Patents

Literature

30results about How to "Stable up and down adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacture machine for stainless steel alloy flange

ActiveCN111469013AFast and stable lockPlay a locking roleGrinding drivesGrinding machinesStructural engineeringAlloy

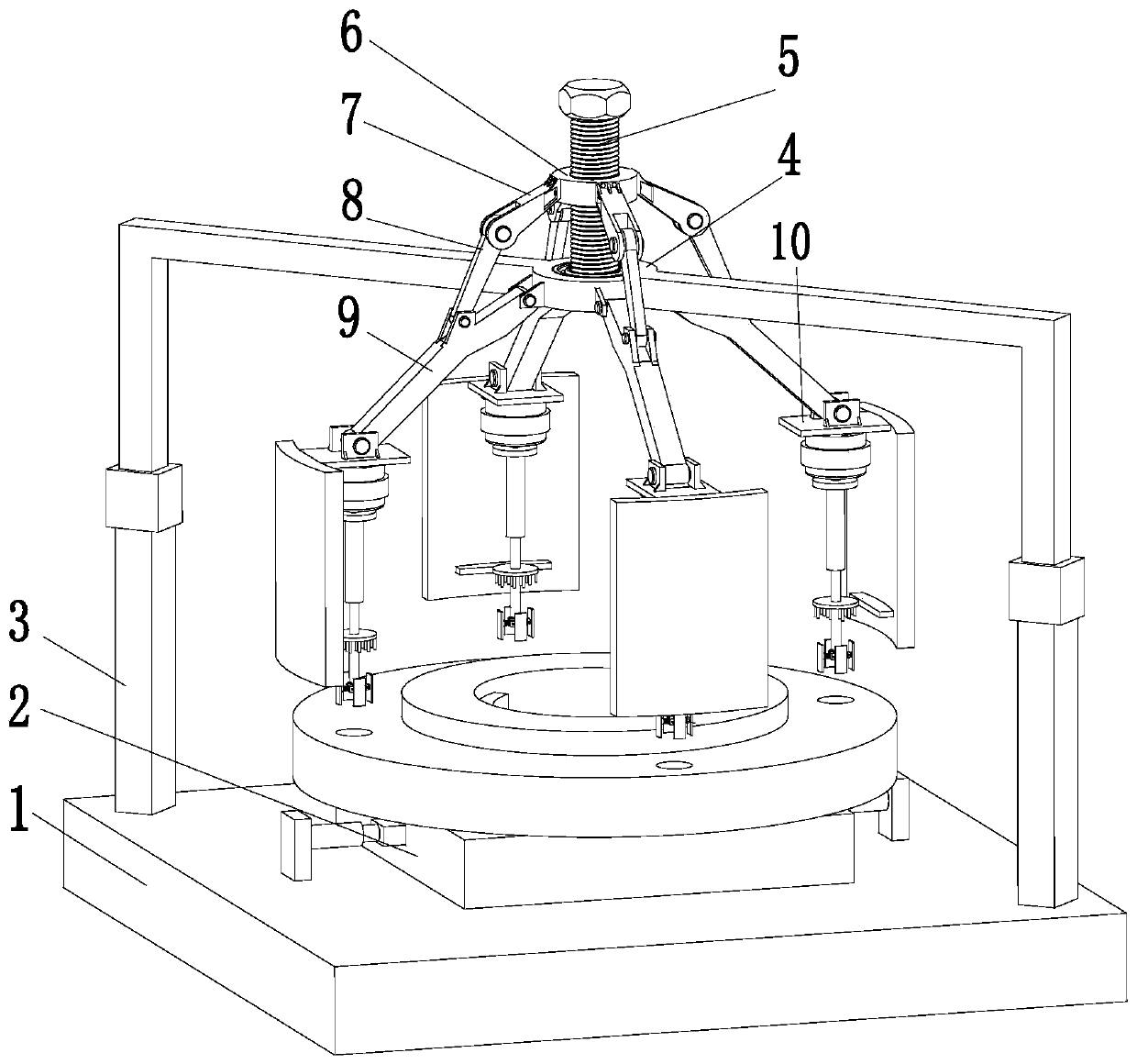

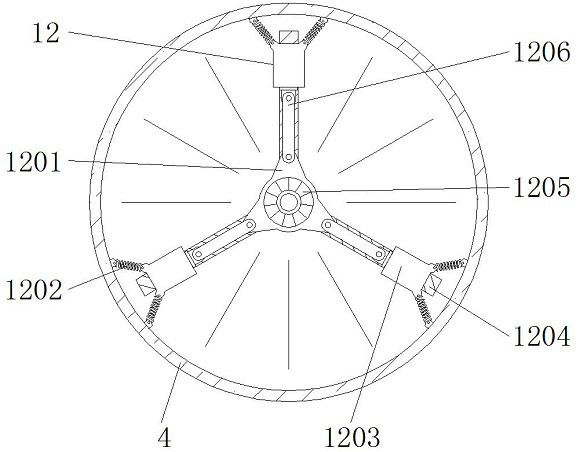

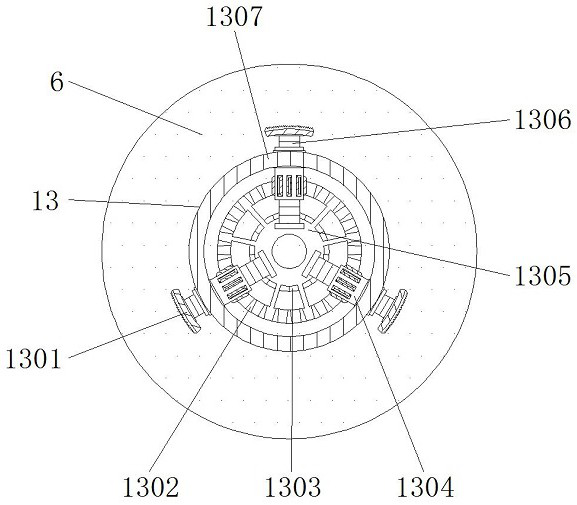

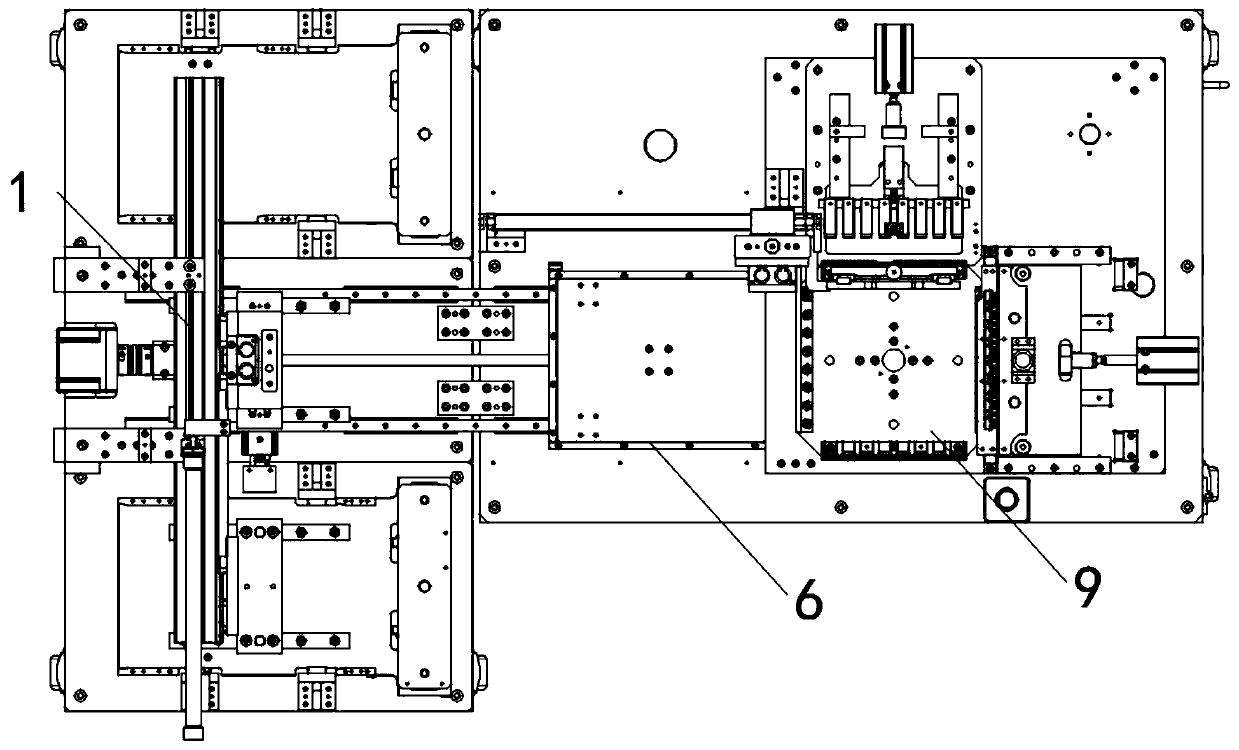

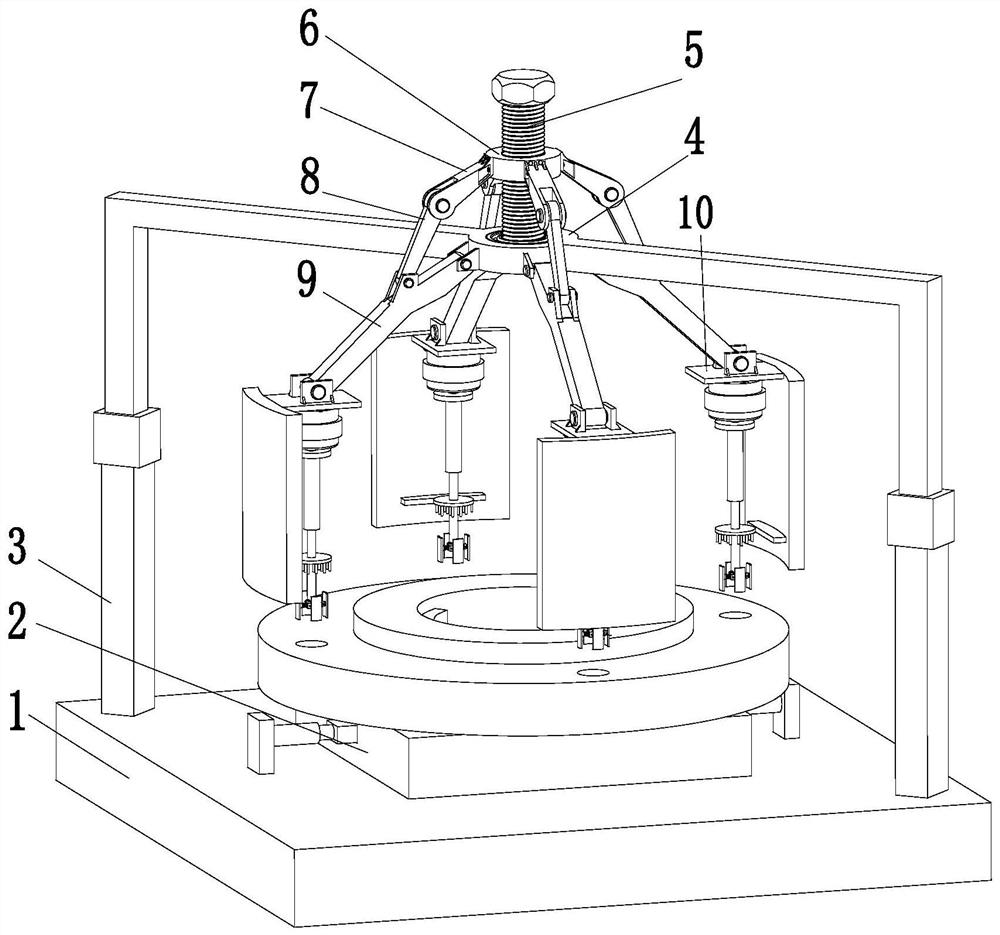

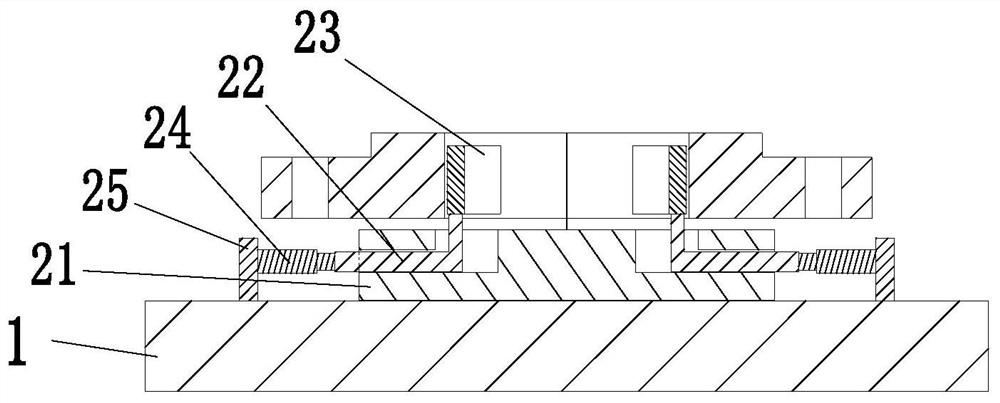

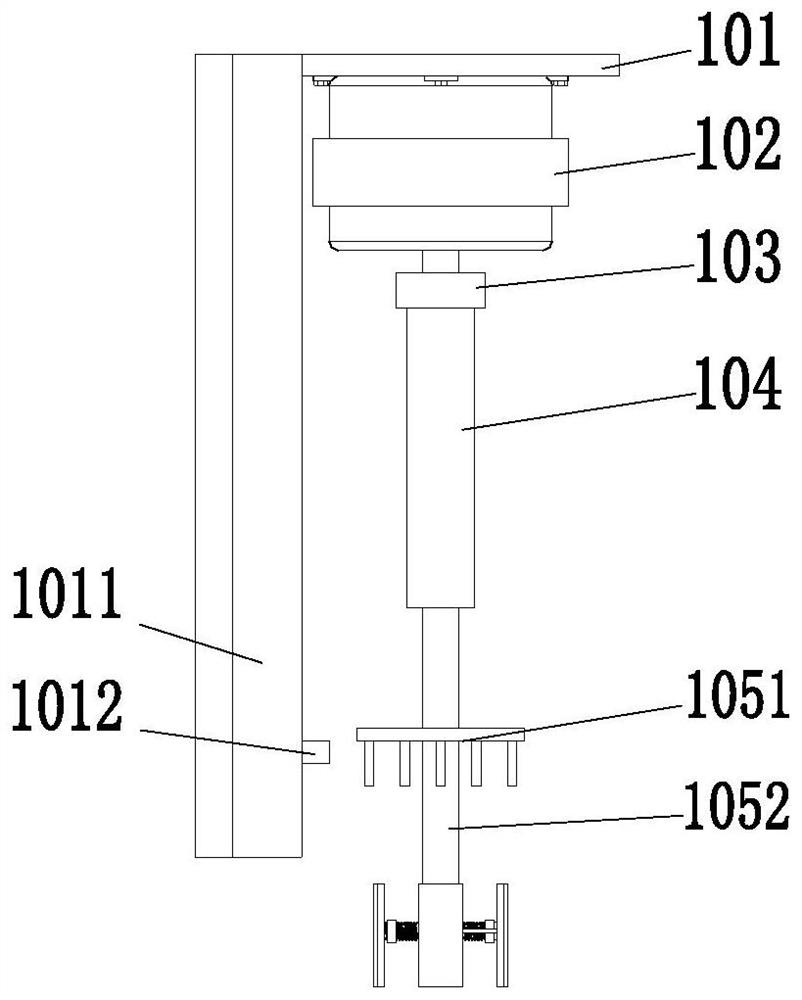

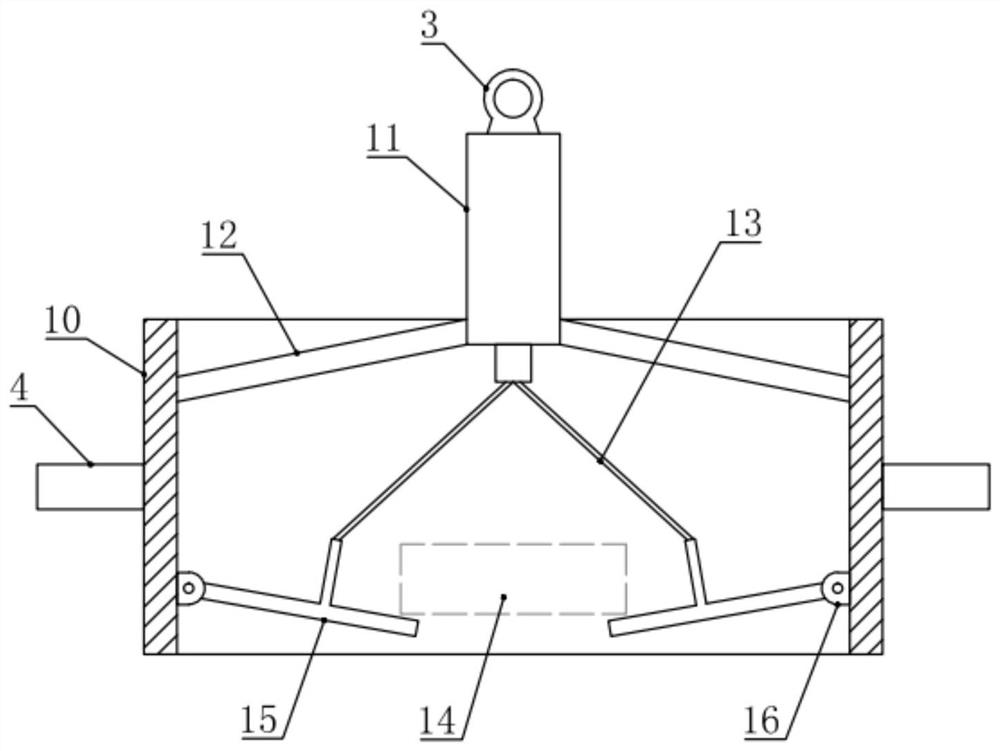

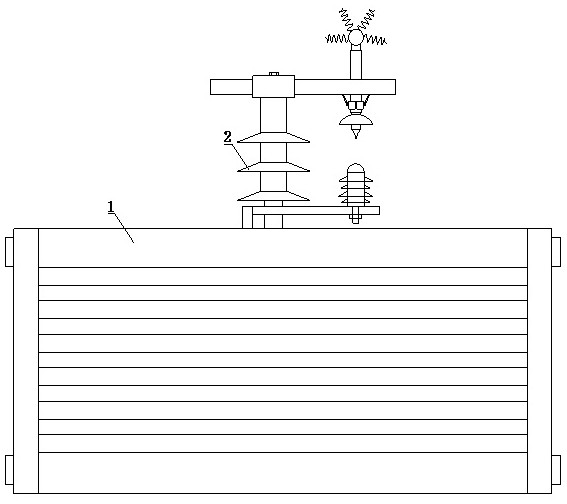

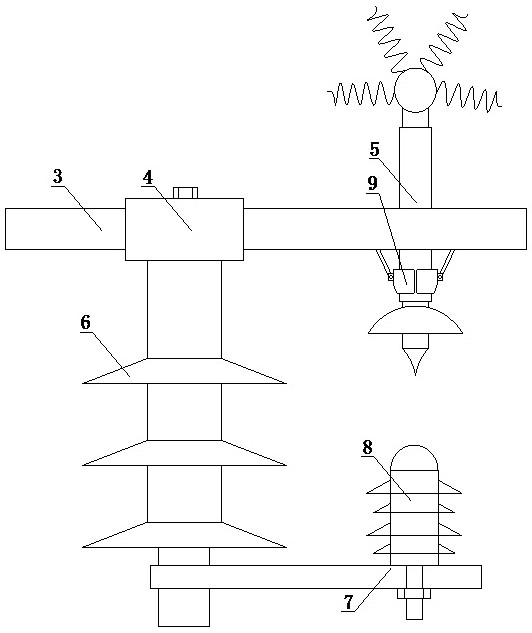

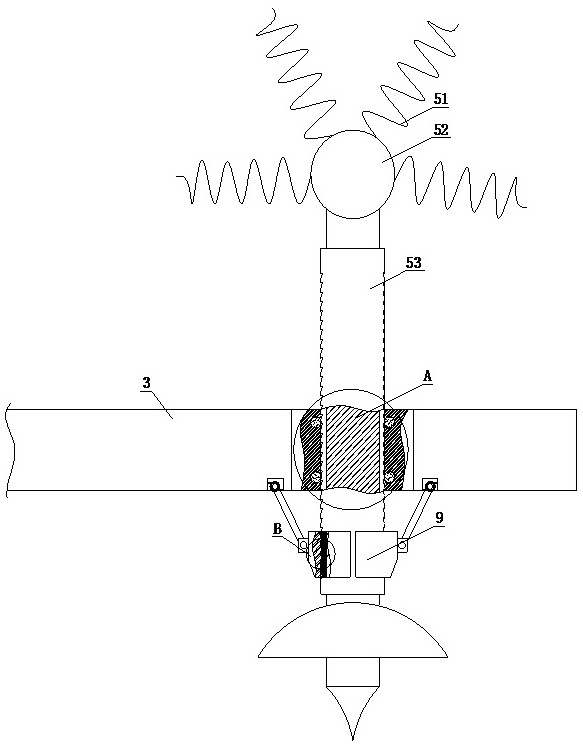

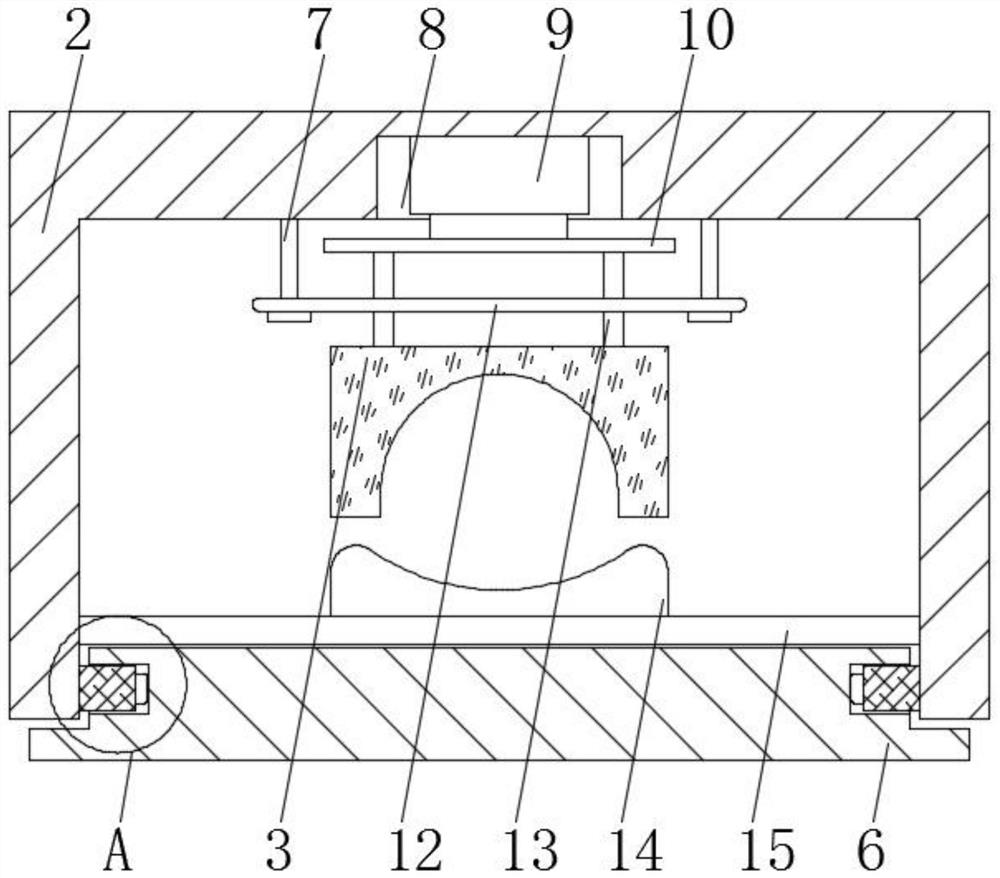

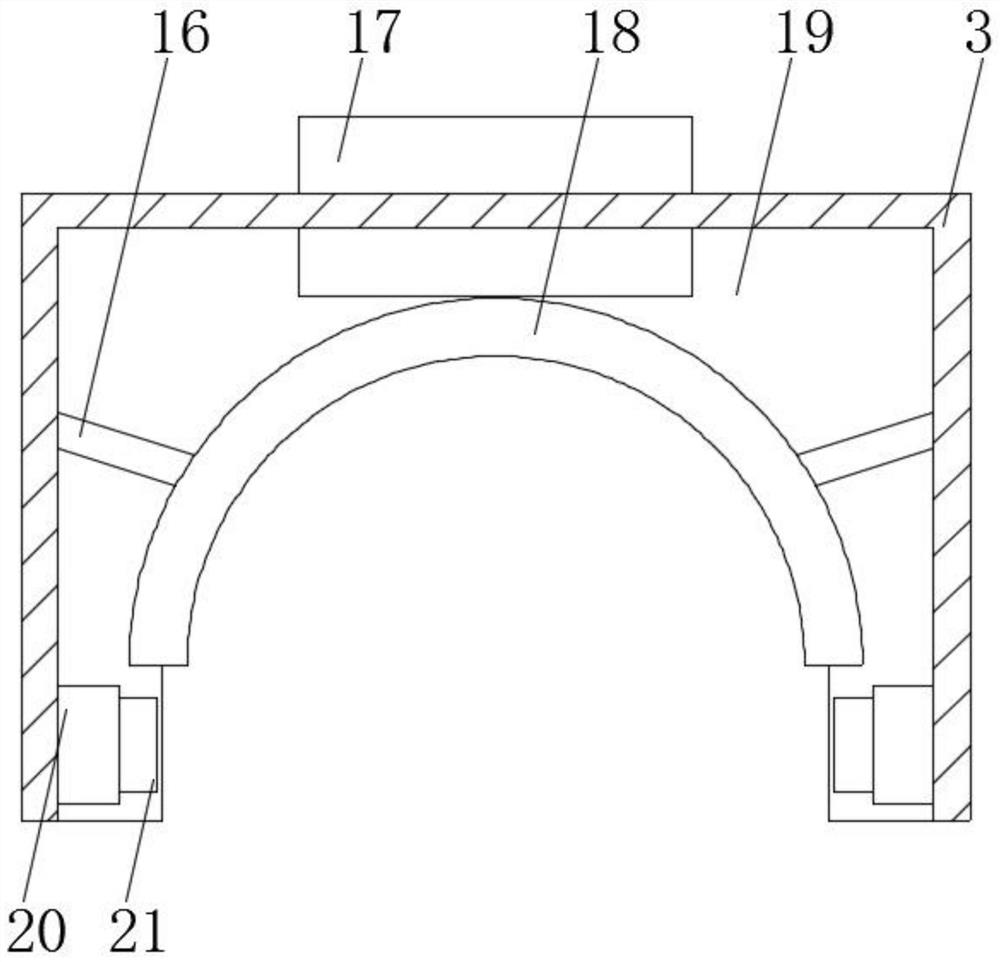

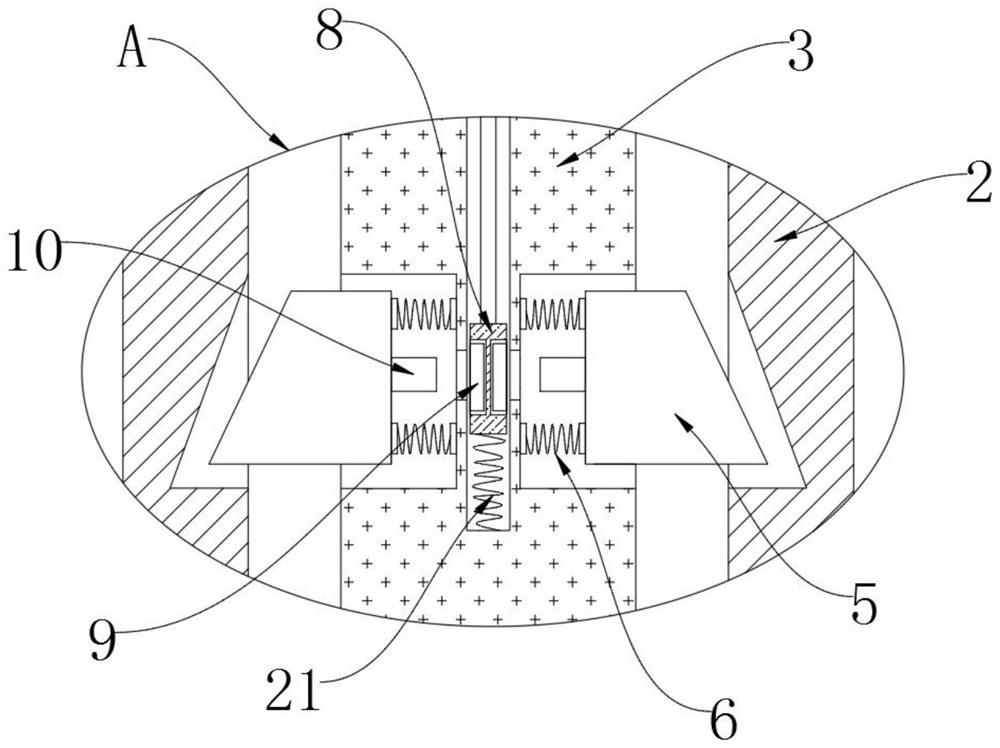

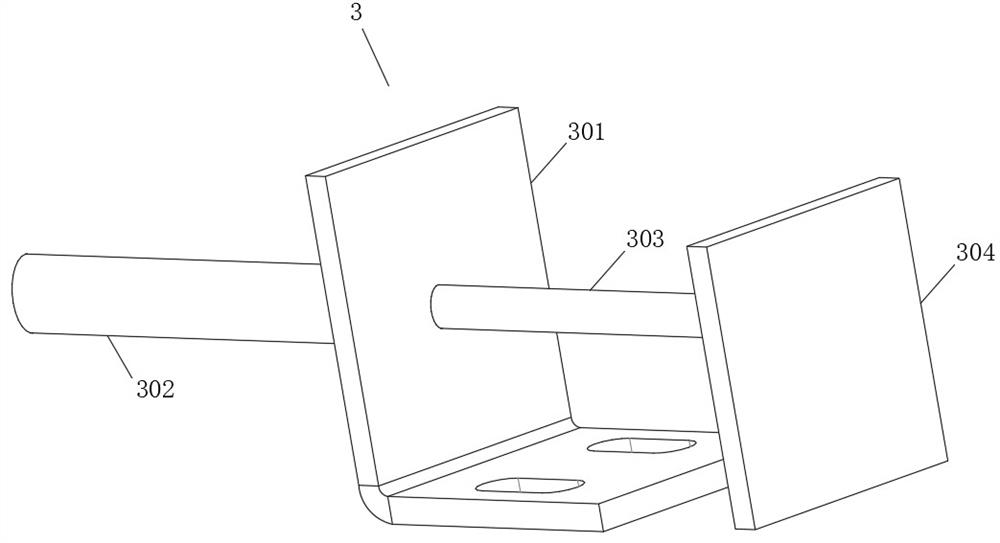

The invention relates to a manufacture machine for a stainless steel alloy flange. The manufacture machine comprises a base, a limit mechanism, L-shaped rods, a circular base, a bolt, an annular block, adjustment arms, connection arms, driven arms and polishing mechanisms. The upper end surface of the base is provided with the limit mechanism, the front right and rear left portions of the upper end surface of the base are provided with the L-shaped rods, the circular base is installed between the inner sides of the upper ends of the L-shaped rods, and the circular base is connected with the lower end of the bolt through a bearing. The annular block is connected to the middle of the bolt in a thread cooperation mode, four adjustment arms are symmetrically installed on the outer side surfaceof the annular block, the lower end of each adjustment arm is connected with the middle of the upper surface of the corresponding driven arm through the corresponding connection arm, and the lower end of each driven arm is provided with the polishing mechanism through a hinge. The manufacture machine can solve the problems that when burrs of a bolt hole in a flange are removed in the prior art, the effect of locking the flange by a clamp of processing equipment is poor, the processing equipment can only process one bolt hole, and burrs of the upper surface of the bolt hole need to be subjected to secondary processing through other equipment.

