in the direction of engine seals, bearing components, engine components, etc., can solve problems such as inability to refuel or repair, affecting bearing service life, sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

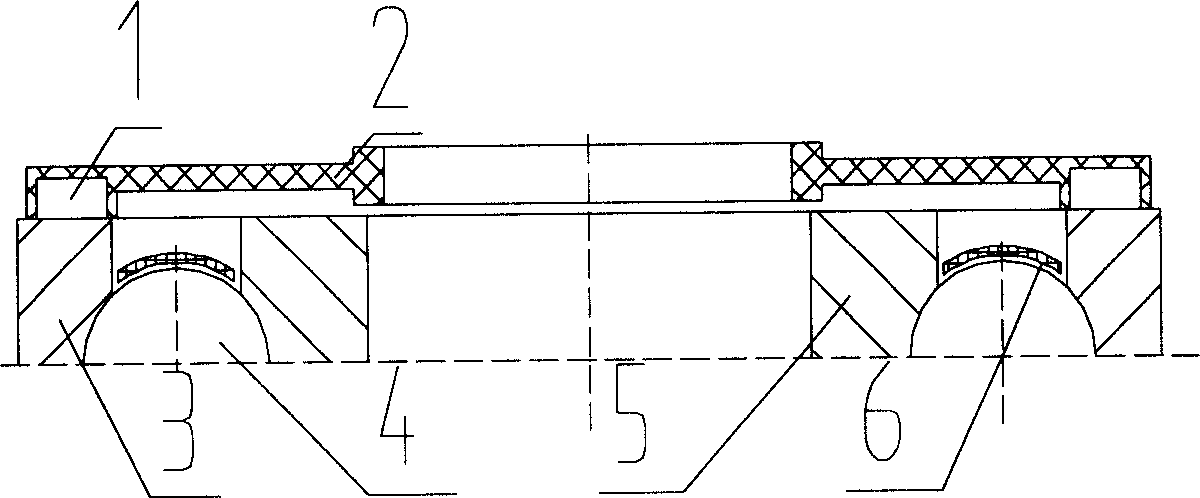

[0017] Embodiment 1: The magnetic seal has a circular base 2 with a magnet 1 on the base 2 .

[0018] There is a shaft hole at the center of the base body 2; there is a transition body between the shaft hole of the base body 2 and the magnet 1, and the transition body is corrugated. The magnet is in the form of a ring and is located on the edge of the substrate; the magnet is inlaid on the substrate. The bearing has an outer ring 3, an inner ring 5, rolling elements 4 and a cage 6, and the magnet 1 is attracted to the outer ring 3 of the bearing.

[0019] When in use, the central shaft does not move, and the outer ring of the bearing rotates together with the rotating object. Since the inner hole of the magnetic seal is bundled on the shaft and fits tightly with the shaft, no relative movement occurs. The outer ring of the magnetic seal is in contact with the bearing under the action of magnetic force The outer ring is tightly fitted, and the base of the magnetic seal is made...

