Drilling power tool, drilling tool and drilling method for forming boreholes

A technology of power tools and drilling tools, applied in drilling equipment and methods, drilling equipment, drill pipes, etc., can solve the problems of large damage, slow drilling speed, and short life of drilling tools, and achieve the goal of improving rock breaking efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

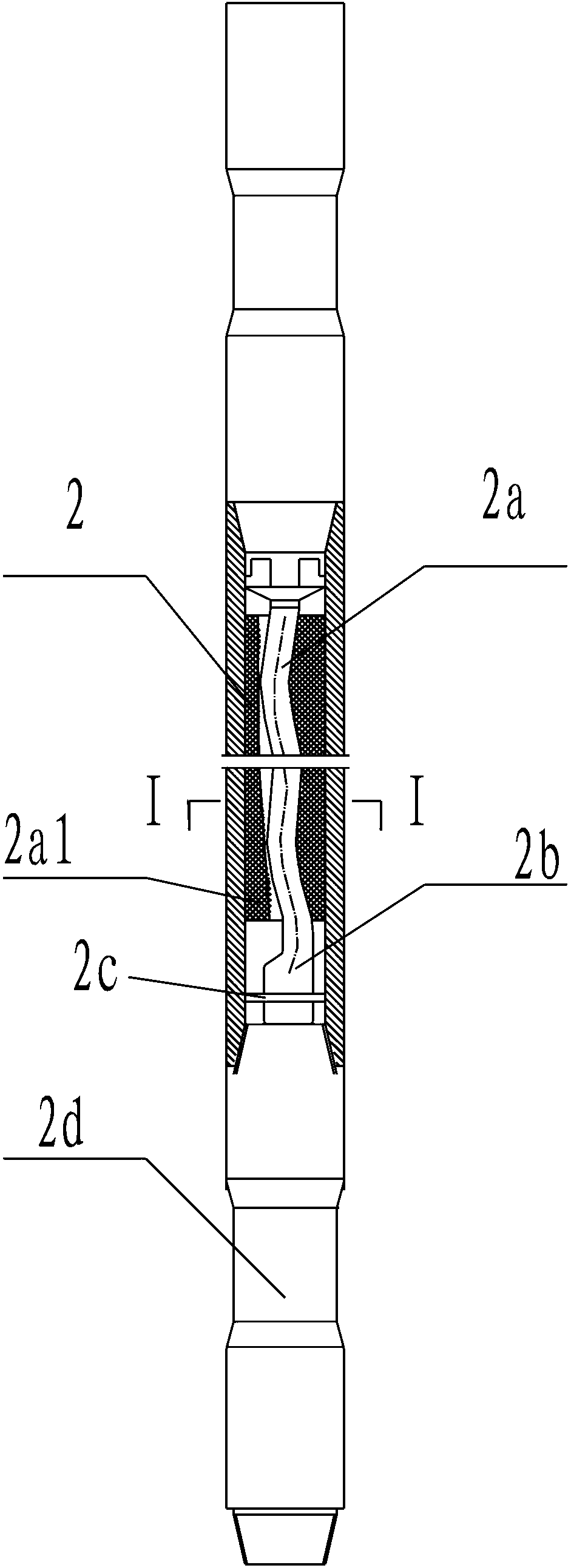

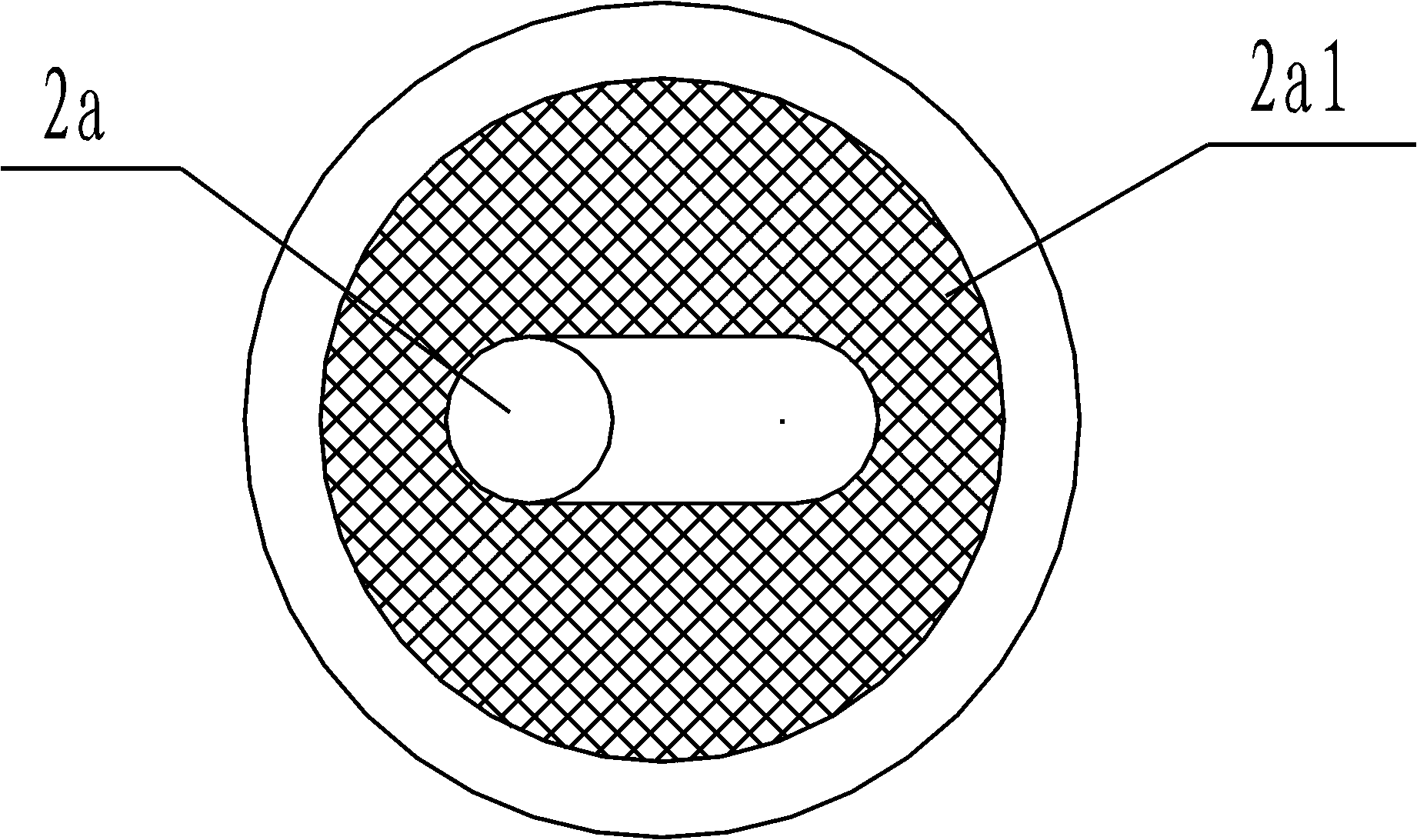

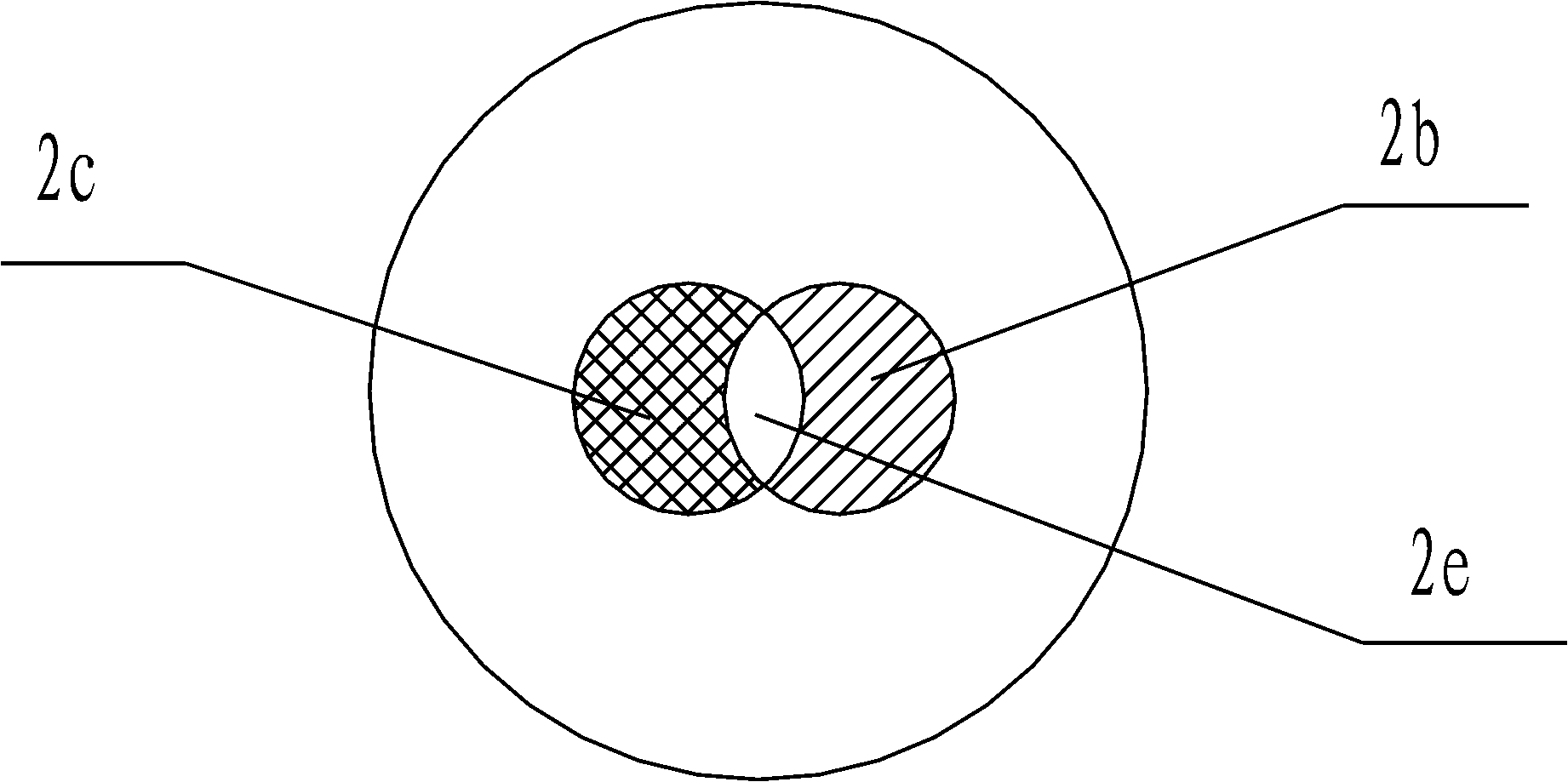

[0088] see Figure 1-3 : a drilling power tool 2, comprising an energy conversion mechanism and a valve shaft system, characterized in that the energy conversion mechanism is a