Owner:盐城斯天康精密制造有限公司

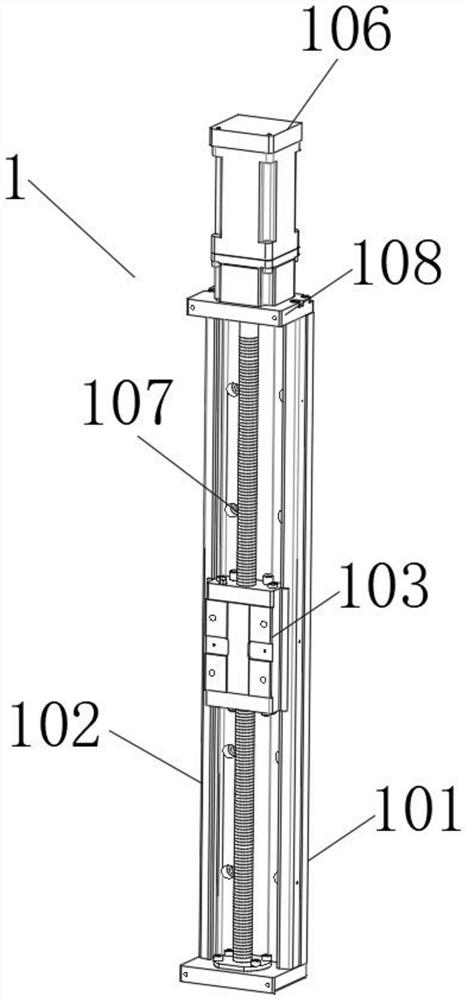

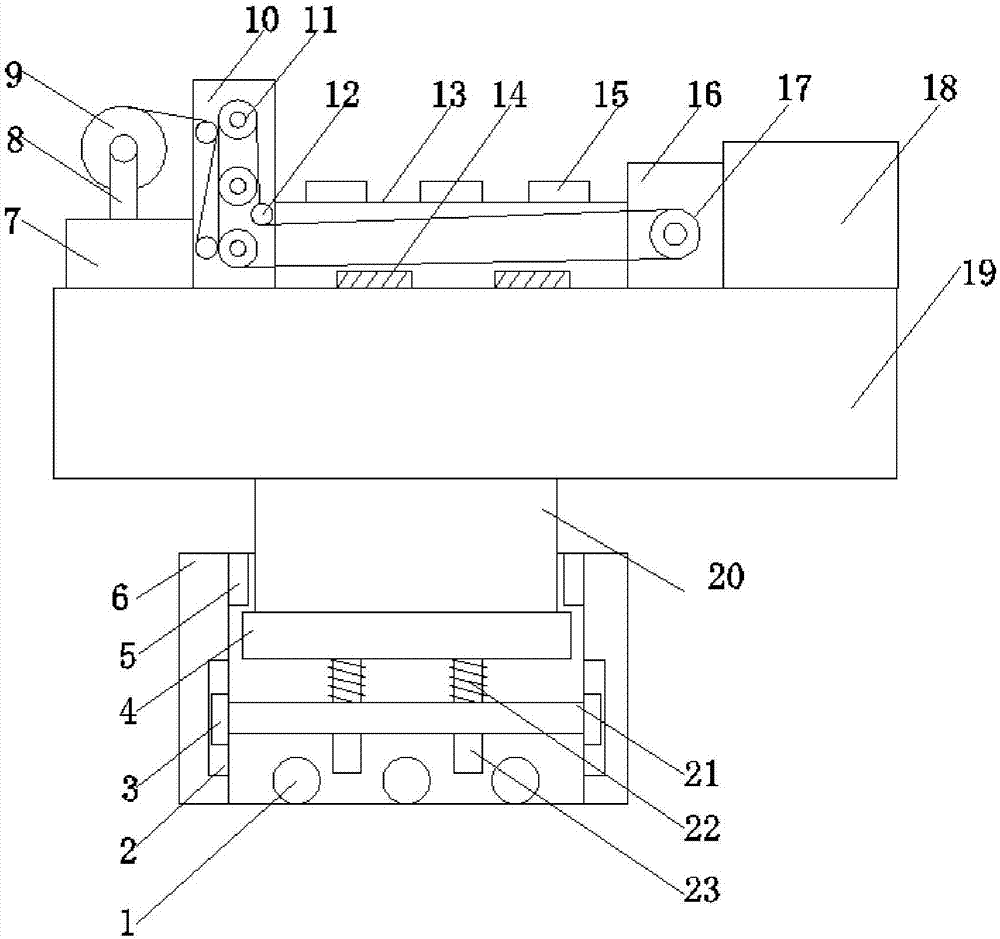

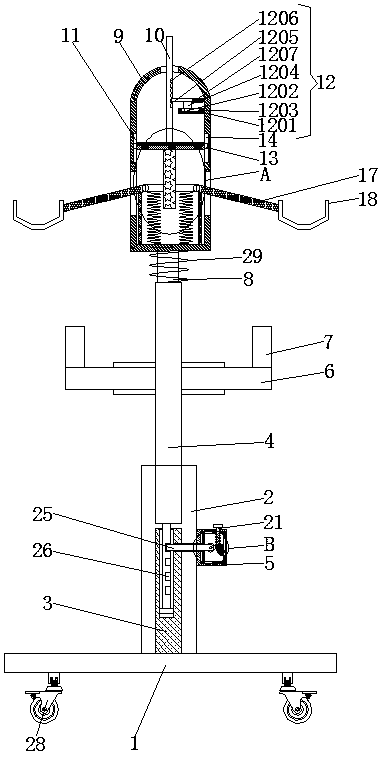

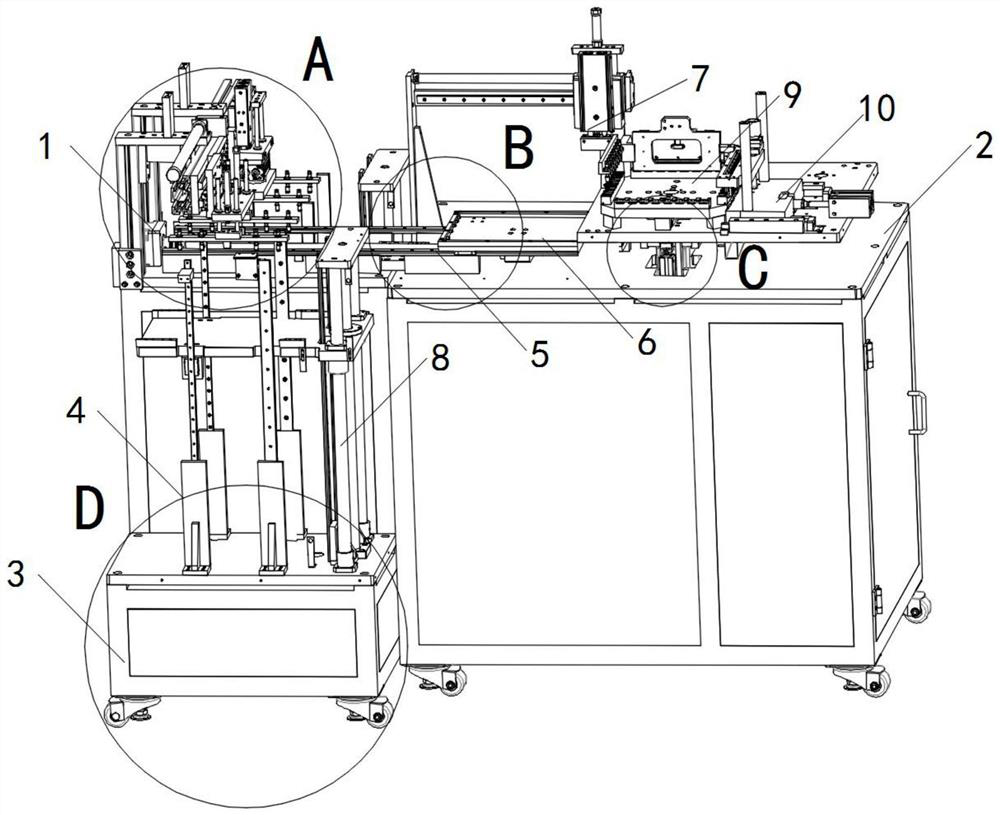

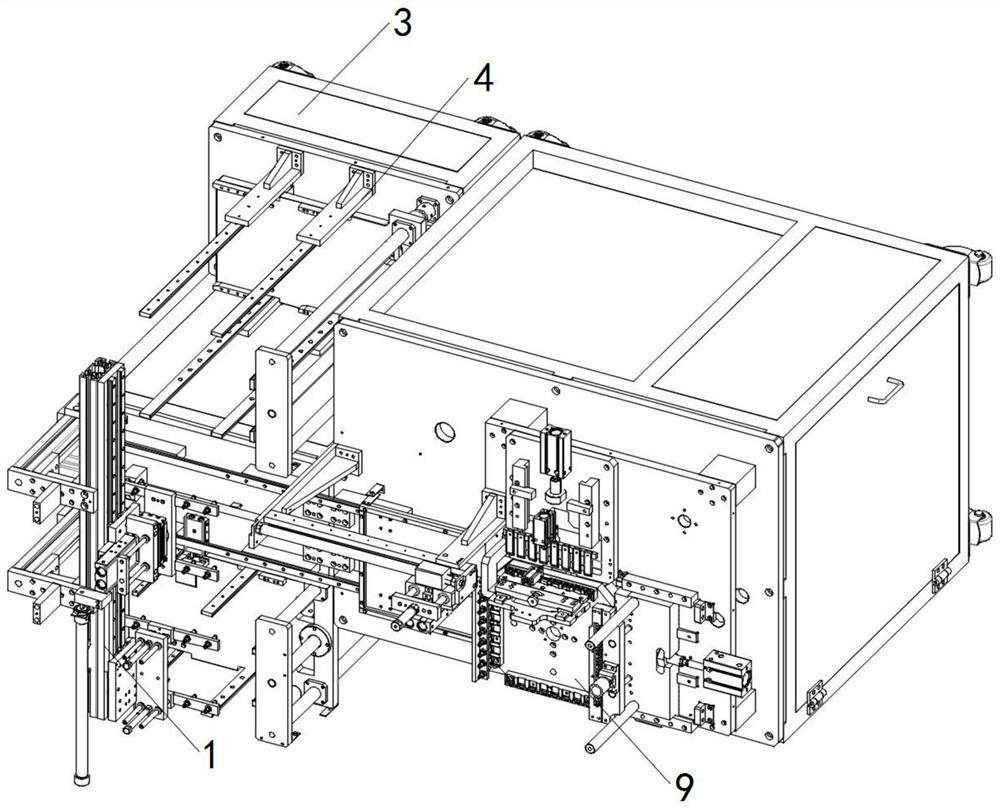

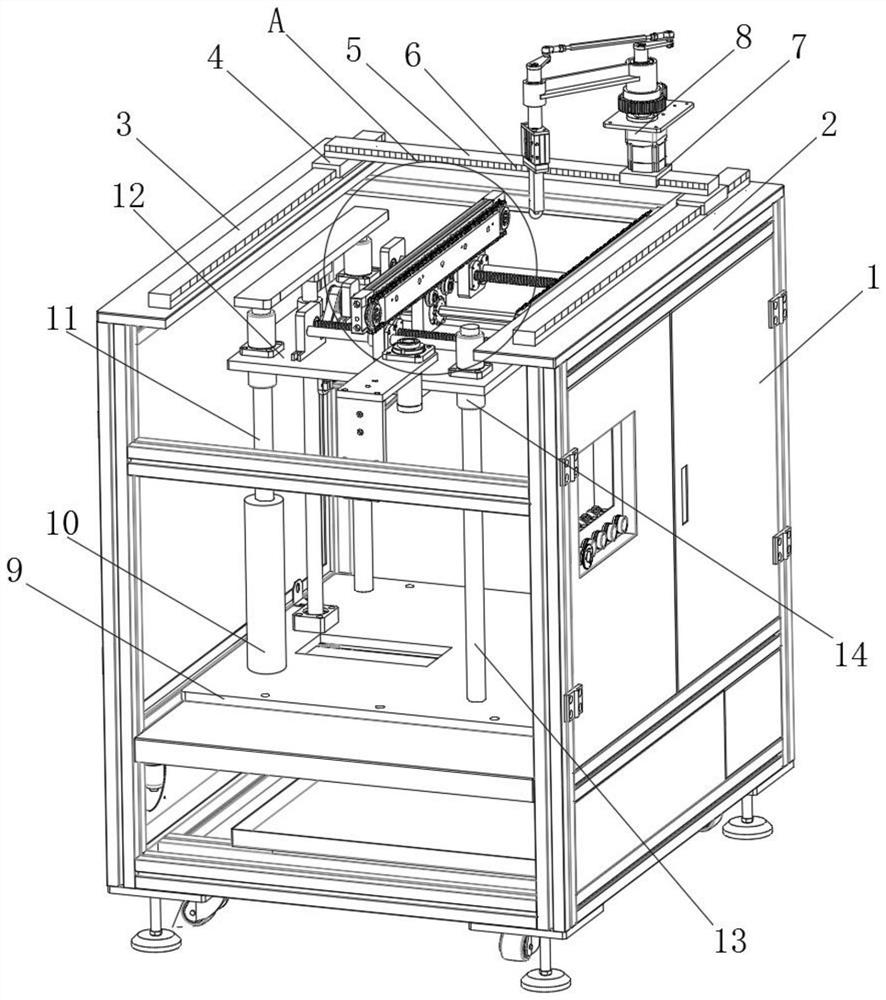

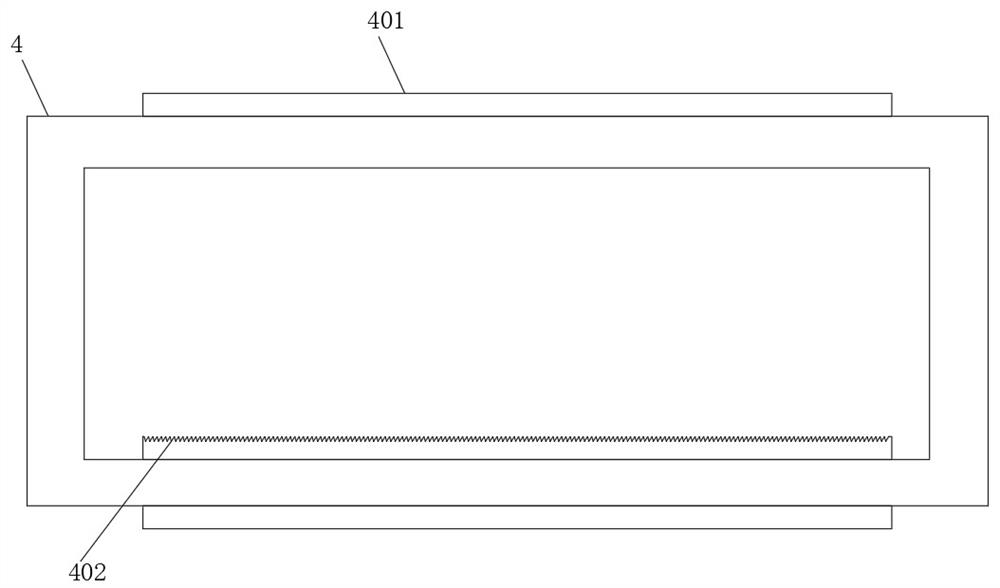

Winding equipment for automatically detecting pressure in spring production

InactiveCN112378645AReasonable structureQuick checkMachine part testingApparatus for force/torque/work measurementControl engineeringServo

The invention discloses automatic spring production pressure detection winding equipment, which comprises a main body, a push plate, a top plate and a baffle, wherein a clamping structure is movably connected to the interior of the main body, a gravity sensor is fixedly connected to the top end of the main body, a third servo motor is fixedly connected to the top end of the gravity sensor, secondsliding grooves are evenly formed in the top end of the main body, limiting rods are movably connected to the interiors of the second sliding grooves, and baffles are fixedly connected to the two sides of the top end of the main body correspondingly. According to the invention, the top end of the top plate is fixedly connected with the hydraulic air cylinder, the hydraulic air cylinder is startedto control the hydraulic telescopic rod to push the push plate to be adjusted up and down, and due to the fact that the sliding structure is formed between the limiting sliding block and the first sliding groove, the moving direction of the push plate can be limited under the action of the limiting sliding block and the first sliding groove, so that the height of the push plate can be adjusted upand down very stably, and the vertical pressure of the spring can be measured more accurately.

Owner:东莞市信恒智能装备科技有限公司

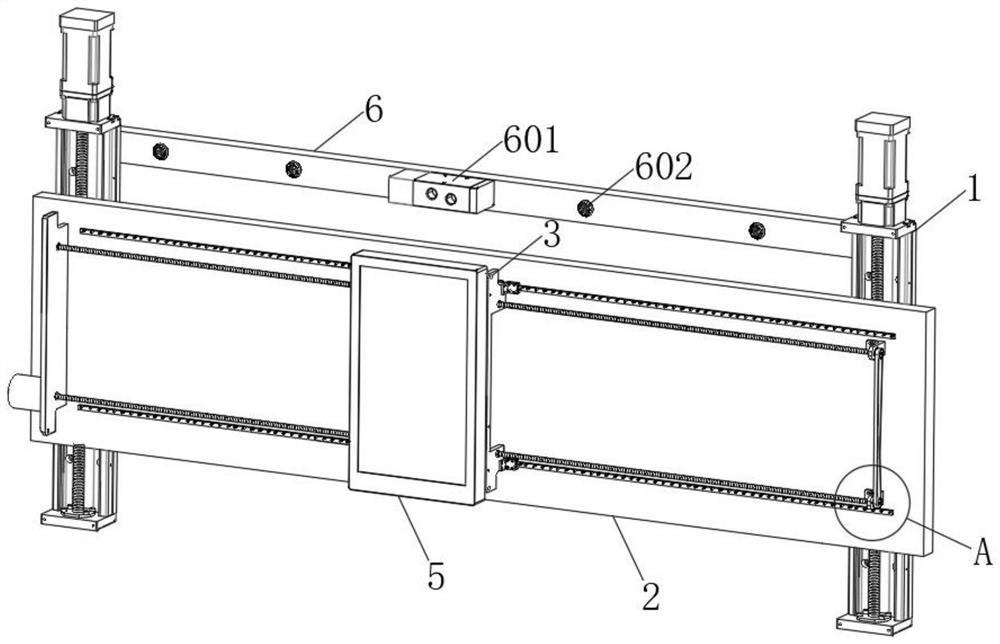

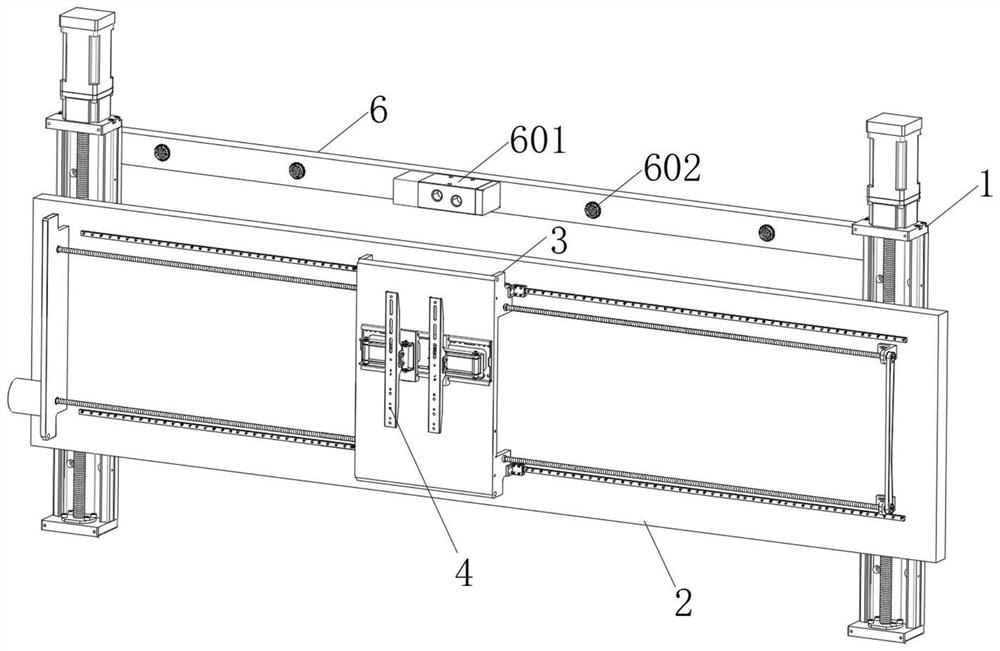

Intelligent sliding rail screen based on voice control

PendingCN113739018AEasy to operateImprove convenienceStands/trestlesSpeech recognitionSpeech controlSpeech sound

The invention relates to the technical field of intelligent sliding rail screens, in particular to an intelligent sliding rail screen based on voice control. The intelligent sliding rail screen comprises a lifting assembly, a back plate, a moving assembly, a mounting frame and a connecting plate. The intelligent sliding rail screen is characterized in that the display range of a display screen is larger by adjusting the position of the display screen left and right, so that the display effect of the sliding rail screen is further improved; the display screen slides and is matched with the back plate, so that the dynamic and static combination effect is achieved, and the demonstration effect of the sliding rail screen is further improved; a second sliding block is used for being in sliding fit with a second sliding rail, so that sliding of the display screen is smoother; a transmission lead screw and a driven lead screw are used, so that the display screen can move more accurately and slide more stably, and the accuracy of control management of the sliding rail screen is improved; and the display screen can be pulled out by pulling the mounting frame, and convenience is provided for replacement and maintenance of the display screen.

Owner:苏州拓凡互动科技有限公司

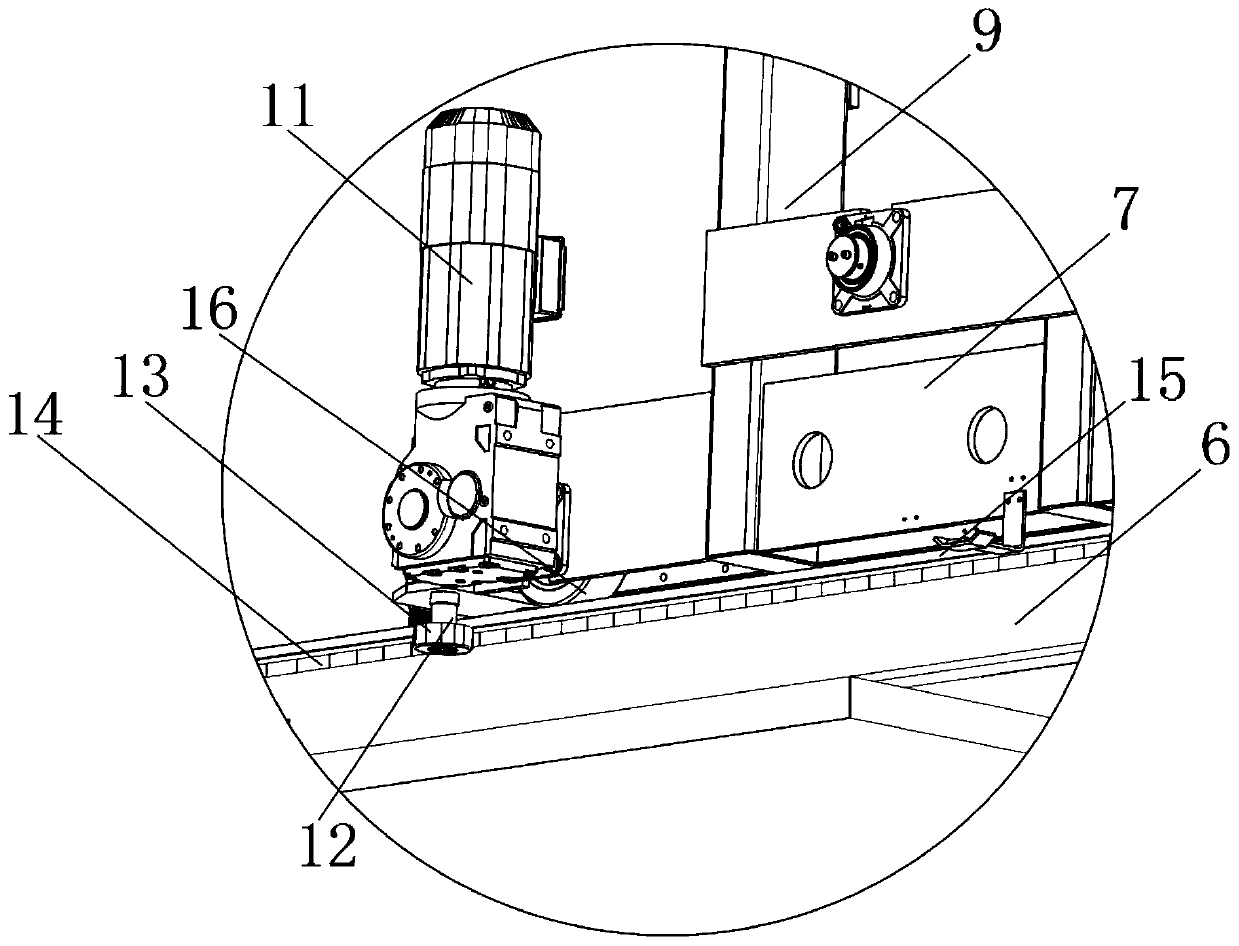

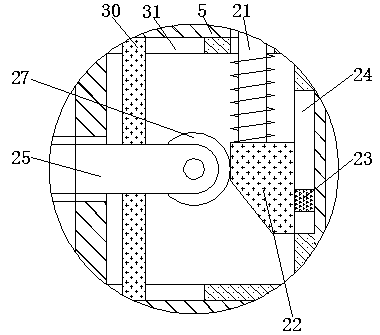

Power generation and energy storage equipment adjusting device and method

ActiveCN110729819AEasy to disassembleQuick and easy disassemblyElectrical storage systemSupports/enclosures/casingsMotor driveElectric machine

The invention discloses a power generation and energy storage equipment adjusting device, which comprises a first motor of a cylindrical structure, a supporting plate, side supporting frames, upper conveying tables and vertical installing tables. A rotary base is arranged above the first motor. A cuboid-shaped rotary adjusting base is horizontally arranged at the top of the rotary base, and the side supporting frames are arranged at the two ends of the rotary adjusting base. In the process of installing power generation and energy storage equipment on the device, fifth motors drive a clampingbase to rotate for adjustment through rotary columns to change the connection position and angle of buckling plates and the power generation and energy storage equipment, a sixth motor drives seventhmotors and the buckling plates to turn over up and down for adjustment through turning and swinging shafts, and the seventh motors drive the buckling plates to rotate for position adjustment through third transmission shafts. On one hand, it is guaranteed that the position of a component can be adjusted more flexibly and rapidly, the efficiency of installing the power generation and energy storageequipment on the device is greatly improved. On the other hand, the accuracy of the installing position of the device and the power generation and energy storage equipment is greatly improved.

