Battery electrode assembly, cover plate assembly and battery

A battery electrode and component technology, applied in the field of battery safety protection, can solve problems such as limited internal air pressure, limited battery over-current capacity, poor battery over-current capacity, etc., to optimize performance, improve over-current capacity, and increase breaking force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

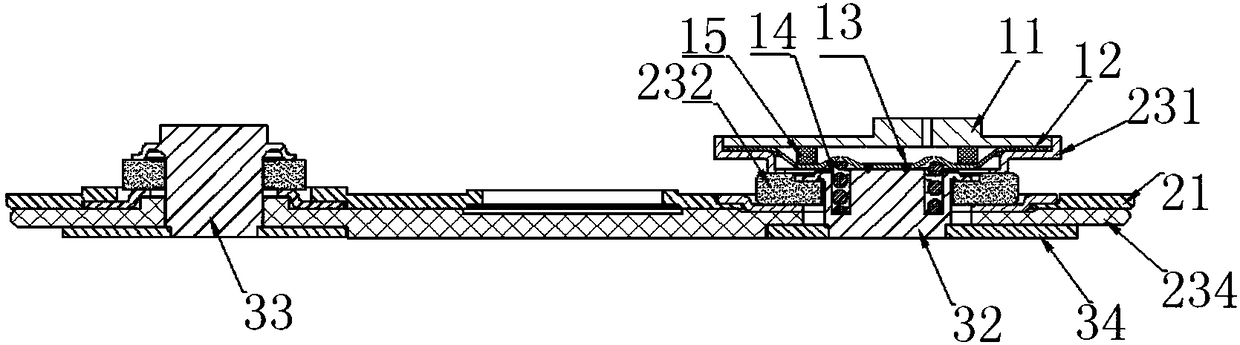

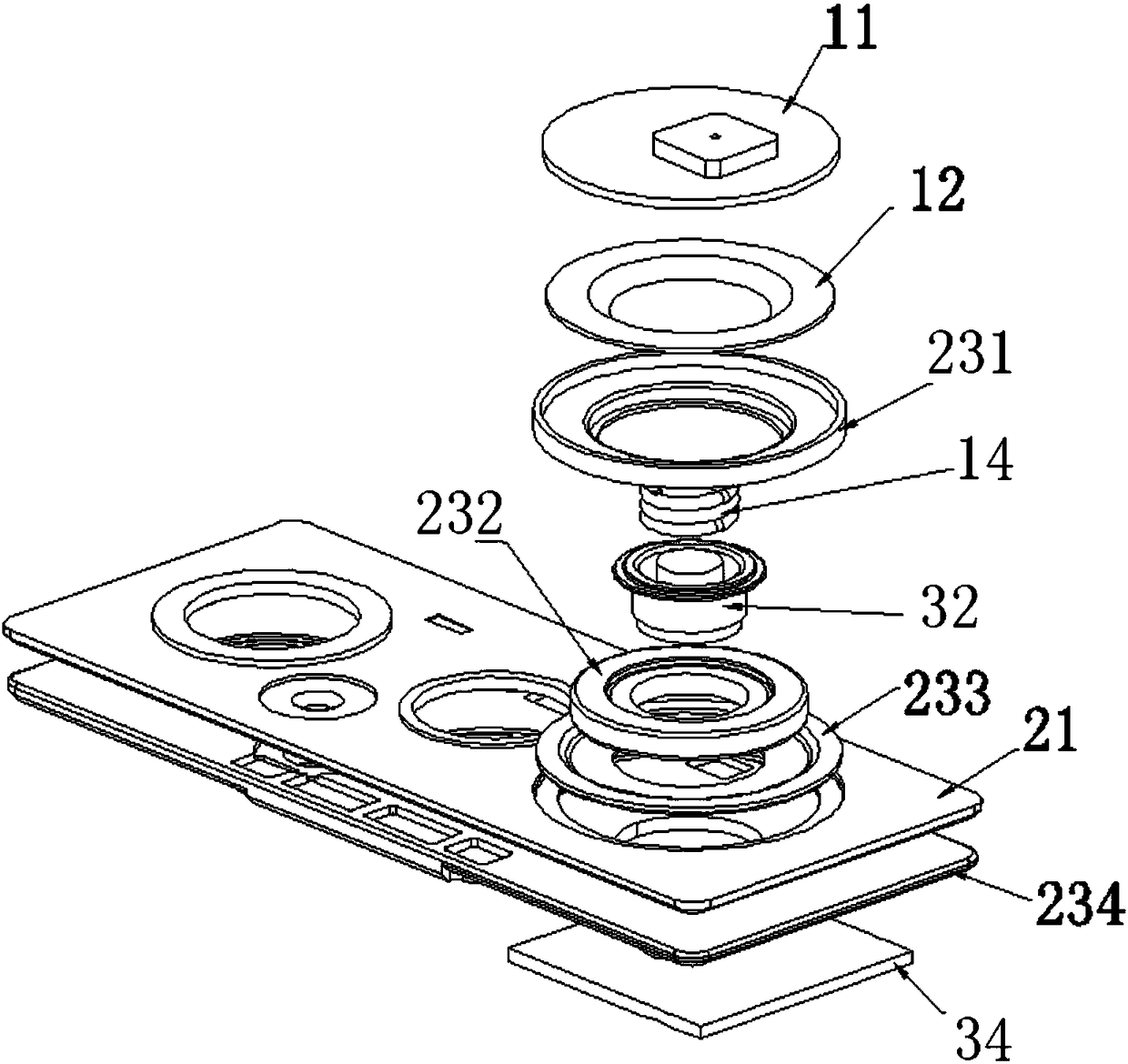

[0046] Specific embodiment 1: as Figure 1 to Figure 3 As shown, when abnormal conditions such as collision, extrusion, overcharge, and internal short circuit occur inside the battery, the internal temperature of the battery rises, and when the temperature reaches 60 to 80 degrees Celsius, the temperature memory elastic element 14 deforms and elongates, pushing upward to conduct electricity. sheet 12, the conductive sheet 12 is lifted upwards, the conductive sheet 12 is disconnected from the welding point of the electrode terminal, the cap 11 is disconnected from the electrode terminal, and the positive terminal 33 and / or the negative electrode are disconnected from the cap 11. Open the connection, so as to realize the disconnection of the internal circuit of the battery, cut off