Multi-layer non-woven geotextile and preparation method thereof

A technology of non-woven geotextile and base fabric layer, which is applied in chemical instruments and methods, textile, layered products, etc., can solve the problems of non-woven geotextiles being torn and damaged by force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

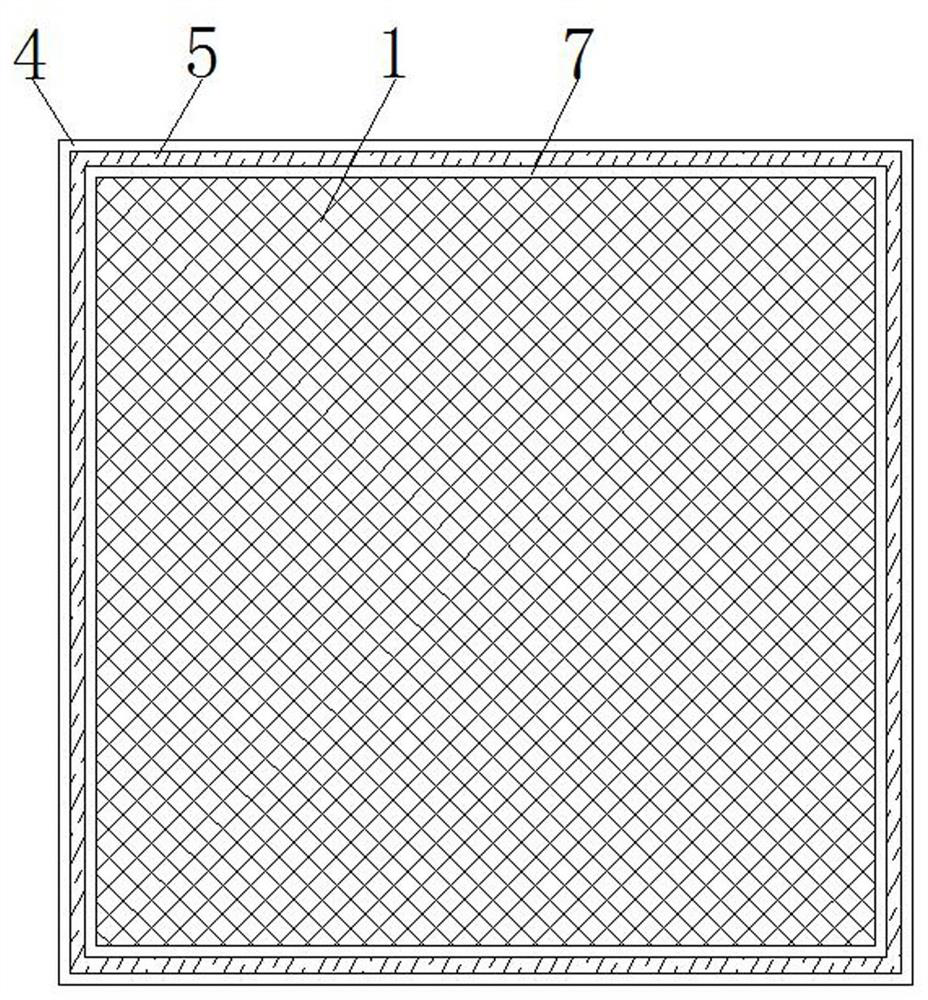

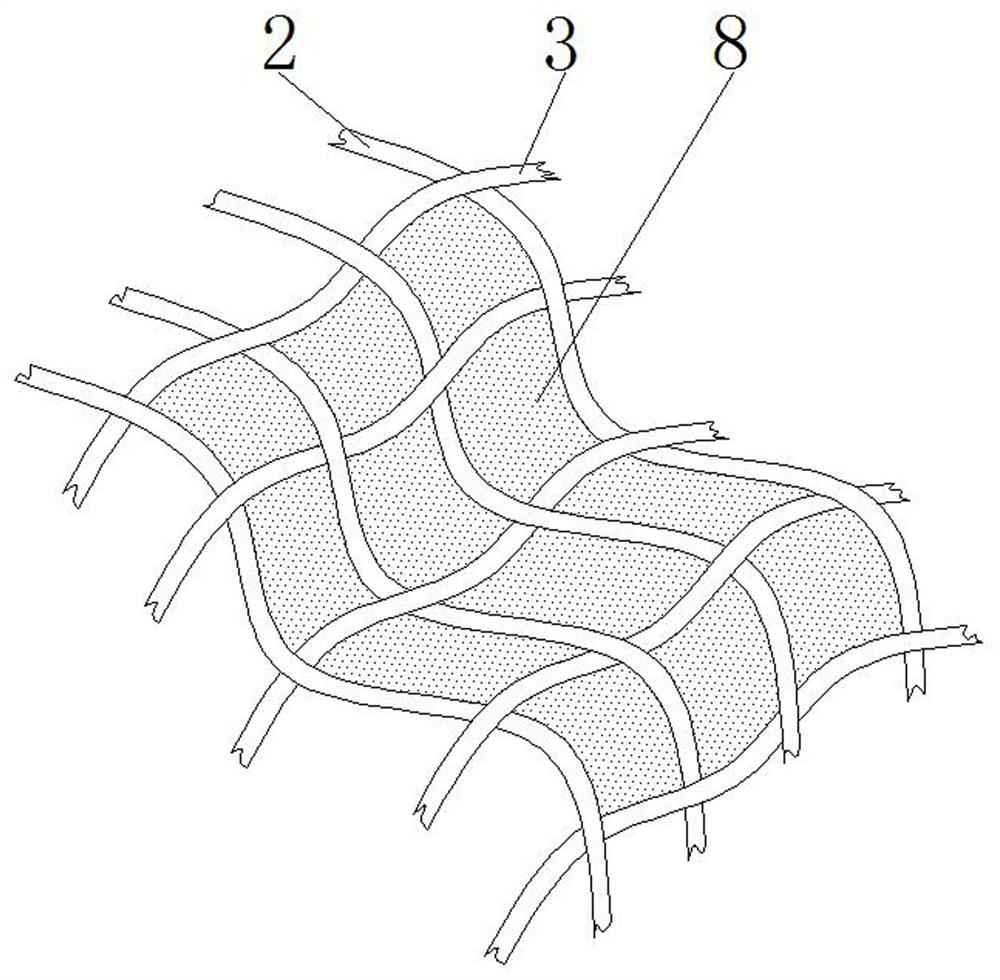

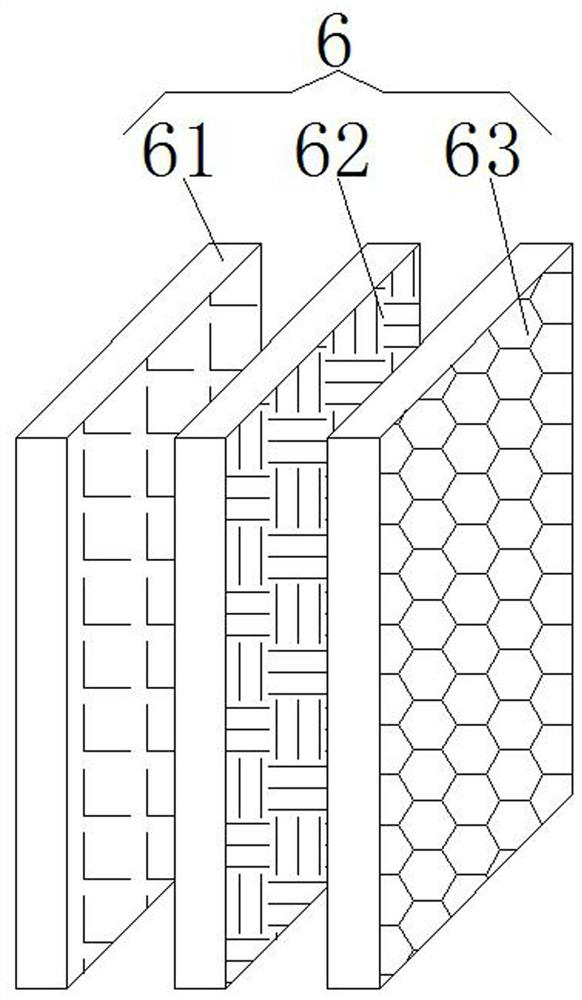

[0023] Please refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 ,in figure 1 A structural schematic diagram of a preferred embodiment of a multi-layer non-woven geotextile provided by the present invention; figure 2 for figure 1 Structural front view of warp and weft shown; image 3 for figure 1 The front view of the structure of the shown cotton and linen textile layer, woven wire mesh layer and wear-resistant paint layer; Figure 4 for figure 1 Structural front view of the shown meridian; Figure 5 for figure 1 The front view of the structure of the weft shown, a multi-layer non-woven geotextile, including a base fabric layer 1, the base fabric layer 1 is formed by intersecting warp yarns 2 and weft yarns 3, and the outside of the base fabric layer 1 is made of nylon The thread 5 is sewn with a hemming layer 4, and the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com