Screw compressor shaft seal with automatic compensation function

A screw compressor and automatic compensation technology, which is applied in the direction of machines/engines, sealing devices of piston pumps, mechanical equipment, etc., can solve the increase in the use cost and maintenance cost of screw compressors, and the wear of the contact surface between the shaft sleeve and the lip seal Increase the size of the lip seal and reduce the service life of the lip seal to solve the defects of the lip seal, reduce the cost of use and maintenance, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The applicant will describe in detail the specific implementation of the present invention below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution, and any changes made in form but not in substance according to the concept of the present invention should be regarded as the present invention. scope of protection.

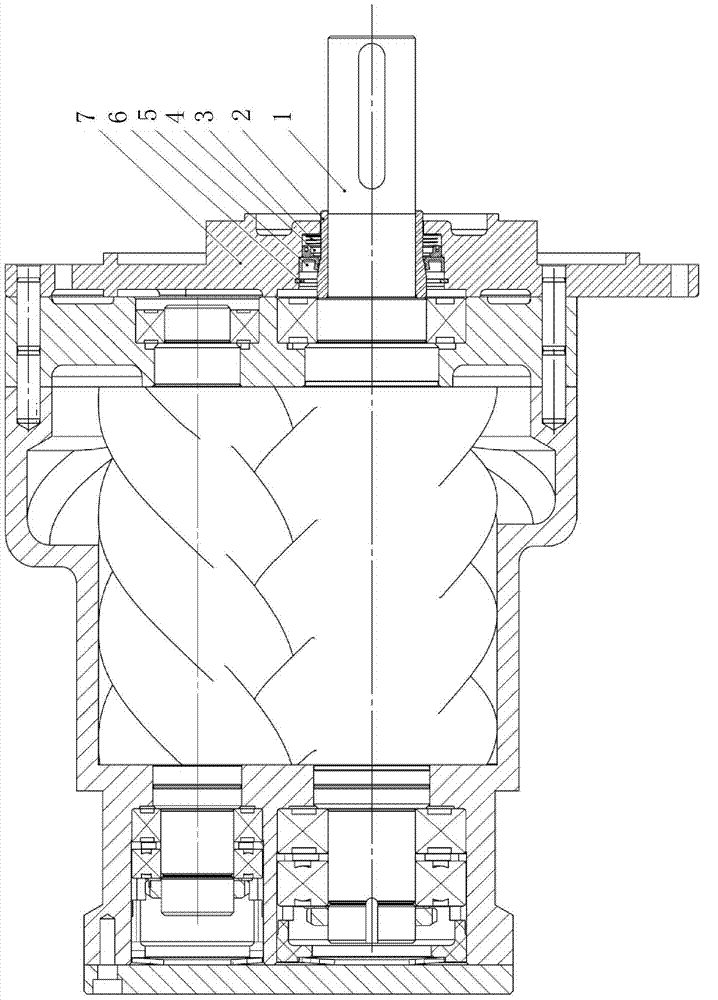

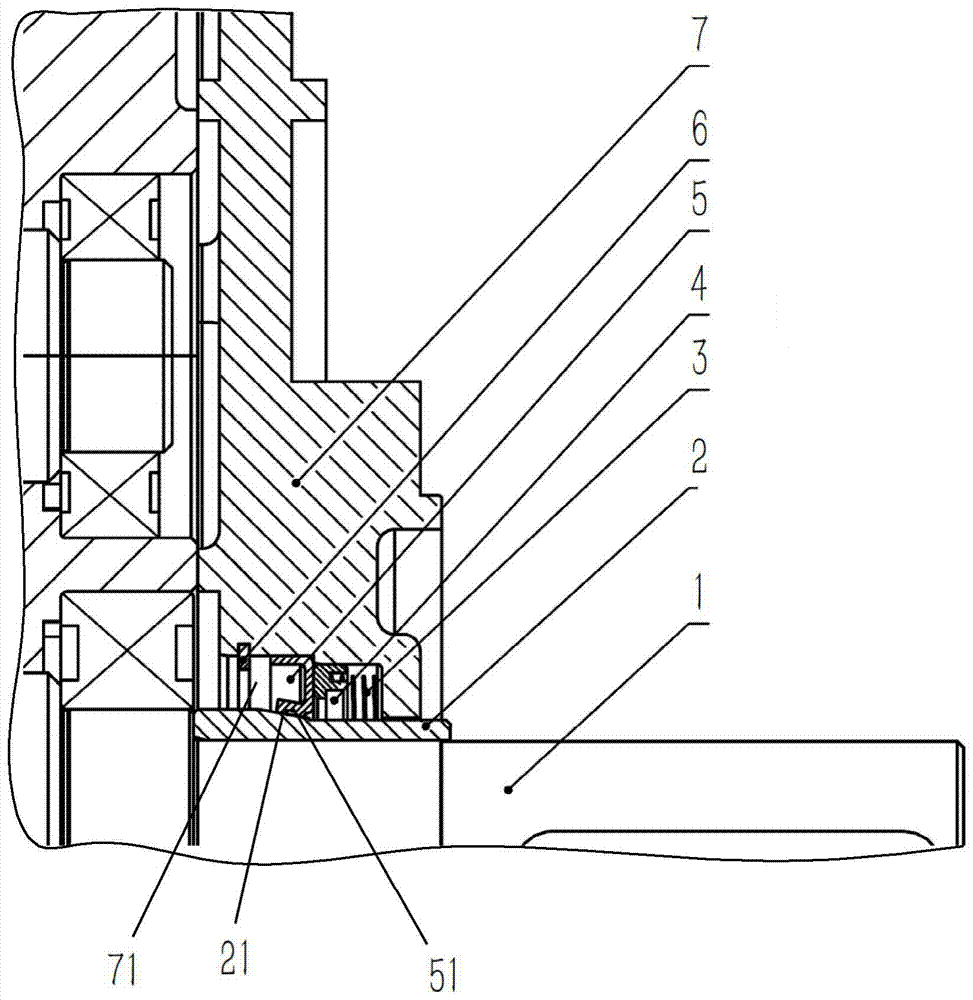

[0015] see figure 1 and figure 2 , the present invention relates to a screw compressor shaft seal with automatic compensation function, said screw compressor includes an extended shaft 1 and an end cover 7 arranged at the end of the compressor. The shaft seal includes a shaft sleeve 2 sleeved on the extended shaft 1 and a lip seal 5 embedded in the center hole 71 in the axial middle of the end cover 7 . The outer wall of the shaft sleeve 2 gradually narrows toward the extension direction of the shaft 1 to form a conical surface 21. The lip seal 5 has a sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com