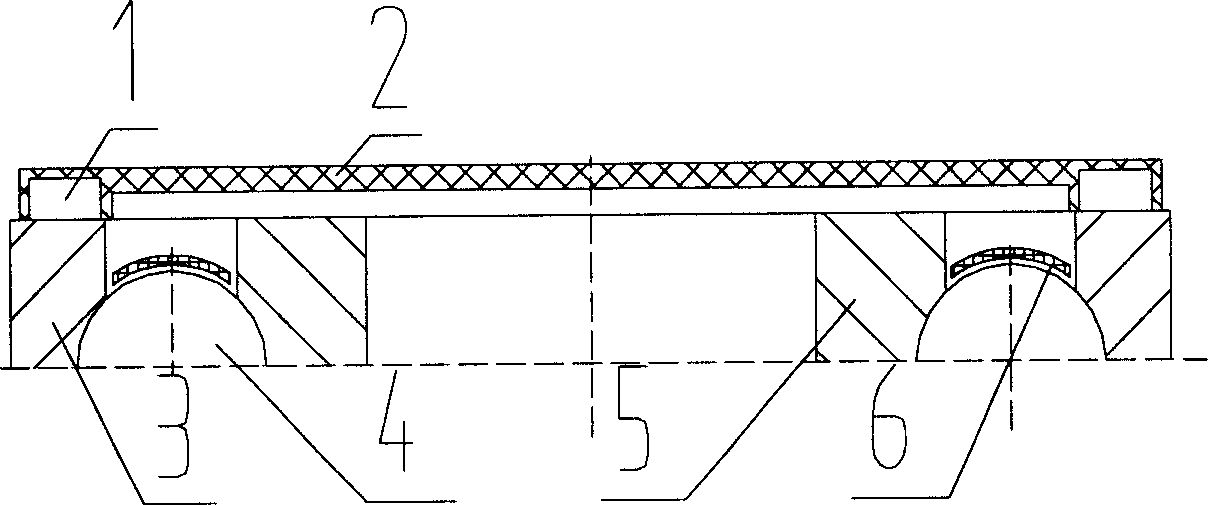

Embodiment 2

[0020] Embodiment 2: The base body 2 is a whole body, and the magnet 1 is a ring, located on the edge of the base body; the magnet is embedded on the base body. Others are the same as embodiment 1, omitted.

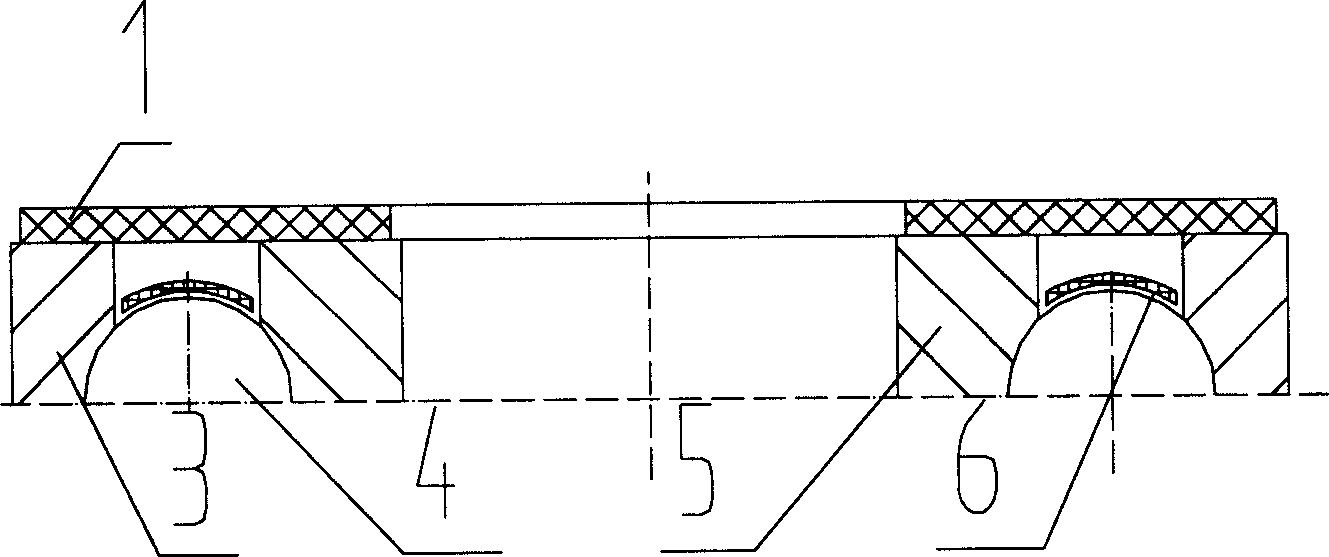

Embodiment 3

[0021] Embodiment 3: There is a shaft hole at the center of the base body 2, and the magnet 1 is ring-shaped and integrated with the base body. Others are the same as embodiment 1, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com