Small-stroke proportional output LVDT compensation coil process

A compensation coil and proportional output technology, which is applied in coil manufacturing, transformer/inductor coil/winding/connection, etc., can solve the problems of large sum voltage and non-adjustable, etc., and achieve the effect of improving performance and meeting technical index requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

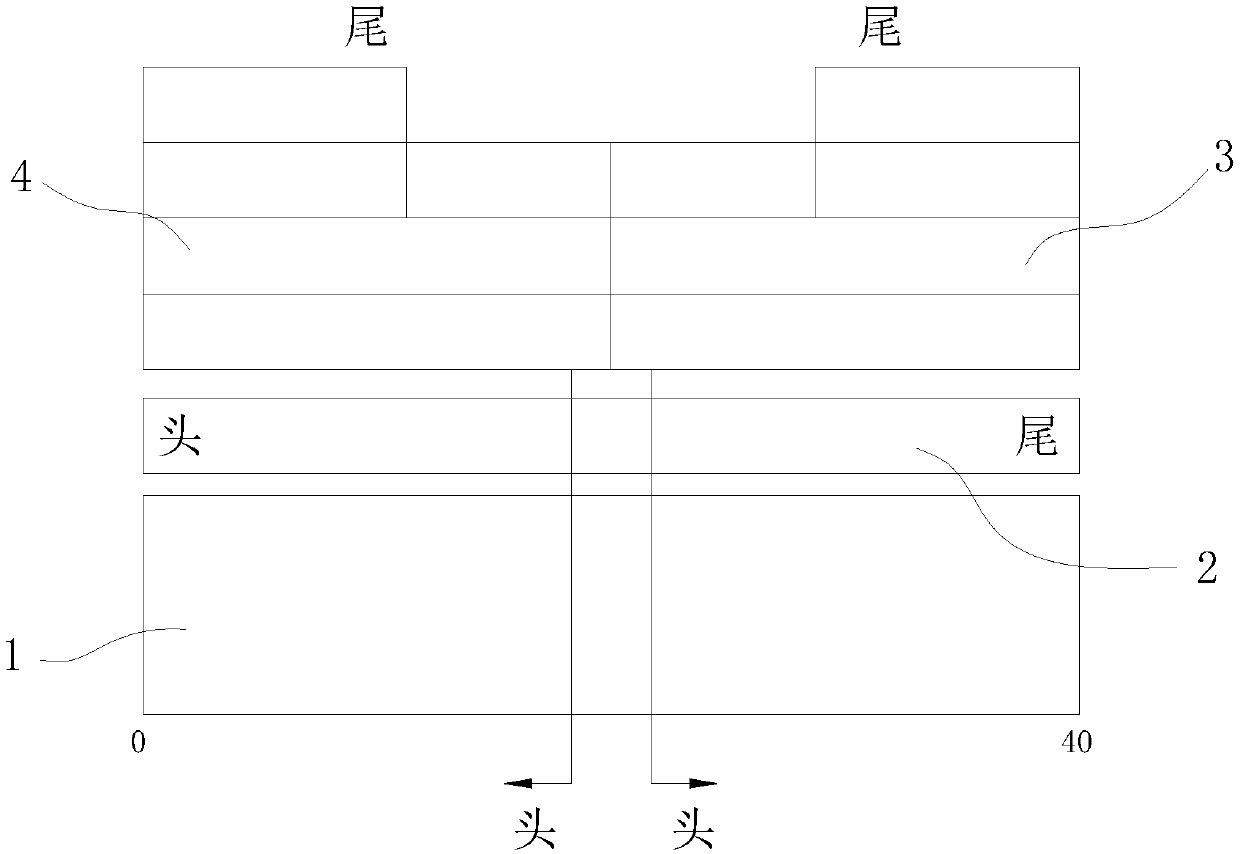

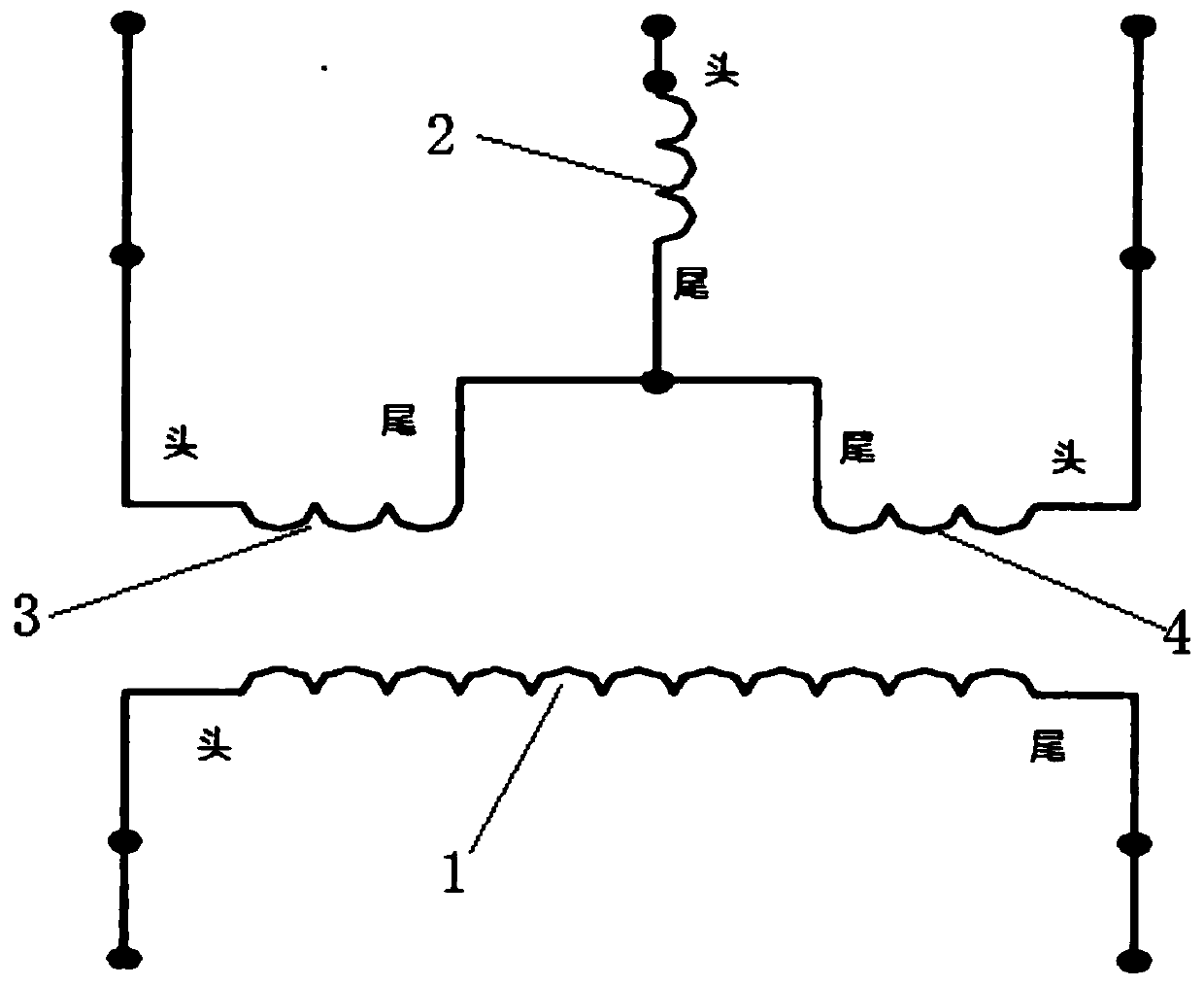

[0041] like Figure 1 to Figure 2 As shown, the small stroke ratio output LVDT compensation coil process includes the following steps:

