Self-consumable simple thermal insulation cover of molten iron transport tank and its application method

A technology of heat preservation cover and conveying tank, which is applied in metal processing equipment, manufacturing tools, casting molten material containers, etc. It can solve the problems of difficult transformation of old enterprises, large one-time investment, and easy water accumulation and moisture absorption of carbon insulation layer. , to avoid difficulties in molten iron slag removal and pretreatment, improve reliability and stability, and facilitate in-line capping operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

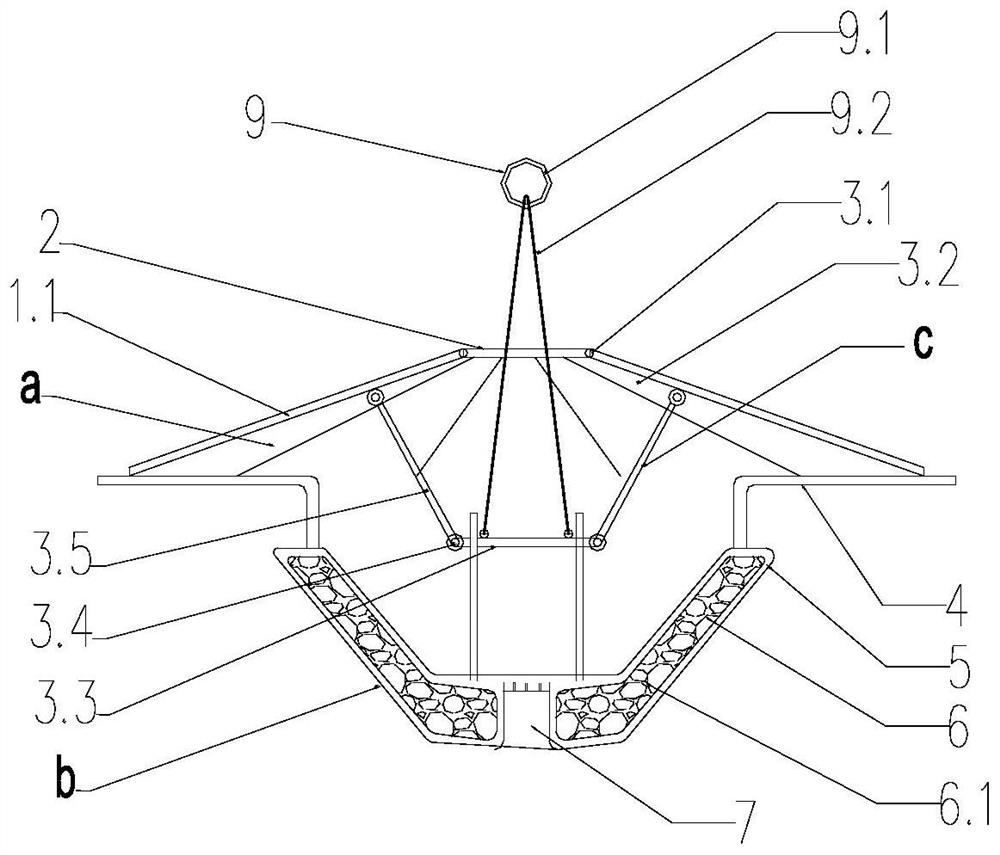

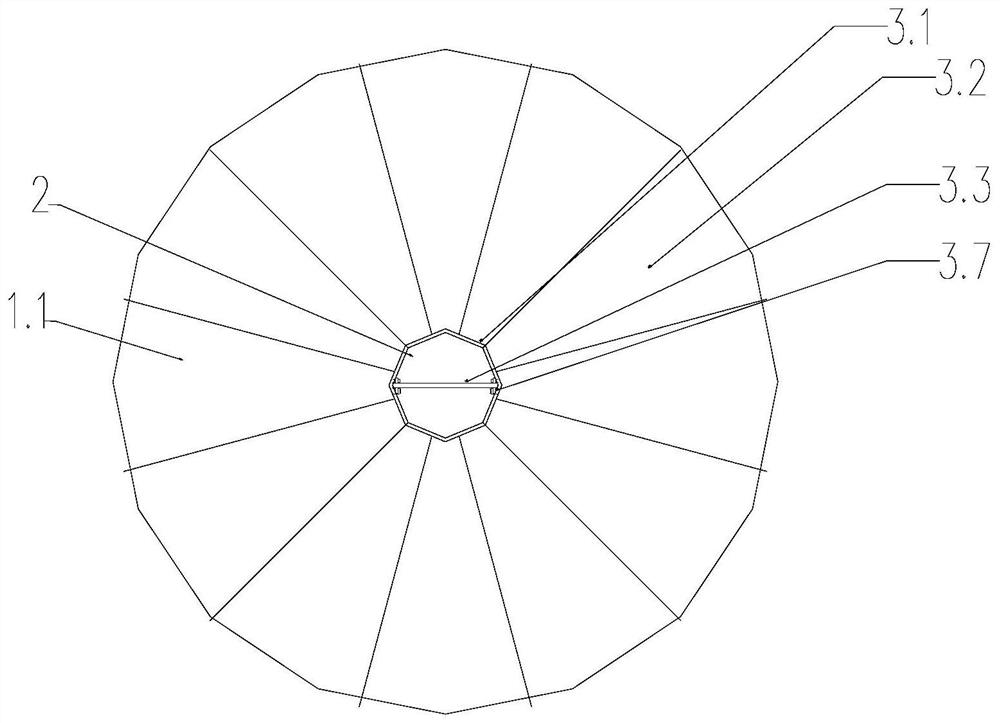

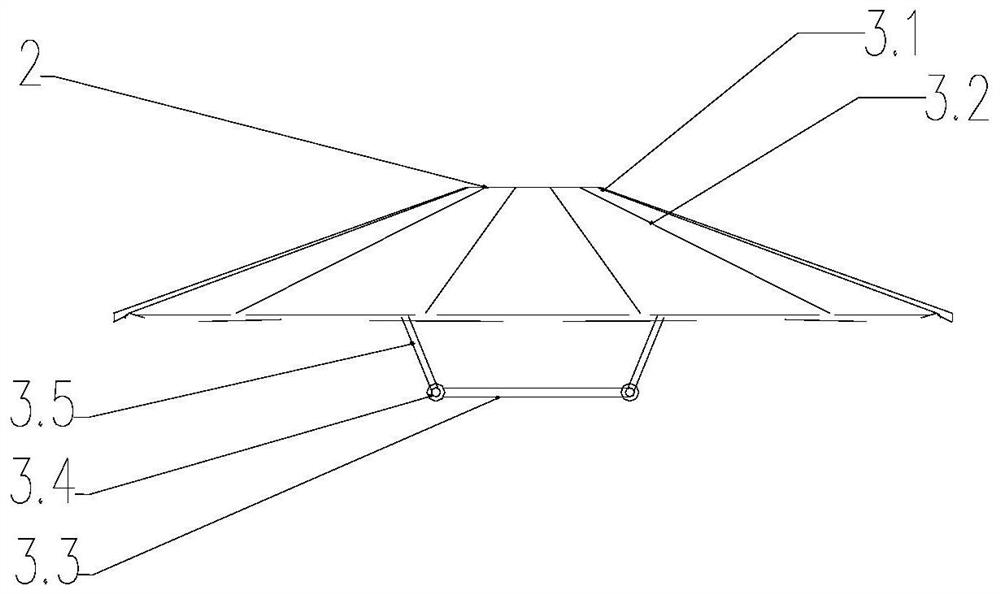

[0043] Such as Figure 1~4 The shown self-consumption type simple thermal insulation cover of the molten iron transport tank is arranged on the container mouth of the molten iron container 10 (hot metal tank or torpedo tank). The thermal insulation cover includes an upper "umbrella" rainproof assembly a and a lower concave thermal insulation assembly b. The upper "umbrella"-shaped rainproof assembly a is connected and fixed with the lower concave heat preservation assembly b through a support mechanism c; the "umbrella"-shaped rainproof assembly a includes a rainproof umbrella surface 1, which is composed of a plurality of fan-shaped pieces 1.1 Arranged along the circumferential lap, or along the circumferential and radial laps, the sector pieces 1.1 are connected by wire threading and binding, and the anti-rain umbrella surface 1 and radial thin steel bars 3.2 are connected by wire threading and binding; the sector pieces 1.1 It is a thin metal plate with a thickness of ≤0.5m...

Embodiment 2

[0060] Such as Figure 5-6 The shown self-consumption type simple thermal insulation cover of the molten iron transport tank is arranged on the container mouth of the molten iron container 10 (hot metal tank or torpedo tank), and the thermal insulation cover includes a concave thermal insulation component b, which is the top A spherical crown, a cone, or a spherical crown structure with an opening and the outer diameter gradually decreases from top to bottom; the concave heat preservation component b is embedded in the container mouth, and the concave heat preservation component includes a hollow A concave sheet metal box 5, the bottom surface of the concave sheet metal box 5 is provided with a bottom leak hole 7, and the edge end surface of the concave sheet metal box 5 is symmetrically provided with an inverted L-shaped tank opening support frame 4, so The bottom of the vertical section of the tank opening support frame 4 is connected to the upper end surface of the concave ...

Embodiment 3

[0065] Such as Figure 7 The shown self-consumable simple thermal insulation cover of the molten iron delivery tank is basically the same in structure as that of Example 2, except that the top surface of the concave metal sheet box 5 is provided with a metal horizontal shielding sheet 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com