Novel double-compacted steel wire rope and production technology thereof

A production process and technology for steel wire ropes, which are applied in the field of new double-compacted steel wire ropes and their production processes, can solve problems such as the impact of wear resistance and service life of steel wire ropes, and the inability of rope strands to be tightly compacted, and achieve compact structure, increased breaking force, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

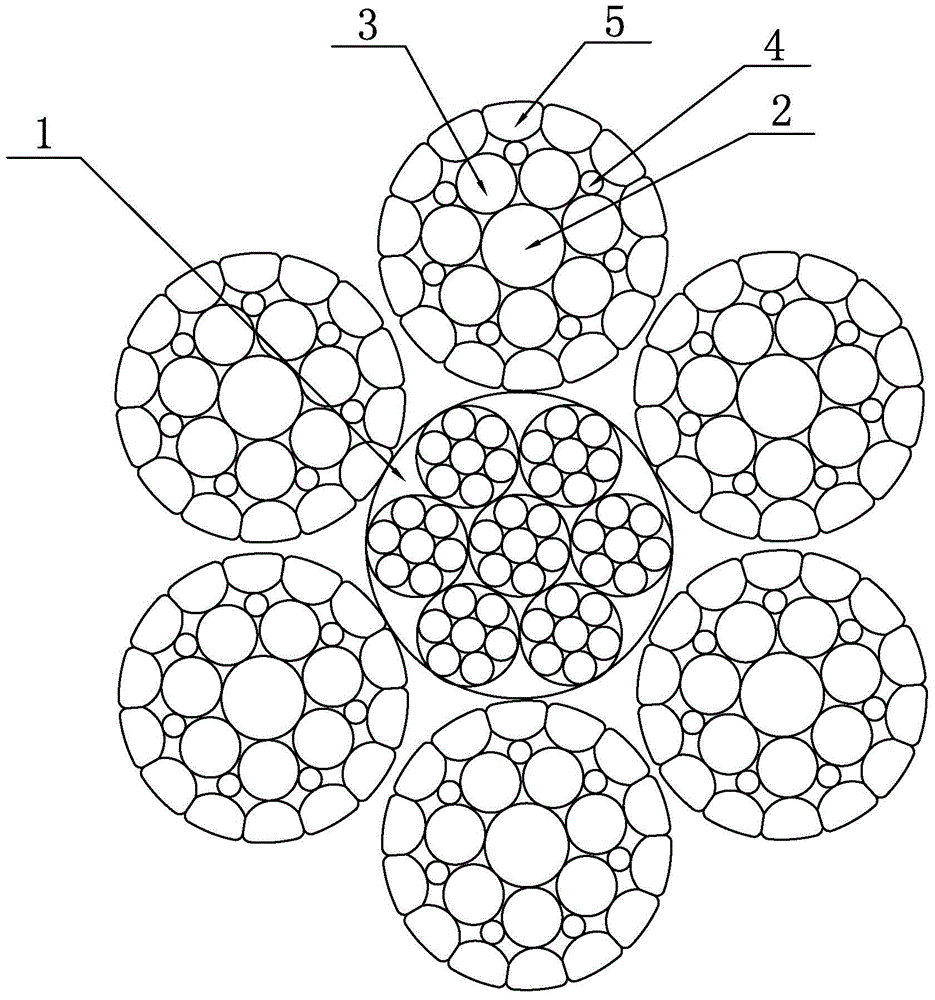

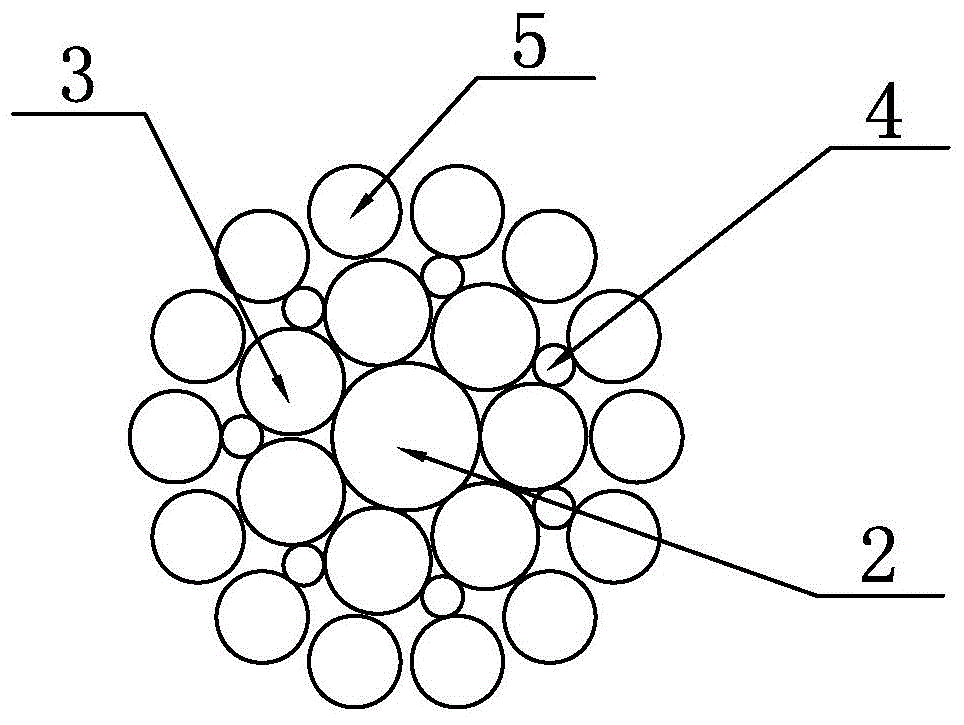

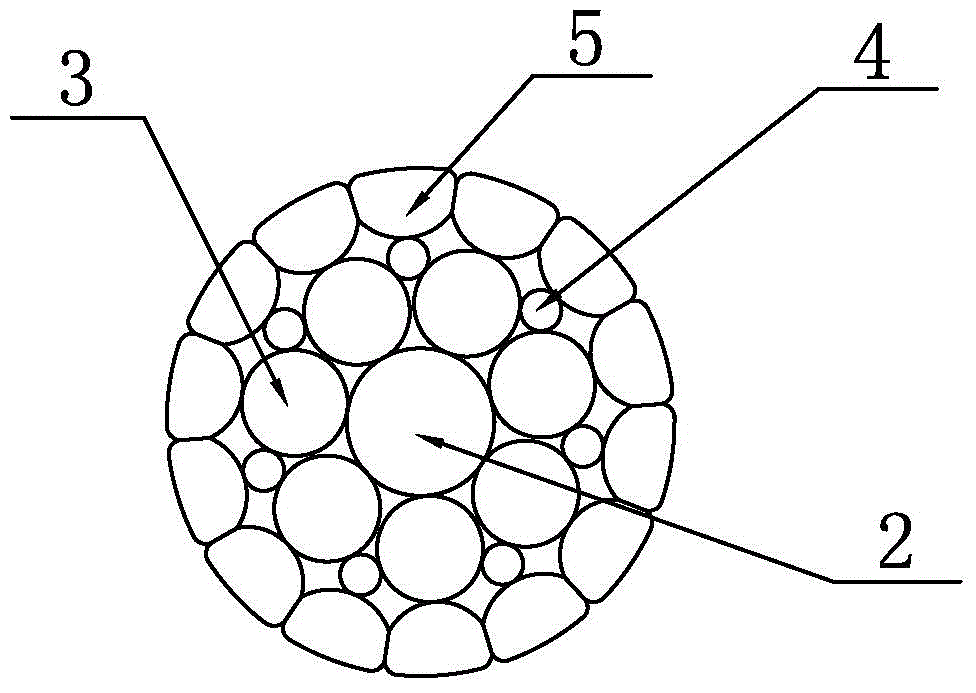

[0021] Such as figure 1 As shown, it is a cross-sectional view of a novel double-compacted steel wire rope of the present invention without secondary compaction, including the rope core 1 and the first outer layer strand of the steel wire rope, and the first outer layer of six steel wire ropes is uniformly twisted on the outside of the rope core 1 share. The first outer layer strand of each steel wire rope includes a third central steel wire 2, an inner layer steel wire 3, a filling steel wire 4 and a third outer layer steel wire 5, and seven inner layer steel wires 3 are uniformly twisted on the outside of the third central steel wire 2. Fourteen third outer layer steel wires 5 are evenly wrapped and twisted on the outer side of the layer steel wires 3 , and filling steel wires 4 are respectively wrapped and twisted in the gap between two adjacent inner layer steel wires 3 and the third outer layer steel wires 5 .

[0022] Such as Figure 4 As shown, it is a cross-sectional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com