A belt feeder

A technology of feeder and armor belt, which is applied in the field of industrial belt conveyor feeder, can solve the problems of not fundamentally solving the problem, difficulty in adjusting the distance between the armor belt and the trough, and inconvenient adjustment, etc., and achieves good economy and social benefits, the effect of inhibiting the deviation of the lining tape and the deviation of the armor belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

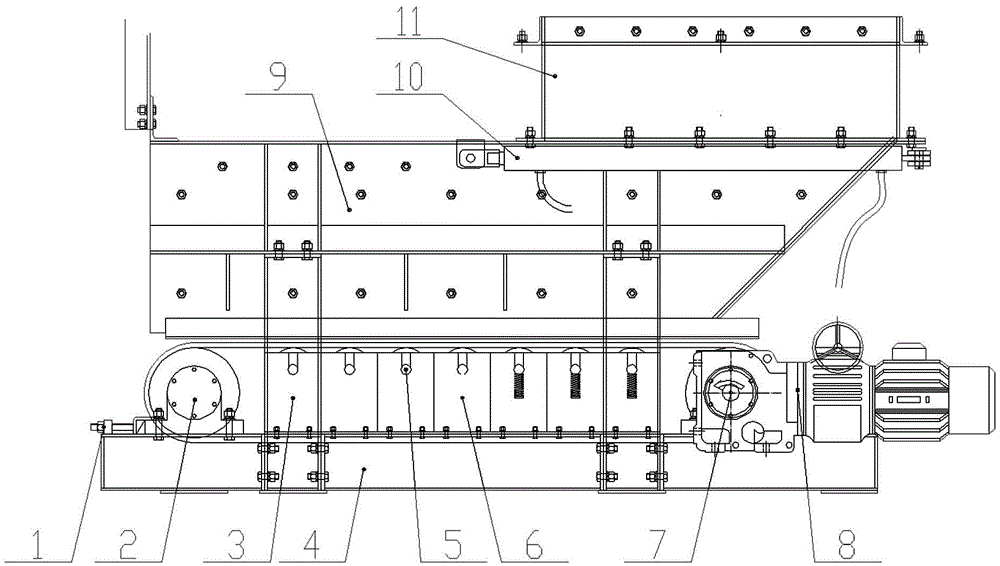

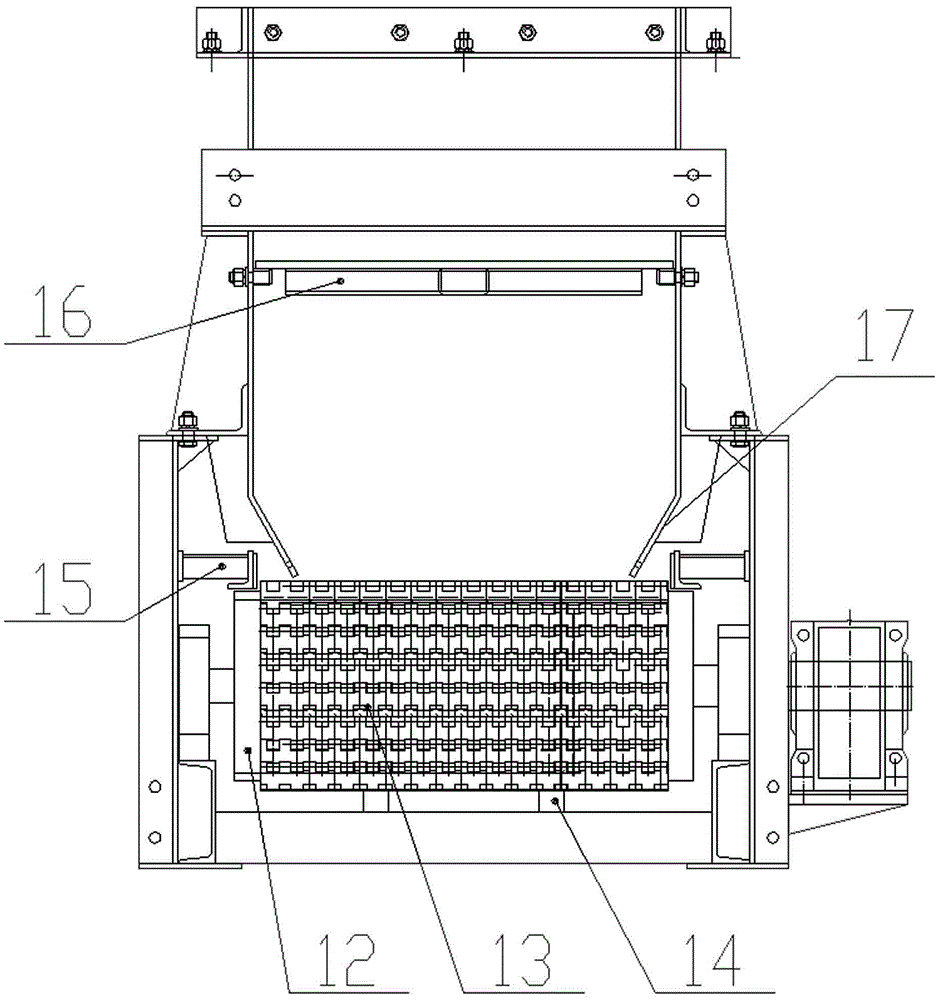

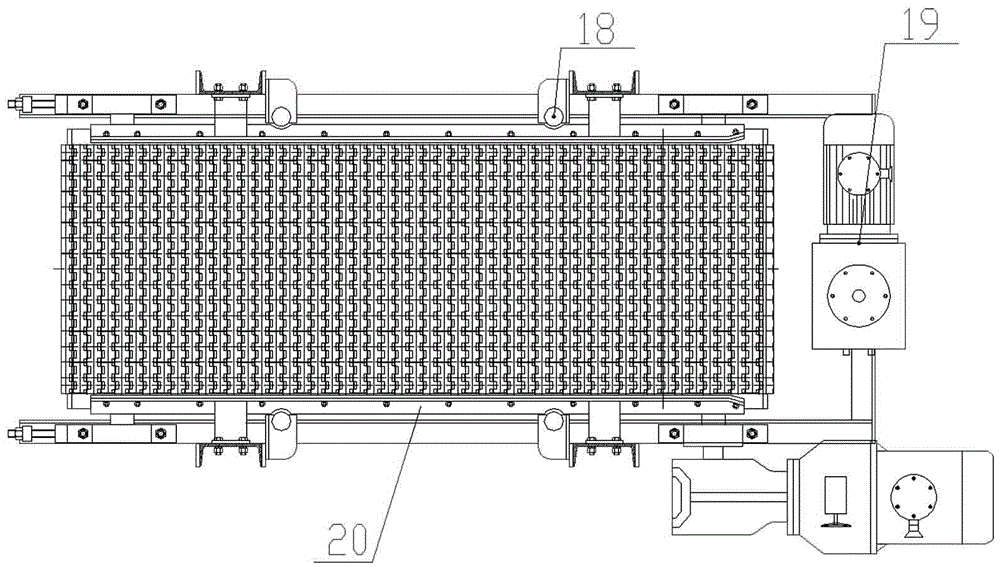

[0024] A belt feeder of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] as attached figure 1 , figure 2 , image 3 As shown, a belt feeder is now provided, including a body and a power transmission mechanism. The body includes a chassis 4, a tank body 9 with a gate 16 and a discharge port at the bottom, and a funnel 11. The funnel 11 is installed on the top of the tank body 9 and an electro-hydraulic push rod 10 is arranged at its connection. The tank body 9 is connected and fixed with the underframe 4 through the outrigger 3. The above-mentioned power transmission mechanism is arranged between the tank body 9 and the underframe 4 and connected with The bottom of the tank body 9 is connected, and the power transmission mechanism includes a conveyor belt that is correspondingly arranged at the bottom of the tank body 9. The conveyor belt is closed and installed between the driving drum 7 and the redirecting drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com