Method for reinforcing working surface of loose and soft coal bed by utilizing nonmetal grouting anchor cable

A technology for grouting anchor cables and soft coal seams, which is applied in earthwork drilling, bolt installation, mining equipment, etc. It can solve the problems of hidden safety hazards, high cost, and easy sparks, etc., and achieve safe and reliable use and high tensile strength , High breaking force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

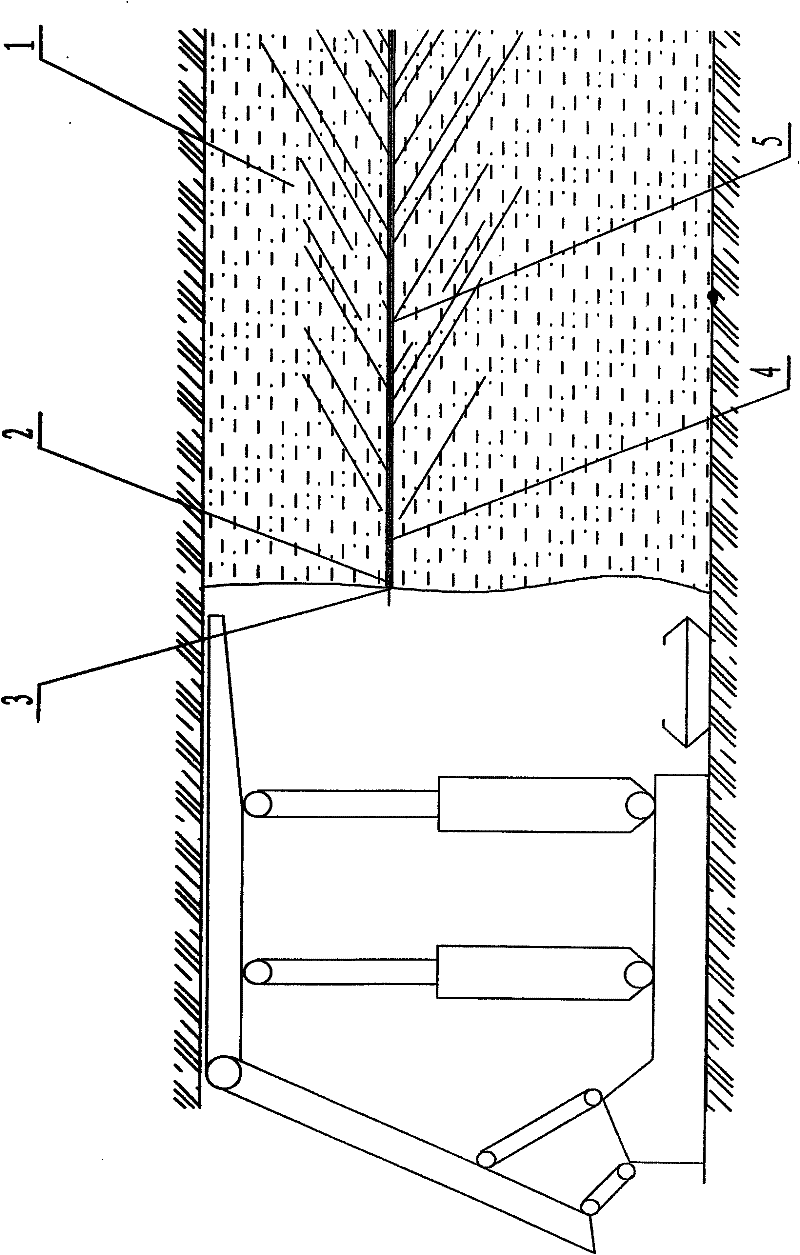

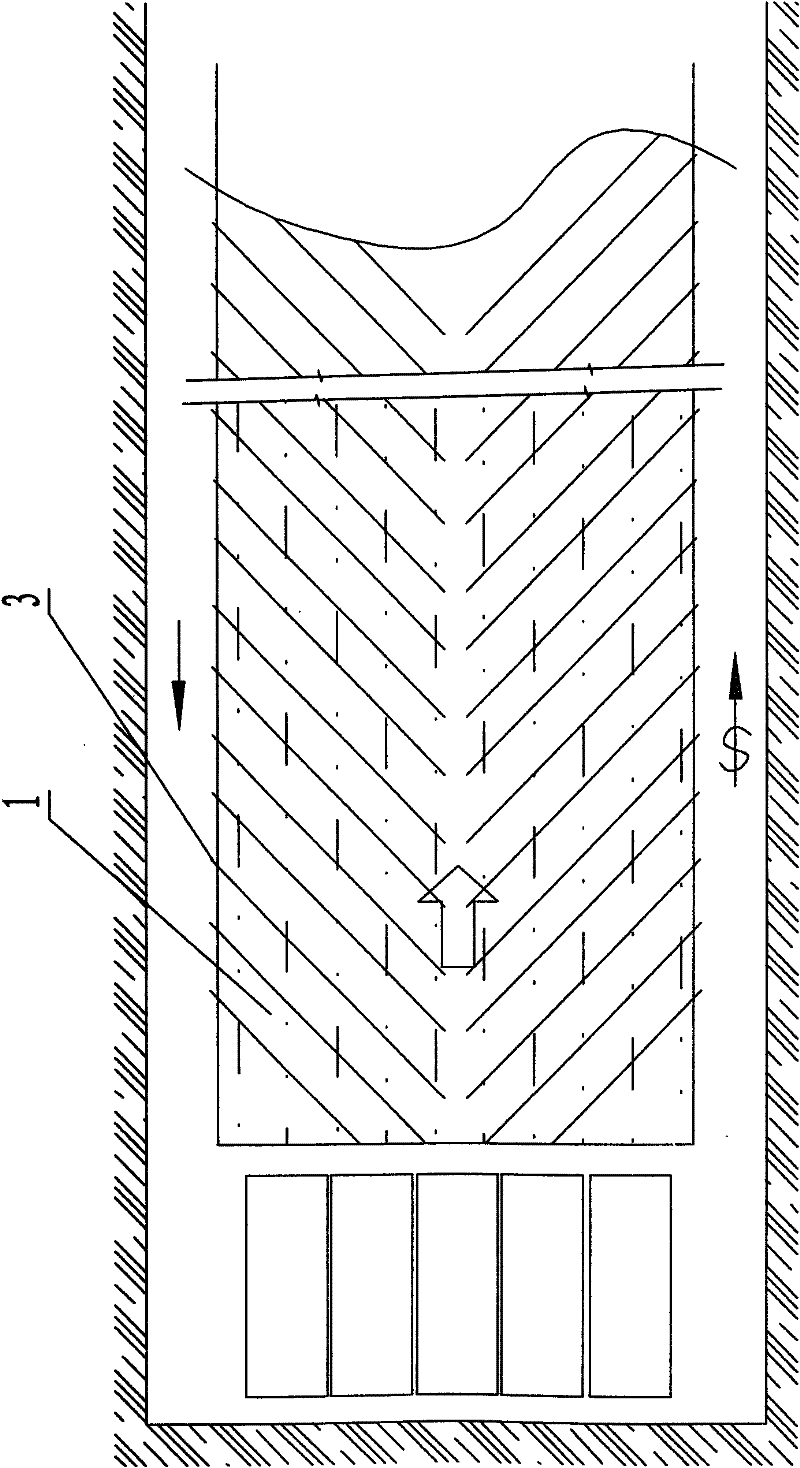

[0021] refer to Figure 1~4 The method for reinforcing the soft coal seam working face with non-metallic grouting anchor cables provided by the embodiments of the present invention can be carried out through the following five steps:

[0022] a. First detect the loose coal body 1, design the depth of the borehole 2 according to the thickness of the loose coal body 1, then measure and stake out, implement the drilling operation, and complete the borehole 2;

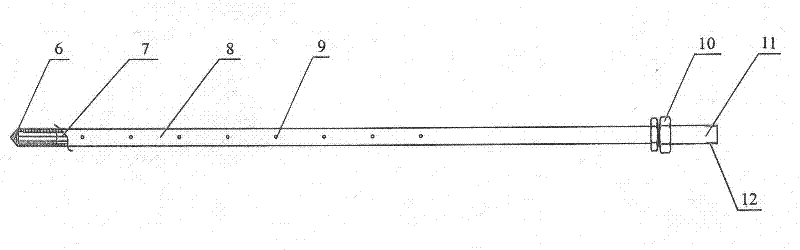

[0023] b. Make grouting anchor cable 3 of corresponding length according to the depth of borehole 2, and put it into borehole 2;

[0024] c. Install a sealing device 4 between 0.5 and 1 meter downwards from the borehole 2, which is composed of hemp rope, cotton cloth and other braided fabrics, and then inject chemical slurry into it, and the chemical slurry reacts in the sealing device 4 , expansion, solidification, until the orifice is blocked;

[0025] d. After the hole sealing is completed, the chemical grouting mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com