Electronic product drop test equipment

A technology for testing equipment and electronic products, which is applied in impact testing, testing of machines/structural components, measuring devices, etc. It can solve problems that affect the effect and accuracy of drop testing of electronic products, cannot test height stability adjustments, and are inconvenient to operate. , to improve the effect and accuracy of the drop test, facilitate the drop test, and improve the convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

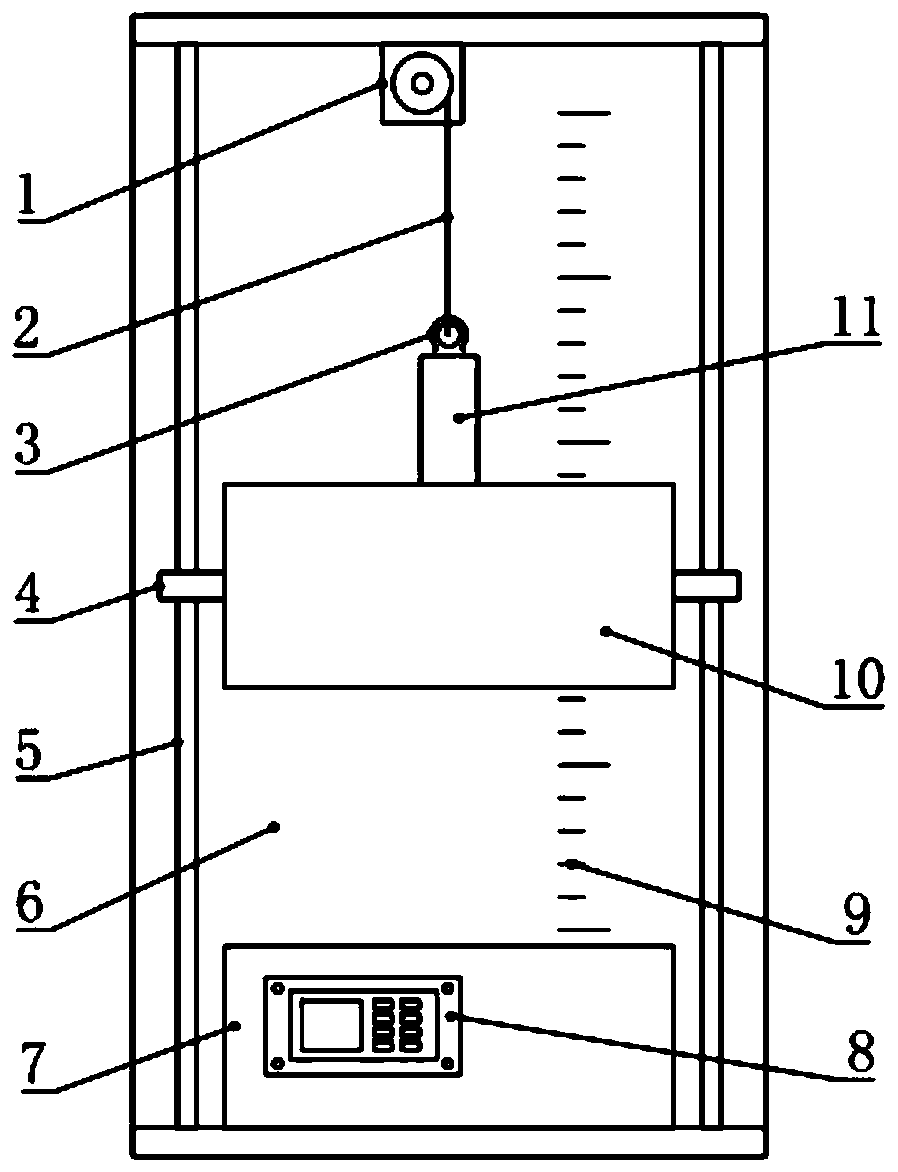

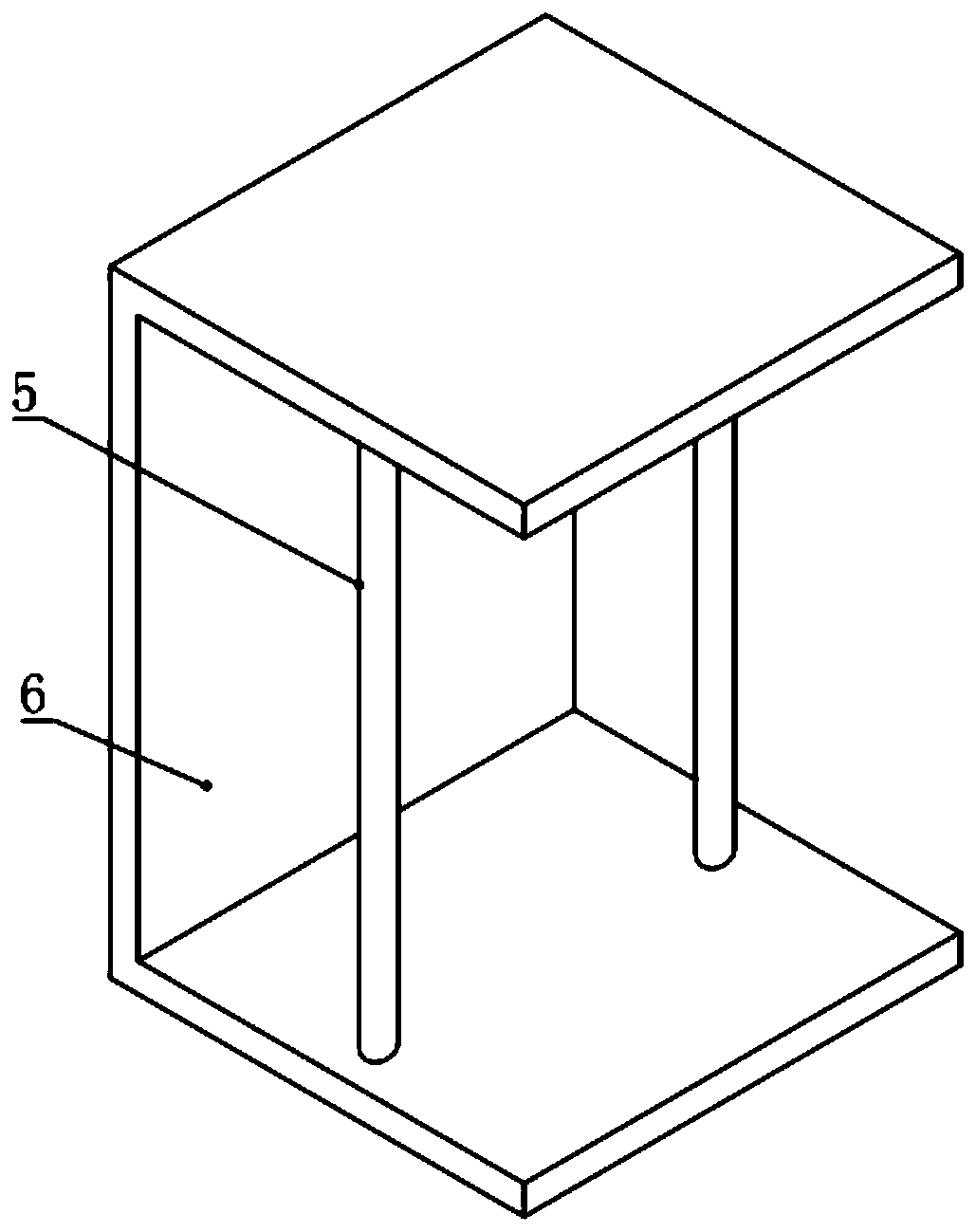

[0020] see Figure 1-2 , in an embodiment of the present invention, a drop test device for electronic products includes a U-shaped frame 6, a drop mounting seat 10 is provided on the inner side of the U-shaped frame 6, and a guide is respectively installed and fixed on the left and right sides of the drop mounting seat 10. Ring 4, the guide ring 4 is cooperating and slidingly provided with a guide rod 5, the upper and lower ends of the guide rod 5 are respectively connected and fixed with the inner top and inner bottom of the U-shaped frame 6, and the drop control assembly is installed in the drop mounting seat 10, The inner top of the U-shaped frame 6 is installed and fixed with a winding device 1, the winding device 1 is connected with the drop control assembly through the first rope 2, and the inner bottom of the U-shaped frame 6 is installed and fixed with a drop base 7. A drop bearing assembly is installed in the drop base 7 .

[0021] In the embodiment of the present in...

