Method for cold-bending dovetail groove in fireproofing accurate steel materials and device thereof

A steel profile and dovetail groove technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of auxiliary roller installation, adjustment, difficulty in providing forming pressure, unstable production process, etc. The effect of small size, fast forming speed and simplified equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

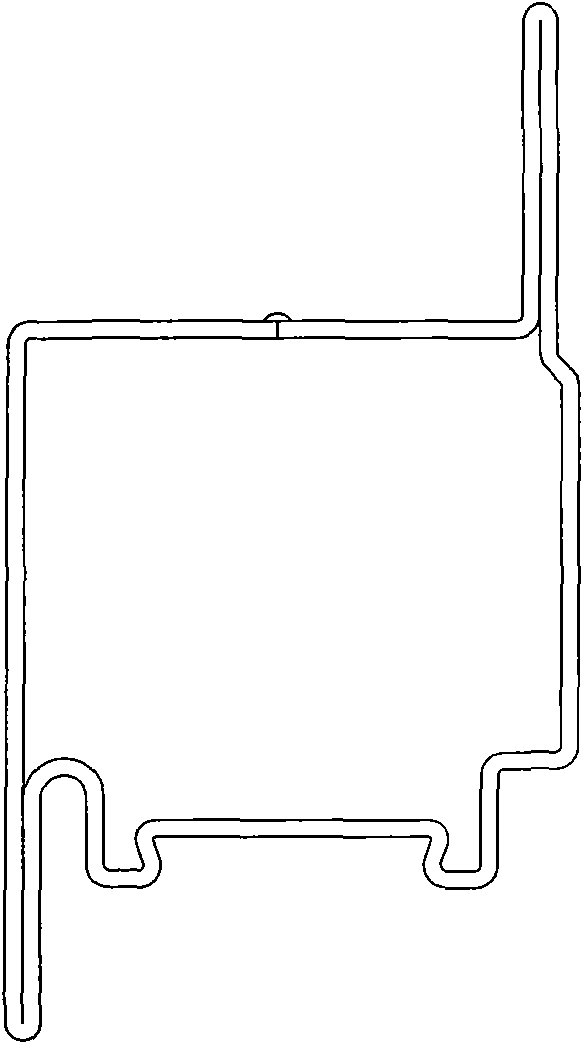

[0019] figure 1 The profile shown includes a dovetail groove located at the lower part. Due to the difficulty of bending, the dovetail groove generally needs to be completed first in the cold bending forming process of the profile, and then other parts are bent.

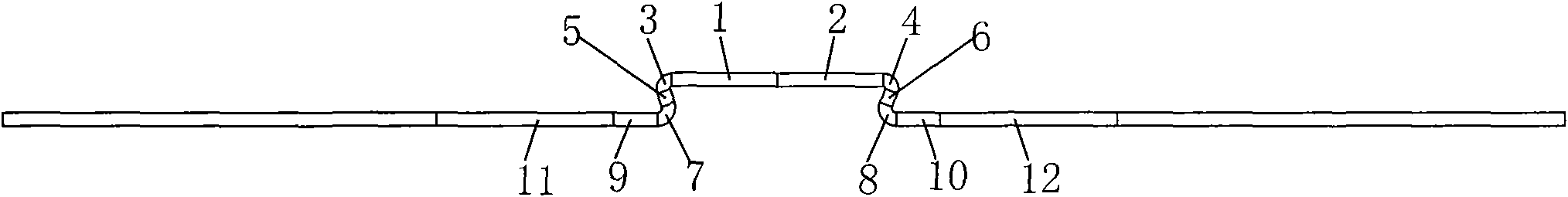

[0020] figure 2 It shows the profile after dovetail groove processing, and divides the section of the profile into 12 entities, among which entities 3, 4, 7, and 8 are arcs of bending points, and entities 1, 2, 5, 6, 9, 10, 11, and 12 are On the plane, the top of the tank is composed of entities 1 and 2, entities 5 and 6 are the walls of the tank, entities 9 and 11 and entities 10 and 12 are the two sides of the tank, and are located on the same plane. The thickness of the profile is 1.5mm, and the distance between the top and side of the groove is the depth of the dovetail groove is 4.5mm. The profile contains two symmetrical 70° dovetail angles, namely the angle between entities 1 and 5, the angle between entitie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com