Split flange feeding gate of electronic quantitative weigh

A quantitative scale and split-type technology, which is applied in the field of feeding mechanism of electronic weighing device, can solve the problem that the weighing of double scales cannot meet the needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

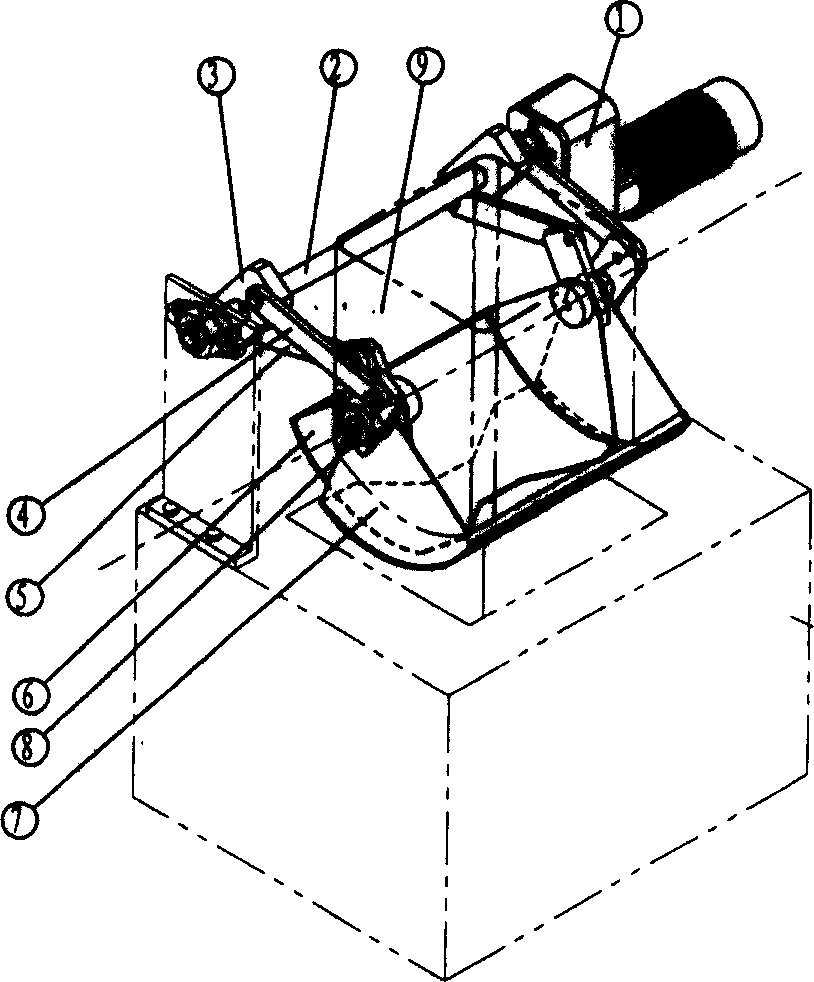

[0020] Embodiment one. The composition of the split feeding door of the electronic quantitative scale includes a driving device installed on a frame, a material door mechanism and a transmission mechanism connected between the driving device and the material door mechanism. combine figure 1 , The material gate mechanism is made up of two material gates of loading gate 6 and discharge gate 7, and the two material gates are connected with the blanking cylinder 9 of the quantitative scale through the material gate shaft 8. The transmission mechanism includes one end connected with the driving device, and the other end mounted on the frame through bearings to drive the shaft 2. The two ends of the drive shaft are respectively equipped with pendulum blocks 3. There is a key connection between the pendulum block and the drive shaft. The two pendulum blocks of each pendulum block One end is connected with the outer tie rod 4 and the inner tie rod 5 through a joint bearing, and the ...

