Antioxidation bonding copper wire and method for preparing same

A technology for oxidizing bonds and copper wires, which is applied in the field of bonding wires, can solve the problems of increasing costs, affecting the use effect of final products, storage of bare copper wires, and short service life, so as to prevent oxidation, solve copper wire oxidation, and improve metal quality. The effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Bonded copper wire of the present invention is prepared according to the following process steps:

[0026] 1) High purity copper with a purity of 99.999wt% is purified by electrolysis of copper with a purity of 99.99wt%. The copper with a purity of 99.99wt% as a raw material is a commercially available gold material of ordinary purity. The raw material is purified by electrolysis to 99.999wt%, the specific method is: use commercially available copper as the anode, hang it on the anode conductive rod, use the inert carbon material as the cathode, hang it on the cathode conductive rod, keep the anode and the cathode parallel; add copper sulfate solution in the electrolytic cell As the electrolyte, the tank pressure is controlled at 0.6-1.2V during the electrolysis process to ensure the liquid level of the electrolyte. The electrolytic copper is washed with pure water, washed to neutral, and finally put into a protective gas oven to dry to obtain 99.999wt% high-purity copp...

Embodiment 2

[0047] The method of embodiment 1 is repeated by each component content specified in the following table 1:

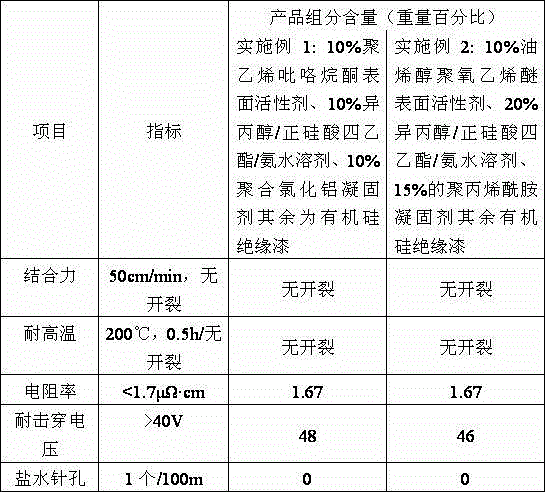

[0048] Table 1 Example 1-2 product component content and product performance index

[0049]

[0050] In Table 1, by coating the organic layer on the surface of the bonding copper wire, the organic layer is 10% polyvinylpyrrolidone surfactant, 10% isopropanol / tetraethyl orthosilicate / ammonia solvent, 10% polyaluminum chloride The rest of the coagulant is silicone insulating varnish; the organic layer can also be 10% oleyl alcohol polyoxyethylene ether surfactant, 20% isopropanol / tetraethyl orthosilicate / ammonia solvent, 15% polyacrylamide The experimental comparison of coagulant all the other organosilicon insulating varnishes, the performance test parameter of each embodiment all illustrate, and bonding copper wire of the present invention can all reach target, has pin-coat binding force height, pinhole rate is low, high temperature resistance, resistance Oxidative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com