Owner:HUAIYIN TEACHERS COLLEGE

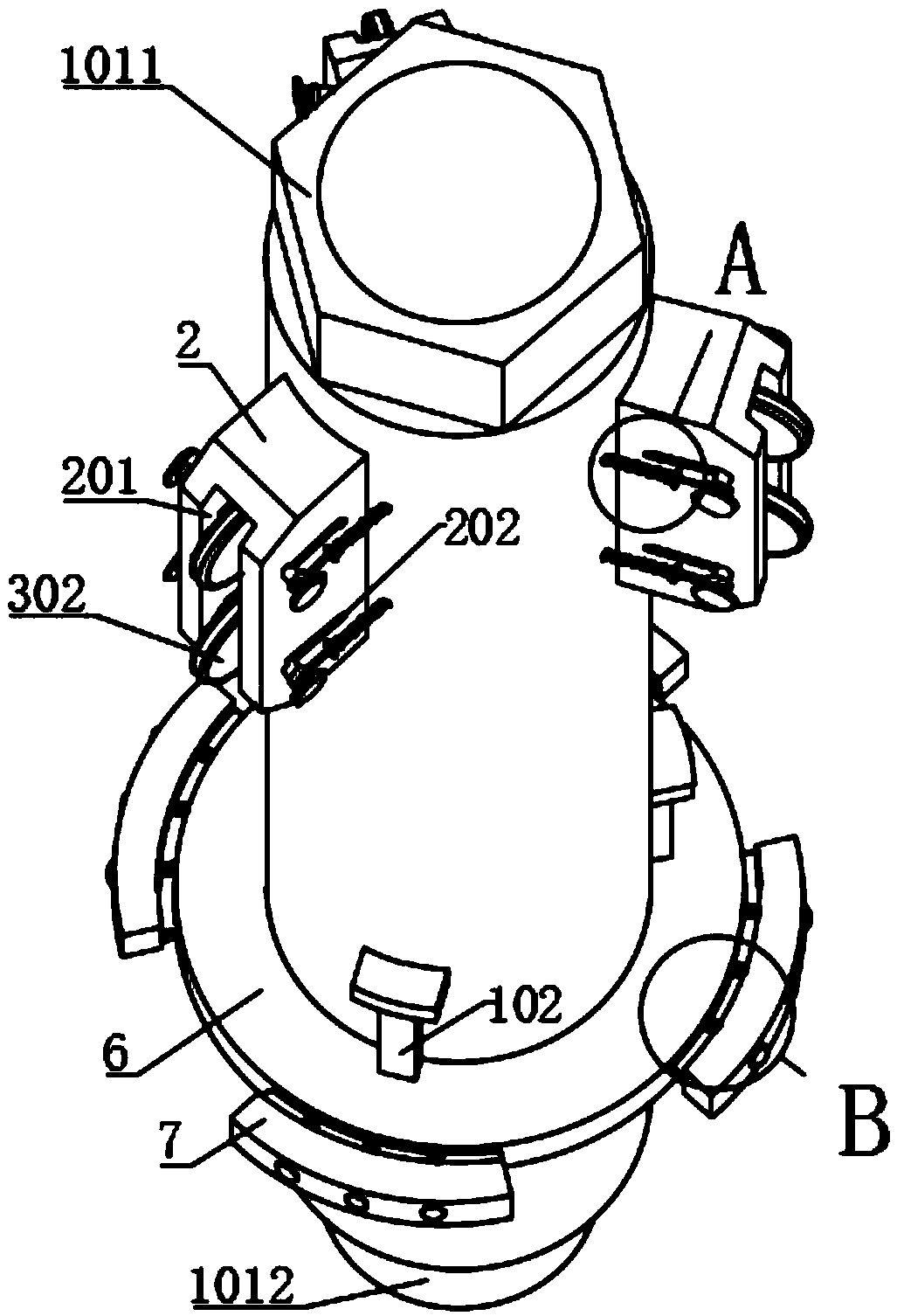

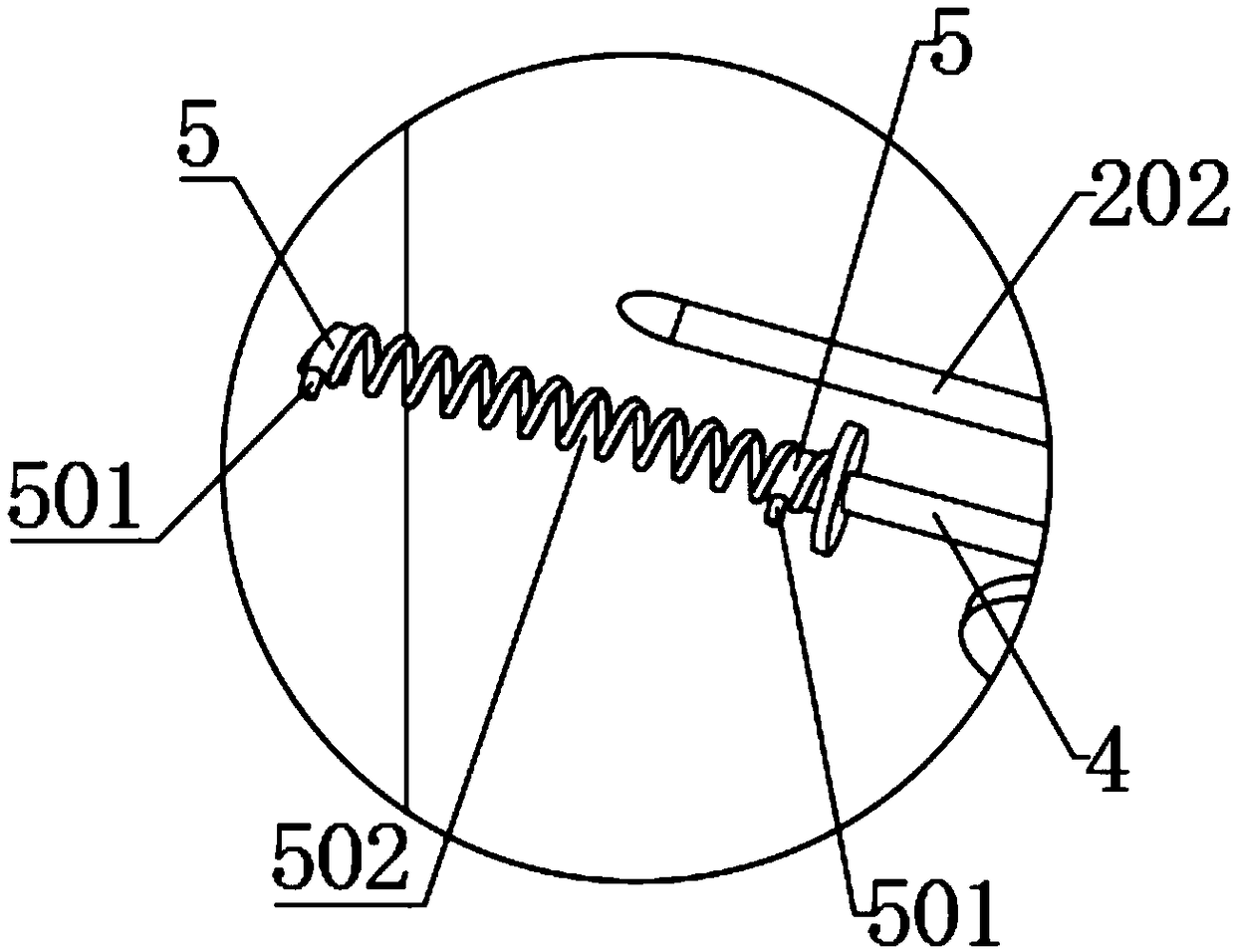

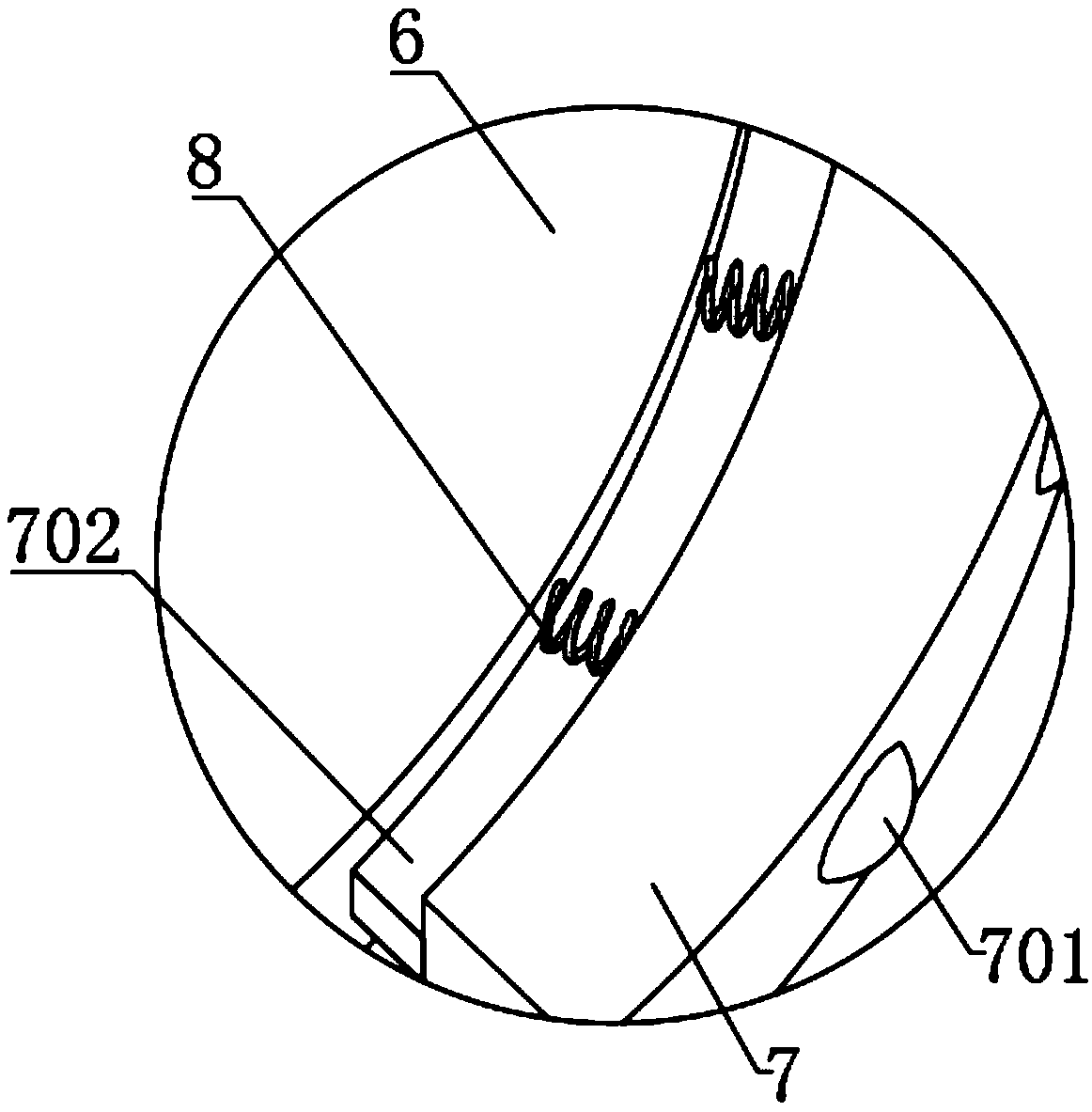

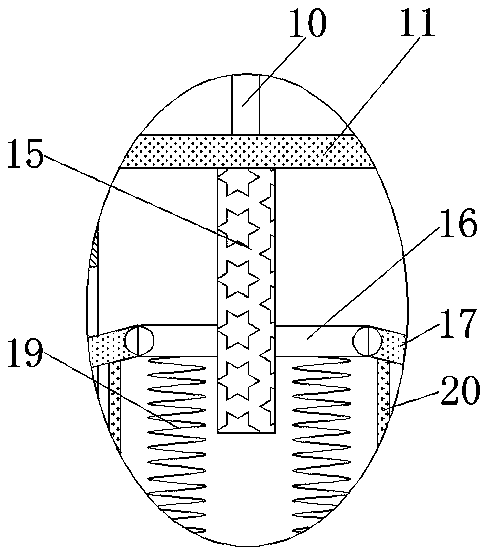

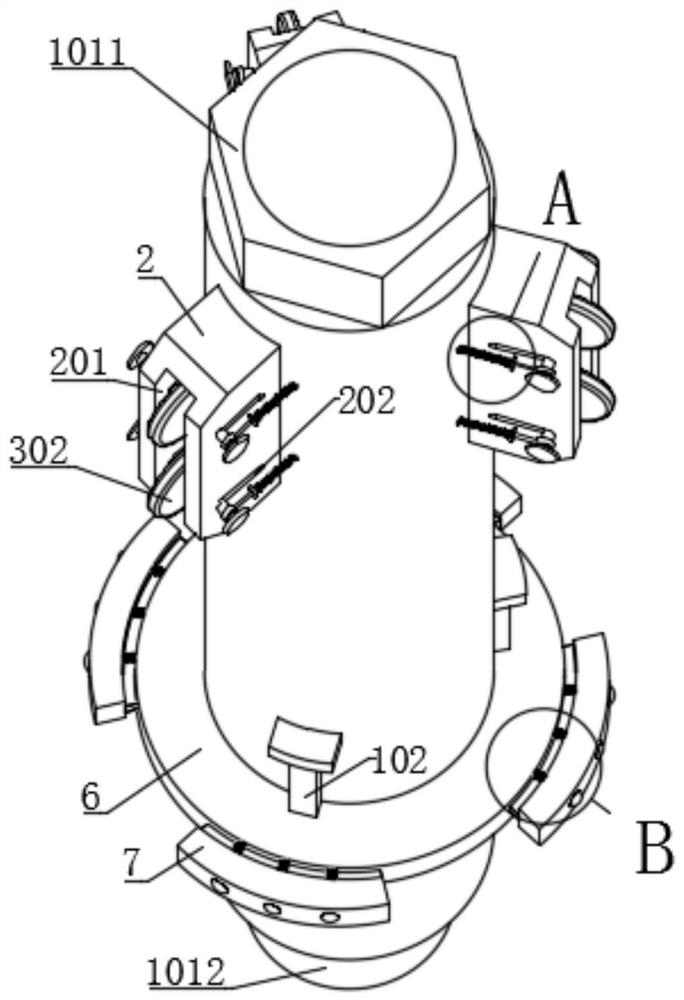

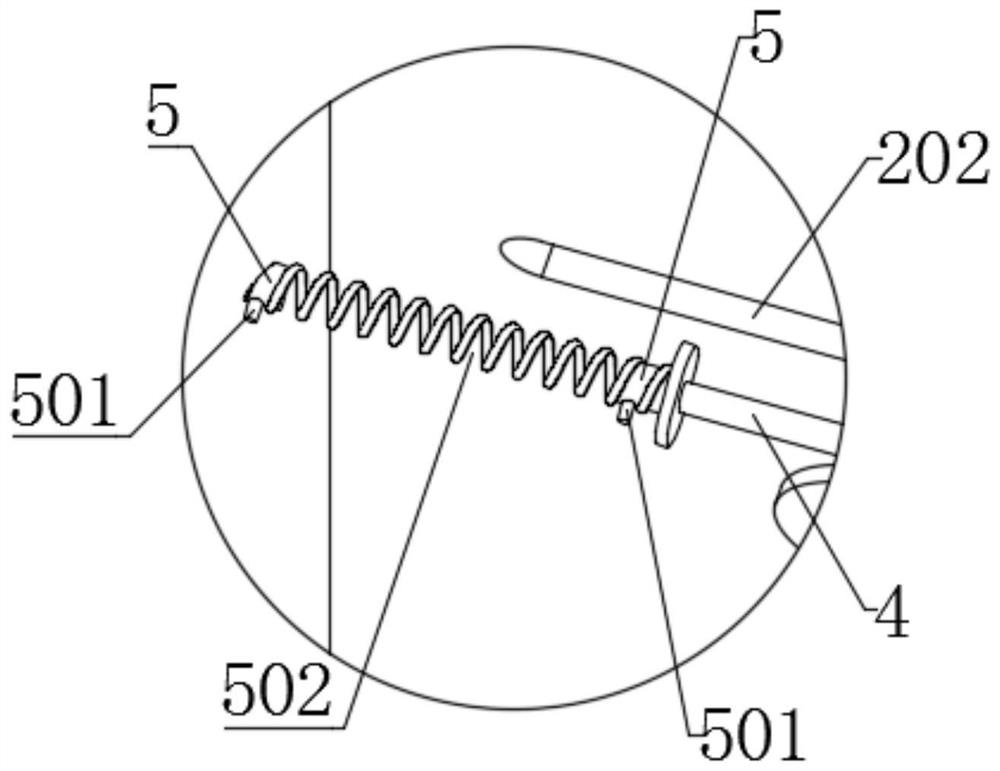

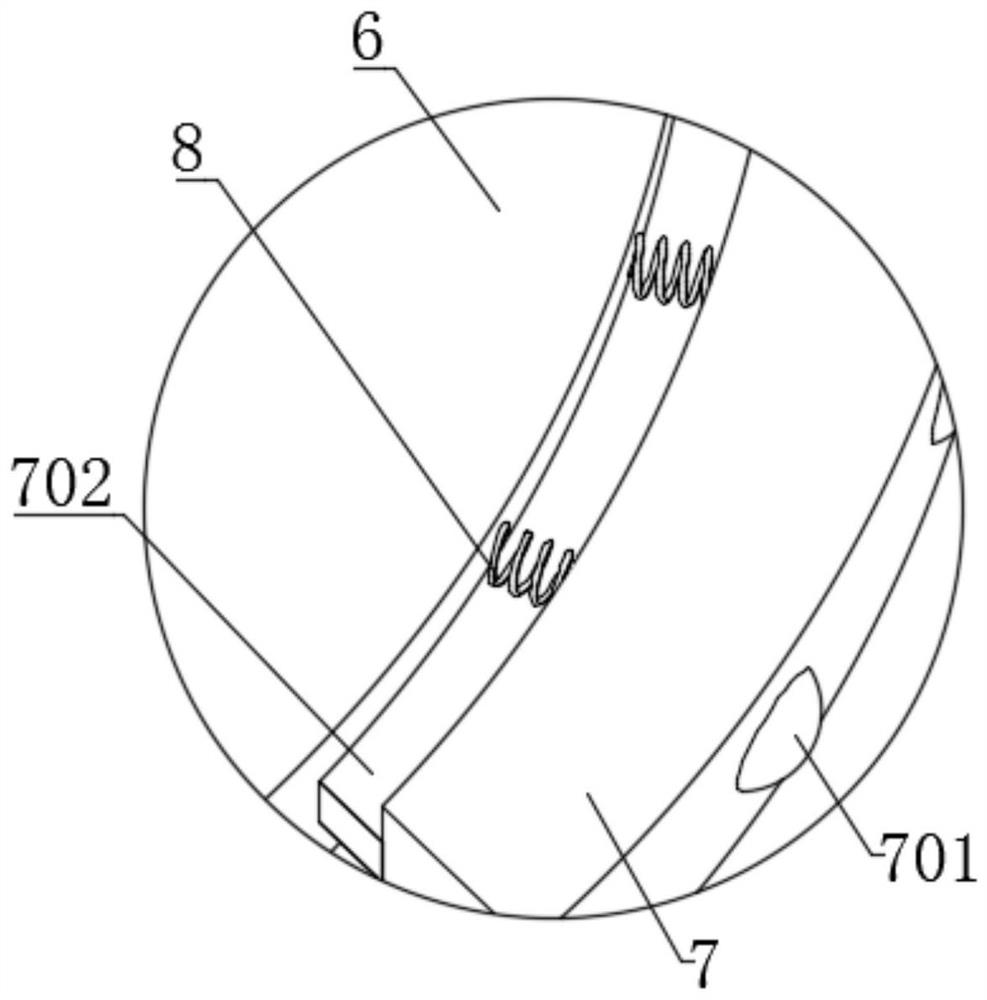

Anti-eccentric-wearing centering guide for sucker rod

The invention provides an anti-eccentric-wearing centering guide for a sucker rod. The anti-eccentric-wearing centering guide comprises entering rollers, shaft sleeves, limiting plates, limiting clamprods, adjusting springs A, clamp slots and rolling balls. The centering rollers are embedded in adjusting shafts arranged at inner sides of grooves by bearings; and the shaft sleeves sleeve the adjusting shafts at the two ends of the outer sides of the groove. Sleeving columns are welded to the outer wall of a centering guide body; and the adjusting springs A are arranged between the two groups of sleeving columns. The annular clamp slots are formed in the outer edge of a centering ring; and integrated adjusting plates are arranged at the rear ends of arc centering plates and are clamped in the clamp slots movably. Three groups of rolling balls are embedded into the outer edges of the arc centering plates. Adjusting springs B are connected in the gaps between the arc centering plates andthe centering ring. The rolling balls arranged at the front ends of the arc centering plates are used for realizing rotation of a sucker rod conveniently; one group of sucker rods are connected into internal thread insertion holes of another groups of sucker rods in a screwing manner; the centering rollers are in contact with the well wall under the effects of the adjusting springs A; and thus thesucker rod are adjusted up and down successfully.

Owner:东港智科产业园有限公司

Damping printing machine

InactiveCN107336514AStable up and down adjustmentQuality assuranceScreen printersPrinting press partsComing outEngineering

The invention discloses a shock-absorbing printing machine, which comprises a fixed cylinder, a chute is provided on the inner wall of the fixed cylinder, a slider is arranged inside the chute, and a support plate is fixedly connected to the inner side of the slider. The support plate is slidably connected with the chute through the slider, the bottom of the inner cavity of the fixed cylinder is fixedly connected with a sphere, the inside of the fixed cylinder is provided with a connecting block, and the top end of the connecting block penetrates the top of the fixed cylinder and extends to the outside of the barrel. The present invention is provided with a sphere, a support plate, a connecting rod and a buffer spring, and uses the support of the sphere to the support plate and the back and forth adjustment of the buffer spring to reduce and absorb the vibration generated by the device, thereby reducing the damage to the equipment caused by the vibration and prolonging the life of the device. While the service life is guaranteed, the quality of the printing is guaranteed. By setting the chute and slider, the up and down adjustment of the support plate is smoother, and the friction between it and the fixed cylinder is reduced. The limit block and the fixed block prevent the connecting block Remove the retaining cylinder.

Owner:姚飞

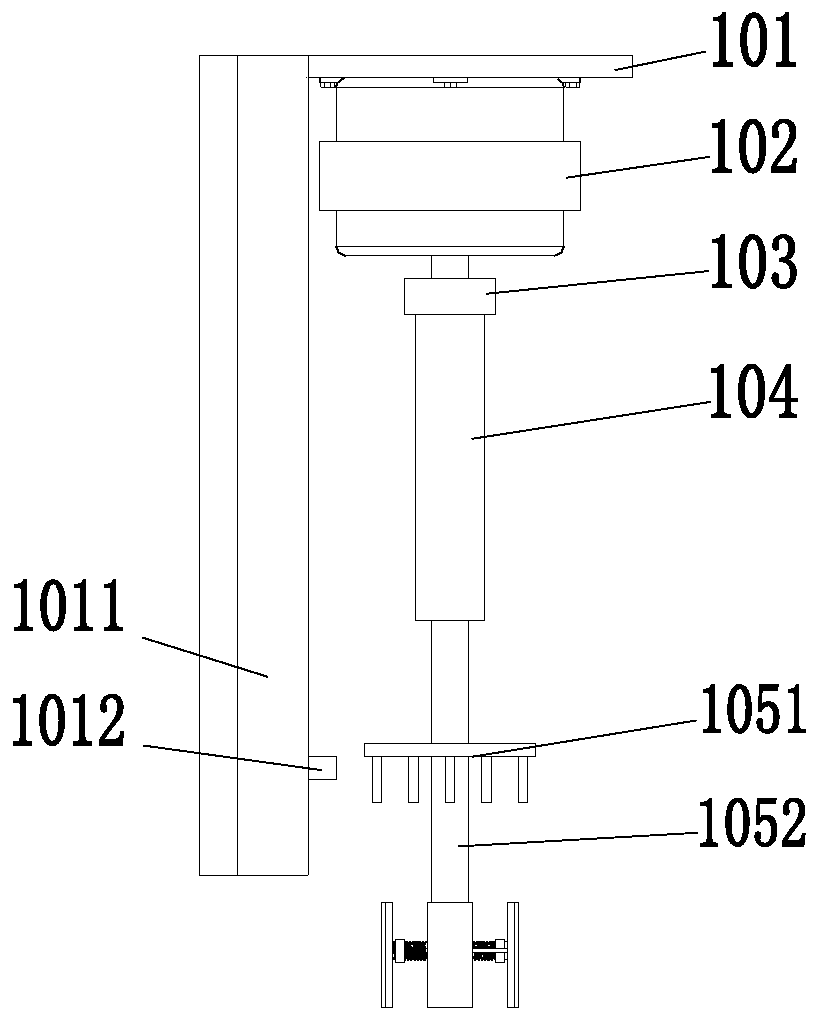

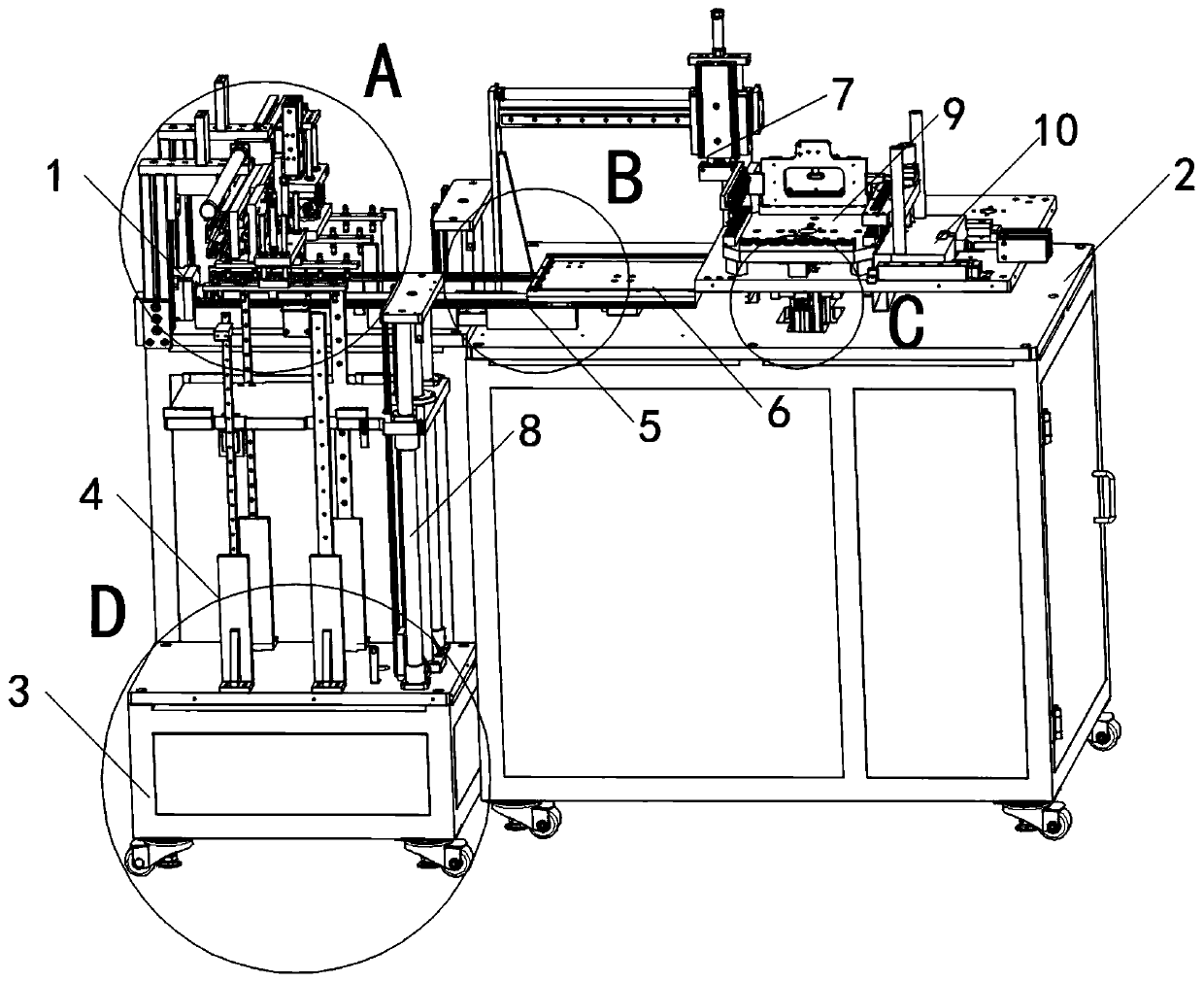

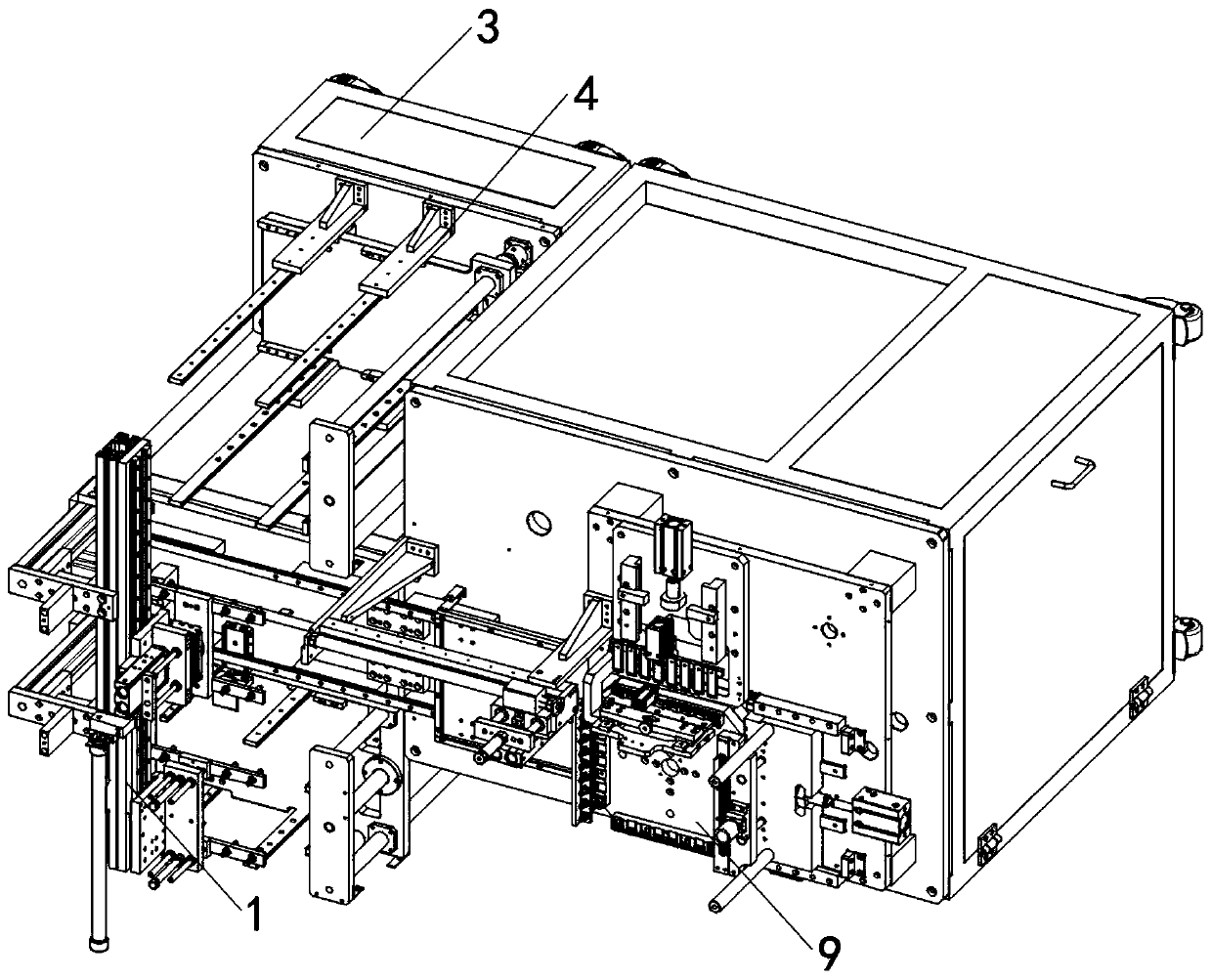

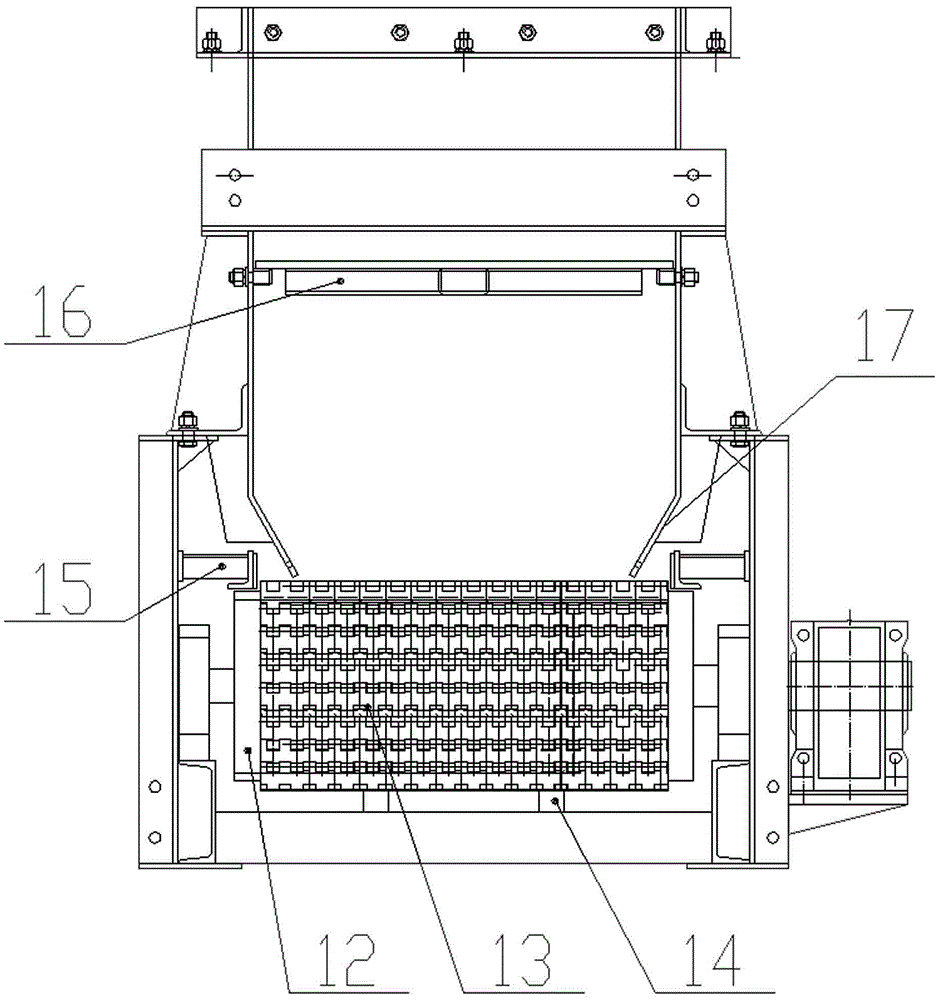

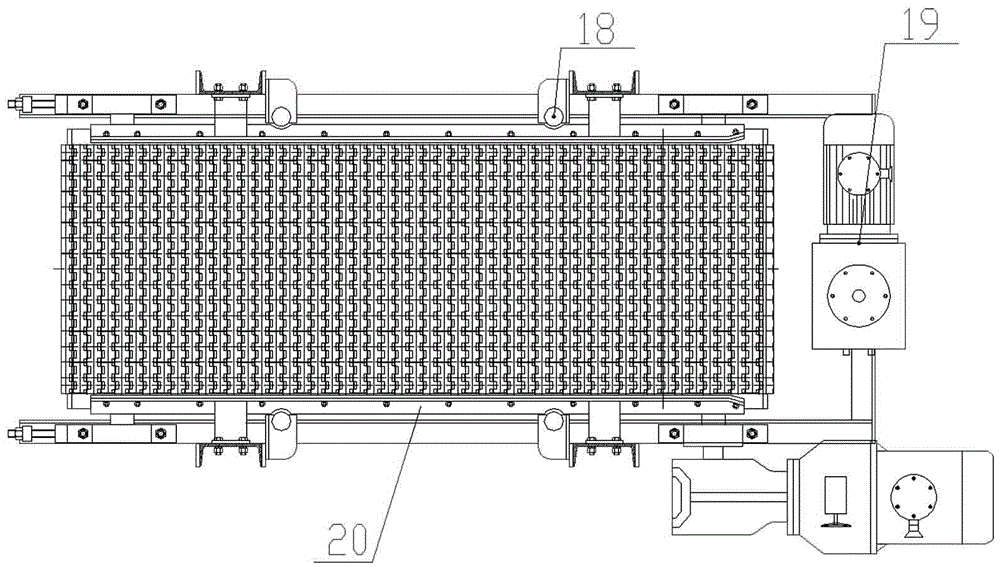

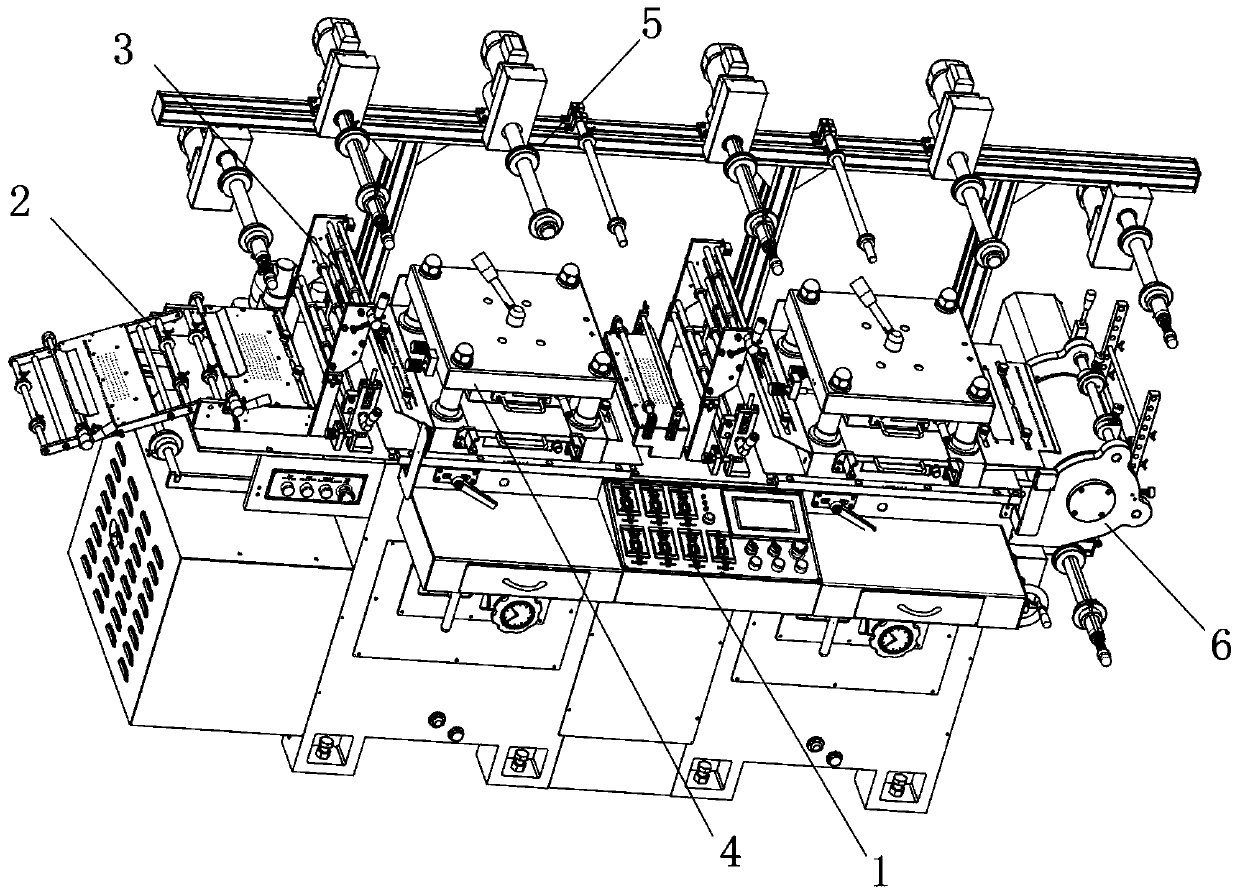

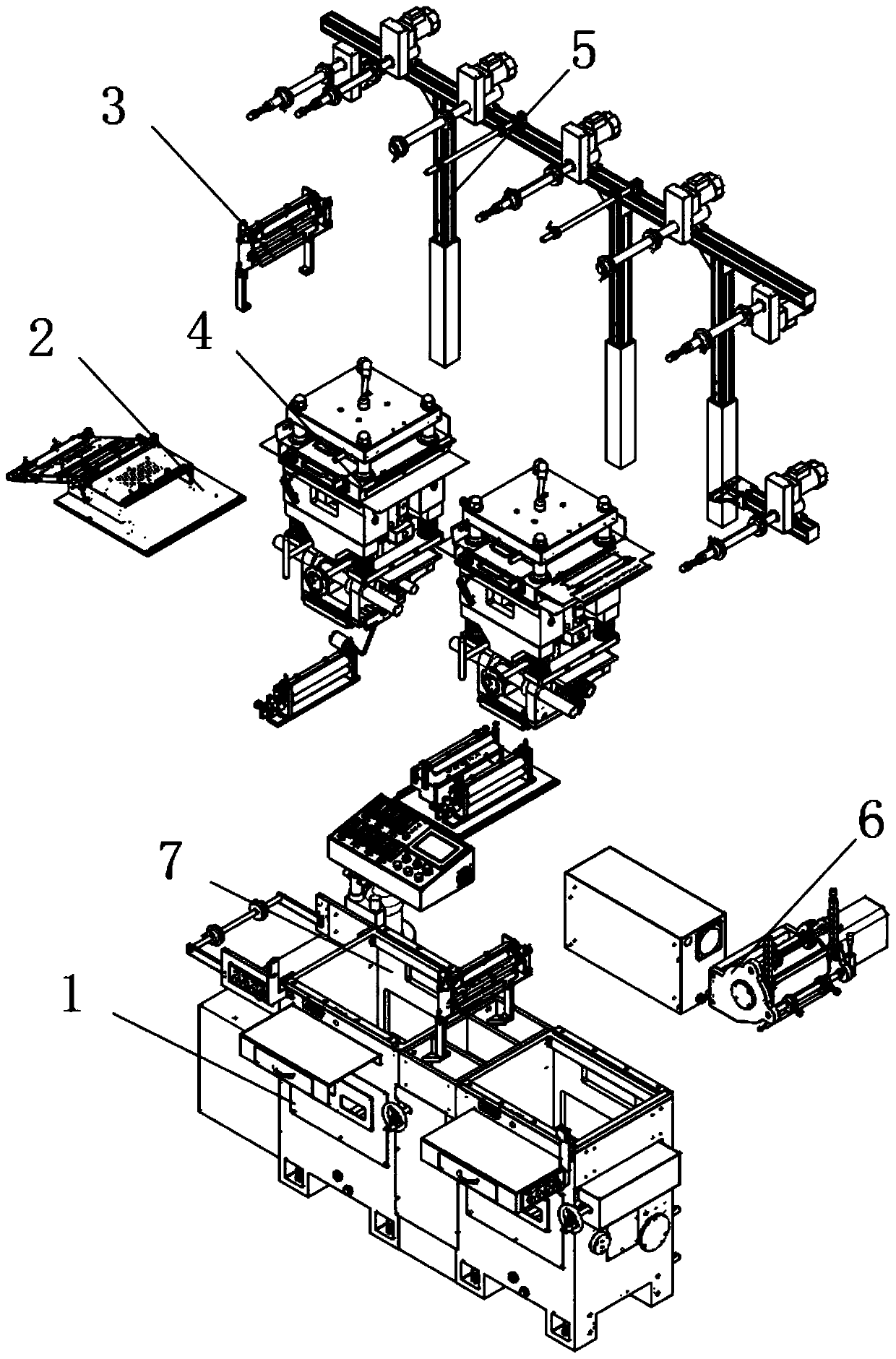

High-efficiency impact grinding and slotting device used for aviation equipment pipe bodies

