Gravity adjusting device for underwater robot

An underwater robot, center of gravity adjustment technology, applied in the directions of underwater operation equipment, transportation and packaging, ships, etc. The effect of endurance, weight reduction, and number reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

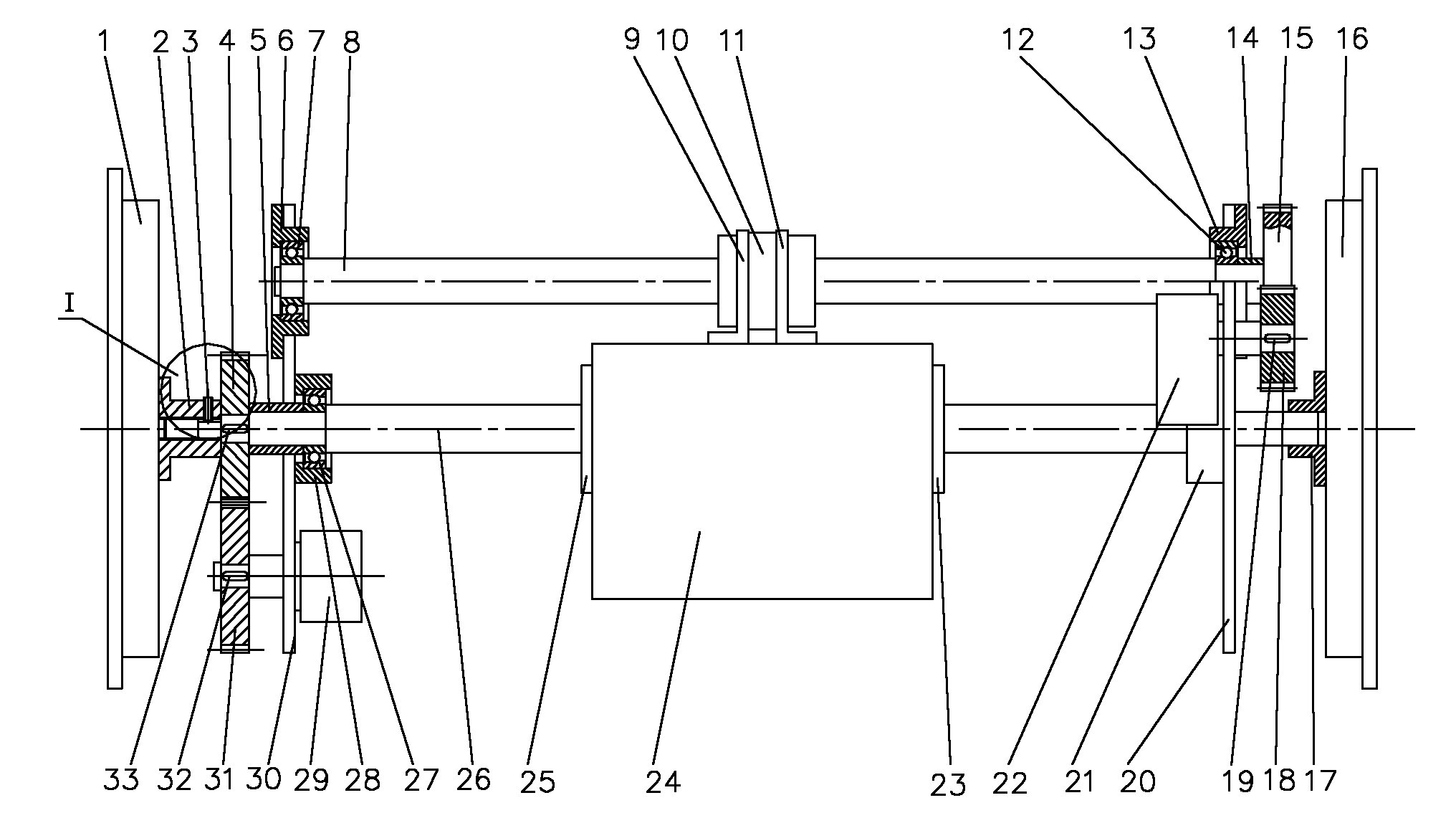

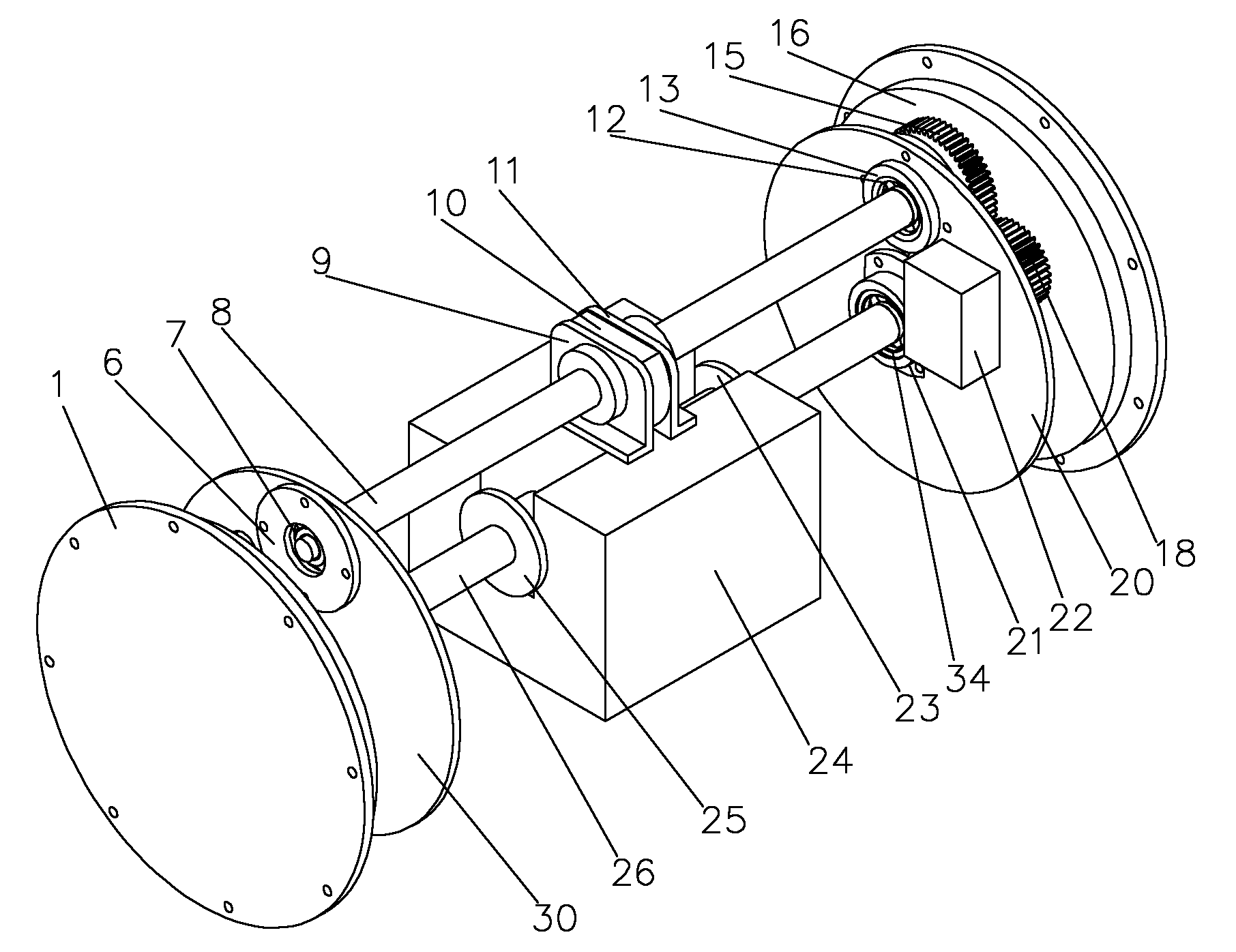

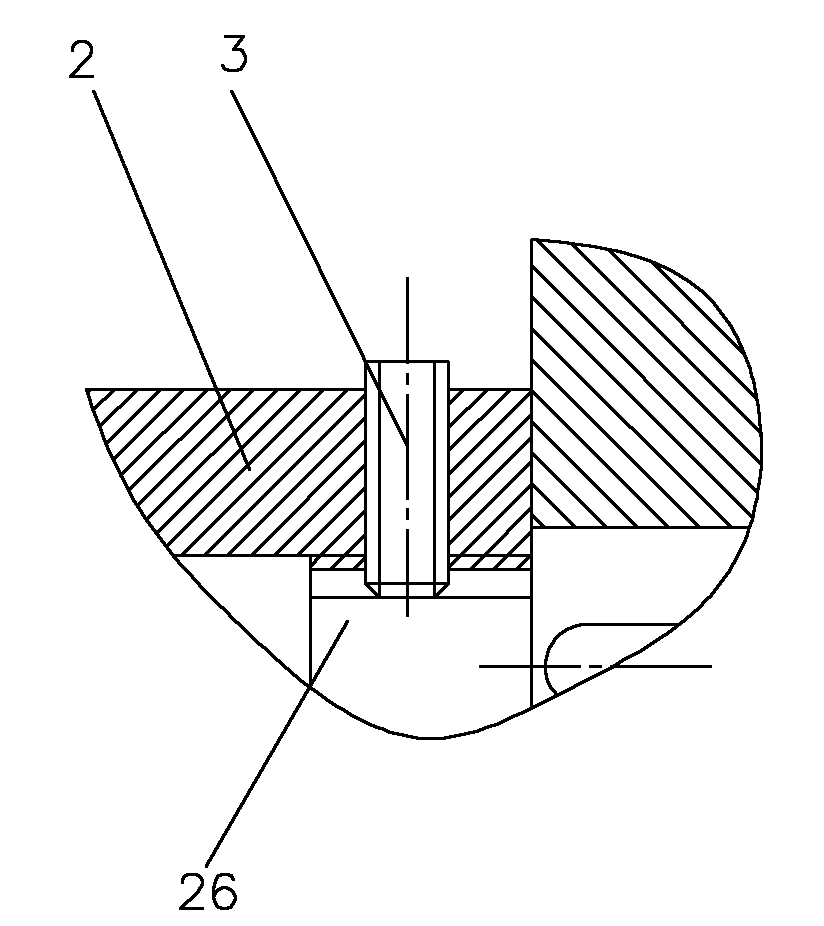

[0024] combine figure 1 , figure 2 , Figure 4 and Figure 5 , screw bearing supports 6, 13 are respectively installed on the supporting discs 20, 30, angular contact ball bearings 7, 12 are housed in the supports, the two ends of the ball screw 8 are respectively connected with the angular contact ball bearings 7, 12, the ball screw Bar 8 is free to