Drum washing machine

A drum washing machine and washing machine technology, which is applied in the field of washing machines, can solve the problems of regular cleaning of the drum of the washing machine, and achieve the effect of saving water and taking and placing clothes conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

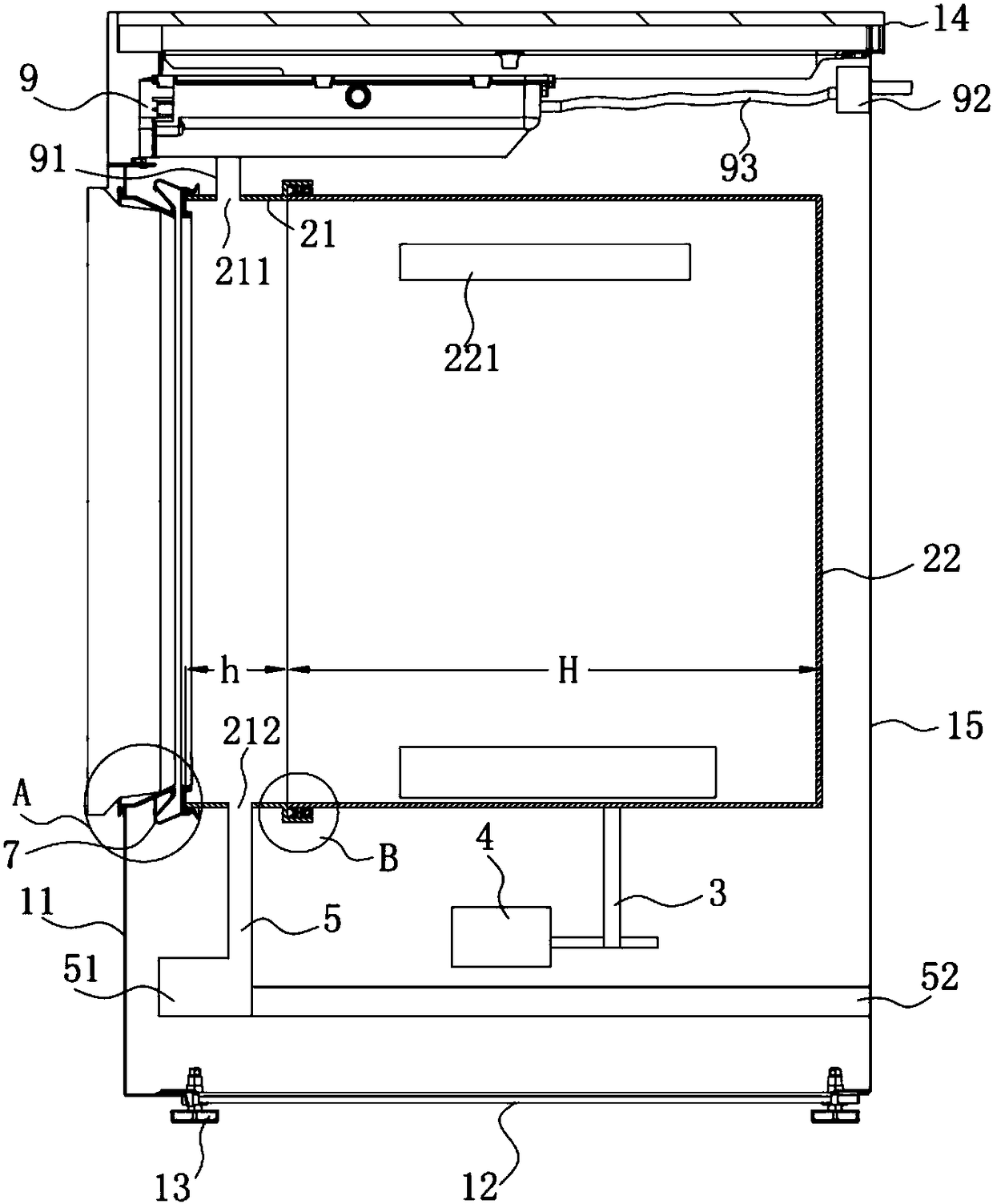

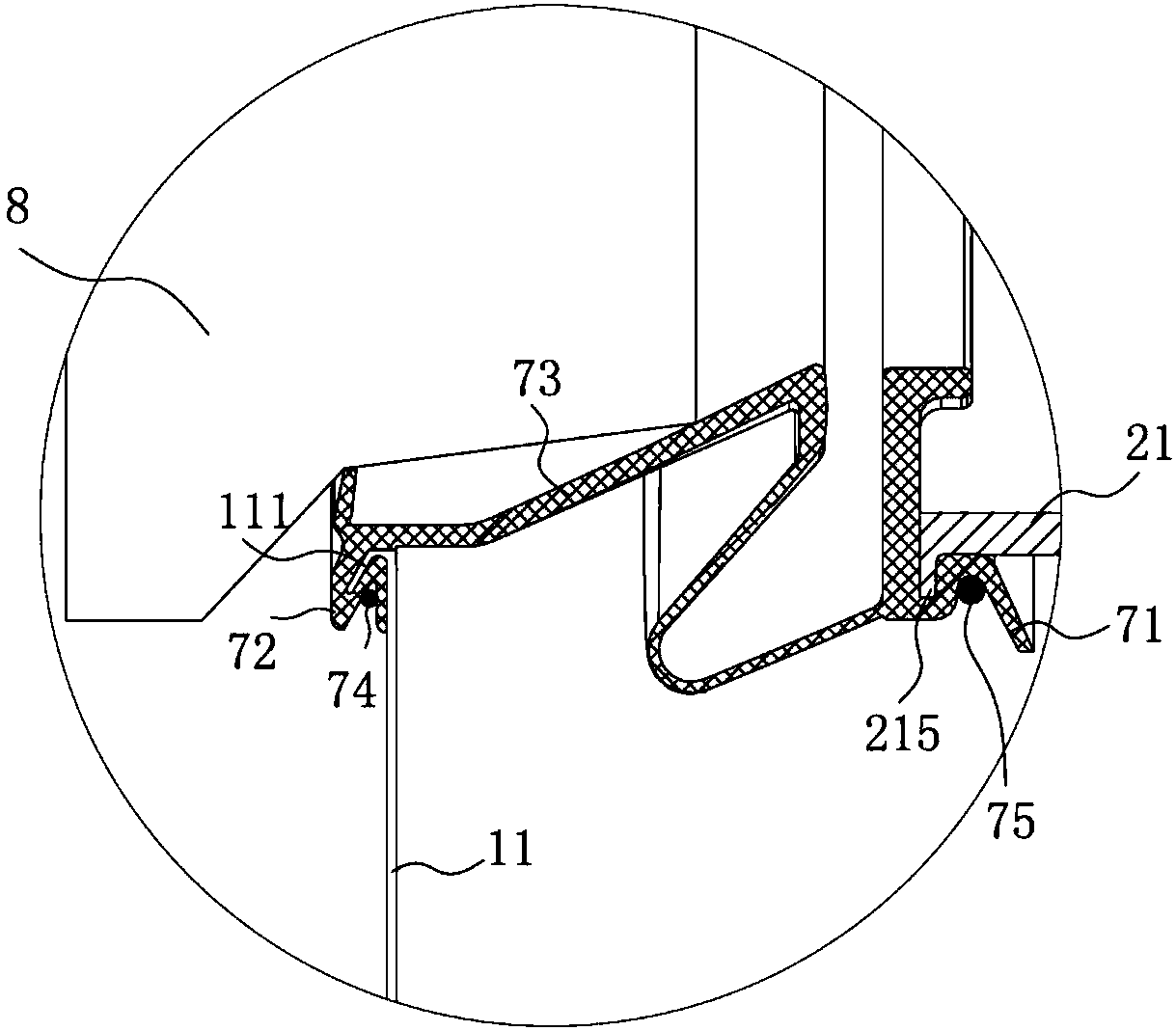

[0038] like Figure 1-4 As shown, this embodiment provides a drum washing machine, which can save regular cleaning of the dirt on the outer wall or inner wall of the washing tub, and at the same time save more water. The drum washing machine comprises a washing machine shell 1, and a washing drum is arranged in the washing machine shell 1 for rotating and cleaning clothes. The washing drum includes a washing front drum 21 and a washing rear drum 22, wherein the washing front drum 21 and the washing rear drum 22 are hermetically connected, and the washing machine The rear cylinder 22 is rotatable relative to the washing front cylinder 21, and the washing front cylinder 21 is still during the rotation of the washing rear cylinder 22, thereby ensuring that the water in the washing drum rotates with the washing rear cylinder 22 to play the role of washing clothes; 22 is connected with the motor 4 through the belt 3, and the washing cylinder 22 rotates with the motor 4, that is, th...