ActiveCN109746811AImprove grindingImprove polishing efficiencyEdge grinding machinesGrinding carriagesAviationHydraulic pump

The invention discloses a high-efficiency impact grinding and slotting device used for aviation equipment pipe bodies. The high-efficiency impact grinding and slotting device comprises a front grinding table, a holding seat, a mounting box, first hydraulic pumps, first sliding rails, a transport tray, a rear grinding table and a slotting table; the bottom part of the front grinding table is provided with the mounting box, and one side of the front grinding table is provided with the holding seat in a cuboid shape; and the first hydraulic pumps are longitudinally arranged at the four corners ofthe mounting box correspondingly. The high-efficiency impact grinding and slotting device disclosed by the invention has the beneficial effects that a plurality of first motors arranged on each of mounting rods equidistantly are used for performing impact grinding on the pipe bodies synchronously at different positions through rotary grinding heads, so that the efficiency of performing impact grinding and polishing on the pipe bodies by the device is increased, and it is guaranteed that the working gap between every two supporting plate rods is more suitable; impact grinding components on thedevice cannot be scratched or damaged when the pipe bodies are processed by the impact grinding components; and the mounting rods are driven to vertically shifted synchronously through two second hydraulic columns by connection blocks, so that the mounting rods can be vertically adjusted and moved more steadily, the rotary grinding heads and the pipe bodies are prevented from being forcefully collided, and it is guaranteed that the surface of each pipe body is more smooth by impact grinding and has no dents.

Owner:灵璧县浩翔信息科技有限公司

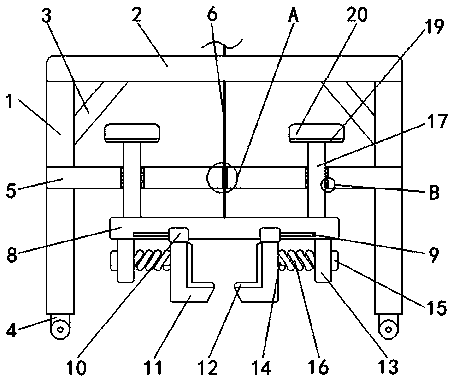

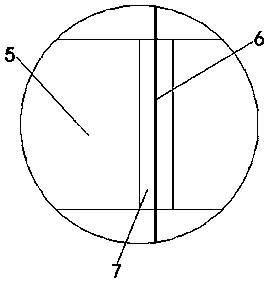

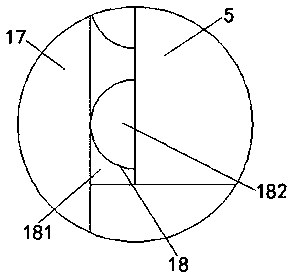

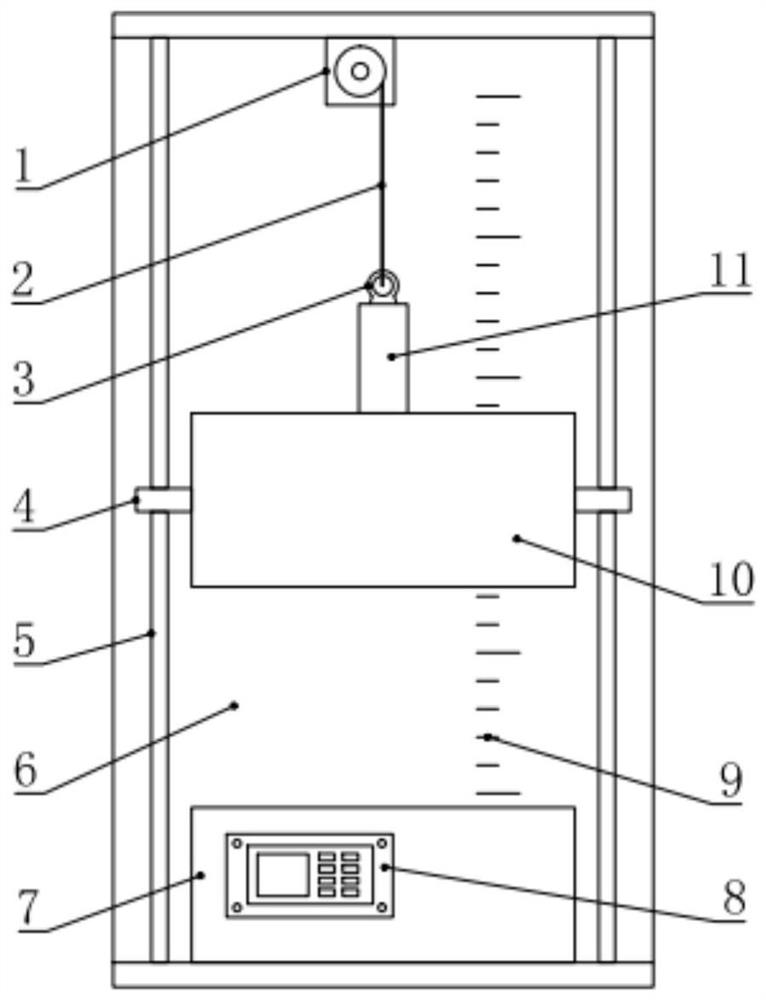

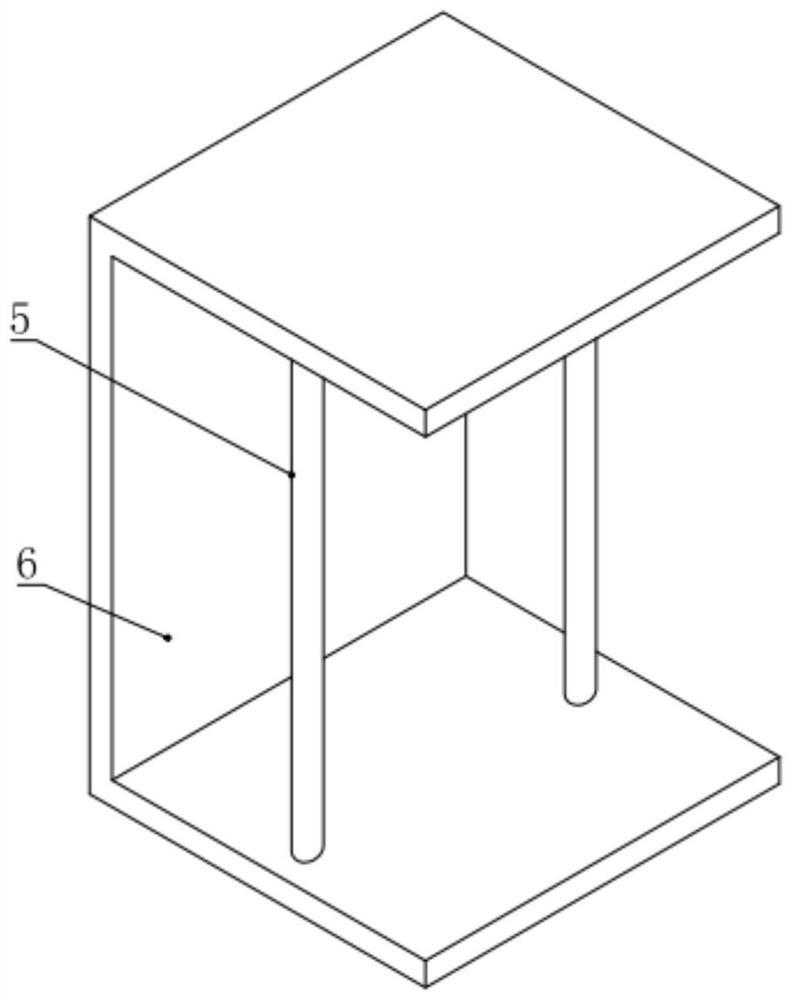

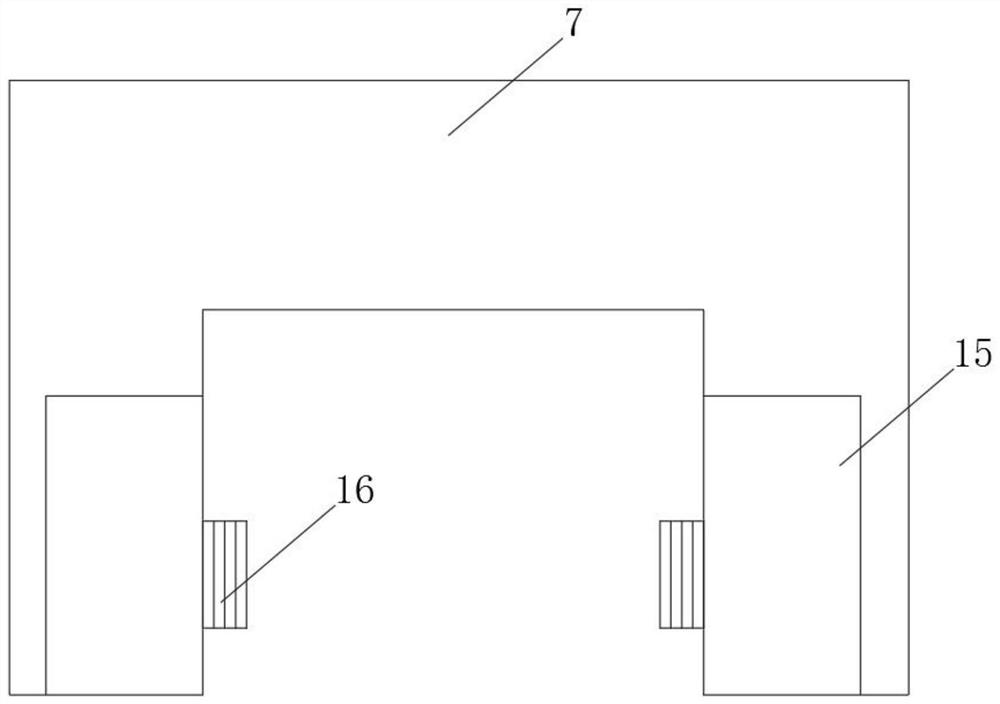

Movable lifting frame for medical and chemical equipment overhaul

InactiveCN108455469AEasy to useStable up and down adjustmentPortable liftingArchitectural engineeringPulley

The invention relates to the field of medical technology, and discloses a movable lifting frame for medical and chemical equipment overhaul. The movable lifting frame for medical and chemical equipment overhaul comprises vertical plates, wherein a top plate is fixedly arranged on the top parts of the vertical plates; inclined rods connected with the vertical plates are fixedly arranged at two endsof the lower surface of the top plate; pulleys are movably arranged on the bottom parts of the vertical plates; a cross plate is inserted to middle sections of the inner surfaces of the vertical plates; a steel wire rope penetrating through the cross plate and extending to the lower part of the cross plate is inserted to the upper surface of the top plate; a first circular hole matched with the steel wire rope is formed in a middle section of the upper surface of the cross plate; and a bottom plate located under the cross plate is fixedly arranged on the bottom part of the steel wire rope. According to the movable lifting frame for medical and chemical equipment overhaul, through the pulleys arranged on the bottom parts of the vertical plates, the device can move as a whole and is convenient to use; through the installed inclined rods, the device is stable to install as a whole; and through the installed steel wire rope, the device can be adjustable in height so as to be convenient touse.

