Hole wall grouting anchor cable

A technology for grouting anchor cables and anchor cables, applied in the field of anchor cables, can solve the problems of reducing the breaking force of the anchor cables, reducing the anchoring performance and supporting performance of the anchor cables, and the length of the grouting pipeline, so as to improve the supporting strength or The effect of breaking force, stable and reliable anchoring quality, and smooth grouting channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

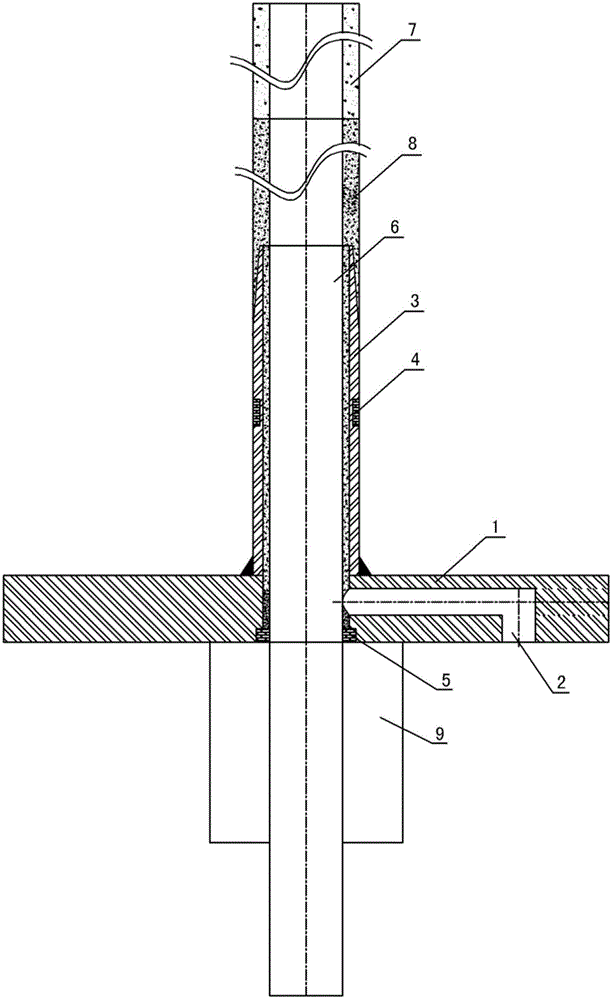

[0025] see figure 1 , the structural form of the hole wall grouting anchor cable in the present embodiment is:

[0026] An "L"-shaped grouting hole 2 is set in the anchor cable supporting plate 1, and one end of the grouting hole 2 communicates with the anchor cable hole in the anchor cable supporting plate 1, and is formed on the steel strand and the anchor cable through the anchor cable hole. The annular grouting cavity between the borehole walls is connected, and the other end of the grouting hole 2 is located on the surface of the anchor cable supporting plate 1 for connecting the external grouting pipe; the orifice pipe 3 in the borehole is connected with the anchor cable The supporting plates are connected together, and there is a groove on the outer periphery of the orifice pipe 3, and the hole wall sealing ring 4 is installed in the groove to seal the gap between the hole wall and prevent the grouting liquid from flowing between the orifice pipe and the hole wall. Gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com