Double twisting rope laying machine

A rope machine and assembly technology, which is applied in the field of double-twist rope forming machines, can solve the problems of difficulty in the stability of the surface quality of the cord, difficulty in paying off the tension from a full reel to an empty reel, and easy looseness in the twisting of the cord. Small ground area, constant tension and good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

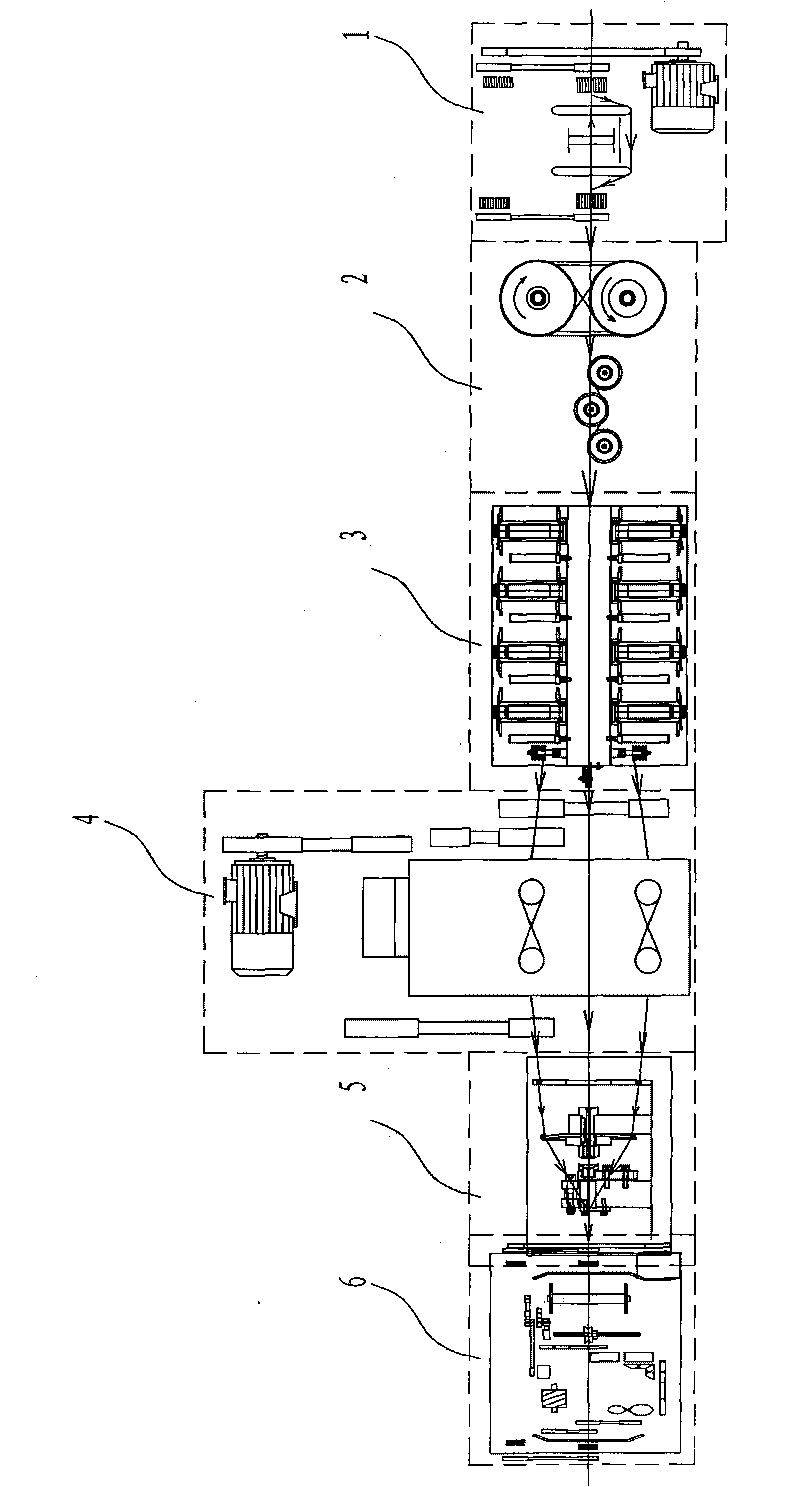

[0021] figure 1 As shown, the double-twist rope forming machine includes a core wire pay-off machine 1, a core wire tension mechanism 2, an upper thread pay-off mechanism 3, a monofilament pre-twisting machine 4, a wire collection mechanism 5, and a wire take-up machine 6 arranged in sequence. .

