Stirrer magnetic fluid sealing device

A ferrofluid seal and mixer technology, which is applied to engine seals, mechanical equipment, engine components, etc., can solve problems such as poor sealing performance, reduced sealing effect, and low machine efficiency, so as to improve product qualification rate and production efficiency. The effect of prolonging the service life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

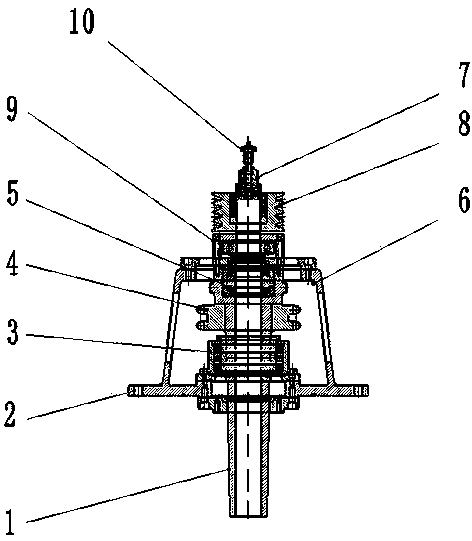

[0011] The magnetic fluid sealing device of the mixer is installed at the main transmission position of the mixer. The sealing structure is composed of an inner ring and an outer ring. The bearing pressure plate 6 is installed above the high-speed spindle 1. The high-speed spindle 1 is vertically installed in the pillow block 2. The high-speed spindle 1 Install the pulley 8, high-speed bearing housing 9, gear 4, and pillow block 2 from top to bottom in sequence, and the small magnetic seal is installed above the pulley and on the temperature control wiring guide. There is a small magnetic fluid seal 7 and an electronic slip ring 10 on the upper part of the pulley 8; the bearing pressure plate 6 under the high-speed bearing seat 9 is located on the pillow block 2, and the medium magnetic fluid seal 5, the gear 4, and the large No. magnetic flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com