High-efficiency wood cutting machine and cutting method for construction engineering

A construction engineering and cutting machine technology, applied in wood processing appliances, special forming/shaping machines, manufacturing tools, etc., can solve the problems of unsafe working environment for operators, inaccurate positioning, cumbersome cutting operations, etc. The effect of improving flexibility and cutting efficiency, simple adjustment and switching, and promoting reset efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

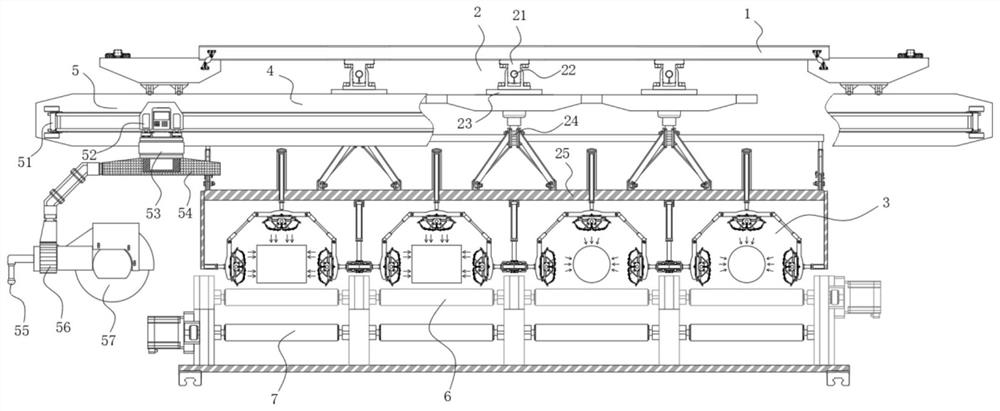

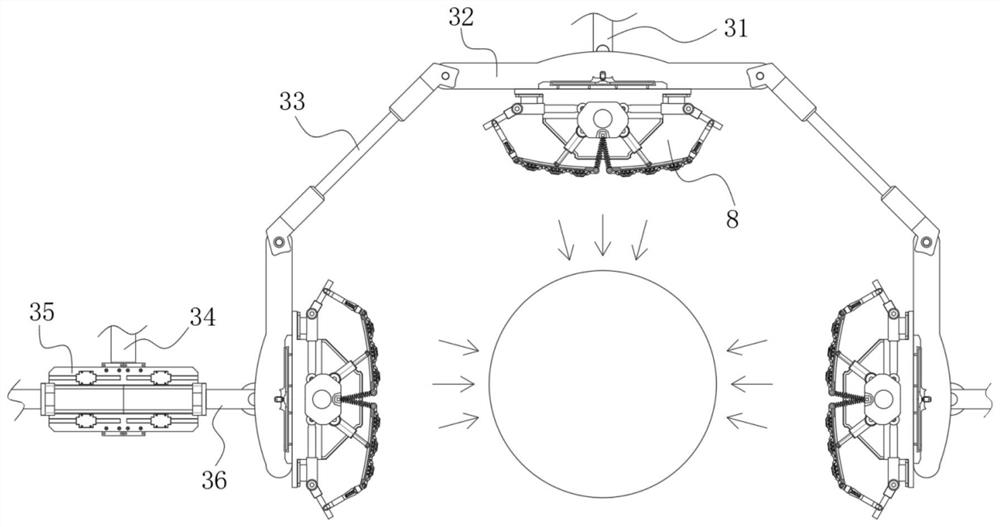

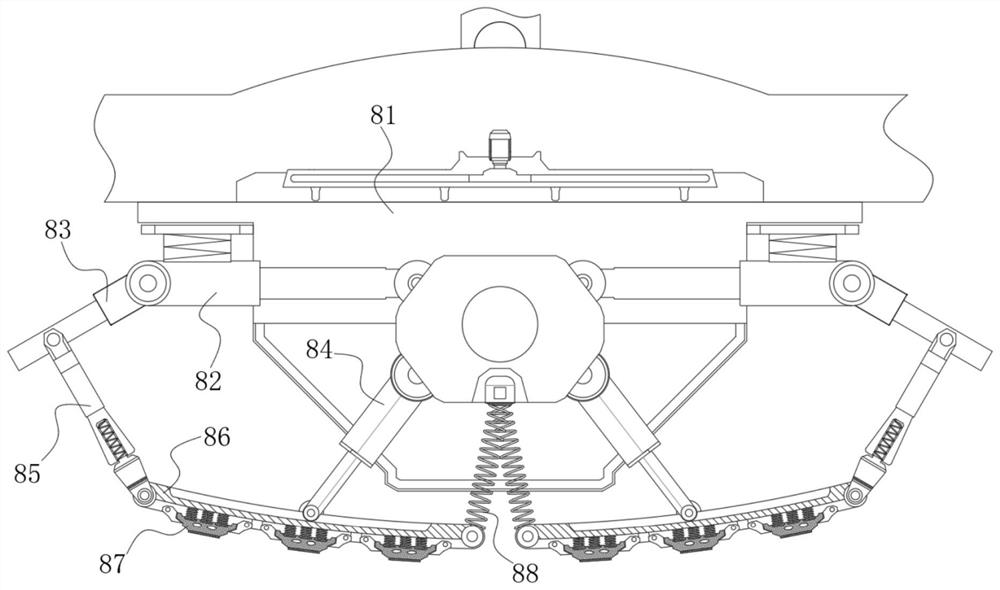

[0029] refer to Figure 1-4 , the present invention provides a technical solution: a high-efficiency wood cutting machine for construction engineering, which includes a hanger 1, a hoisting device 2, a positioning and clamping device 3, a side plate 4, a cutting device 5, a feeding device 6 and a conveying device Feeding device 7, described feeding device 6 is arranged on the right side, and described feeding device 7 is arranged next to the left end of feeding device 6 and on the lower side, and the center of the hanger 1 is equipped with a hoisting device 2, so The positioning and clamping device 3 is installed in the lifting device 2, and the timber in the feeding device 6 is positioned and clamped for hoisting. The lower ends of the left and right side end plates of the hanger 1 are fixed with horizontally arranged side plates 4, And located at the front end of the lifting device 2, the side plate 4 is equipped with a cutting device 5 that moves laterally from side to side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com