spin. The right end of the ball screw 8 is fixedly connected with the gear 15. A ball nut 10 is mounted on the ball screw 8 . The eccentric battery block 24 is fixedly connected with the ball nut 10 through the connecting pieces 9 , 11 . The left and right ends of the eccentric battery block 24 are equipped with linear bearings 23, 25, which cooperate with the central axis 26 so that the eccentric battery block 24 can move linearly along the central axis 26. An axially adjusting motor 22 with a worm gear reducer is housed on the support plate 20, and the gear 18 is fixedly connected with the motor output shaft through a key...

specific Embodiment approach 2

[0027] combine figure 1 , Figure 4 and Figure 6 , the axial adjustment gear transmission composed of gears (18), (15) and the rolling adjustment gear transmission composed of sun wheel (4) and planetary gear (31) described in Embodiment 1 can be replaced by synchronous belt The synchronous belt transmission that wheel (35), (37) and synchronous belt (36) form makes transmission more stable, reduces the noise in the transmission process.

specific Embodiment approach 3

[0028] combine Figure 7 , because the cross-section of the robot is a circular structure, so in order to utilize the inner space of the robot to the greatest extent, the eccentric battery block (24) described in Embodiment 1 can be changed into the structure of a circular eccentric battery block (38), increasing the size of the battery The capacity is conducive to improving the endurance of underwater robots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com