Pallet calibration device and method

A technology of a calibration device and a calibration method, which is applied in the direction of a lifting device, etc., can solve problems such as limited tray guide angle, abnormal displacement of the tray, and limited limit range, so as to avoid damage to the tray, improve calibration efficiency, and ensure calibration accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

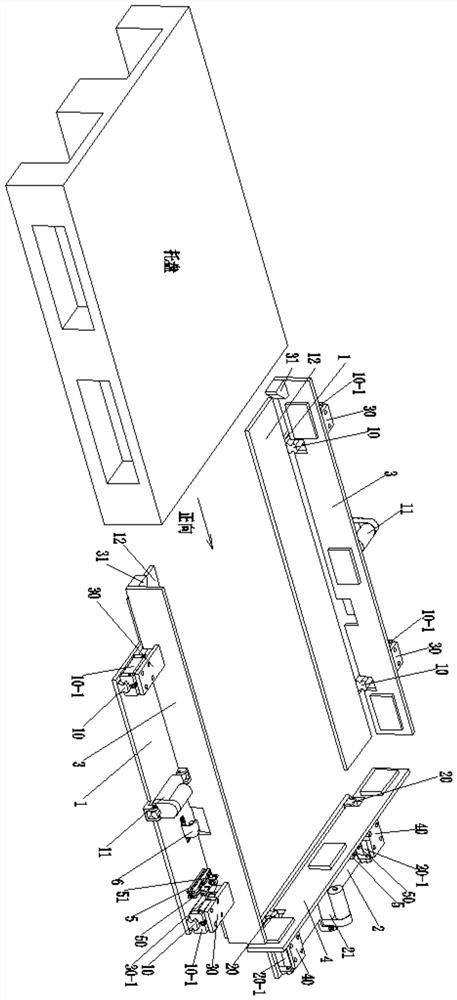

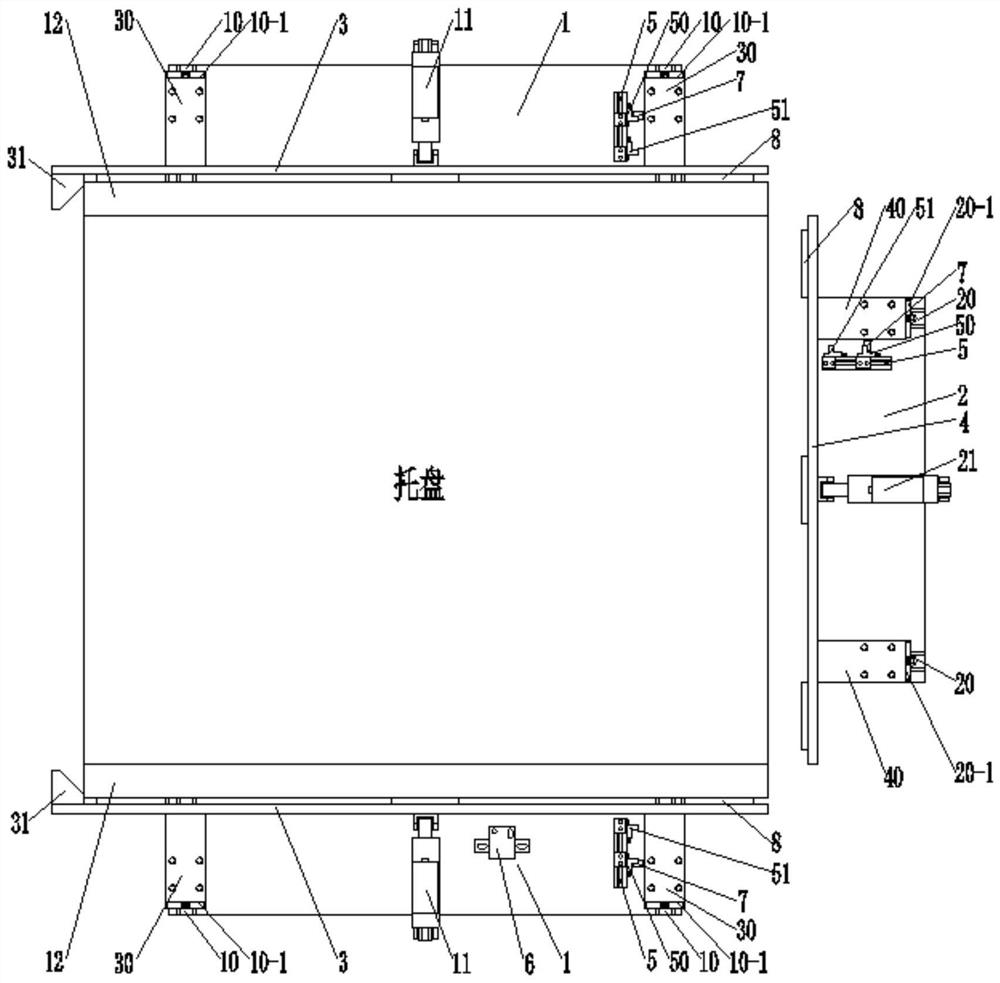

Embodiment 1

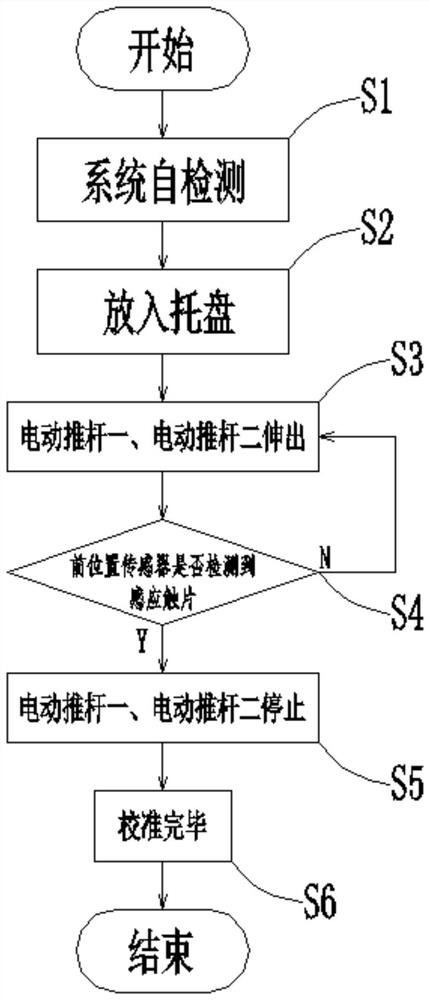

[0078] First, the system performs a self-inspection to determine whether the rear position sensor 50 of the tray calibration device detects the sensing contact piece 7. If so, it proves that the electric push rod one 11 and the electric push rod two 21 shrink to the rear, that is, the two side push plates 3 and A positive push plate 4 is in a shrinking state, and then it is judged whether an object is detected by the seat switch 6. If so, the alarm system is turned on to give an alarm, prompting the staff that there is an object placed in the tray calibration device, and if not, the tray is calibrated. Place the tray in the unit.

[0079] Then electric push rod one 11, electric push rod two 21 stretch out, until connecting plate one 30 and connecting plate two 40 are provided with induction contact sheet 7 and stop at front position sensor 51, and now the pallet position calibration is completed.

Embodiment 2

[0081] On the basis of Example 1, a plurality of rubber pads 8 are provided on the inner walls of the side push plate 3 and the forward push plate 4, which avoids contact between the tray and the inside of the two side push plates 3 and one forward push plate 4. , to avoid damage to the pallet and pallet alignment device.

[0082] A nylon plate 12 is provided inside the bottom plate 1 to reduce the frictional resistance on the bottom of the tray and avoid damage to the tray.

[0083] The entrance of the side push plate 3 is provided with a nylon guide block 31, and the cut angle of the nylon guide block 31 is less than or equal to 45°, so that when the two side push plates 3 are calibrating the position of the tray, the nylon guide block 31 will also move the tray Push it inward to ensure that the positive push plate 4 also plays the role of pallet position calibration.

Embodiment 3

[0085] In the pallet calibration method of the present invention, system detection is performed before calibration, avoiding false detection and safety accidents, and the system responds quickly and has a high degree of automation.

[0086] A pallet calibration method of the present invention can also perform position calibration on containers with other rectangular frames; and by changing the shape of the inner walls of the side push plate 3 and the forward push plate 4, it can be adapted to the calibration operation of containers with other shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com