[0042] Step 1: Design the number of turns and layers of the primary coil 1 according to the technical indicators for flat winding;

[0043] Step 2: Wind the compensation coil WE2 horizontally from left to right on the primary coil 1;

[0044] The output voltage of the compensation coil WE2 is VE, and the value does not change when the iron core moves, where:

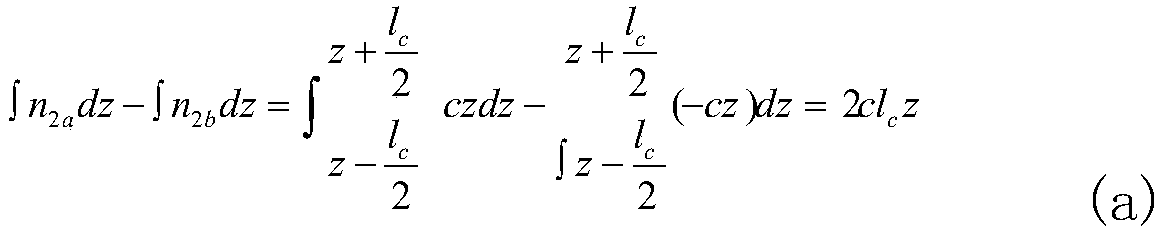

[0045]

[0046] In the formula, (VA+VB) is the measured secondary coil and value voltage, and VF is the required voltage in the technical index;

[0047] The number of turns NE of the compensation coil WE2 is:

[0048] NE=(VE÷V1)×N1 (2)

[0049] In the formula, N1 is the number of turns o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com