Owner:盐城市瑞普医药化工有限公司

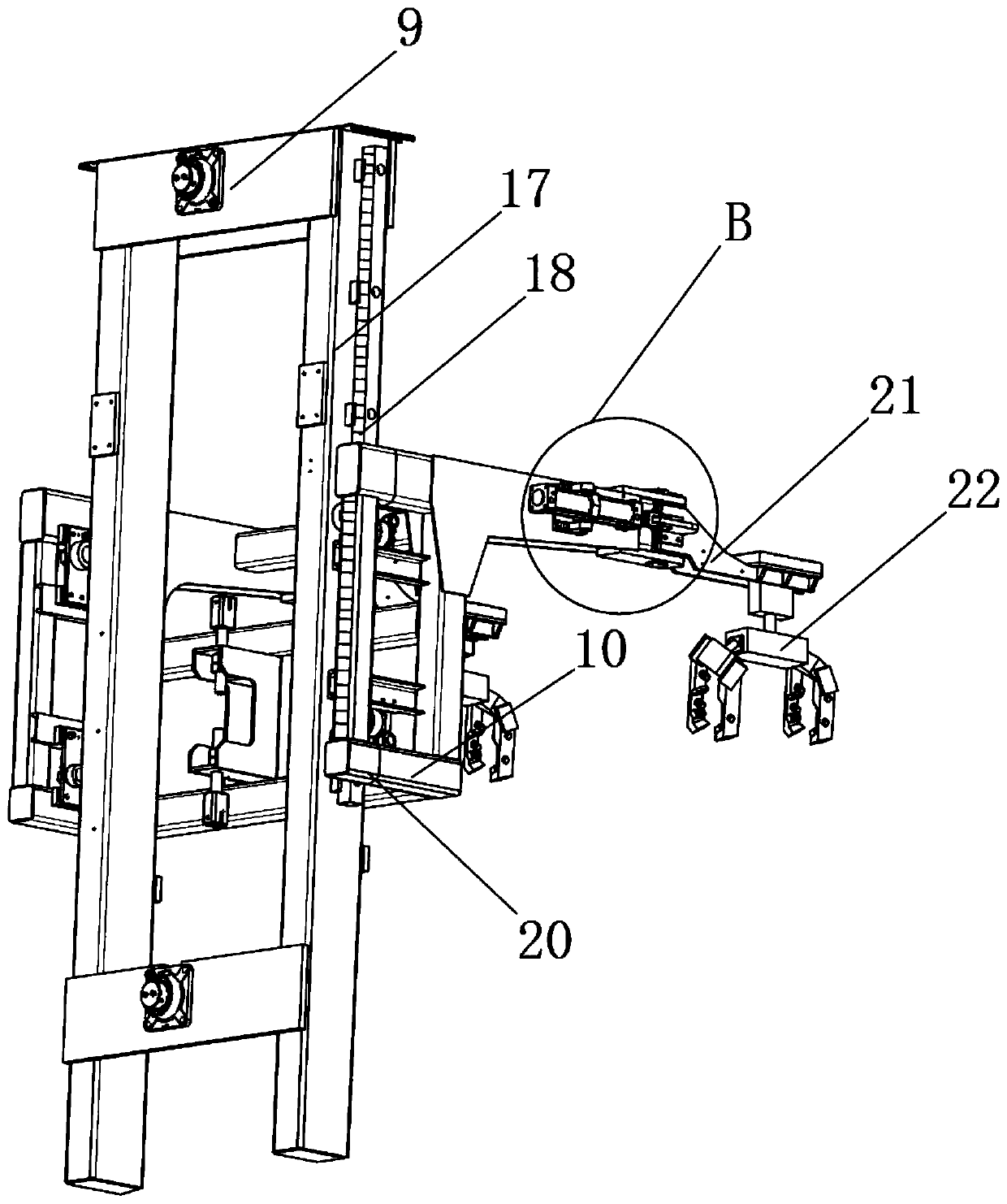

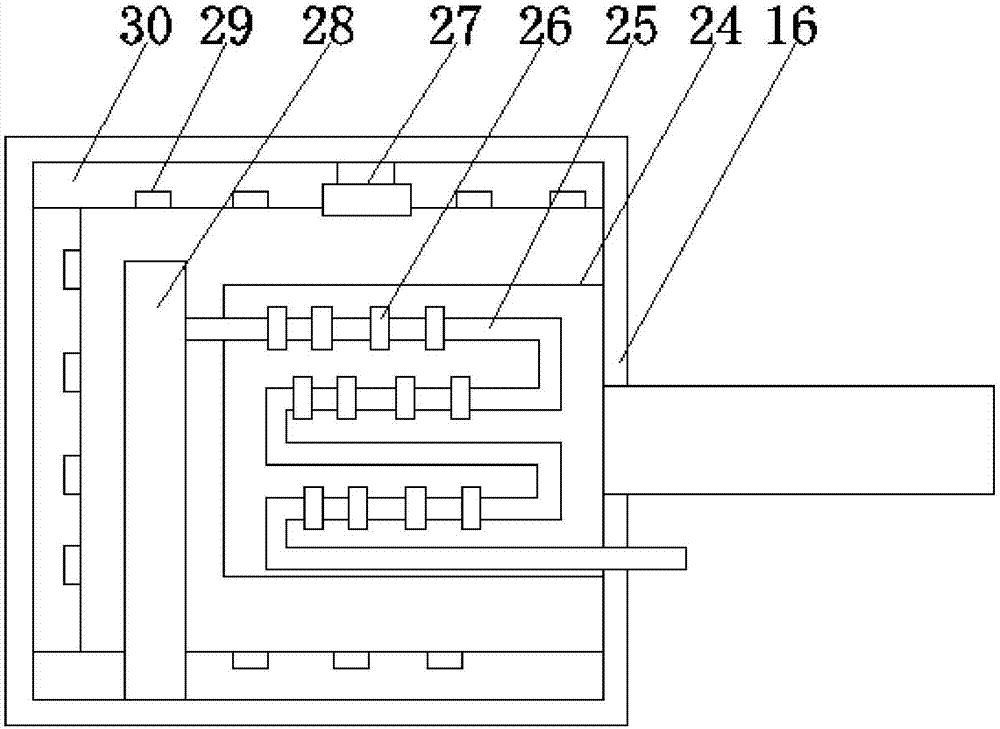

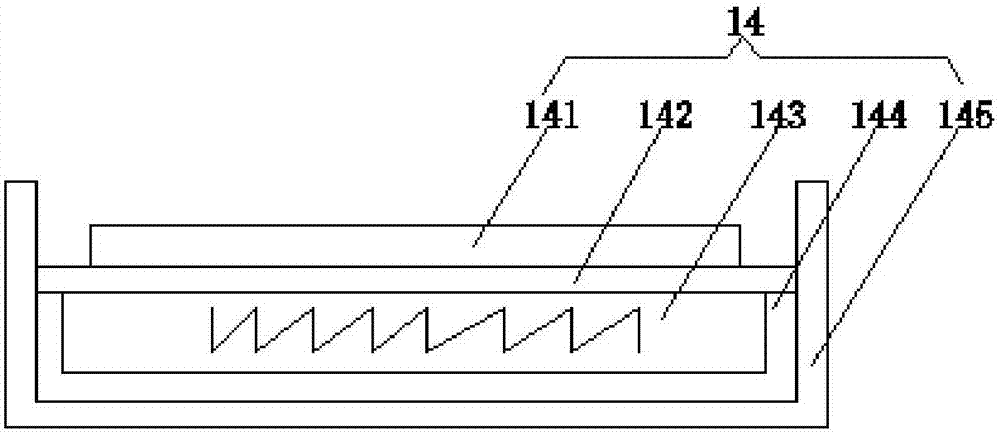

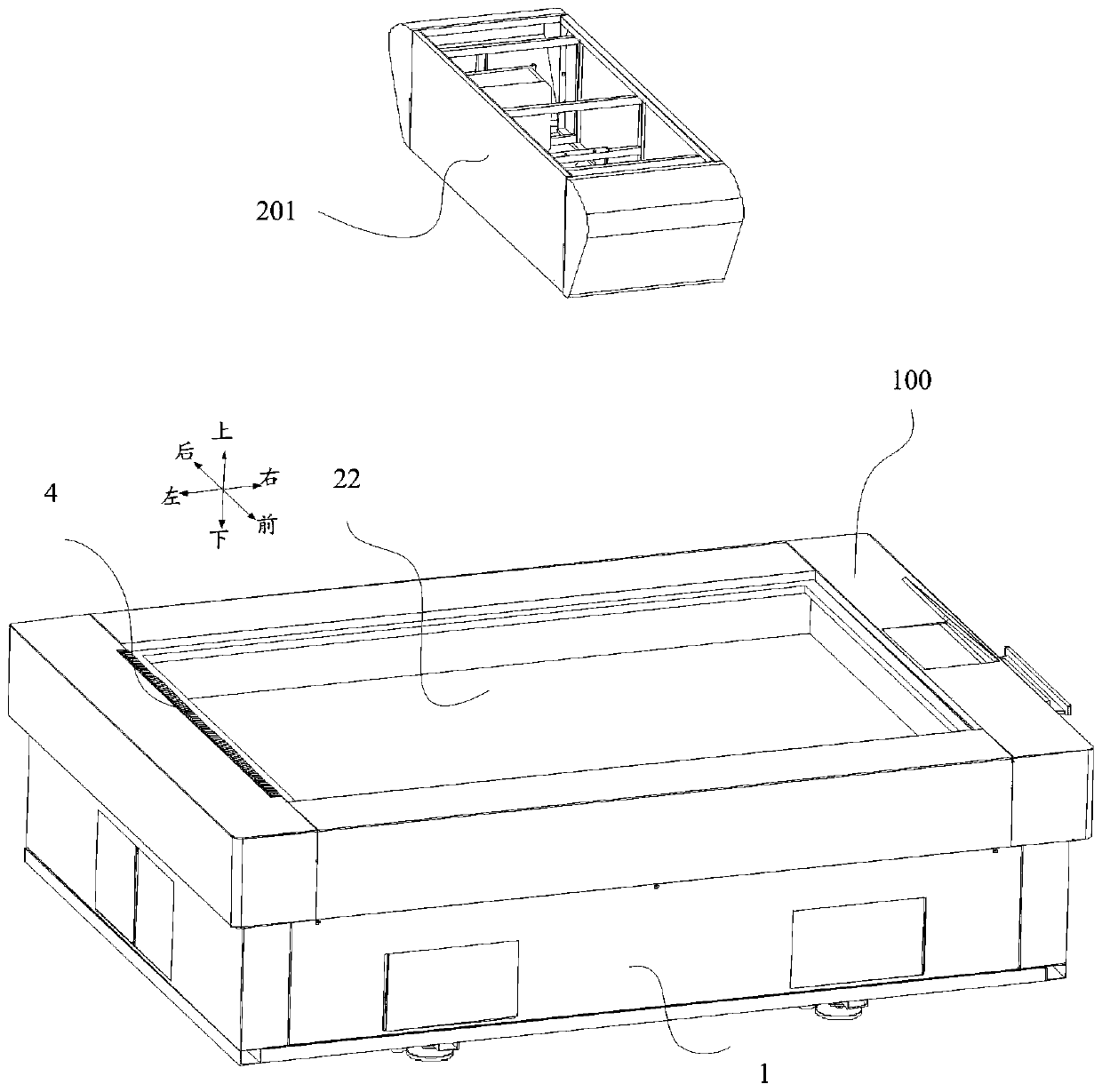

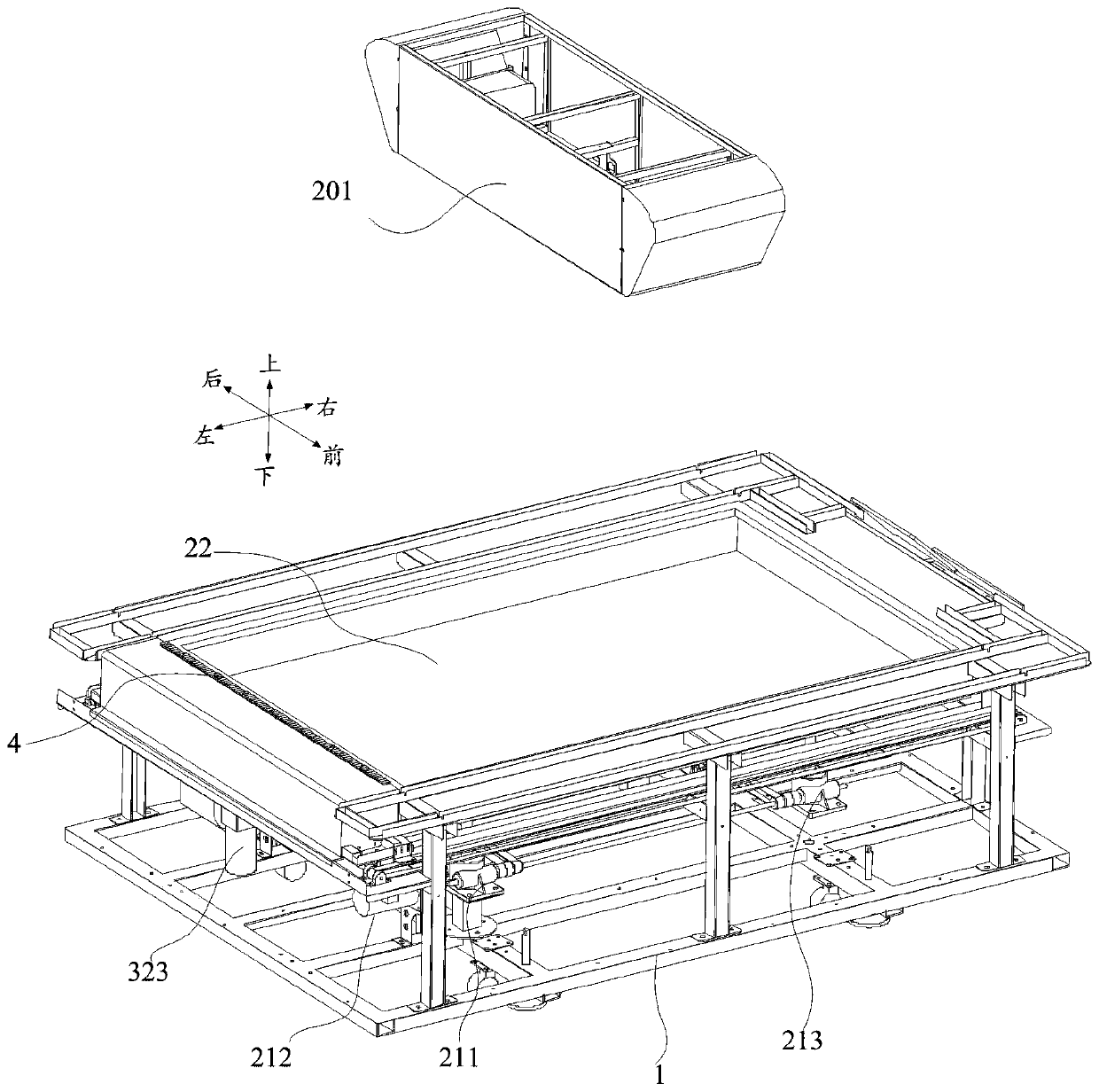

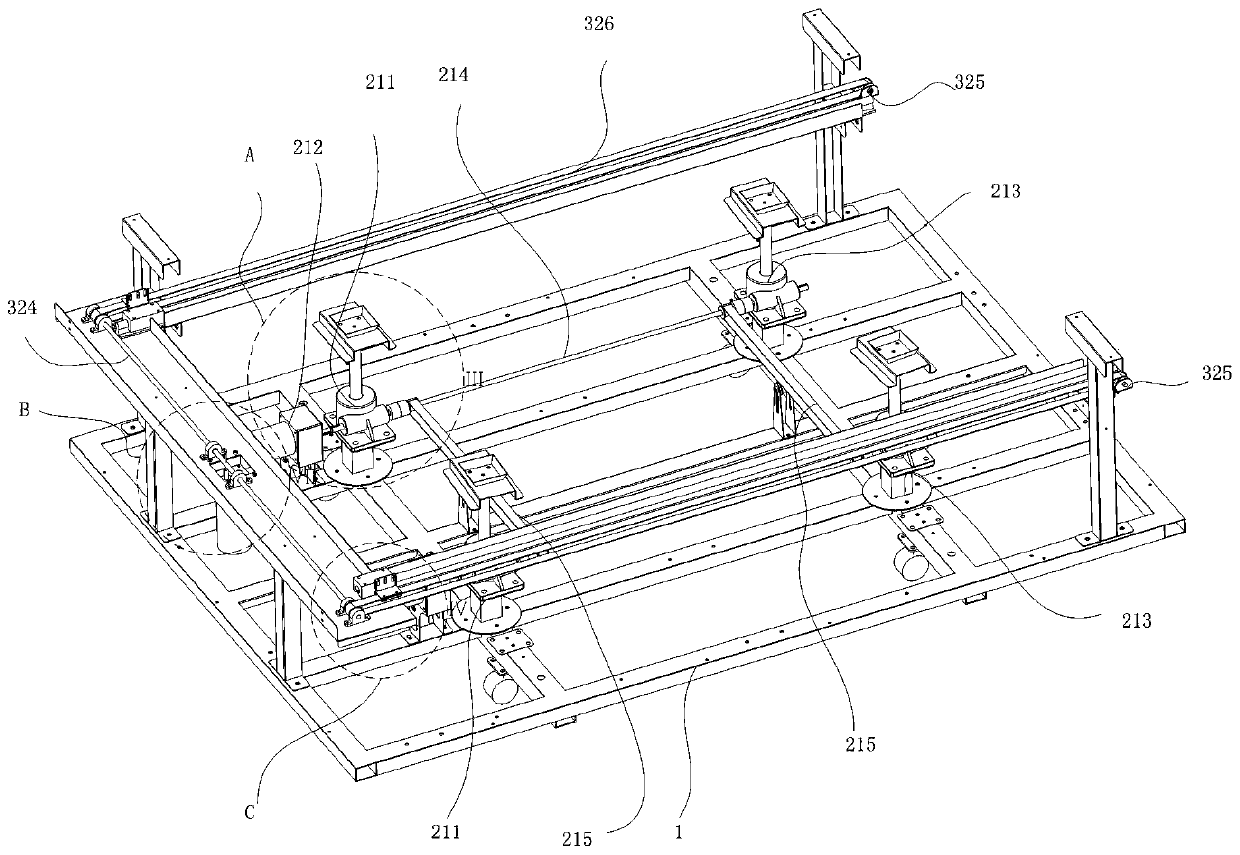

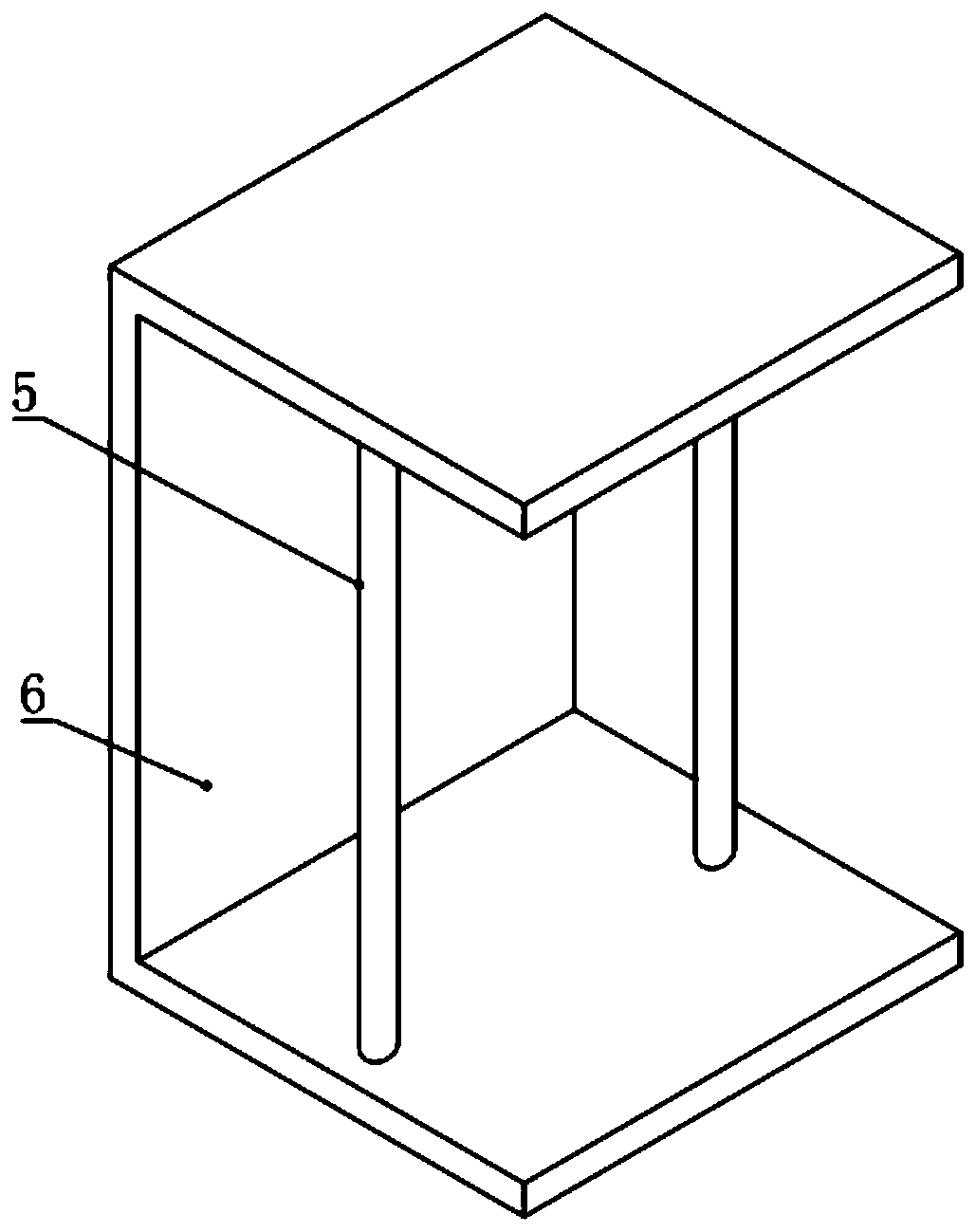

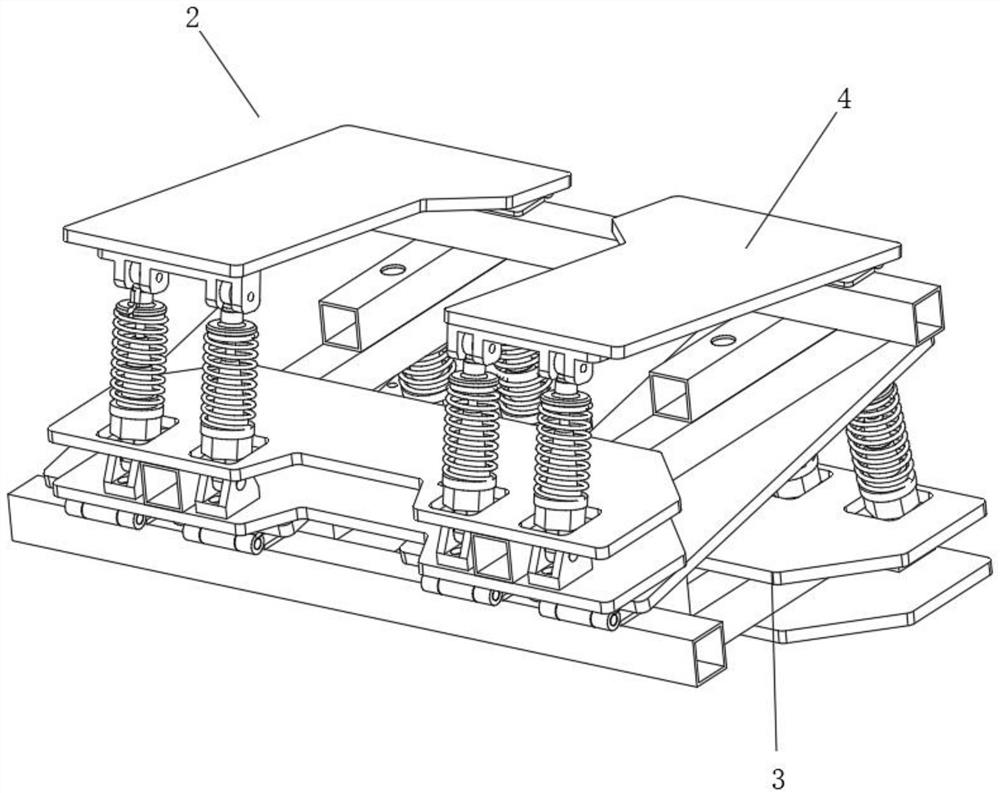

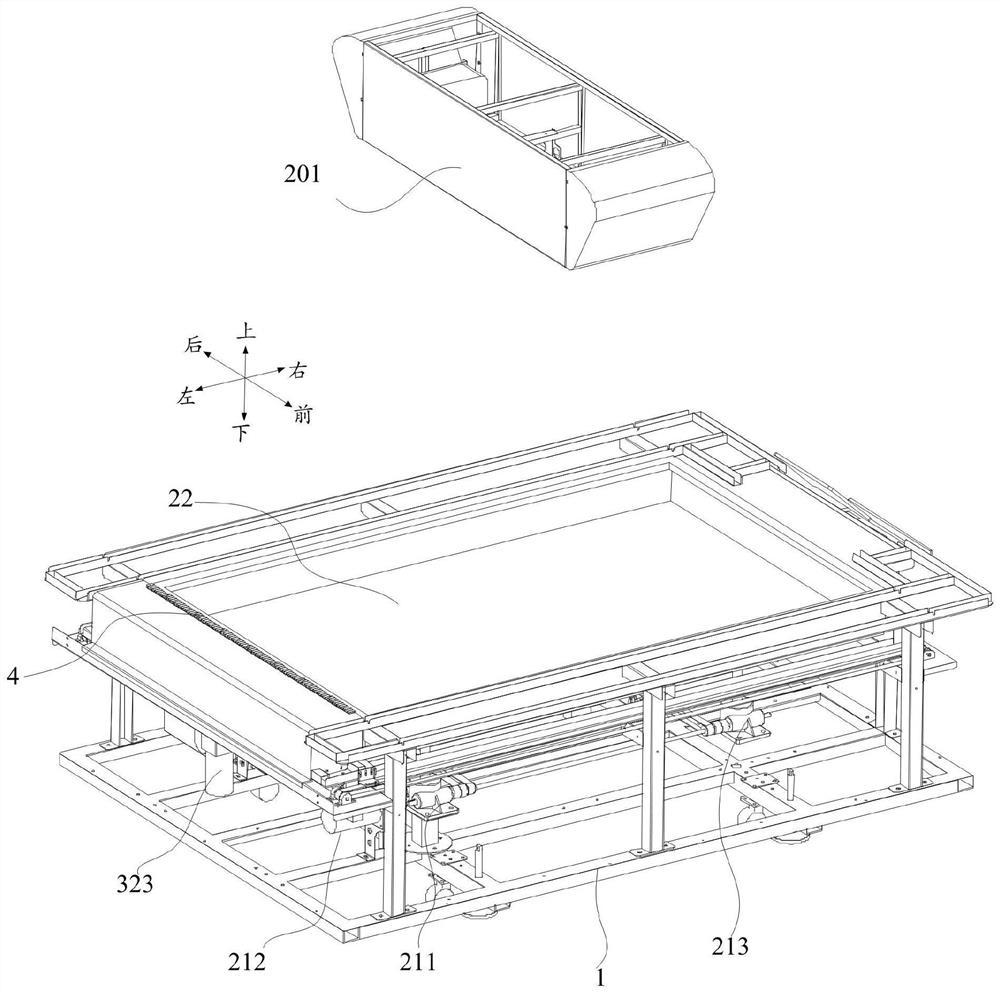

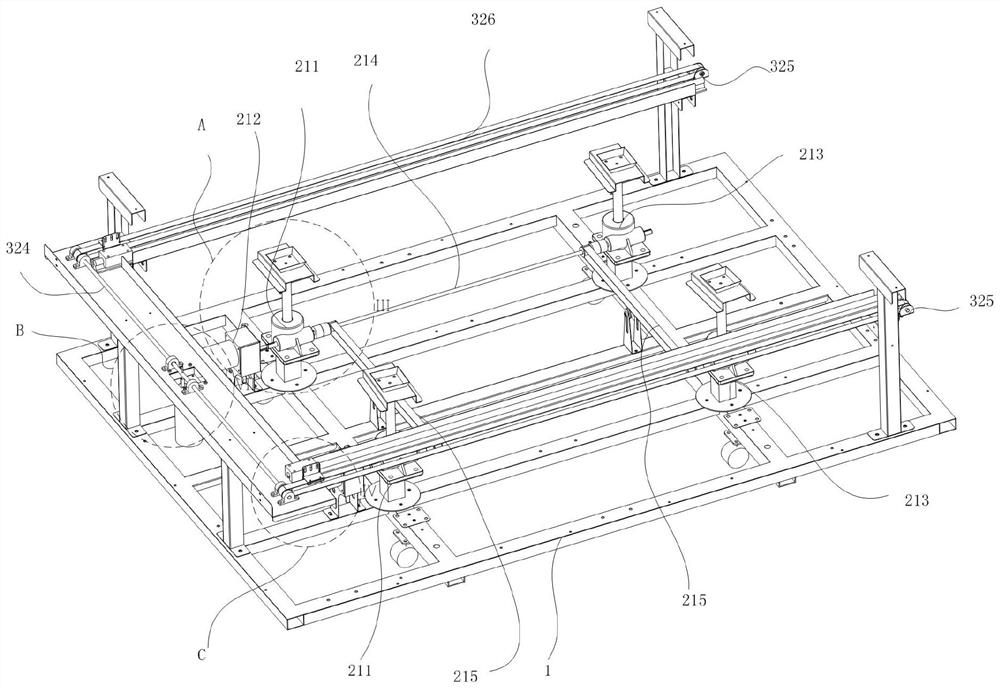

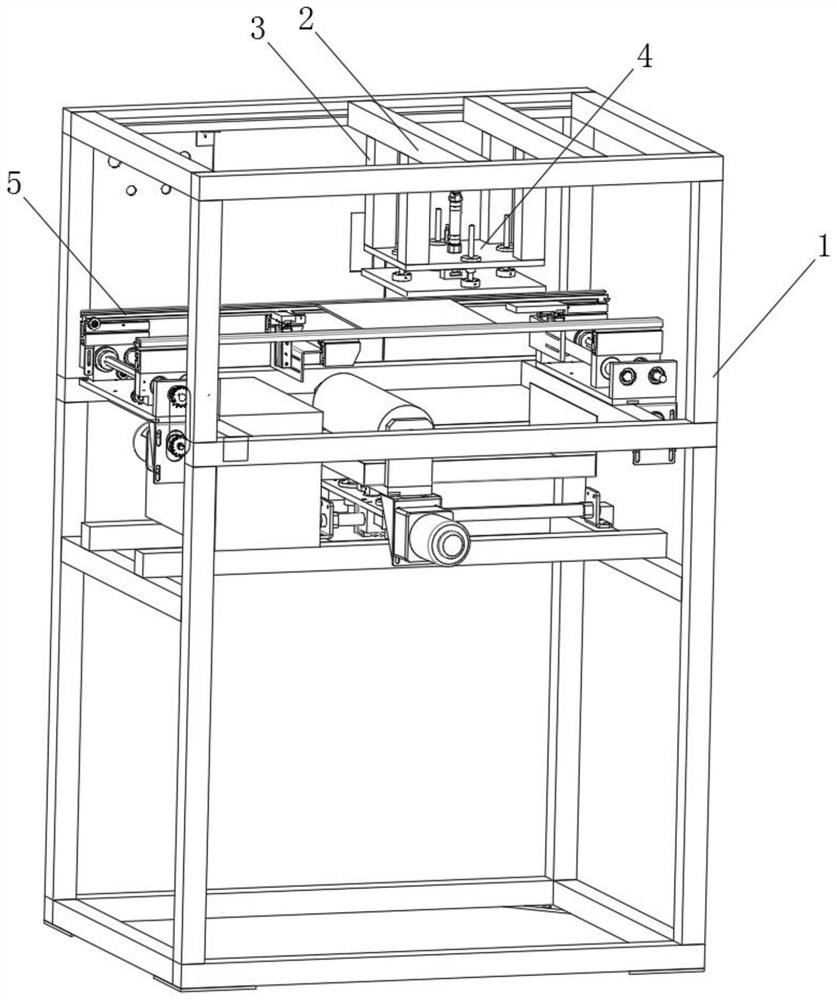

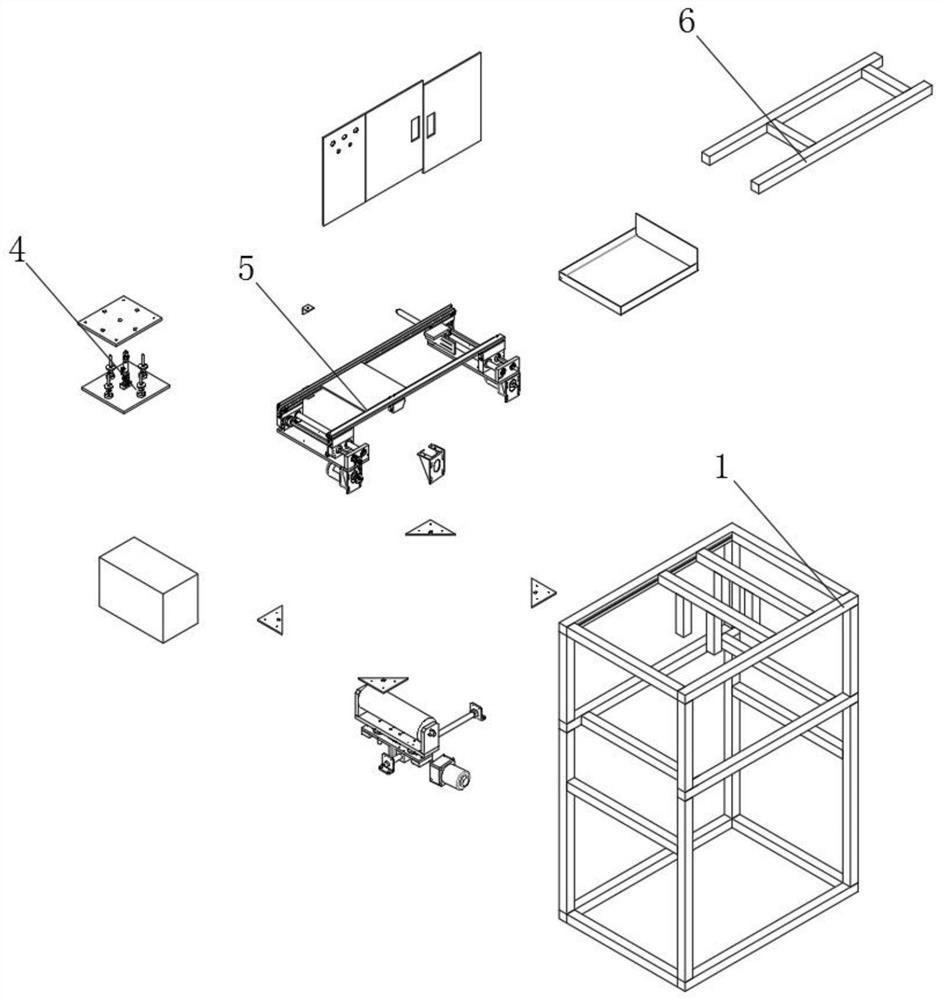

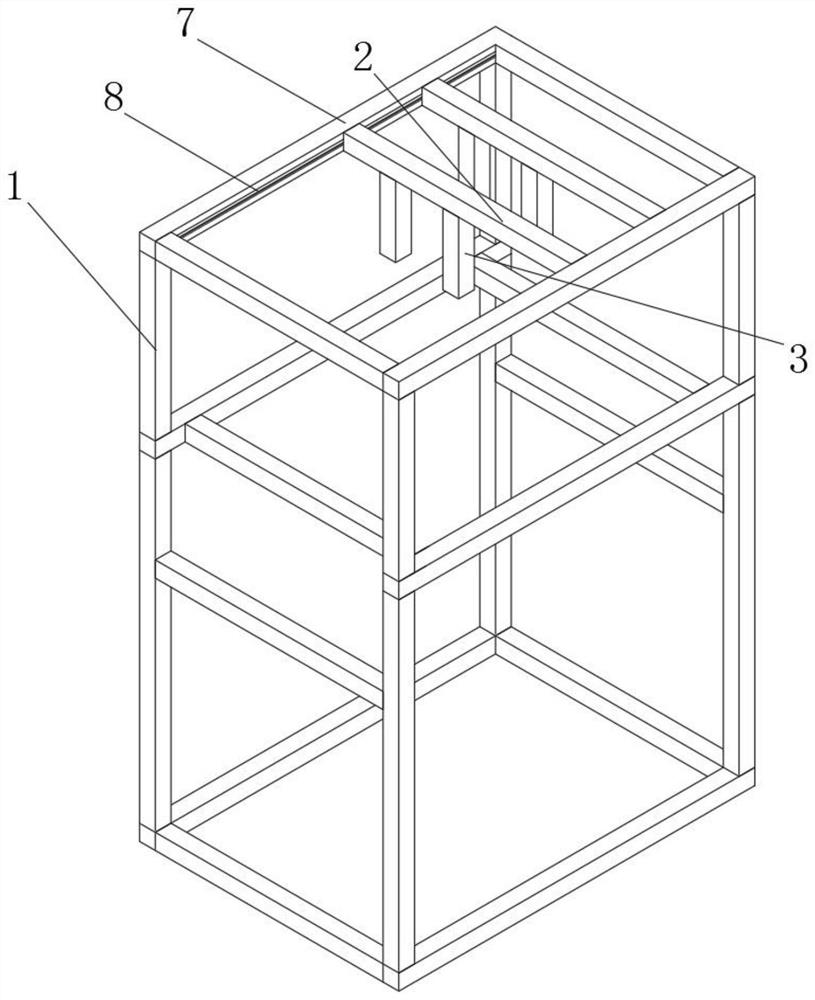

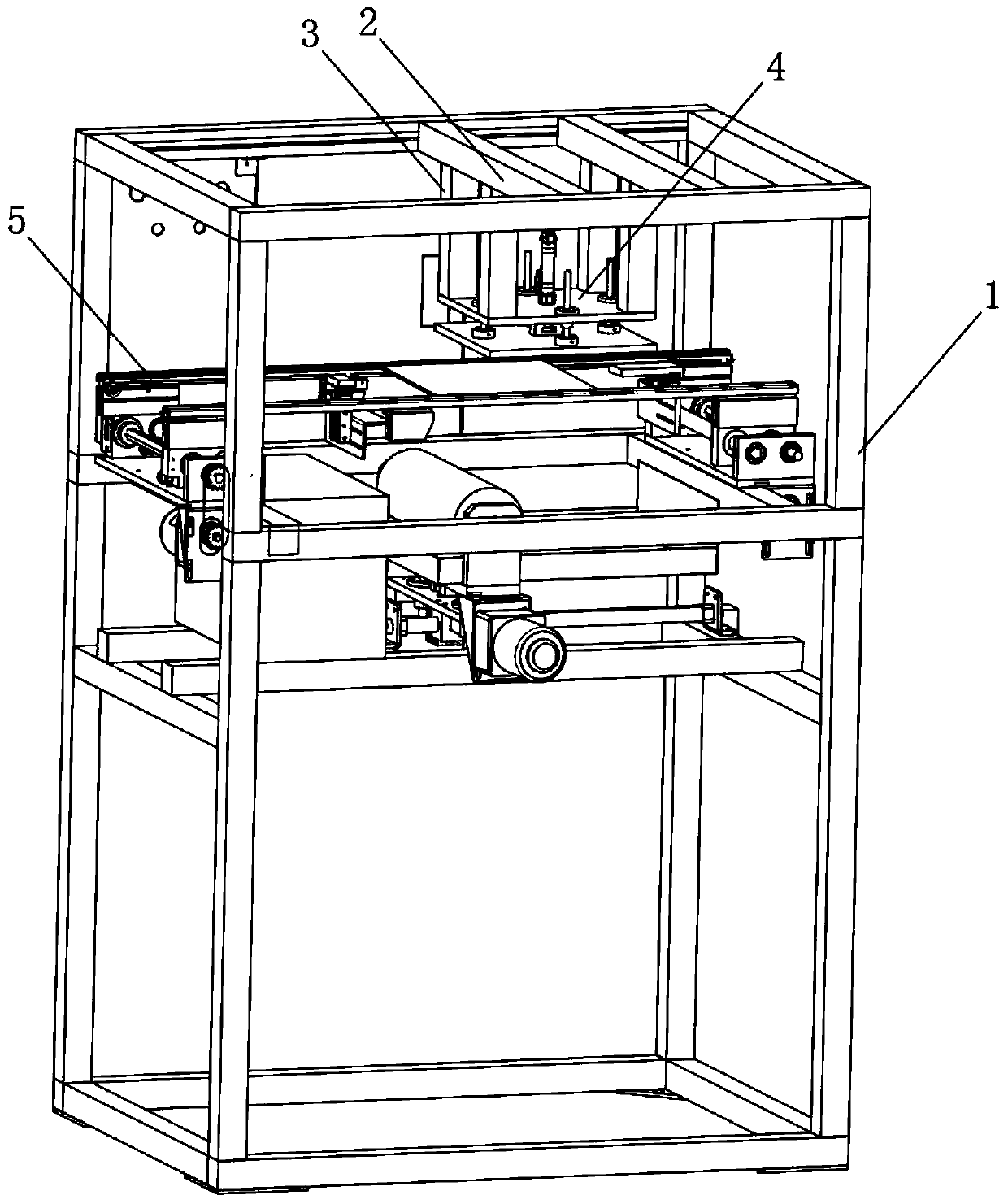

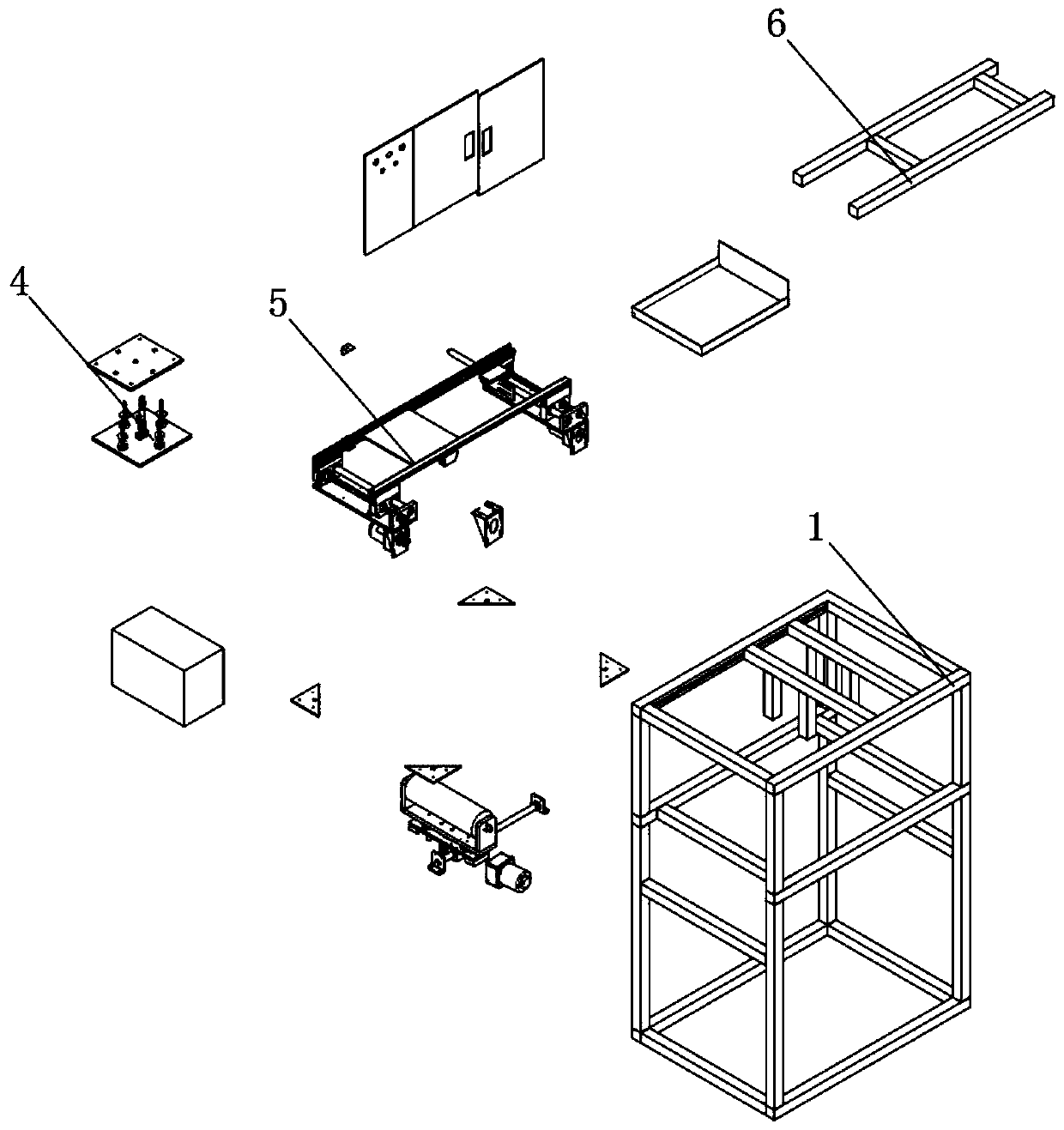

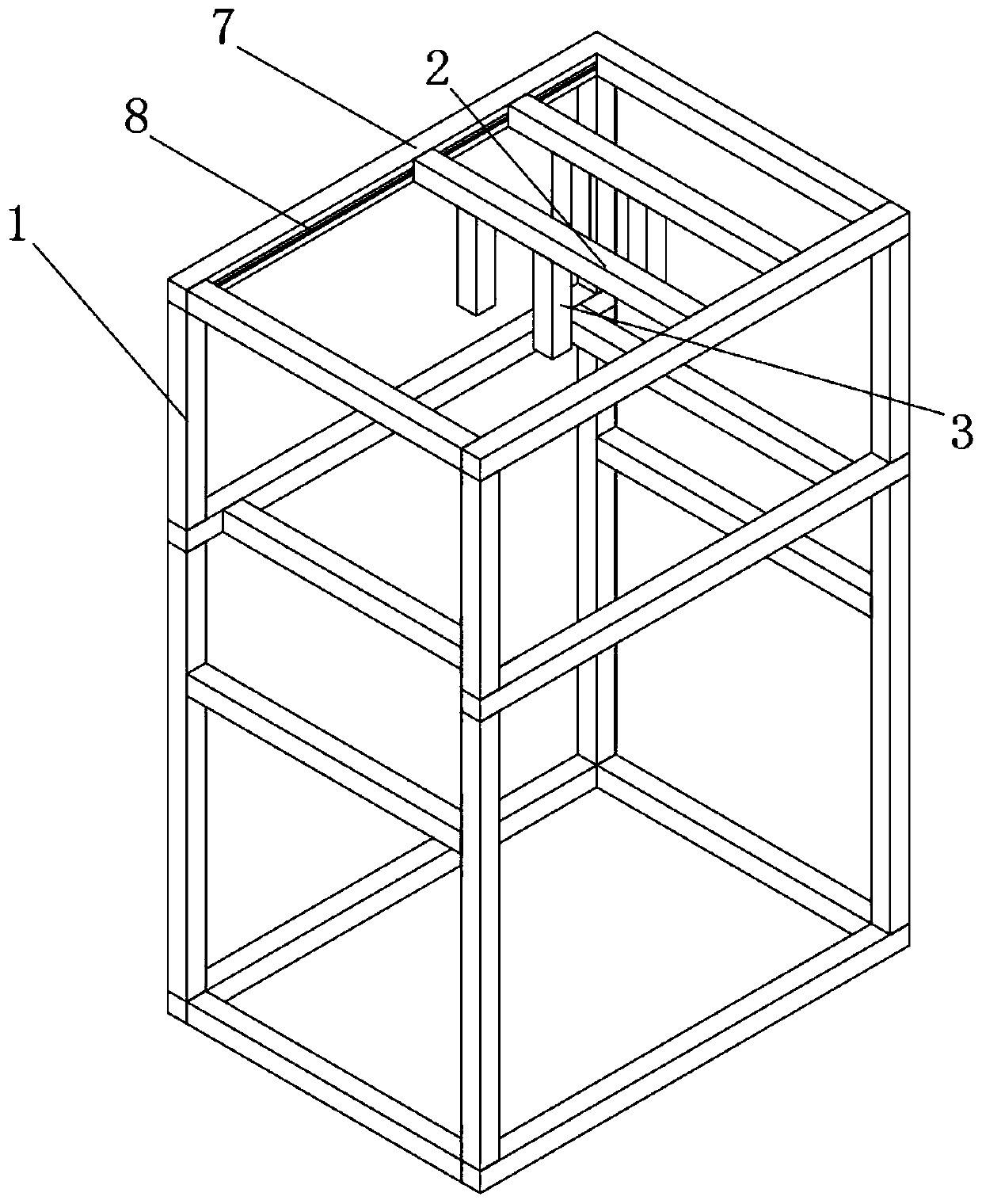

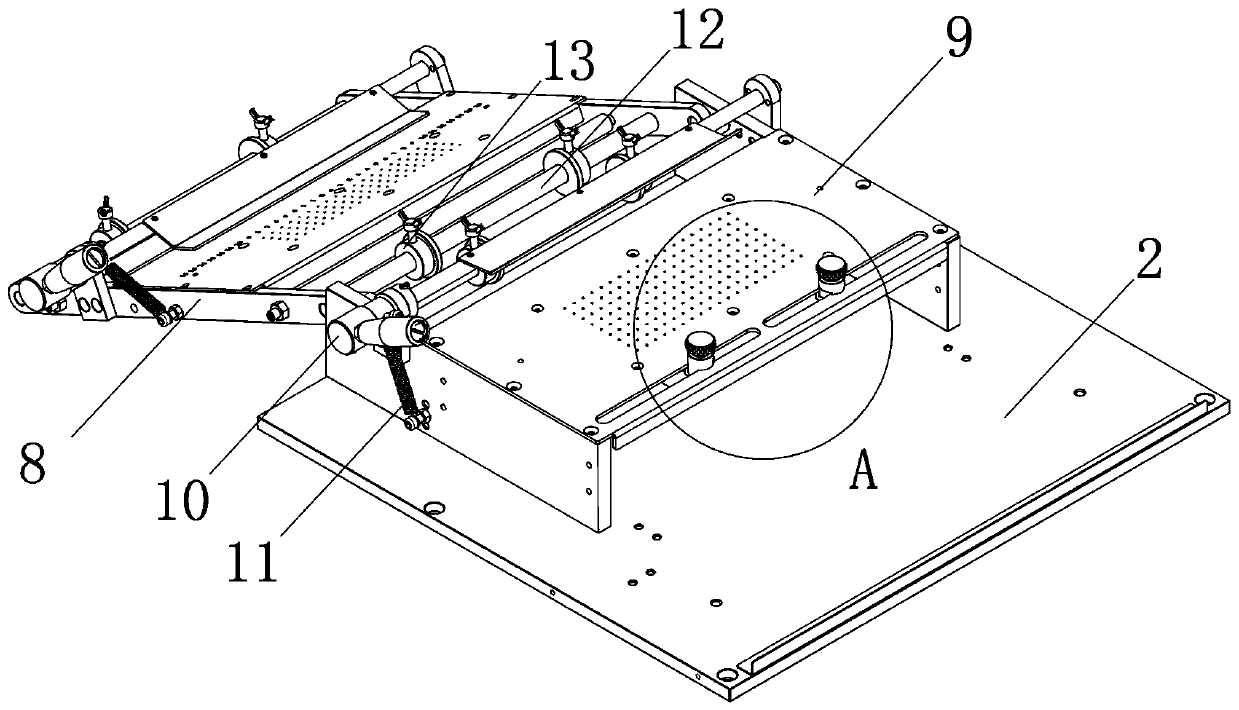

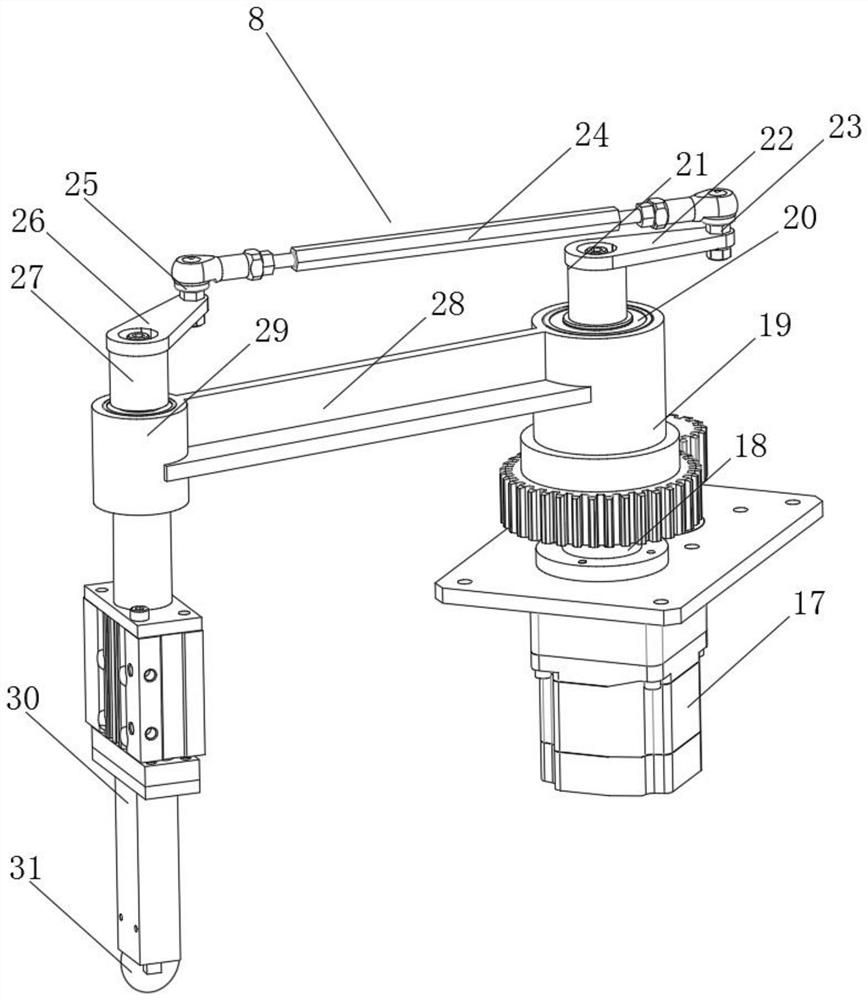

Projection sand table capable of automatically constructing terrain and projection system

