Production method and plus material of high strength and double face polyester peach skin cotton knitting fabric

The technology of a cotton knitted fabric and production method, which is applied in the direction of fabric surface trimming, knitting, weft knitting, etc., can solve the problems that the fabric strength cannot meet the wearing requirements and the softening effect is reduced, and achieve the effect of high strength and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Raw material preparation,

[0044] Choose 60% combed cotton, 40% long-staple cotton yarn count, the count is 28S –80 S , such as 36 S , 40 S , 50 S , 60 S Wait. The raw materials should be balanced at a constant temperature and humidity for at least 24 hours in an environment with a temperature of 23±2°C and a humidity of 65±3% before being put on the machine.

[0045] 2. Weaving on the machine,

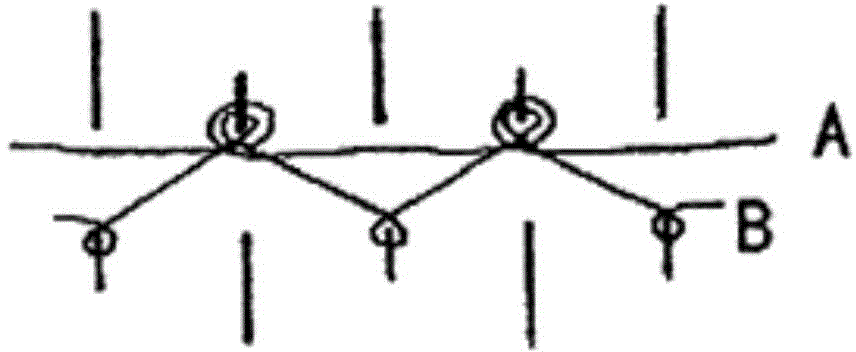

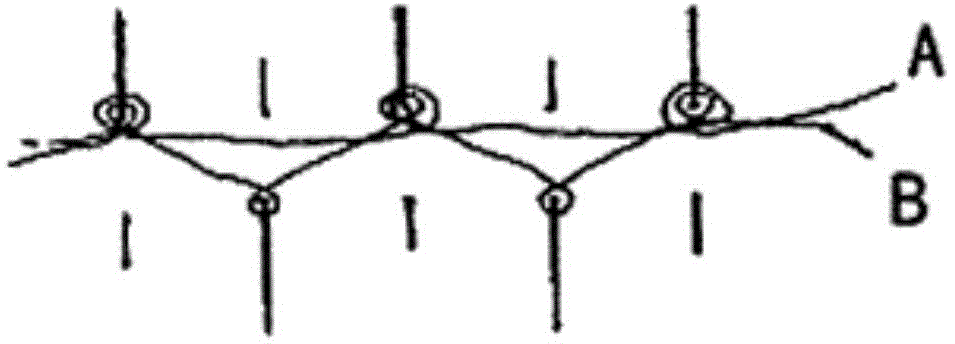

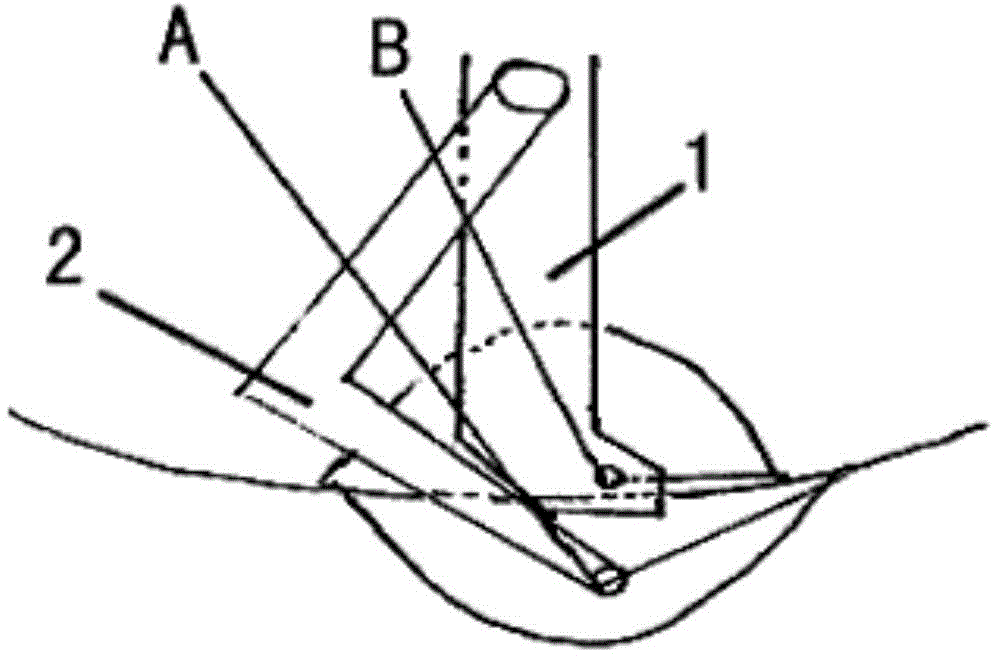

[0046] The weave structure of the present invention is a double-sided weave, and machine numbers 22G-32G are used for weaving. When weaving, a sanded yarn A is placed on one side of the double-sided weave, so that the yarn A and the ground yarn B are looped at the same time. Adjust the angle of yarn feeding, cover yarn A with ground yarn B, make the inner surface of the fabric be yarn A, and adjust the density of the fabric so that the weight per square meter of the finished product is 250g / m 2 , the weaving density of the finished product is 18 wales / cm, and the bur...

Embodiment 2

[0068] 1. Raw materials: 80% of 36 S TK combed cotton with 20% long-staple cotton grade 137 added. Perform constant temperature and humidity balance for 24 hours in an environment with a temperature of 25°C and a humidity of 65%.

[0069] 2. Weaving process:

[0070] Machine type: German double-sided Meyersey large circular knitting machine

[0071] Barrel Diameter: 34"

[0072] Machine number: 28G

[0073] Product organization structure: double-sided organization

[0074] Coil length: 50 coils The length is: 15cm / 50w.

[0075] Rough weight: 170g / m 2

[0076] 3. Pretreatment process:

[0077] Reagent components include:

[0078] Yuzhongbao (cotton) concentration: 1.5g / L

[0079] Penetrant: 1.2g / L

[0080] Hydrogen peroxide: 4g / L

[0081] Hydrogen peroxide stabilizer: 2g / L

[0082] Chelating agent S: 1.2g / L

[0083] Caustic soda: 3g / L

[0084] Chililong: 2g / L

[0085] Acetic acid: 0.3g / L

[0086] 4. Dyeing process:

[0087] Color: dark blue gray

[0088] Dyei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com