Hydraulic simple harmonic oscillator for well drilling

A simple harmonic oscillation and drilling technology, which is applied in the field of hydraulic simple harmonic oscillator for drilling and drilling speed-increasing devices, can solve problems such as stuck pipe, easy damage, and poor efficiency of drilling tools, so as to increase drilling speed, improve frictional resistance, The effect of excellent and fast drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

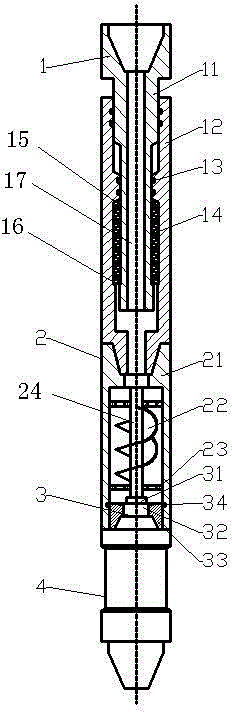

[0022] Such as Figure 1-2 shown.

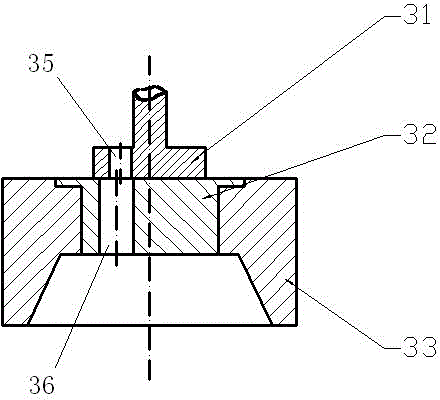

[0023] A hydraulic simple harmonic oscillator for drilling, which is mainly composed of an elastic nipple 1, a power assembly 2, and a bottom assembly 4. Threads are processed at both ends of the bottom assembly 4, threads are processed at both ends of the power housing 21, and the vibration The lower end of the shell 12 is threaded; the upper end of the bottom assembly 4 is threadedly connected with the power shell 21, and the lower end is threaded with the drill bit; the upper end of the power shell 21 is threaded with the lower end of the vibrating shell 12; the elastic short joint 1 is mainly composed of the vibrating shell 12 and the mandrel 11 installed in the vibrating shell 12 that can generate axial simple harmonic vibration, the mandrel is put into the vibrating shell and can slide up and down in the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com