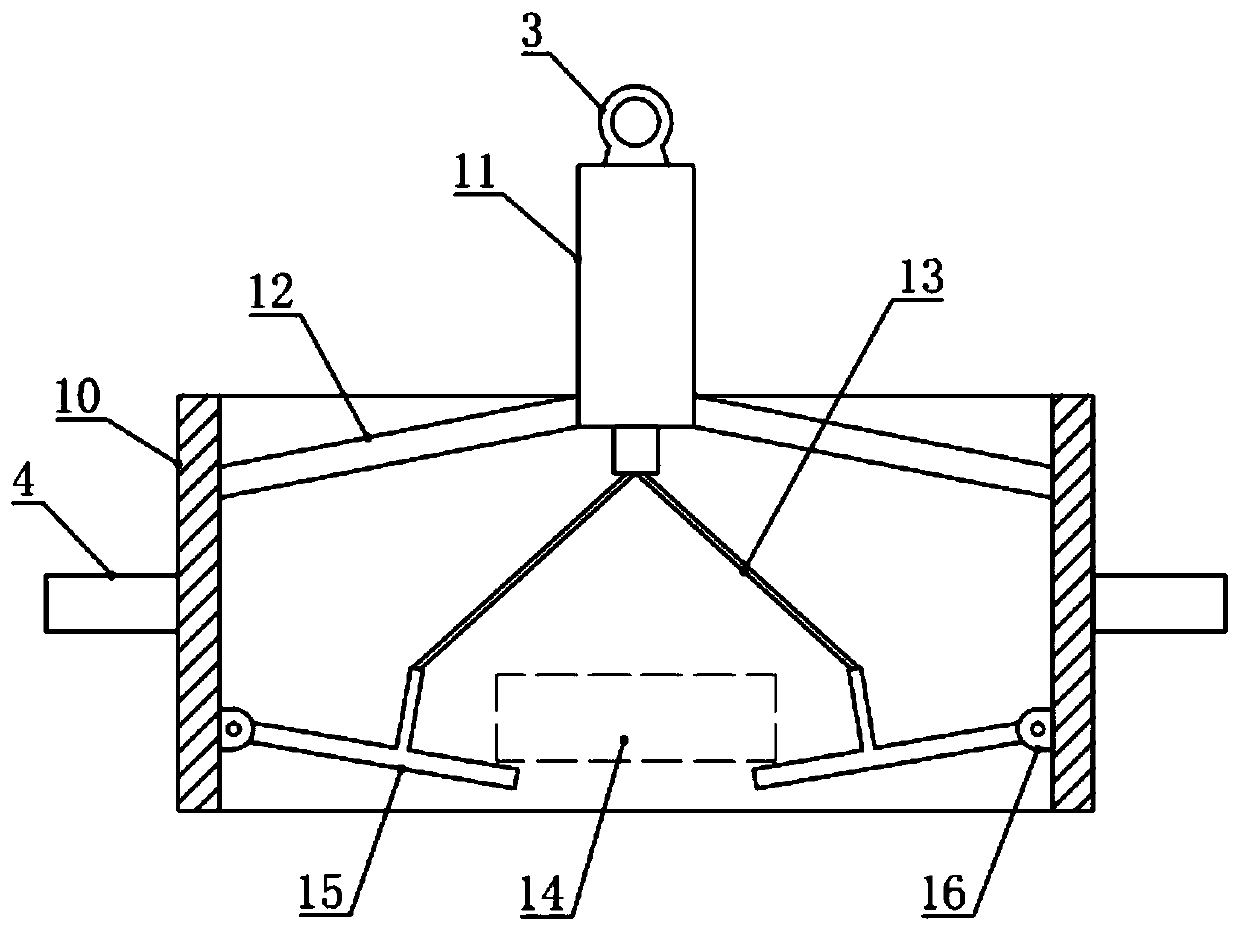

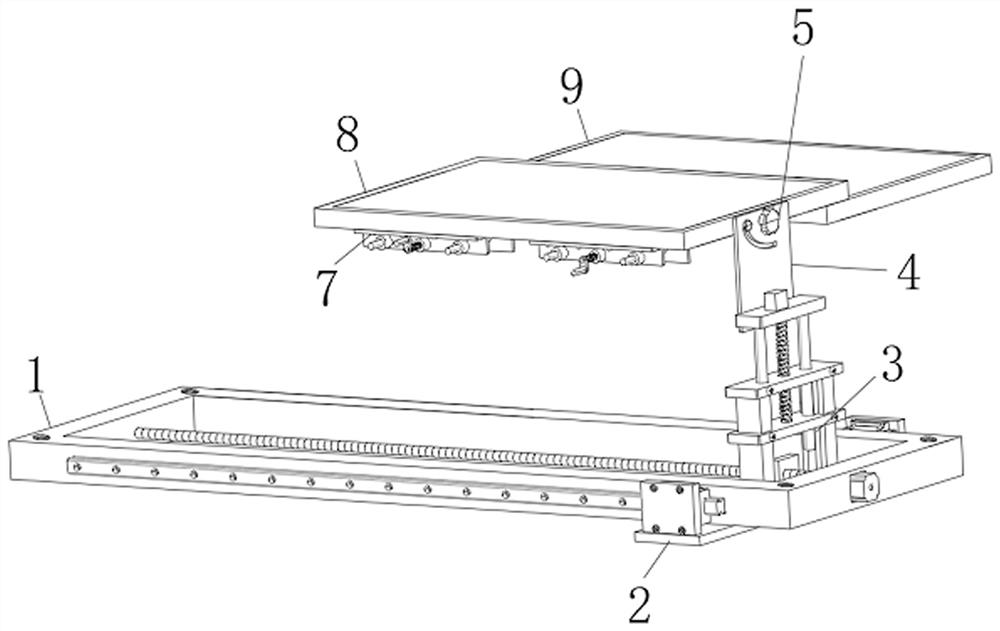

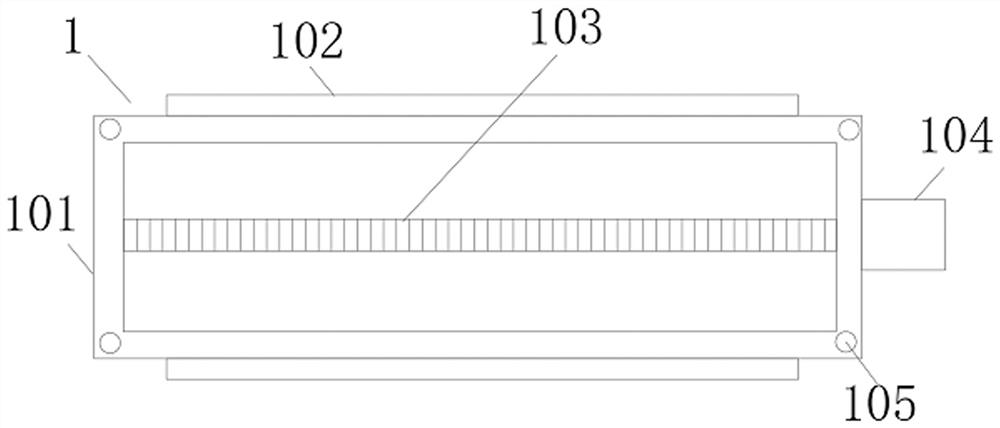

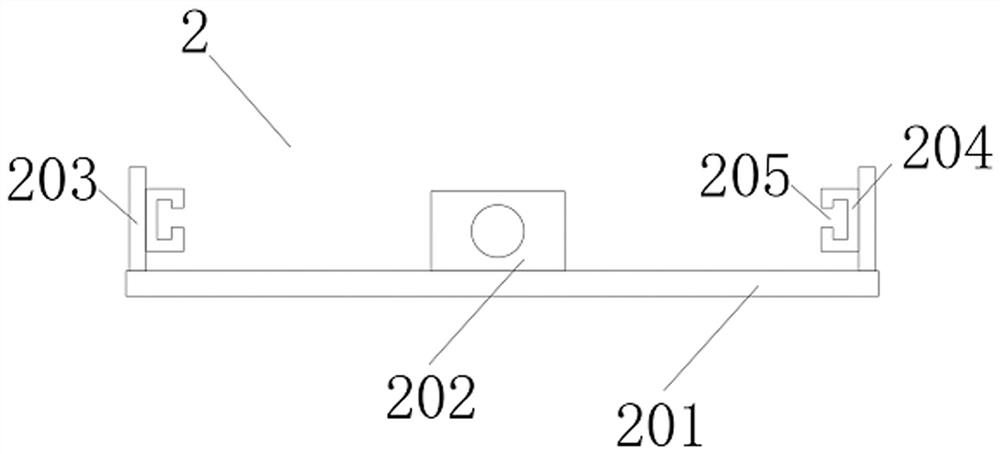

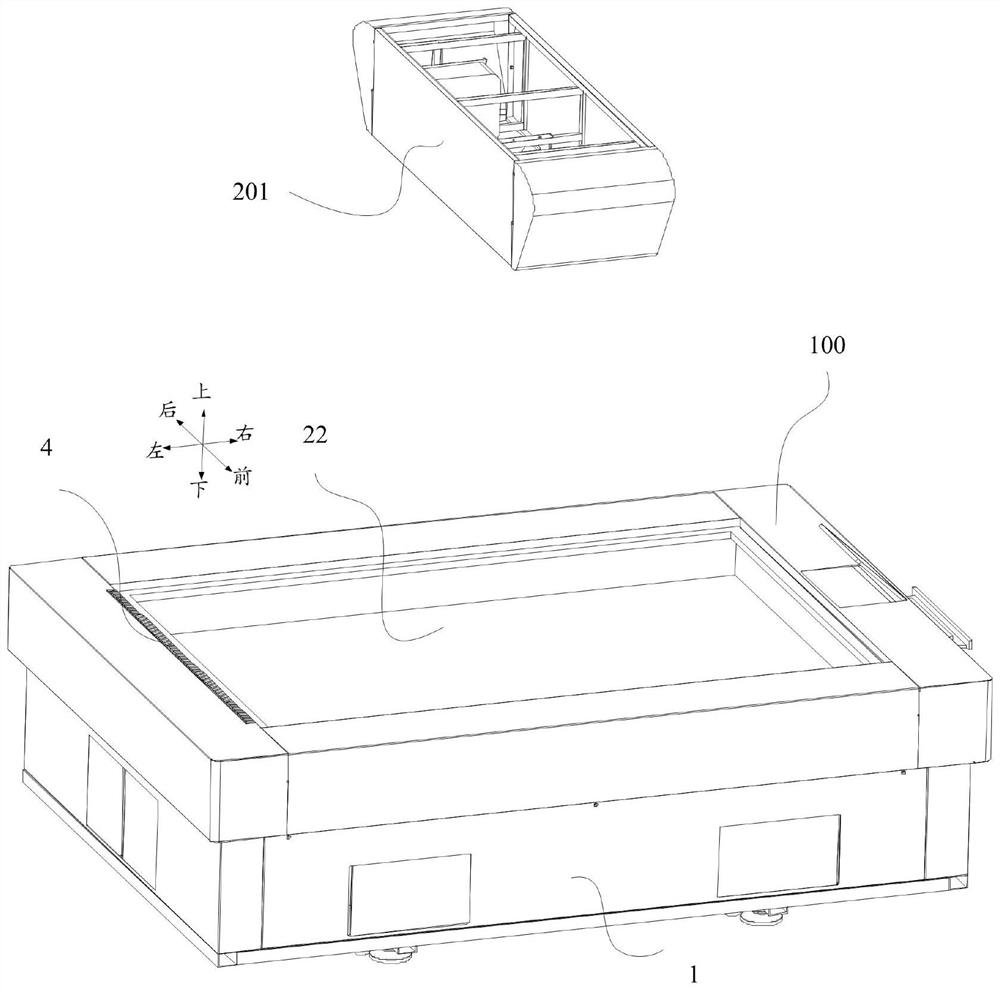

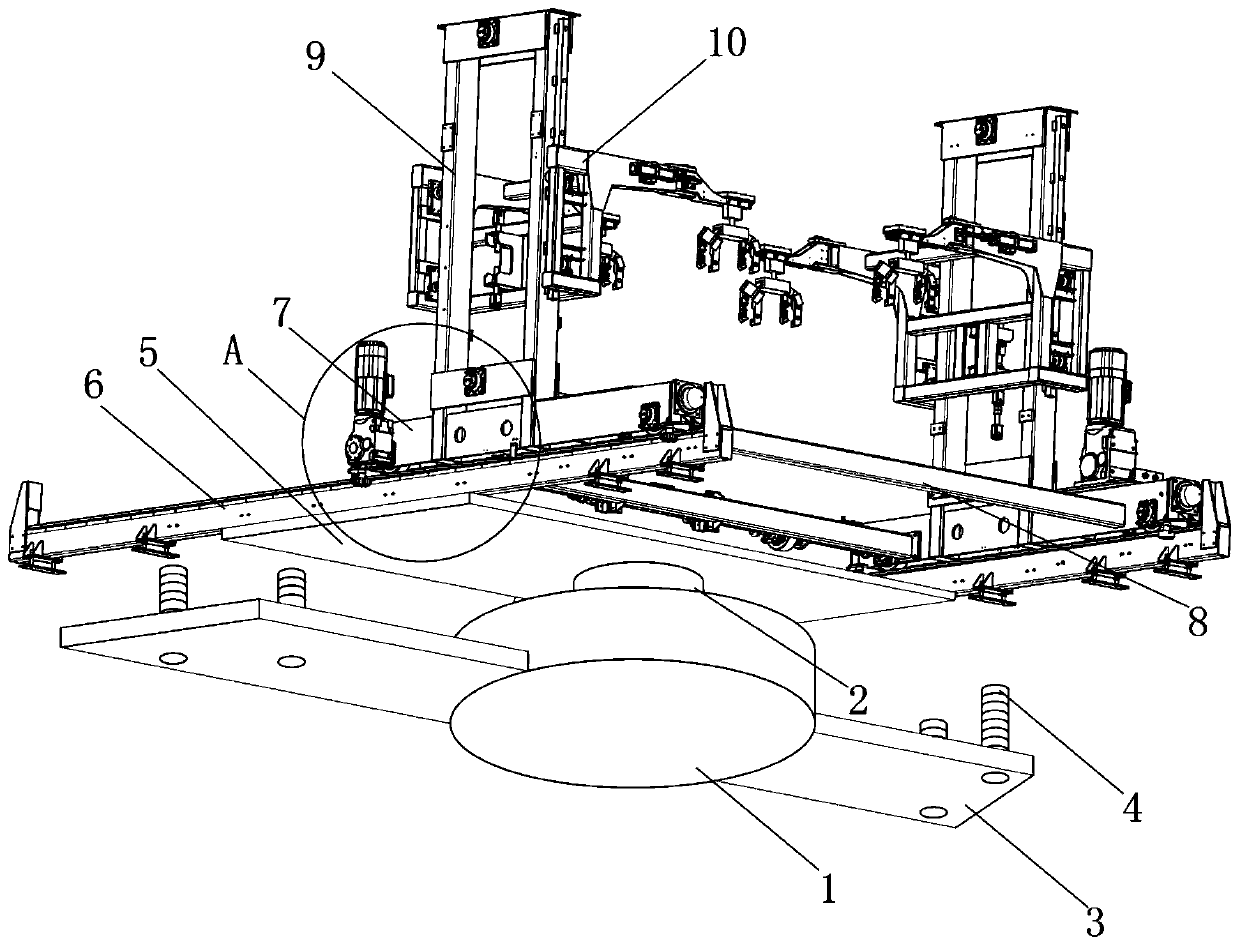

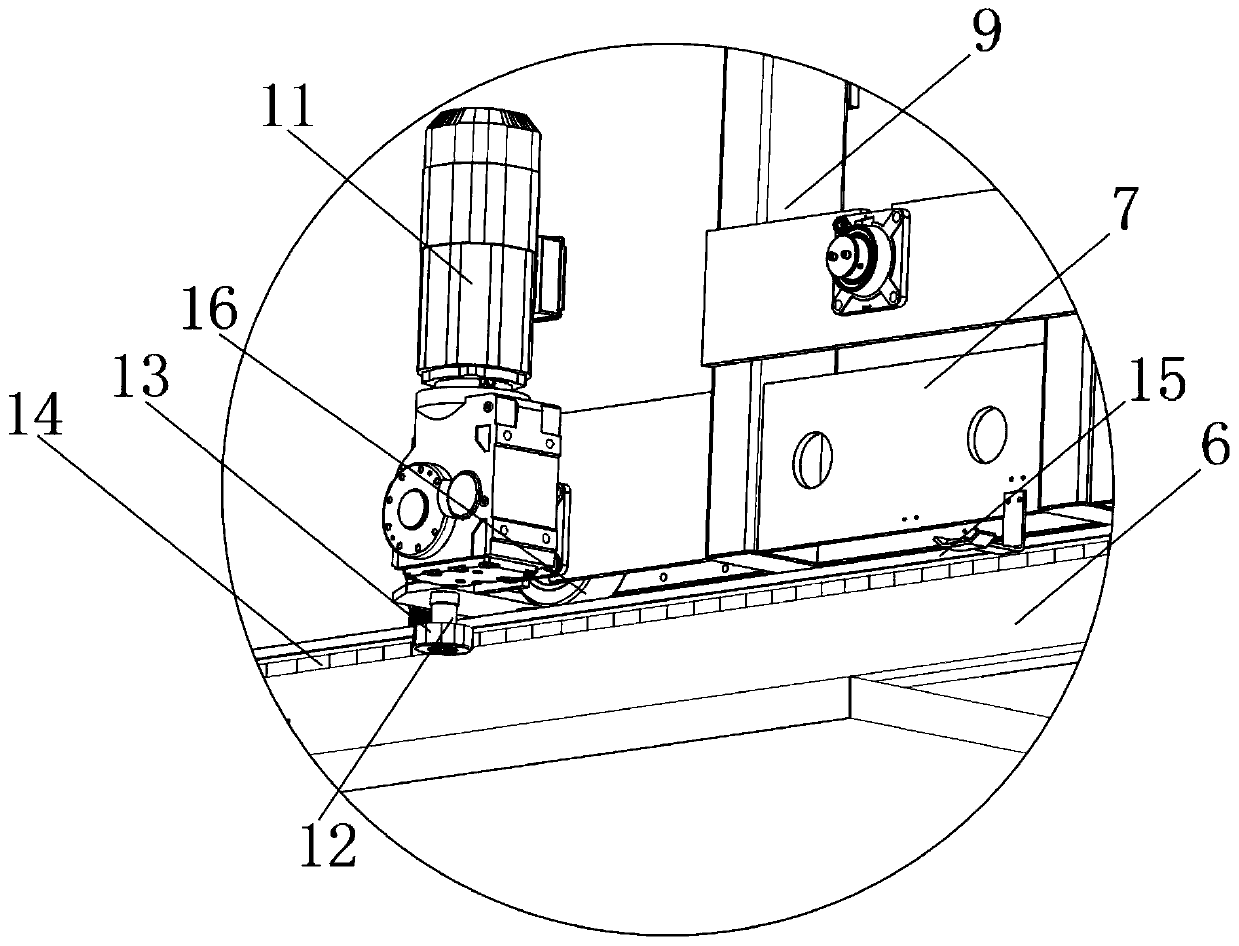

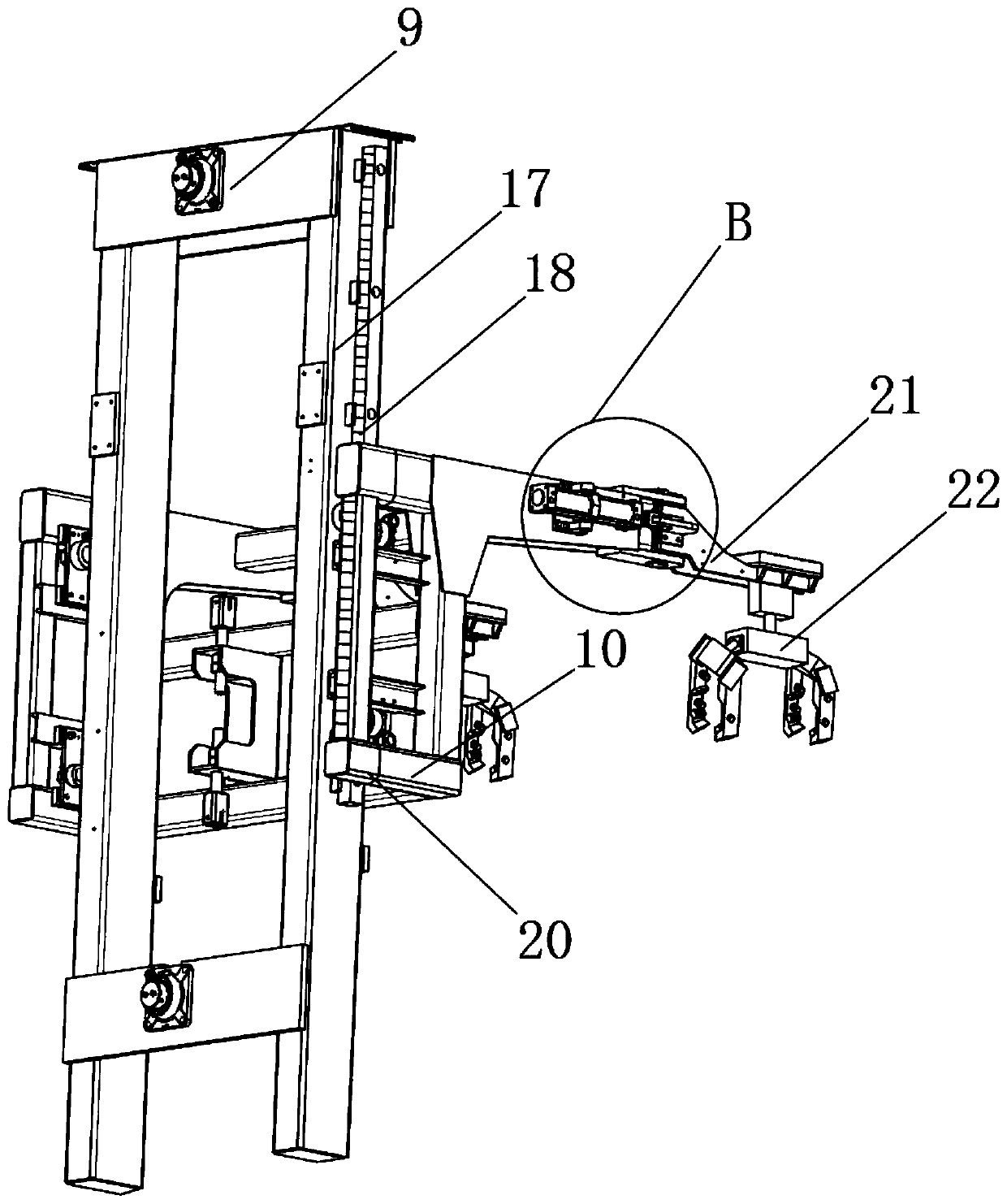

ActiveCN110444100ASolve the problem of not being able to visually observe the topography of the sand tableEasy to jack upEducational modelsTerrainProjection system

The invention relates to a projection sand table capable of automatically constructing a terrain and a projection system, wherein the projection sand table comprises a frame, a sand table lifting assembly, a left-right mounting assembly and a plurality of sand pushing units, wherein the middle part of the frame is provided with an installation space with an upward opening; the sand table lifting assembly comprises a lifting mechanism and a sand containing table, the lifting mechanism is arranged on the frame, the sand containing table is arranged in a mounting space in the vertical direction,and the lifting end of the lifting mechanism is detachably connected with the sand containing table to drive the sand containing table to move in the vertical direction; the left-right mounting assembly comprises a mounting table and a left-right driving mechanism, and the power output end of the left-right driving mechanism is detachably connected with the mounting table to drive the mounting table to move left and right above the sand containing table; and the plurality of sand pushing units are arranged on the mounting table along the front-back direction, each sand pushing unit comprises asand pushing rod and a sand pushing driving mechanism, and the sand pushing driving mechanism is used for driving the sand pushing rods to be close to the sand containing table downwards or to be faraway from the sand containing table upwards. The technical scheme of the invention solves the problems that in the existing three-dimensional electronic sand table, the topography and the landform ofthe sand table cannot be visually observed by a user.

