Floating frame device for medium-high voltage electronic aluminum production line and using method thereof

A production line, medium and high voltage technology, which is applied in the field of floating frame devices of medium and high voltage electronic aluminum production lines, can solve the problems of large floating frame devices, increased production line instability, and occupation of production line space, and achieves compact structure, simple structure, and improved The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

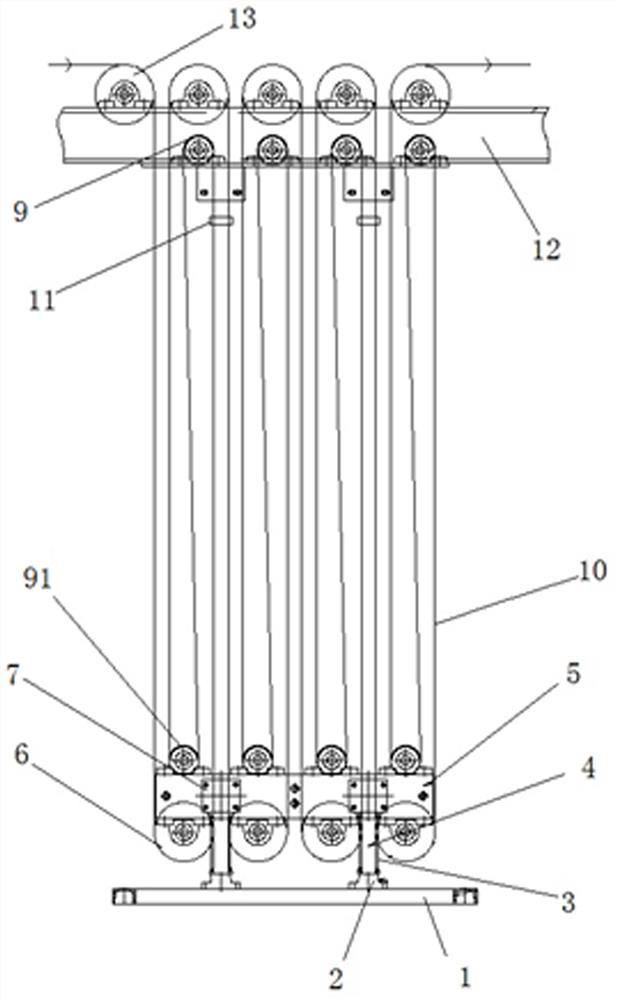

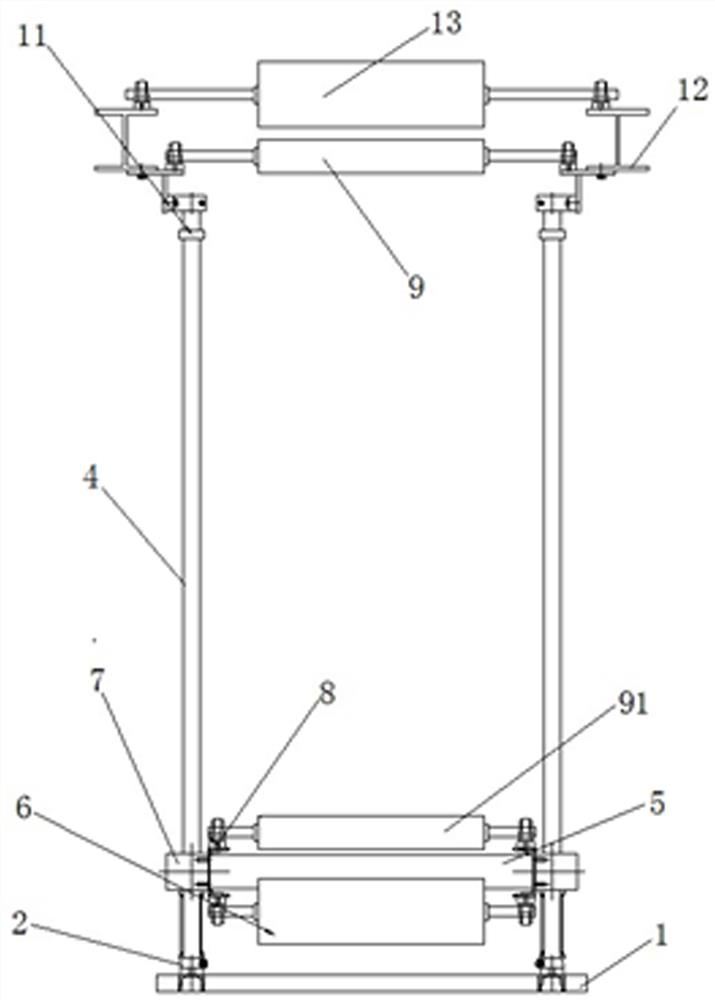

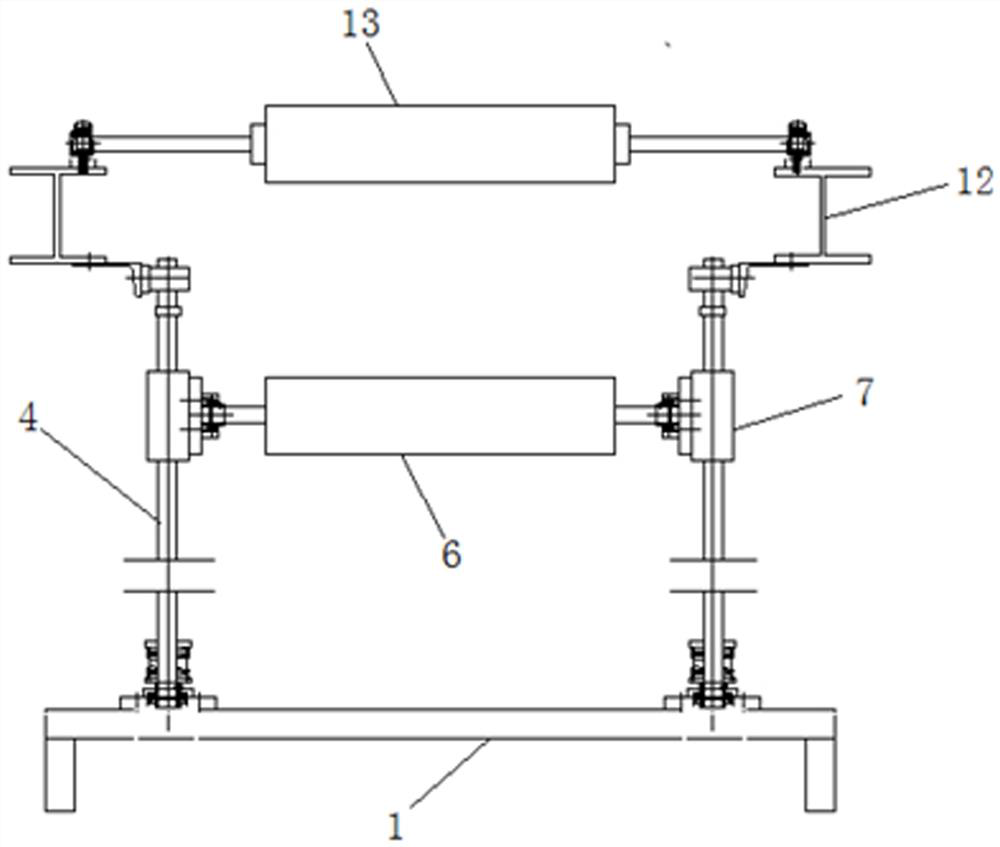

[0027] Such as Figure 1-4 As shown, a floating frame device for a medium and high voltage electronic aluminum production line in this embodiment includes a support frame 1 at the bottom, a guide shaft 4, a floating frame 5 and a roller beam 12; the two sides of the support frame 1 are respectively installed There is guide shaft 4, and the top of guide shaft 5 is provided with roller beam 12, and described roller beam 12 is parallel to supporting frame 1; The top of described roller beam 12 is uniformly distributed transition roller 13, and described transition roller The two ends of 13 are respectively connected to the roller beam 12 through the bearing housing 8; the transition roller 13 is parallel to the support frame 1; A9, the two ends of the small roller A9 are respectively connected to the roller beam 12 through the bearing housing 8, the small rollers A9 are arranged in parallel and adjacent to each other, and are placed directly below each transition roller 13; Desc...

Embodiment 2

[0029] The difference from Embodiment 1 is that: the guide shaft 4 between the floating frame 5 and the roller beam 12 is equipped with a limit block 11; the limit block 11 is movably connected with the guide shaft 4. The limit block 11 is used to limit the floating height of the floating frame 5 and prevent the floating frame 5 from colliding with the roller beam 12 .

Embodiment 3

[0031] The difference from Embodiment 2 is that: the bottom of the guide shaft 4 is provided with a spring member 3 . The spring member 3 is used to prevent the floating frame 5 from sliding downward under the action of gravity, hitting the support frame 1 and causing damage to the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com