Embodiment 2

[0023] see Figure 1-7 , the difference between this embodiment and embodiment 1 is:

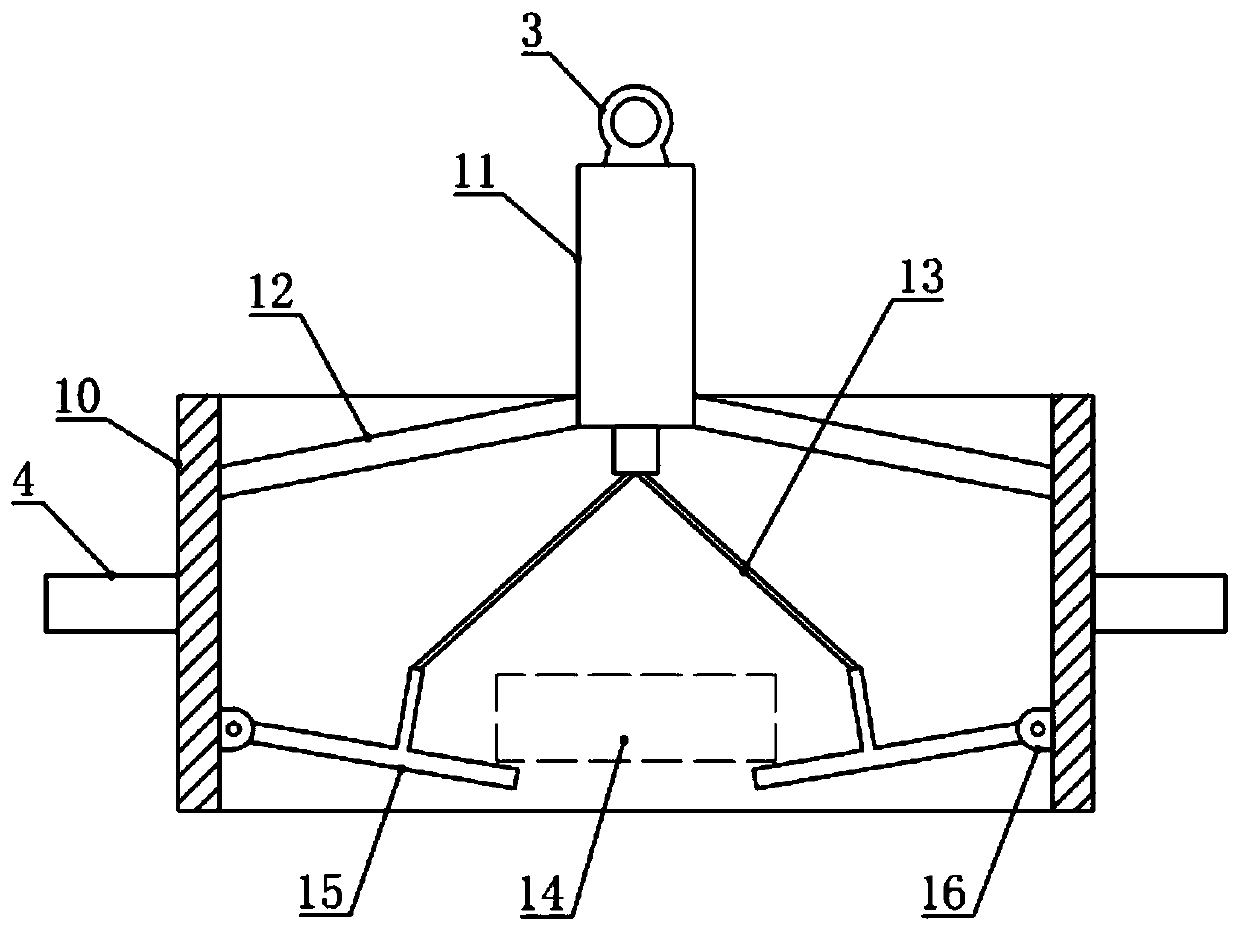

[0024] In this example, if image 3 and 4 As shown, the drop mount 10 is a cylindrical barrel structure with both ends open, and the drop control assembly includes a first telescopic cylinder 11, a diagonal strut 12, a second rope 13, a support rod 15 and a hinge support 16. The first telescopic cylinder 11 is arranged on the upper side of the middle part of the drop mounting base 10, and the first telescopic cylinder 11 is connected and fixed to the inner wall of the drop mounting base 10 through a plurality of diagonal struts 12 distributed in the circumferential direction. The oblique strut 12 can stably support the first telescopic cylinder 11; the inner lower part of the drop mount 10 is circumferentially distributed with a plurality of hinge supports 16, and the hinge supports 16 are hingedly provided with a support rod 15, and the The number of the support rods 15 and the diagonal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com