Owner:湖北安心智能科技有限公司

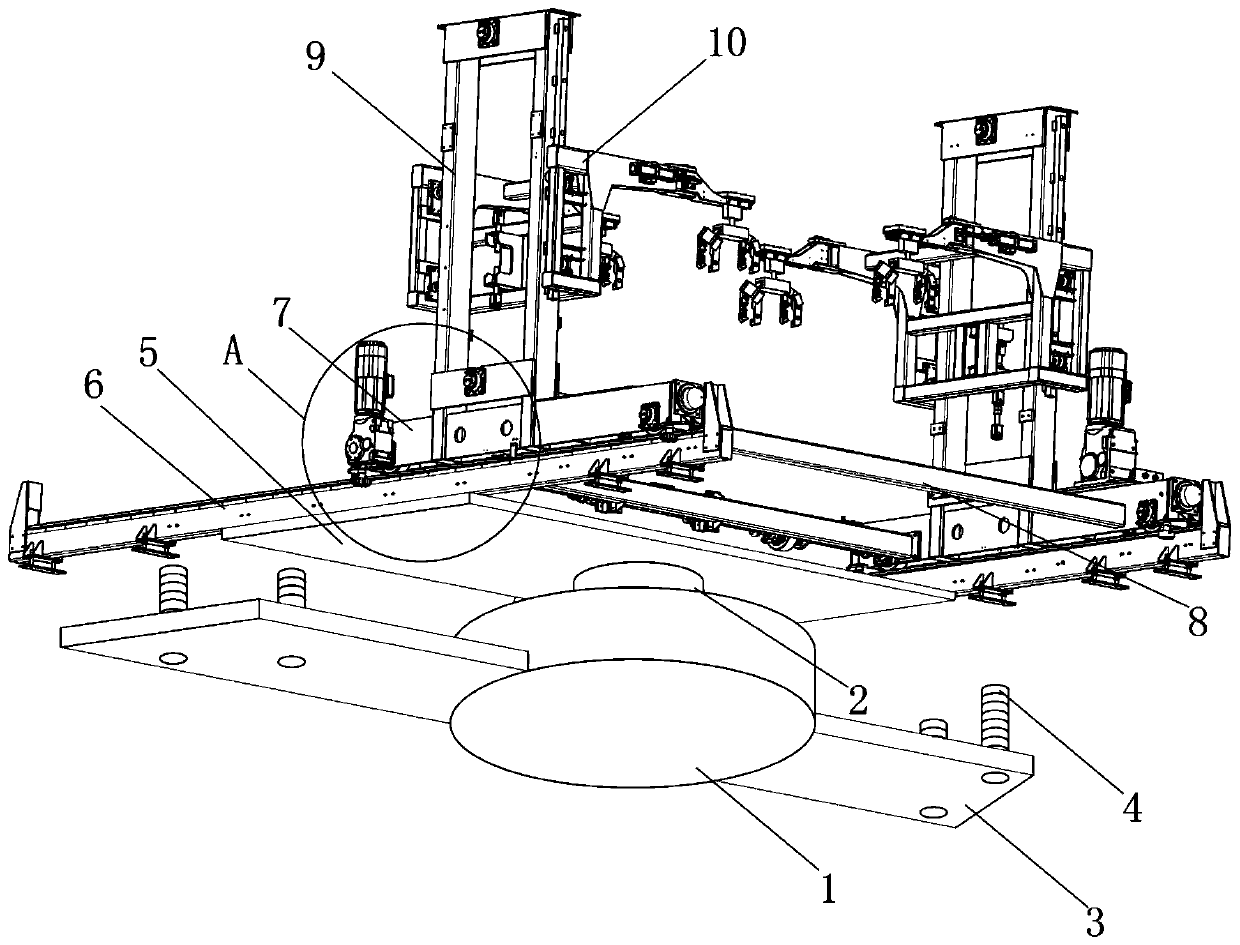

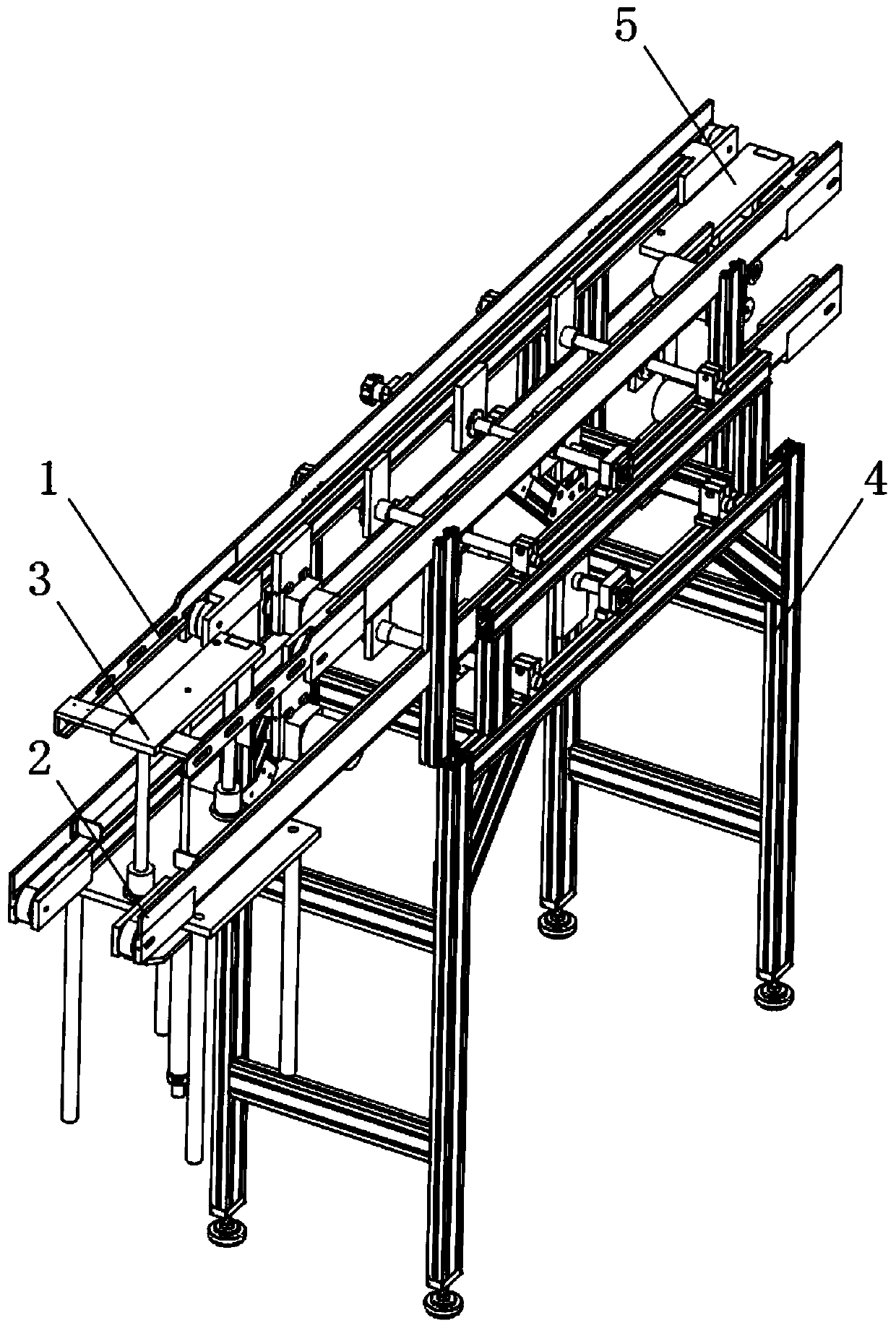

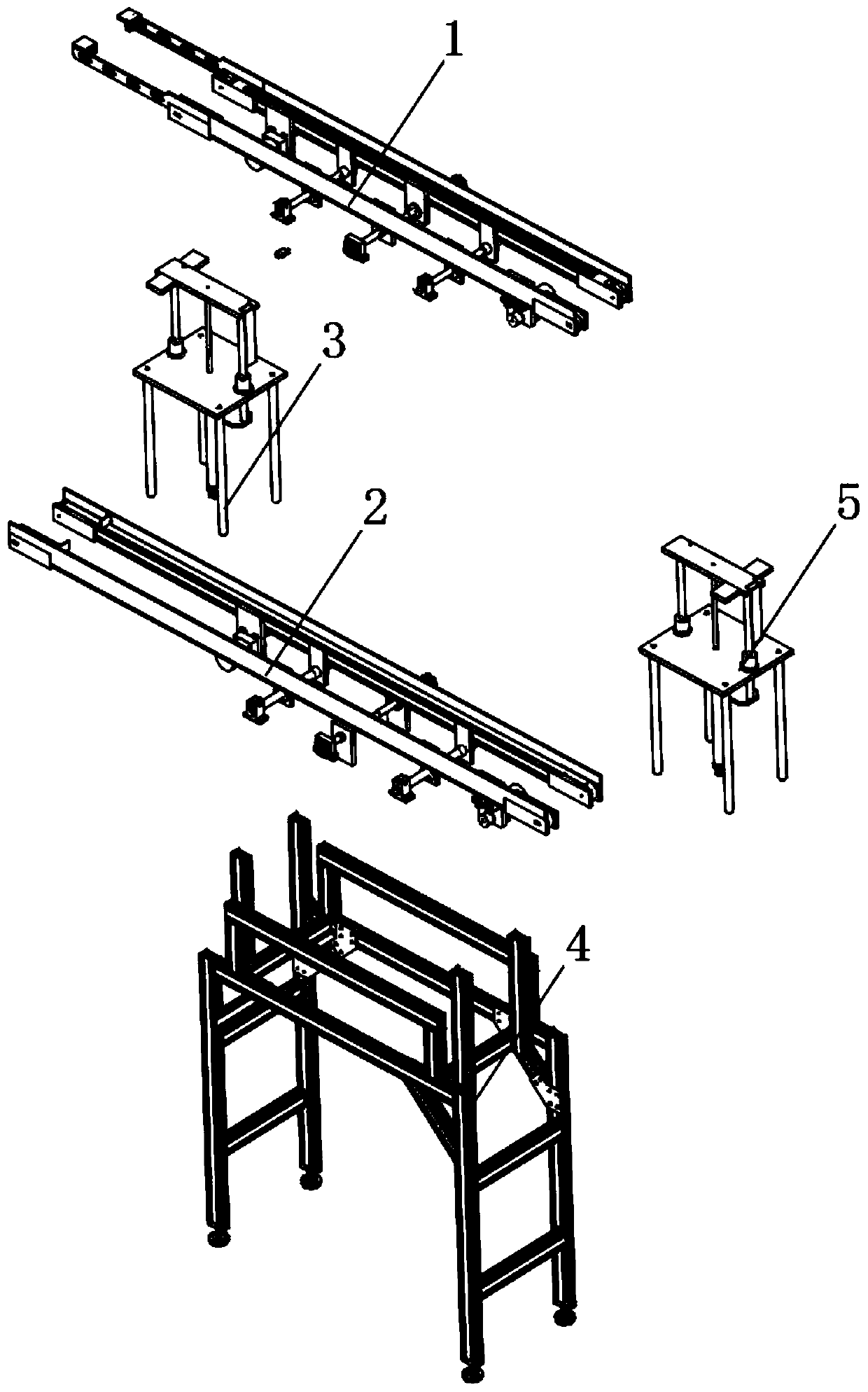

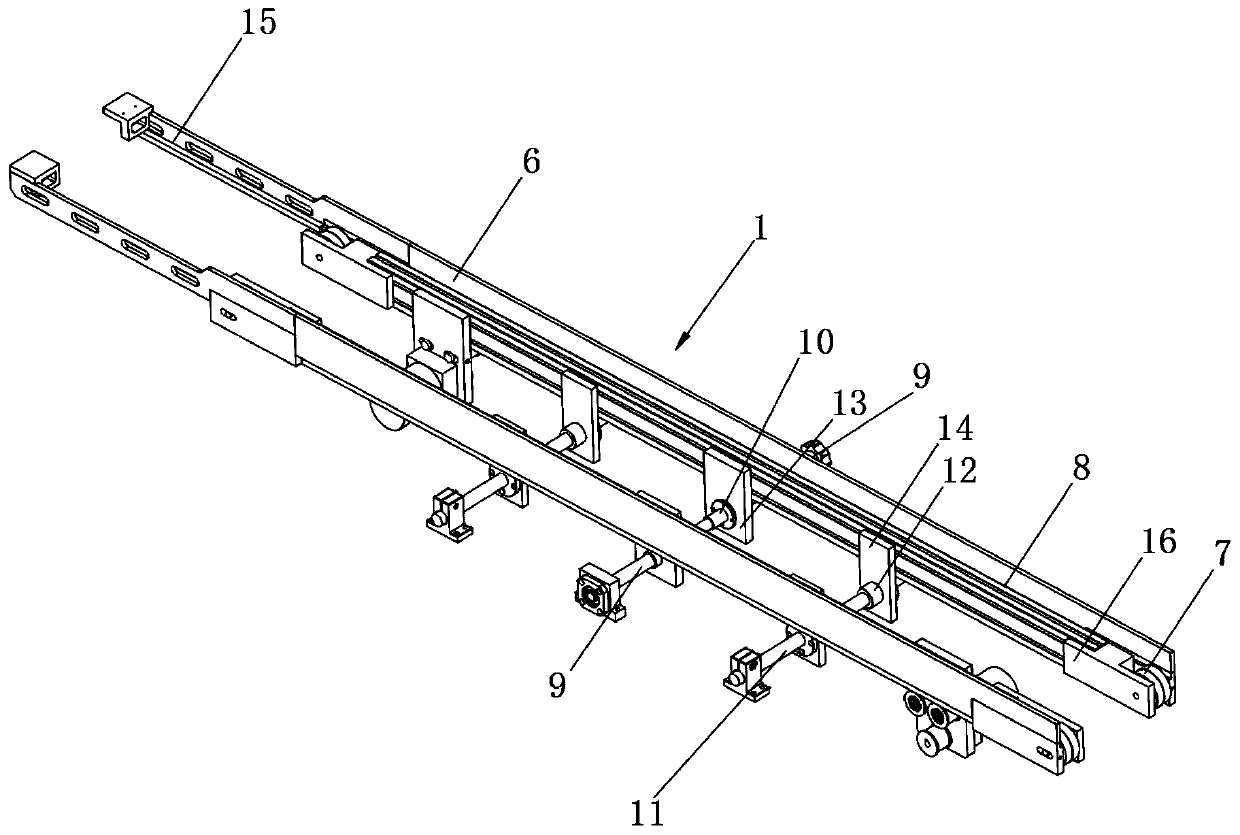

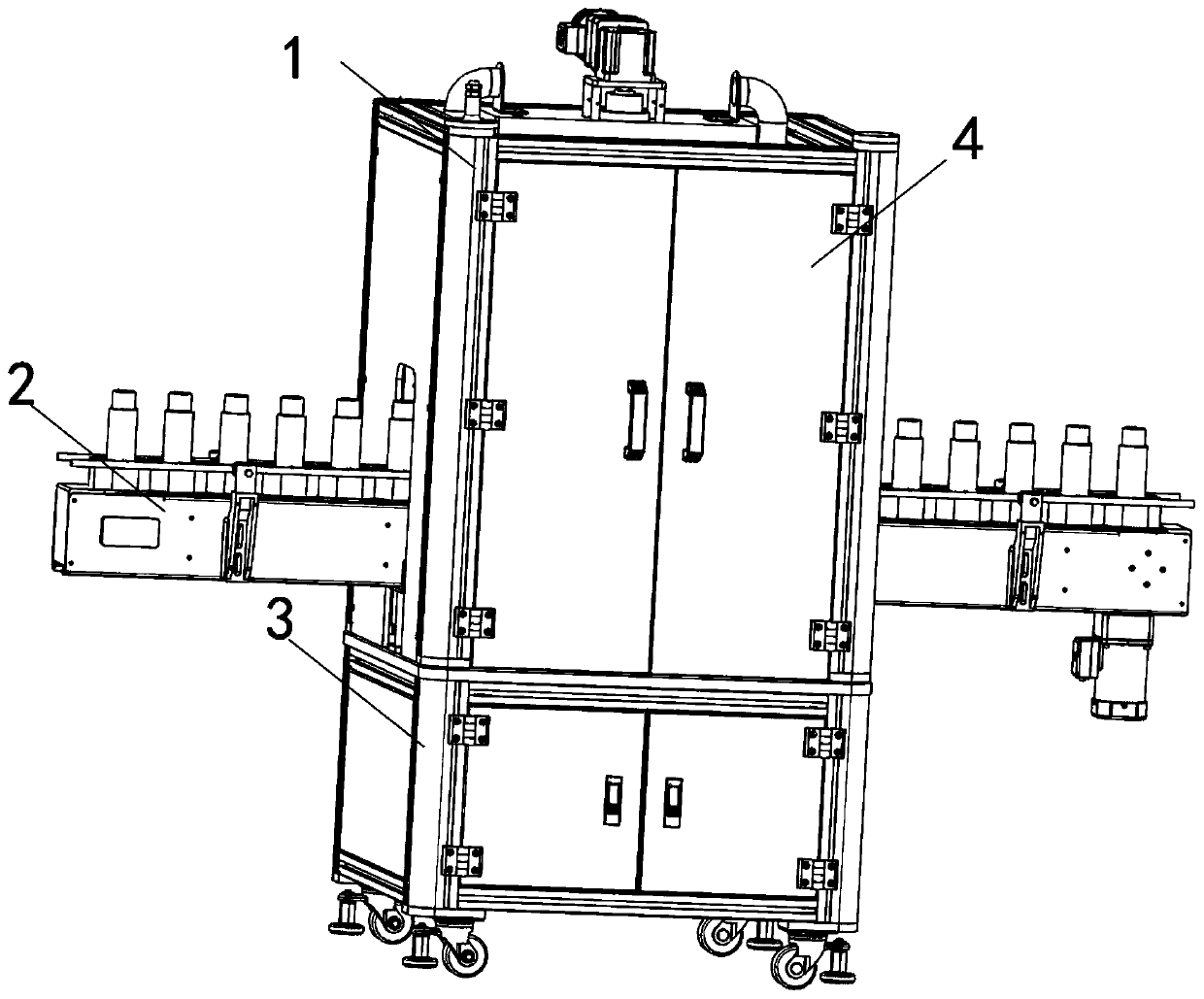

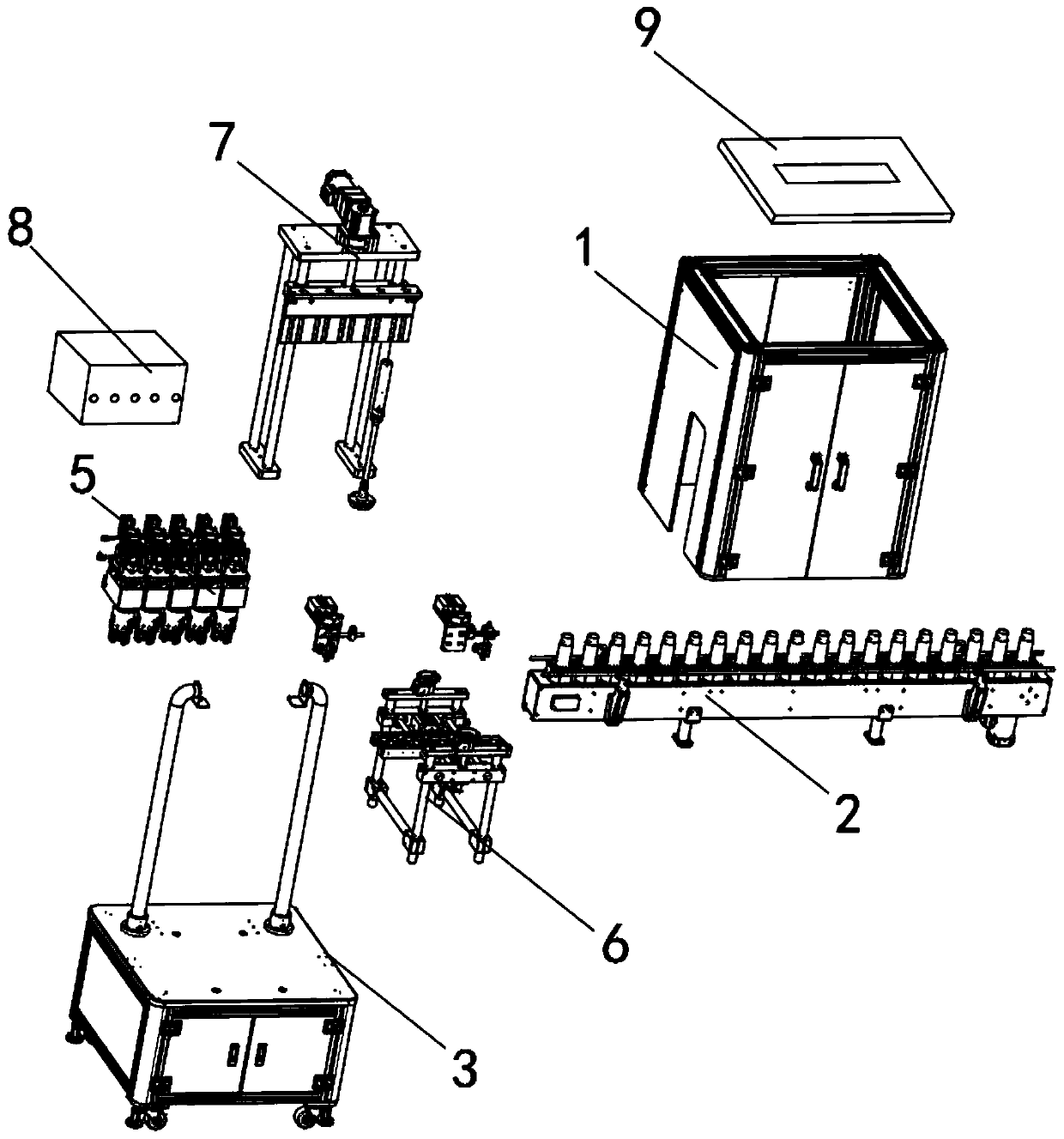

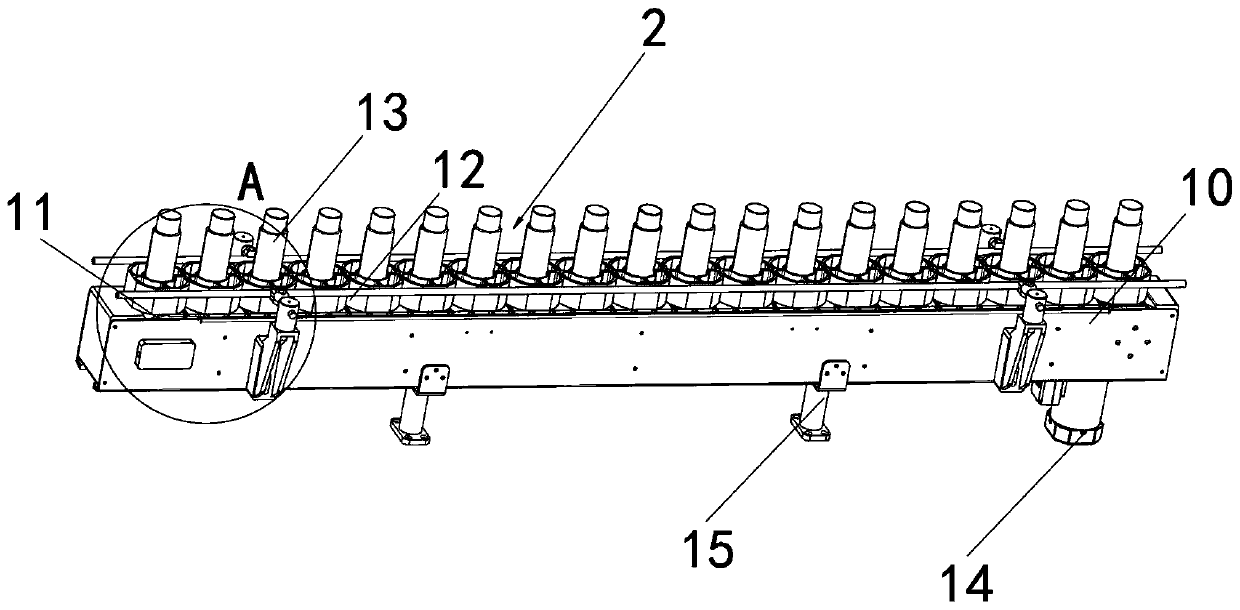

Material transfer device used in plastic uptake process of plastic uptake machine and transfer method of material transfer device

InactiveCN110282351ARegulation stabilityAdjust mobile stabilityPackagingSupporting framesCarrying capacityMotor drive

The invention discloses a material transfer device used in the plastic uptake process of a plastic uptake machine and a transfer method of the material transfer device. The material transfer device comprises an upper transfer platform, a lower transfer platform, a first bracket, a supporting platform and a second bracket; the upper transfer platform and the lower transfer platform are arranged in parallel; and the first bracket is arranged at one end of a part between the upper transfer platform and the lower transfer platform. A worker places used materials in the plastic uptake process of the plastic uptake machine between two side clamping tables of the upper transfer platform and the lower transfer platform, and a first motor and a second motor drive the materials to be transferred and transported through a first conveyor belt and a second conveyor belt, and are arranged at different heights through the upper transfer platform and the lower transporting platform to transfer and transport the materials synchronously, so that the synchronously transported material carrying capacity can be greatly improved, the occupied space of the device is reduced, and the materials are driven at the two ends of the bottoms of the materials to be transferred and transported through the first conveyor belt and a second conveyor belt on the two side clamping tables, and the smooth and firm material movement is ensured.

Owner:GAOYOU MINGYUAN LIGHTING TECH CO LTD

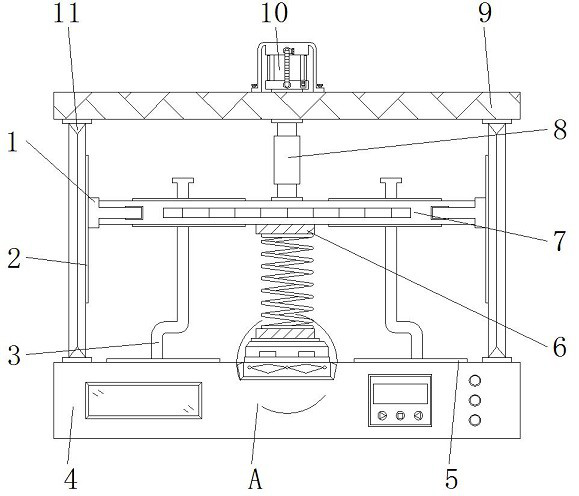

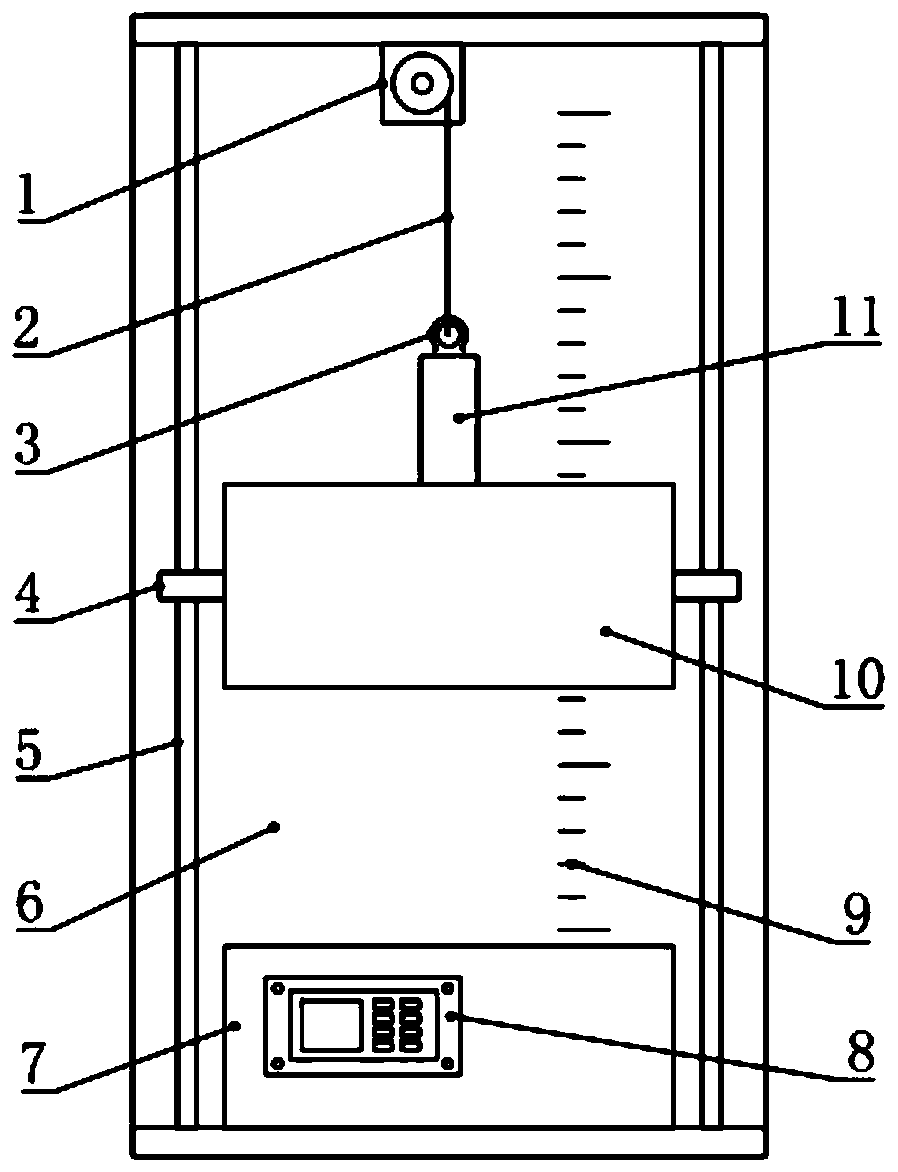

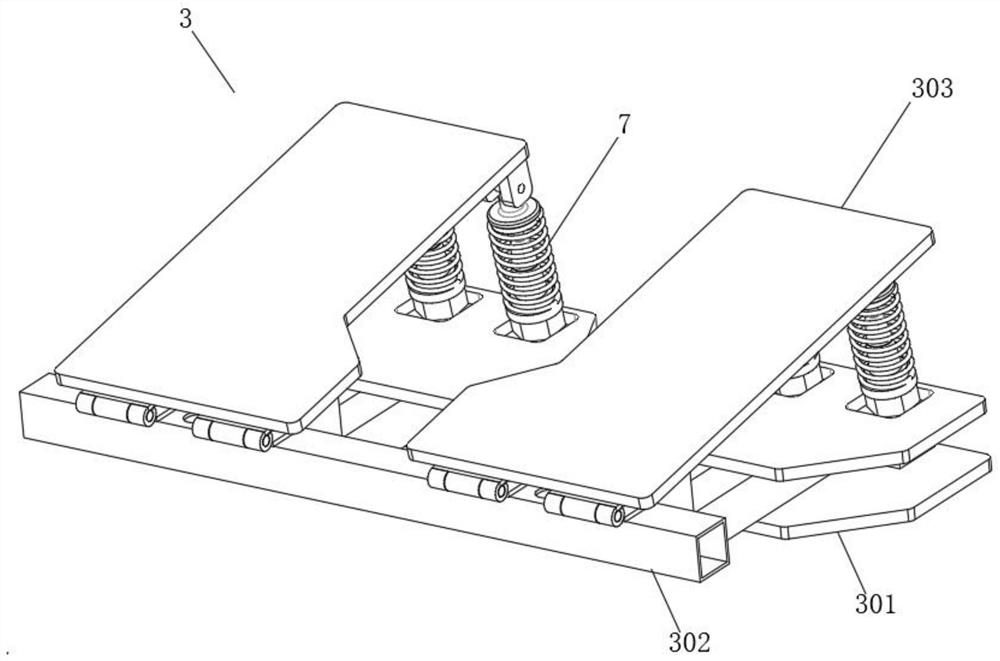

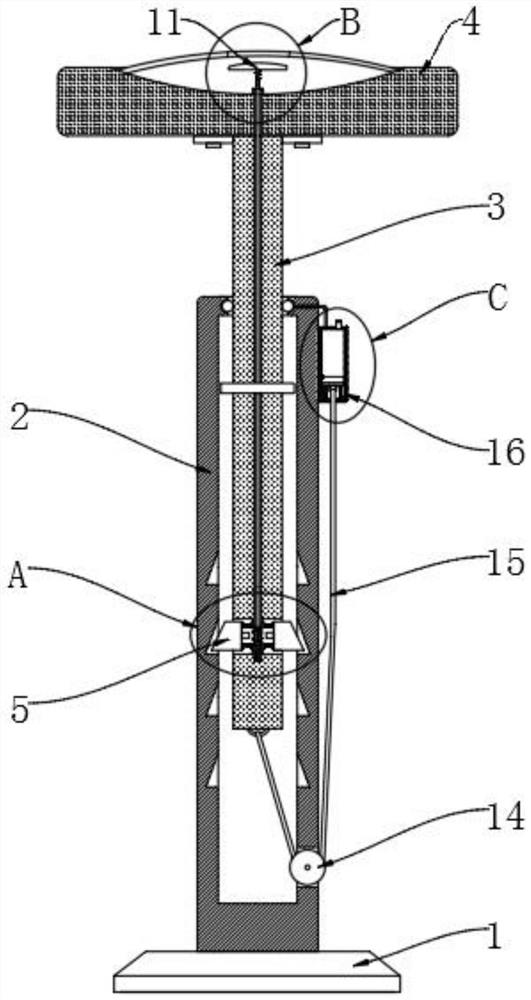

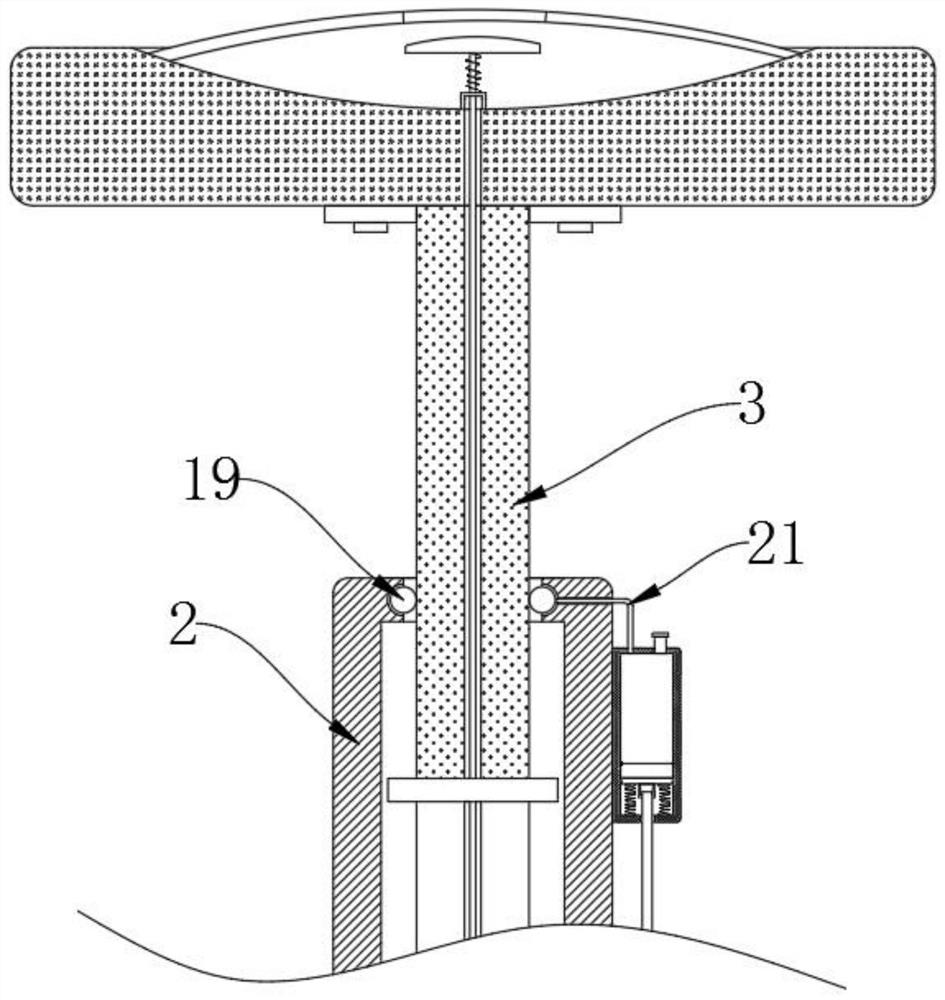

Electronic product drop test equipment

ActiveCN111256937AImprove carrying capacitySmooth releaseShock testingProduct testingMechanical engineering

The invention relates to the field of electronic product testing, especially to electronic product drop test equipment. The electronic product drop test equipment comprises a U-shaped frame, and a falling mounting base is arranged on the inner side of the U-shaped frame; the left side and the right side of the falling mounting base are each fixedly provided with a guide ring; a guide rod is slidably arranged in the guide ring in a matched manner; the upper and lower ends of the guide rod are fixedly connected with the inner top and the inner bottom of the U-shaped frame respectively; a fallingcontrol assembly is mounted in the falling mounting base, a winding device is fixedly mounted at the inner top of the U-shaped frame and connected with the falling control assembly through a first rope, a falling base is fixedly mounted at the inner bottom of the U-shaped frame, and a falling bearing assembly is mounted in the falling base. According to the invention, the operation is convenient,the test height can be stably adjusted, the test environment can be flexibly selected, and the drop test effect and accuracy of the electronic product are improved.

