A sucker rod anti-eccentric wear centralizer

A sucker rod and centralizer technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve problems such as resistance, increased difficulty in use, difficulty in sucker rod movement, etc., to achieve convenient use, avoid eccentric wear, and adjust up and down smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

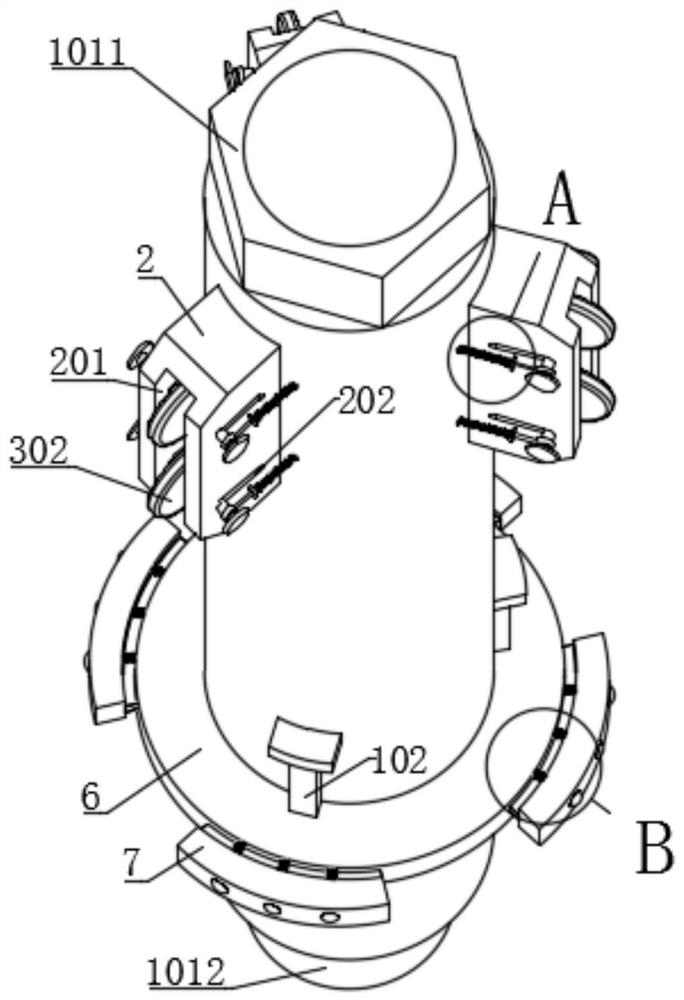

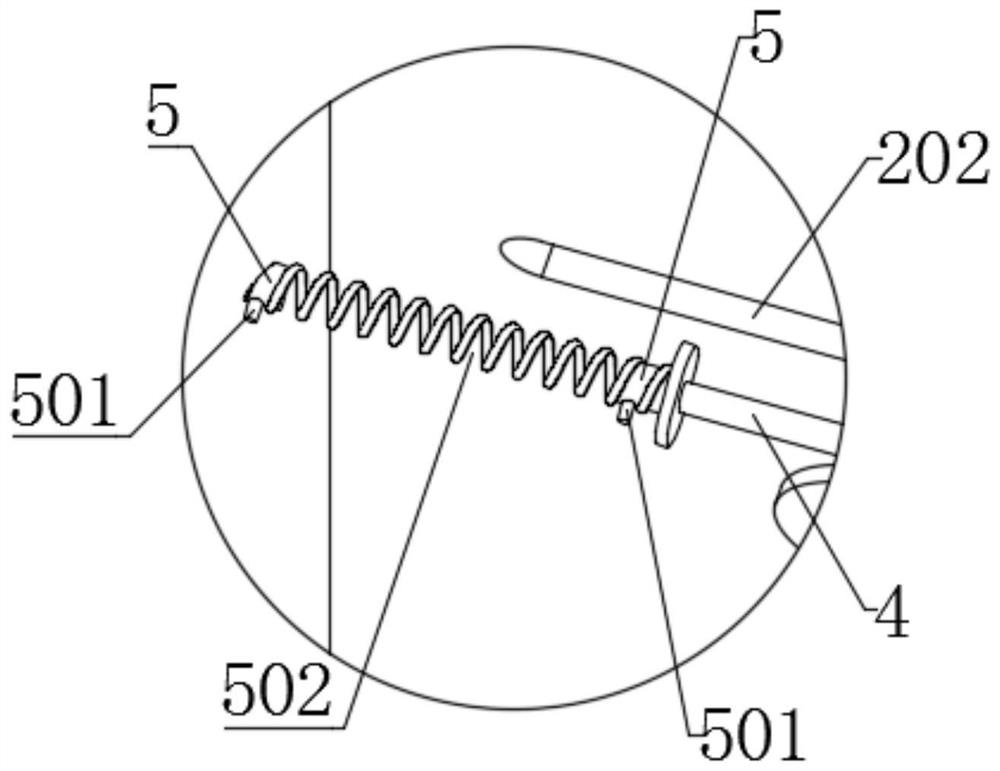

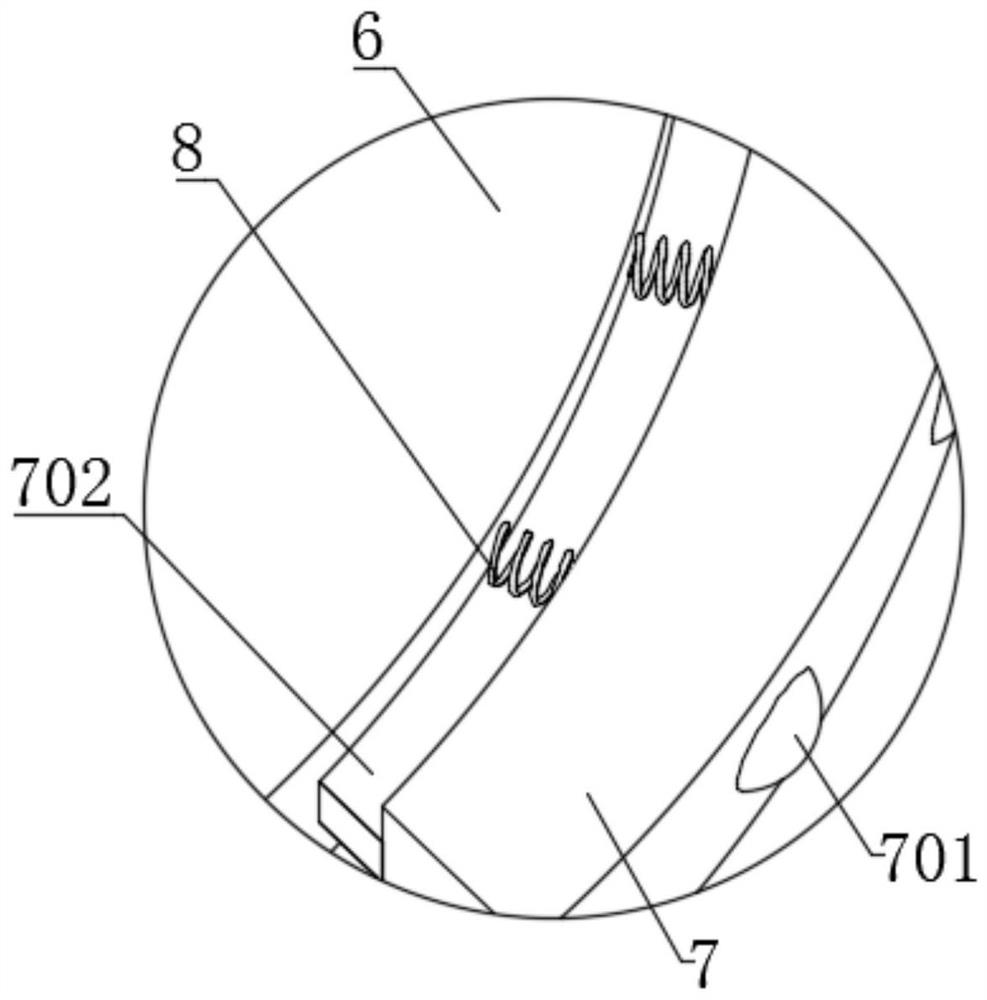

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The invention provides a sucker rod anti-eccentric wear centralizer, which includes a centralizer body 1, an internal thread socket 1011, an external thread connecting pipe 1012, an upper and lower sliding rail 102, a baffle plate 103, a centralizing bump 2, a groove 201, a sliding Groove 202, adjusting shaft 3, limit hand wheel 301, righting roller 302, bushing 303, connecting rod 4, limit plate 401, sleeve column 5, limit card rod 501, adjustment spring A502, centering ring 6, middle pass Hole 601, up and down sliding groove 602, card groove 603, arc-shaped centralizing plate 7, ball 701, adjusting plate 702 and adjusting spring B8; the upper end of the centralizer body 1 of the centralizer body 1 is provided with a hexagonal internal thread socket 1011, the lower end of the centralizer body 1 is provided with an externally threaded connecting pipe 1012, and the outer lower end of the centralizer body 1 is wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com