Embodiment 2

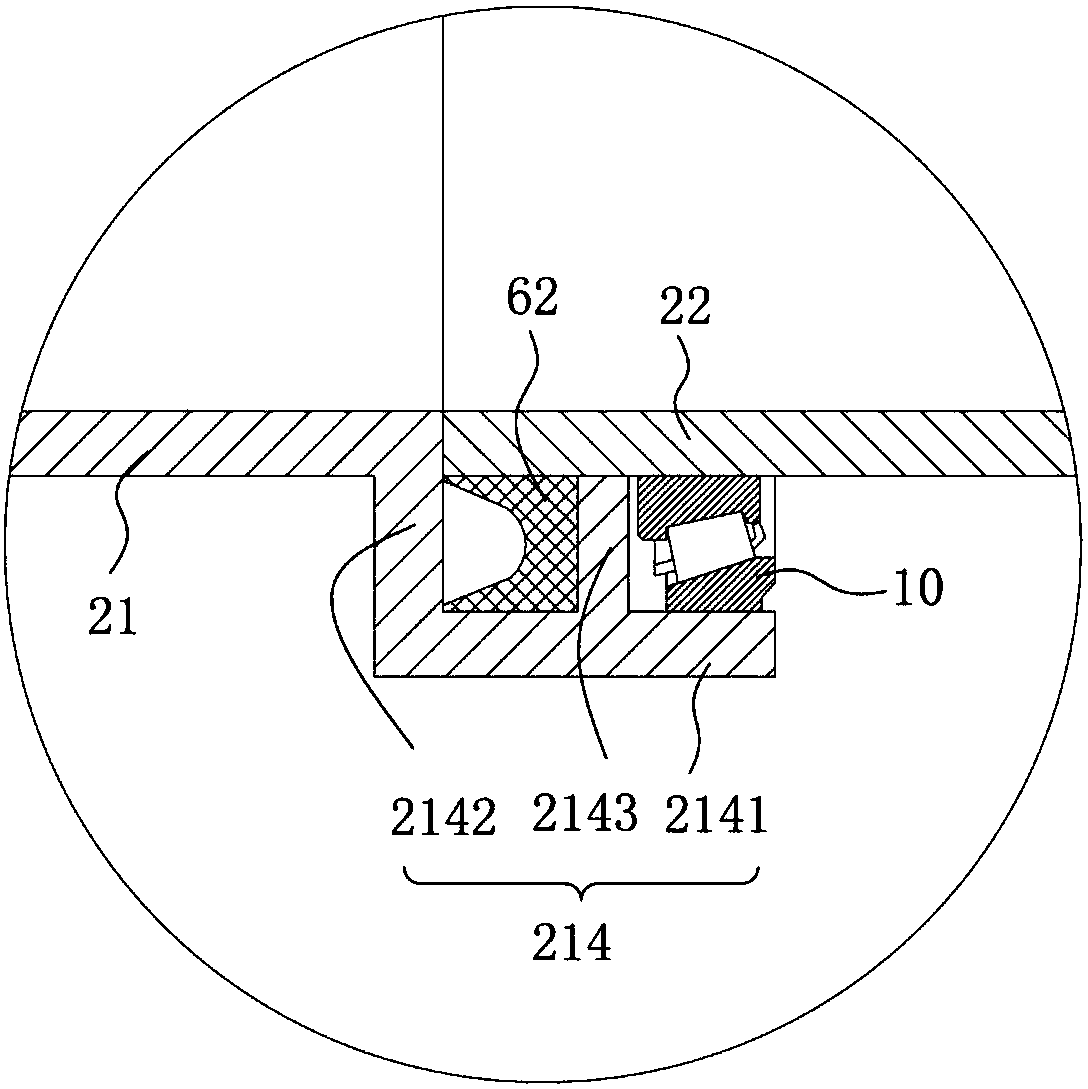

[0054] The difference from Embodiment 1 is that the sealing window gasket 7 is not provided in this embodiment. Since the sealing window gasket 7 is not provided, the drum washing machine provided in this embodiment is relatively simple to set at the door and window 8 of the drum washing machine in Embodiment 1. , wherein a sealing groove 213 is provided on the side wall where the washing front tub 21 is in contact with the washing machine door and window 8 (refer to Figure 5 , Image 6 ), the sealing groove 213 is provided with a first sealing ring 61 . After the door and window 8 are closed, the door and window 8 are in contact with the washing front tub, and since the side wall of the washing front tub 21 is provided with a first sealing ring 61, a static seal can be realized between the door and window 8 and the washing front tub 21 after closing.

[0055] Of course, in other embodiments, the sealing groove 213 can also be arranged on the side wall where the door and win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com