the connection between the abnormal battery and the external normal battery, isolate the normal battery, prevent the occurrence of greater safety hazards, effectively prevent the vicious chain reaction...

specific Embodiment 2

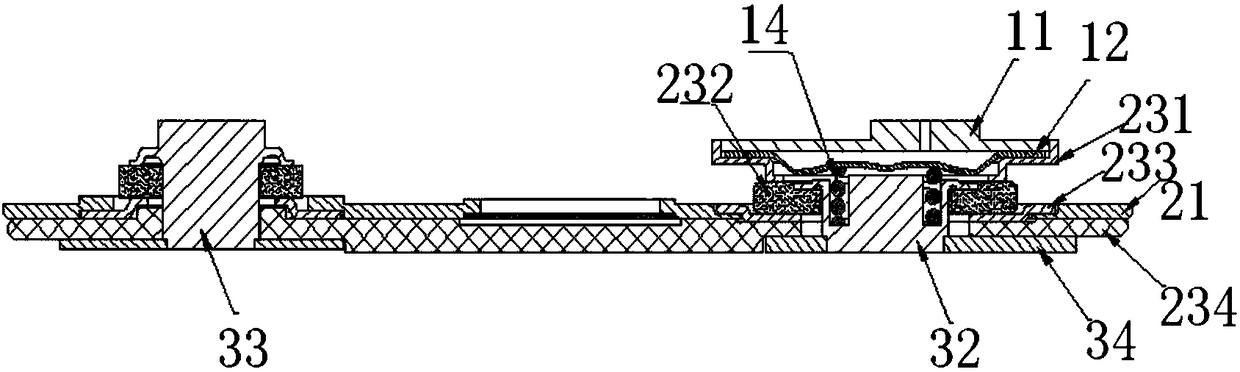

[0047] Specific embodiment 2: as Figure 4 to Figure 6 As shown, the conductive sheet 12 is provided with a support member 15, the conductive sheet 12 is provided with a score on the lower surface, and the temperature memory elastic element 14 is provided below the score. When an abnormality occurs inside the battery, the internal temperature of the battery rises, and when the temperature reaches 60 to 80 degrees Celsius, the temperature memory elastic element 14 deforms and elongates upward, and the temperature memory elastic element 14 pushes up the conductive sheet 12, and the gap between the conductive sheet 12 and the cap 11 The supporting member 15 between them fixes the conductive sheet 12 within a certain condition. When the elastic force of the temperature memory elastic element 14 exceeds a certain value, the weak score of the conductive sheet 12 is disconnected, and the cap 11 is disconnected from the electrode terminal. Although the two caps 11 on the outside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com