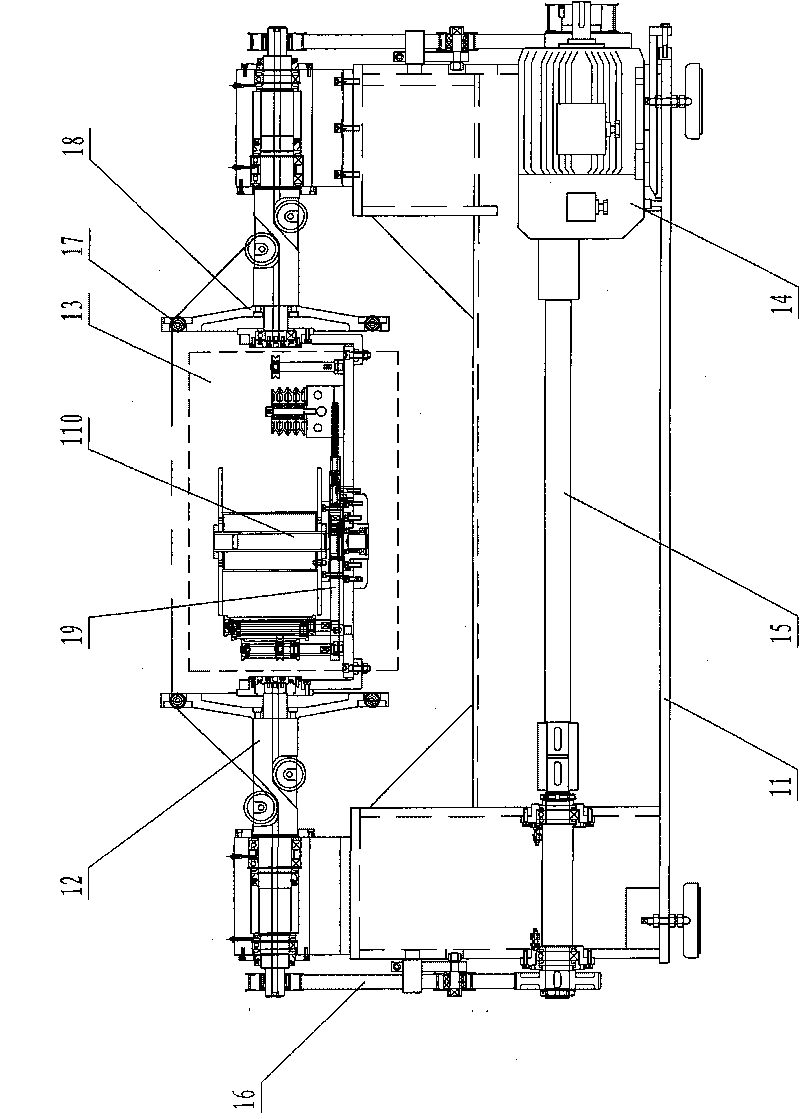

[0022] figure 2 As shown, the core wire pay-off machine 1 of the double-twist roping machine mainly includes a frame 11 and a flywheel shaft assembly 12 installed on the frame, a cradle assembly 13, a motor assembly 14, and a transmission shaft assembly 15. The axle assemblies are respectively installed on the left and right sides above the base, the cradle assembly is located in the middle of the core wire pay-off machine between the two flywheel shaft assemblies, the motor assembly is located under the right end of the base, and the transmission shaft assembly is located Below the seat back, the motor assembly drives the transmission shaft assembly through the transmission timin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com