Owner:陈锋武

High-precision quantitative yogurt filling equipment

PendingCN109956439APrevent fallingHigh degree of automationSafety device in filling machineryHydraulic pumpEngineering

The invention discloses high-precision quantitative yogurt filling equipment. The high-precision quantitative yogurt filling equipment comprises a filling box, a carrying platform and a supporting cabinet, wherein the filling box is of a hollow cuboid structure, the supporting cabinet is arranged below the filling box, and the carrying platform is horizontally arranged between the filling box andthe supporting cabinet in a penetrating mode. The high-precision quantitative yogurt filling equipment has the beneficial effects that before a filling nozzle on a filling assembly is used for fillinga yogurt bottle, a first hydraulic pump drives a hanging plate and the filling assembly to move up and down through a hydraulic rod, so that it is guaranteed that the position of the filling nozzle extending into the yogurt bottle is more accurate, efficiency is high, and the filling height of the filling nozzle is more suitable for yogurt bottles with different diameters and heights; the fillingamount is more accurate, and the two ends of a material box are connected to sliding columns I in a sleeving mode to drive the filling assembly to be adjusted up and down, so that the filling assembly is moved more stably and smoothly; when the filling assembly is adjusted up and down, two second hydraulic pumps on the two sides of the carrying platform drive a base and the conveying platform tobe adjusted up and down through third liquid pumps so as to ensure that the process that the filling nozzle extends into the yogurt bottle for filling is more efficient.

Owner:ANHUI XIQIANG DAIRY GROUP

A stainless steel alloy flange manufacturing and processing machine

ActiveCN111469013BFast and stable lockPlay a locking roleGrinding drivesGrinding machinesStructural engineeringSS - Stainless steel

The invention relates to a stainless steel alloy flange manufacturing and processing machine, comprising a base, a limit mechanism, an L-shaped rod, a circular seat, a bolt, an annular block, an adjusting arm, a connecting arm, a driven arm and a grinding mechanism, and the upper end surface of the base The limit mechanism is installed on the top, and L-shaped rods are installed on the right front and left rear of the upper end surface of the base. A circular seat is installed between the inner side of the upper end of the L-shaped rod. The circular seat is connected with the lower end of the bolt through a bearing, and the middle of the bolt is threaded. A ring block is connected in a matching manner. Four adjusting arms are symmetrically installed on the outer surface of the ring block. The lower end of each adjusting arm is connected to the upper middle part of the slave arm through the connecting arm, and the lower end of the slave arm is installed through a hinge. There is a grinding mechanism. The present invention can solve the existing problem of deburring the bolt holes on the flange: the fixture of the processing equipment has poor locking effect on the flange; the processing equipment can only process one bolt hole at a time, and the burr on the upper end surface of the bolt hole needs other Equipment secondary processing.

Owner:盐城斯天康精密制造有限公司

Noise reduction protection mechanism for dry type spiral vacuum pump and use method of noise reduction protection mechanism

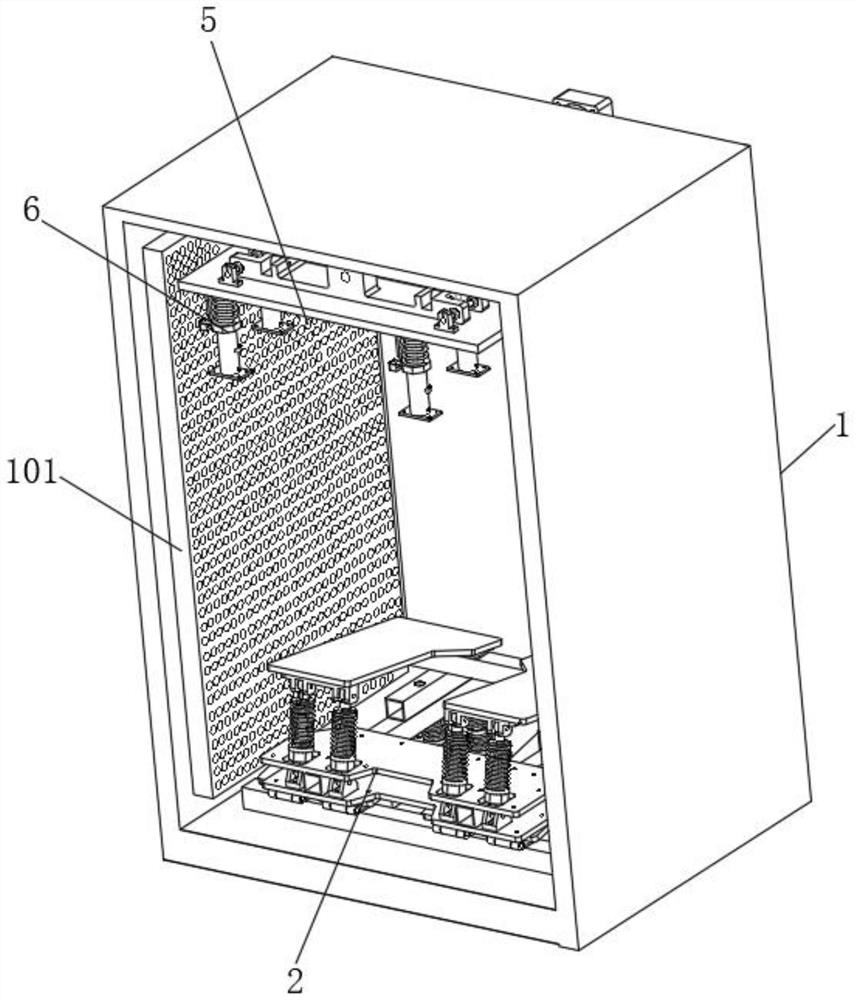

ActiveCN113513561AAchieve protectionImprove reliabilityVibration suppression adjustmentsRotary/oscillating piston pump componentsEngineeringVacuum pump

The invention relates to the technical field of dry type spiral vacuum pumps, in particular to a noise reduction protection mechanism for a dry type spiral vacuum pump and a use method of the noise reduction protection mechanism for the dry type spiral vacuum pump. Vibration generated during working of the dry type spiral vacuum pump can be buffered through a damping assembly, shaking of operation of the dry type spiral vacuum pump is reduced, the shaking of operation of the dry type spiral vacuum pump is reduced through the damping assembly, abrasion between parts of the dry type spiral vacuum pump and abrasion between the dry type spiral vacuum pump and the protection mechanism are reduced, the protection effect on the dry type spiral vacuum pump and the protection mechanism is achieved, the service life of the protection mechanism and the service life of the dry type spiral vacuum pump are prolonged, meanwhile, the shaking of operation of the dry type spiral vacuum pump is reduced through the protection mechanism, and the generated noise can be reduced to a great extent.

Owner:苏州伊桑诺捷光电科技有限公司

A drop test equipment for electronic products

The invention relates to the field of electronic product testing, especially to electronic product drop test equipment. The electronic product drop test equipment comprises a U-shaped frame, and a falling mounting base is arranged on the inner side of the U-shaped frame; the left side and the right side of the falling mounting base are each fixedly provided with a guide ring; a guide rod is slidably arranged in the guide ring in a matched manner; the upper and lower ends of the guide rod are fixedly connected with the inner top and the inner bottom of the U-shaped frame respectively; a fallingcontrol assembly is mounted in the falling mounting base, a winding device is fixedly mounted at the inner top of the U-shaped frame and connected with the falling control assembly through a first rope, a falling base is fixedly mounted at the inner bottom of the U-shaped frame, and a falling bearing assembly is mounted in the falling base. According to the invention, the operation is convenient,the test height can be stably adjusted, the test environment can be flexibly selected, and the drop test effect and accuracy of the electronic product are improved.

Owner:陈锋武

Medical infusion stand convenient to use

InactiveCN108578822ASolve the problem that the height of the hook cannot be adjusted up and downImprove practicalityInfusion devicesEngineeringSlide plate

The invention discloses a medical infusion stand convenient to use. The stand comprises a base plate, and a first support column is fixedly connected to the top of the base plate. According to the medical infusion stand, through the cooperative use of the base plate, the first support column, a second support column, a third support column, a transmission box, a placement frame, baffles, a fifth support column, a transmission base, a finger pressing rod, a transmission plate, a clamping mechanism, a support plate, a third sliding bock, a third sliding groove, a movable block, a positioning column, a second positioning hole, a return spring, a first sliding block, a first sliding groove, a pressing rod, a first transmission rod, second transmission rods, hooks, first springs, a support rod,a bolt, a trapezoidal transmission block, a second sliding block, a second sliding groove, a positioning rod, first positioning holes, a pulley, universal wheels, a second spring, a sliding plate anda sliding groove and the up-down movement of an internal structure of the transmission base, the effect of adjusting the hooks up and down is achieved, and the problem is solved that for existing infusion stands, the up-down height of hooks cannot be adjusted.

Owner:河南明珍方医药科技有限公司

A lightning protection device suitable for outdoor power adapter and its implementation method

ActiveCN111725704BReduce external damageThe effect of conductivityInsulatorsOvervoltage arrestors using spark gapsTorsion springElectrical equipment

The invention discloses a lightning protection device suitable for an outdoor power supply adapter and an implementation method thereof, including an adapter host and a lightning protection mechanism. For damage to the adapter or the surrounding electrical appliances, the cone block is arranged in an umbrella shape so that part of the rainwater will not gather at the lower end of the cone head and the upper end of the arrester body, ensuring that the protection gap remains unchanged and the lightning resistance effect is maximized. The arrangement of the two torsion springs can make the jacket have a certain clamping force, which is convenient to operate, and further improves the stability of the clamping of the conductive components. It will not slide off automatically, comprehensively improve the stability of the clamping of the conductive components, and the insulating sleeve and the ball are movably connected, which not only facilitates the smooth up and down adjustment of the conductive components, but also reduces the friction between the insulating sleeve and the pressing plate, and improves the service life of the insulating sleeve.

Owner:深圳市吉音实业有限公司

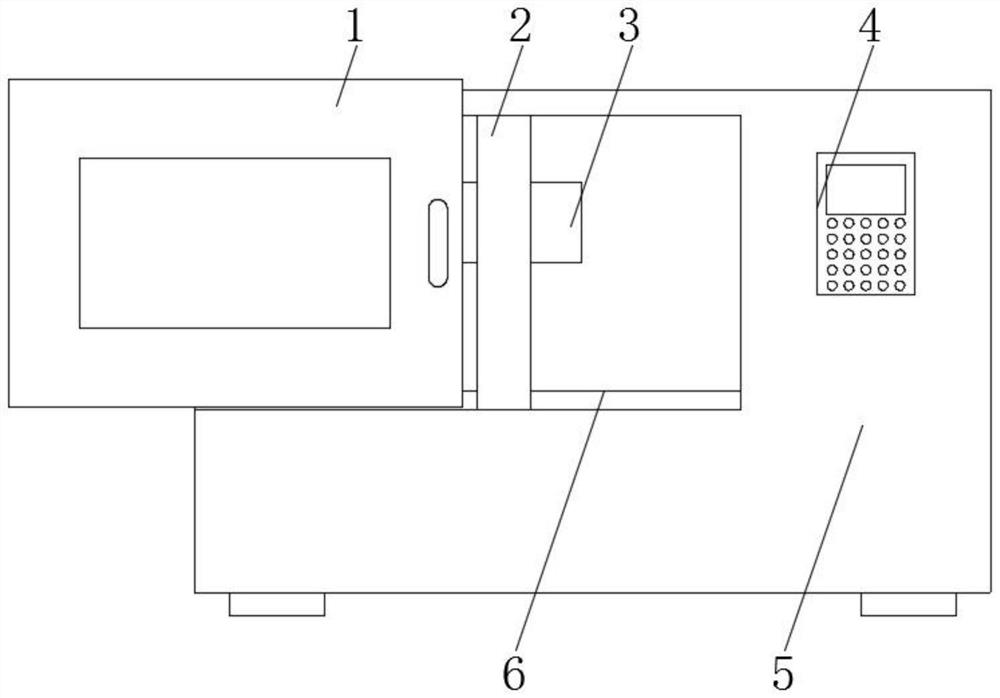

Double-spindle component machining precision data acquisition device for numerical control machine tool

PendingCN114770207AEasy to adjustEasy to detectMeasurement/indication equipmentsLarge fixed membersNumerical controlData acquisition

The invention discloses a double-spindle component machining precision data acquisition device for a numerical control machine tool, and relates to the technical field of numerical control machine tools, and the double-spindle component machining precision data acquisition device comprises a protective door, a control switch, a machine tool body and a workbench, a protective door is slidably connected to the front face of the machine tool body and located on the left side face of the control switch, an observation window is formed in the front face of the protective door, and a workbench is fixedly installed at the bottom of the inner wall of the machine tool body. Through cooperation of the electric telescopic rod, the linkage plate, the linkage rod, a data processor, a data collector, a protective sleeve and a temperature sensor, the linkage plate can be pushed to move through the electric telescopic rod, and the linkage rod is driven to move through the linkage plate, so that the position of the detection block can be adjusted through the linkage rod; and the data collector and the temperature sensor are used for detecting the double-main-shaft part in the machining process, so that various data in the machining process are recorded.

Owner:QUZHOU UNIV

A high-efficiency grinding and slotting device for aviation equipment pipes

ActiveCN109746811BAppropriate working distanceWon't scratchEdge grinding machinesGrinding carriagesAviationHydraulic pump

Owner:灵璧县浩翔信息科技有限公司

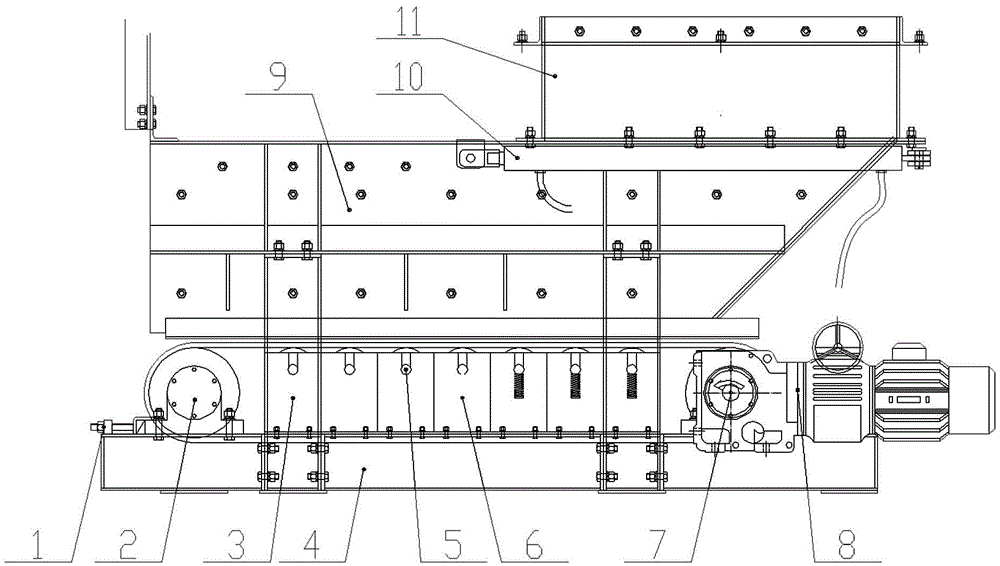

A belt feeder

The invention provides a belt feeder, which includes a machine body and a power transmission mechanism. The machine body includes a bottom frame, a tank body with a gate and a discharge port at the bottom, and a funnel. The funnel is installed on the top of the tank body and The junction is provided with an electro-hydraulic push rod, and the tank body is connected and fixed to the bottom frame through the legs. The above-mentioned power transmission mechanism is arranged between the tank body and the bottom frame and communicates with the bottom of the tank body. The power transmission mechanism includes a corresponding setting The conveyor belt at the bottom of the trough, the conveyor belt is closed and installed between the driving roller and the reversing roller, the driving roller is connected to the drive assembly, and the two sides of the conveyor belt are equipped with anti-deviation devices. The anti-deviation device refers to the limit rollers arranged on both sides of the conveyor belt. Compared with the prior art, this kind of belt feeder has the advantages of small operating power, light weight, large feeding capacity, stable feeding, convenient adjustment, low noise, small maintenance, and strong versatility of parts. , strong practicability and easy promotion.

Owner:山东心传矿山机电设备有限公司

A photovoltaic module that improves stacking efficiency

ActiveCN113066898BImprove stacking efficiencyImprove efficiencyPhotovoltaic supportsFinal product manufactureEconomic benefitsEngineering physics

The present invention relates to the technical field of photovoltaic modules, specifically a photovoltaic module that improves stacking efficiency, including a base, a sliding component, a lifting component, a mounting plate and a photovoltaic panel. By making the angle of the photovoltaic panel of the photovoltaic module adjustable, The photovoltaic module can adjust the installation angle of the photovoltaic panel according to the solar energy recommended by the World Meteorological Bureau, thereby improving the flexibility of the use of the photovoltaic module. By adjusting the angle of the photovoltaic panel, the power generation of the photovoltaic module can be maximized , improve the power generation of the photovoltaic module, and then improve the economic benefits of the photovoltaic module. By fixing the photovoltaic panel with bolts, the adjustment and fixation of the photovoltaic panel of the photovoltaic module is more stable, thereby improving the reliability of the photovoltaic module. sex.

Owner:杭州青琅玕管理咨询有限公司

A projection sand table and projection system for automatically constructing terrain

ActiveCN110444100BEasy to jack upEasy to observeEducational modelsStructural engineeringProjection system

The invention relates to a projection sand table and a projection system for automatically constructing terrain. The projection sand table includes a frame, and the middle part has an installation space with an opening facing upwards; The sand table is installed in the installation space along the up and down direction, and the lifting end of the lifting mechanism is detachably connected with the sand table to drive the sand table to move up and down; the components are installed in the left and right directions, including the mounting plate and the left and right driving mechanism, and the power output of the left and right driving mechanism The end is detachably connected to the mounting plate to drive the mounting plate to move left and right above the sand holding tray; multiple sand pushing units are arranged on the mounting plate along the front and rear directions, and each sand pushing unit includes a sand pushing rod and a sand pushing The driving mechanism, the driving mechanism for pushing sand is used to drive the sand pushing rod to approach the sand tray downward or away from the sand tray upward. The technical scheme of the invention solves the problem that the existing three-dimensional electronic sand table cannot directly and vividly observe the topography of the sand table and the like.

Owner:湖北安心智能科技有限公司

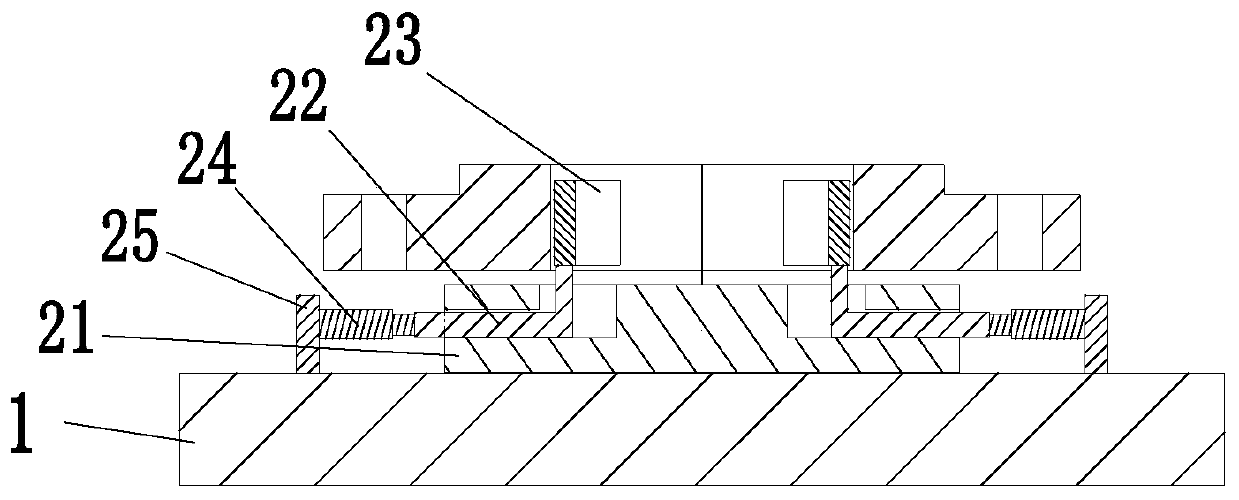

A pressing and positioning mechanism used in the process of cutting suit fabrics

ActiveCN111005203BEasy to processGuaranteed pressing and positioning workSevering textilesGear wheelElectric machinery

Owner:界首市永顺服饰有限公司

A sucker rod anti-eccentric wear centralizer

The invention provides a sucker rod anti-eccentric wear centralizer, which includes a centralizing roller, a shaft sleeve, a limit plate, a limit clamp rod, an adjustment spring A, a clamp groove and a ball; the adjustment shaft inside the groove passes through a bearing The centralizing rollers are inlaid, and the adjusting shafts at the two ends of the groove are fitted with bushings. The outer wall of the centralizer body is also welded with sleeves, and an adjusting spring A is arranged between the two sets of sleeves. The centralizing ring There is still a ring-shaped card slot on the outer edge of the arc-shaped centralizing plate. The rear end of the arc-shaped centralizing plate is provided with an integrated adjustment plate, and the adjusting plate is movably stuck in the card-in slot. Three groups of balls are inlaid, and an adjustment spring B is connected in the gap between the arc-shaped centralizing plate and the centralizing ring. The ball at the front end of the arc-shaped centralizing plate facilitates the rotation of the sucker rod. This group of sucker rods is screwed into the internal thread socket of another group of sucker rods. The centralizing roller touches the well wall under the action of the adjustment spring A The up and down adjustment of the sucker rod is smoother.

Owner:东港智科产业园有限公司

Compressing and positioning mechanism in suite fabric tailoring process

ActiveCN111005203AEasy to processGuaranteed pressing and positioning workSevering textilesGear wheelElectric machinery

The invention discloses a compressing and positioning mechanism in the suit fabric tailoring process. The compressing and positioning mechanism comprises a loading frame, a pressing platform and a carrying seat, wherein side loop bars are arranged at two ends above the loading frame, and two motors I are arranged between the two side loop bars, and motors II are vertically arranged below the two motors I. The compressing and positioning mechanism disclosed by the invention has the beneficial effects that each motor II drives a rotating gear II to roll in a rolling groove II in a manner of matching with a hobbing, thereby driving a pressing plate to adjust back and forth; on the one hand, the mechanism can be guaranteed to compress and position different areas of the suit fabric; on the other hand, the pressing plate can be move and adjusted more flexibly and quicker, and the compressing and positioning precision on the suit fabric by the mechanism can be greatly improved; in cooperation with the up-down adjusting movement of a hydraulic rod, the pressing plate can be adjusted up and down more stably and smoother, and the pressing plate can apply the pressure on the suit fabric moregently; and a carrying frame is prevented from being damaged by scraping, and the compressing and positioning accuracy on the suit fabric by the pressing plate is improved.

Owner:界首市永顺服饰有限公司

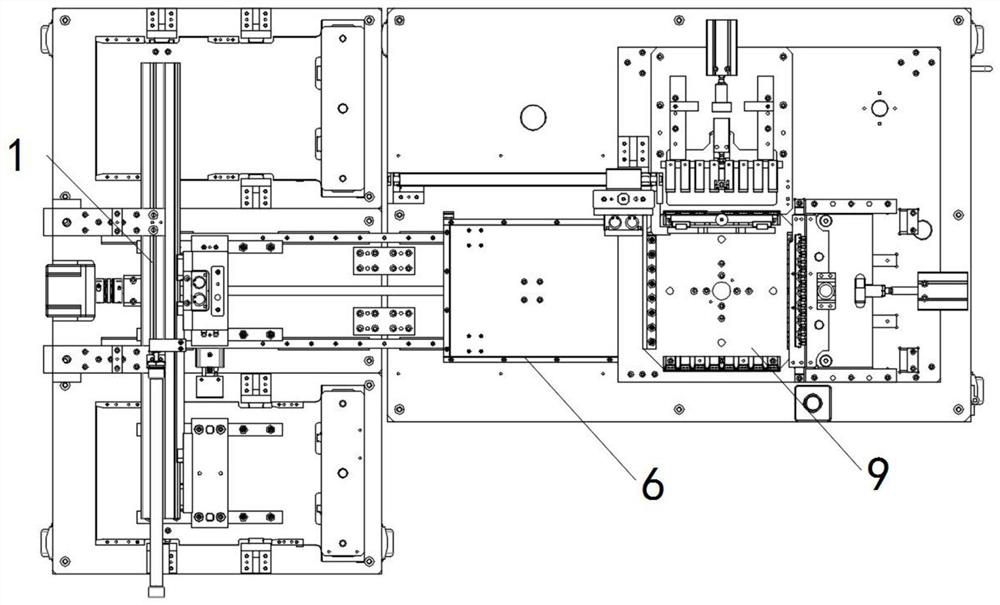

A splitting and trimming device for aviation equipment panels and its working method

ActiveCN109571034BHigh degree of automationHighly integratedOther manufacturing equipments/toolsAviationHobbing

The invention discloses a segmenting and trimming device for an aeronautical facility plate and a work method of the segmenting and trimming device for the aeronautical facility plate. The segmentingand trimming device for the aeronautical facility plate comprises a console, a front bearing frame, supporting and feeding frames, holding platforms, a cutting and trimming platform and a back feedingframe. The front bearing frame is arranged at one end of the upper side of the console in an inclined manner. The supporting and feeding frames are longitudinally arranged at the two ends of the upper end face of the console. The two ends of the console are both longitudinally provided with the holding platforms. The cutting and trimming platform is longitudinally arranged above the edge of one side of the console. The segmenting and trimming device for the aeronautical facility plate has the beneficial effects that after cutting discs cut and segment plates, third hydraulic pumps on moving seats drive fifth motors to extend front and back, and polishing sheets are aligned with the cut faces of the plates to conduct polishing; besides, during polishing, each sliding connection block at the bottom of the corresponding moving seat drives a rotating gear through a fourth motor to roll in cooperation with a plurality of rolling teeth in a rolling hopper, so that each moving seat and eachpolishing ring are driven to move front and back to conduct polishing; and in this way, it is guaranteed that the segmenting and trimming device for the aeronautical facility plate more completely andmore thoroughly polish the plate segments, and meanwhile the segmenting and trimming device for the aeronautical facility plate can more efficiently polish and trim the plate segments.

Owner:HUAIYIN TEACHERS COLLEGE

Portable supporting device for building construction

InactiveCN113187234AReduce work intensityConvenient for auxiliary constructionStoolsAdjustable chairsArchitectural engineeringCushion

The invention discloses a portable supporting device for building construction. The portable supporting device comprises a supporting base and a supporting cylinder fixedly installed on the upper surface of the supporting base, a movable supporting column is slidably connected to the inner wall of the supporting cylinder, a cushion is fixedly installed at the top end of the movable supporting column, and an installation groove is formed in the surface of the movable supporting column. According to the portable supporting device for building construction, by arranging the movable supporting column, a trapezoidal clamping block and a clamping groove, when a constructor needs to adjust the height of the supporting device, the constructor only needs to drive the cushion upwards, the cushion drives the movable supporting column to move upwards, the trapezoidal clamping block slides out of the clamping groove, then the trapezoidal clamping block is attracted through a magnetic block, so that the trapezoidal clamping block cannot move, after the height is adjusted, the trapezoidal clamping block and the magnetic block can be separated only by pressing a pressing plate on the cushion, then the trapezoidal clamping block is restored to the use state, and the effect of conveniently adjusting the height of the device is achieved.

Owner:丁奥林

A plate cutting device for numerical control machining and its operating method

ActiveCN111230200BImprove efficiencyHigh degree of automationMachine tool componentsShearing machinesAutonomationAutomation

The invention discloses a plate cutting device for numerical control machining and an operation method thereof, which comprises a vertically arranged vertical loading frame, a vertical cutting table, a flat support plate and two clamping frames, and the top of the vertical loading frame is horizontally arranged There is a top support plate, the two sides of the top support plate are provided with a sleeve slide rail 1, and the sleeve frame 1 of a hollow inverted U-shaped structure is sleeved on the two sleeve slide rails 1. The beneficial effects of the present invention are: the motor 4 drives the cutting piece to rotate to cut the plate, and cooperates with the sleeve frame 1 and the sleeve frame 2 to move on the sleeve slide rail 1 and the sleeve slide rail 2 respectively to adjust the cutting blade to cut the plate position, and cooperate with motor five to drive the chain through gear two, so as to drive the front and rear movement adjustment of the board. On the one hand, it greatly improves the cutting efficiency of the device for CNC machining boards and ensures that the device can cut the boards. The degree of automation of the work is higher, and the use of the work is more time-saving and labor-saving. On the other hand, it ensures that the device cuts the position of the plate more accurately.

Owner:正德职业技术学院

Regulating device and method for power generation and energy storage equipment

ActiveCN110729819BEasy to disassembleQuick and easy disassemblyElectrical storage systemSupports/enclosures/casingsElectric machineDrive shaft

The invention discloses a power generation and energy storage equipment adjusting device, which comprises a first motor of a cylindrical structure, a supporting plate, side supporting frames, upper conveying tables and vertical installing tables. A rotary base is arranged above the first motor. A cuboid-shaped rotary adjusting base is horizontally arranged at the top of the rotary base, and the side supporting frames are arranged at the two ends of the rotary adjusting base. In the process of installing power generation and energy storage equipment on the device, fifth motors drive a clampingbase to rotate for adjustment through rotary columns to change the connection position and angle of buckling plates and the power generation and energy storage equipment, a sixth motor drives seventhmotors and the buckling plates to turn over up and down for adjustment through turning and swinging shafts, and the seventh motors drive the buckling plates to rotate for position adjustment through third transmission shafts. On one hand, it is guaranteed that the position of a component can be adjusted more flexibly and rapidly, the efficiency of installing the power generation and energy storageequipment on the device is greatly improved. On the other hand, the accuracy of the installing position of the device and the power generation and energy storage equipment is greatly improved.

Owner:HUAIYIN TEACHERS COLLEGE

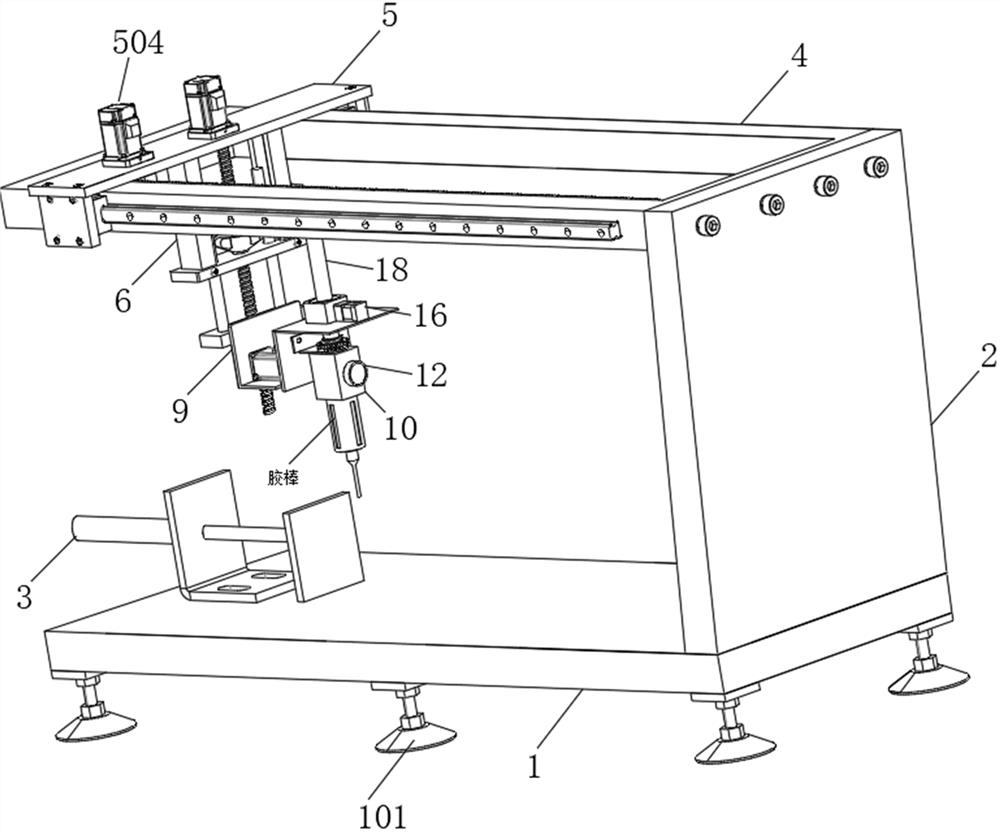

Gluing machine for building construction

InactiveCN113182127AEasy to fixHigh precisionLiquid surface applicatorsCoatingsElectric machineryGlue stick

The invention relates to the technical field of gluing machines, in particular to a gluing machine for building construction, which comprises a base table, a clamping assembly, a supporting frame, a moving assembly, a rotating assembly, a mounting head and a push rod; the gluing height is adjusted through driving of a second motor, the use flexibility of the gluing machine is improved, meanwhile, the gluing machine can carry out gluing operation on plates with different thicknesses, and therefore, the use range of the gluing machine is widened; sliding rods are in sliding fit with the interiors of sliding rails, and the gluing machine can be adjusted up and down more stably, so that the use stability of the gluing machine is improved; through driving of a fourth motor, the push rod downwards extrudes a sealing glue stick for glue discharging, glue discharging of the gluing machine for building construction is more stable and uniform, and the processing effect of the gluing machine on plates is improved; and control over movement of the push rod is improved through meshing of a second gear and a tooth groove, and therefore the gluing dosage precision of the gluing machine is improved.

Owner:安徽宏兴项目管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com