Embodiment 2

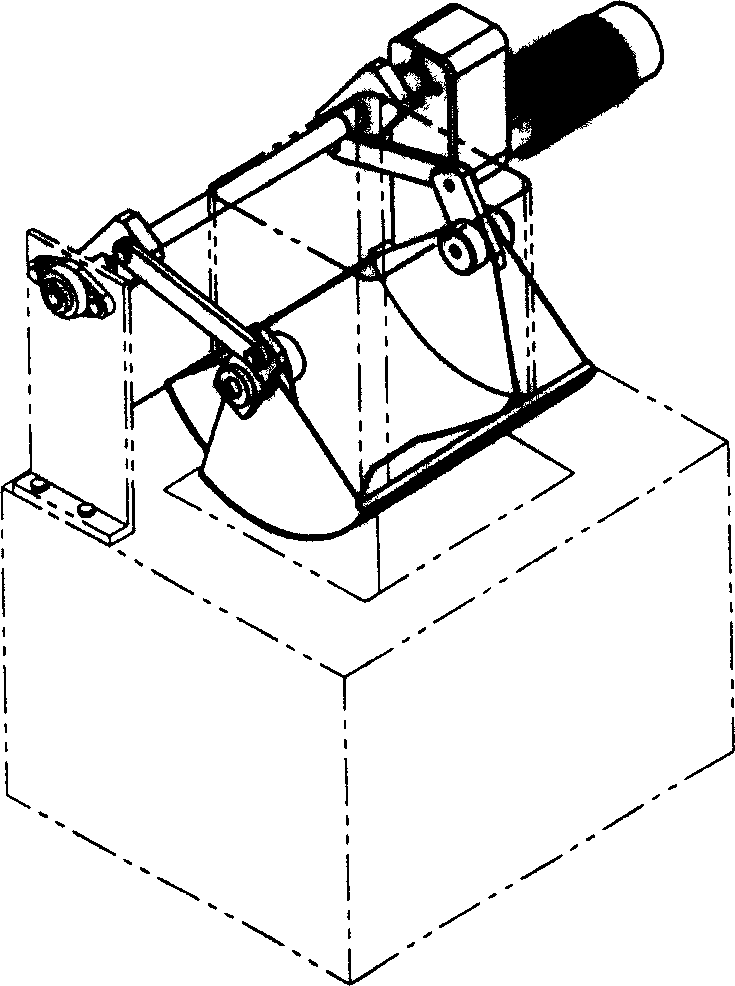

[0021] Embodiment two. combine figure 2 , the second embodiment of the present invention is: there are two pendulum blocks installed on the drive shaft, one end of the loading door is provided with an inner rod hinged with the pendulum block, and one end of the unloading door is provided with an inner rod hinged with the pendulum block. Outer rod. Other parts are the same as in Embodiment 1.

Embodiment 3

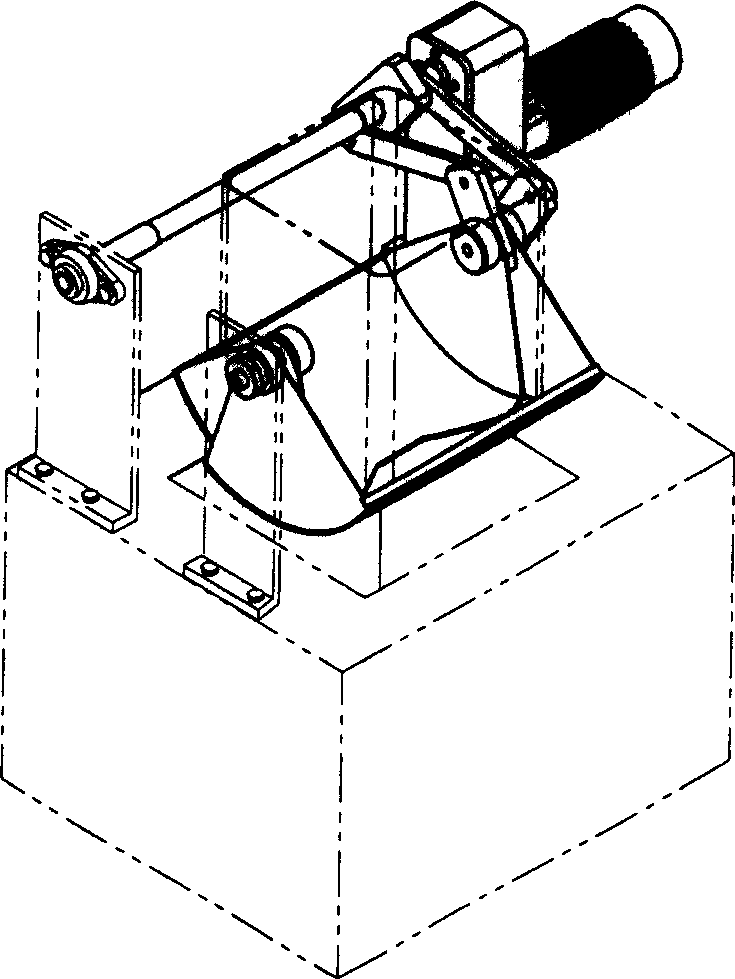

[0022] Embodiment three. There is one pendulum block installed on the drive shaft, and the other end of the inner pull rod hinged with the loading door and the outer pull rod hinged with the discharge door is hinged with the two ends of the same pendulum block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com