rotation generator or a torsion generator, generally a screw or a turbine or an impeller; the valve shaft system is arranged on an energy The lower end of the conversion mechanism is connected with the energy conversion mechanism through threads; the valve shaft system includes a stator 2a1, a rotor 2a, a moving valve plate assembly 2b, a fixed valve plate assembly 2c and a shaft assembly 2d, and the rotor 2a is on the side of the stator 2a1 The left and right reciprocating pendulum movement is performed in the cavity; the rotor 2a passes through the round hole of the fixed valve plate assembly 2c at the lower end and does not contact the fixed valve plate assembly 2c; the moving valve plate assembly 2b is located at the lower end of the rotor 2a, and The rotor 2a is integral or directly connected and f...

Embodiment 2

[0090] see Figure 1-4 , a new type of drilling power tool, the drilling power tool 2 in embodiment 1 is arranged between the drill collar 1 and the drill bit 3 of the drill string;

Embodiment 3

[0092] see Figure 1-3 , 5, a new type of drilling tool, the drilling power tool 2 in embodiment 1 is arranged between the drill collar 1 and the drill bit 3 of the drill string, and the conventional power drilling tool 5 is arranged between the drilling power tool 2 and the drill bit 3 ; The cardan shaft assembly is respectively arranged at the joints at both ends of the conventional power drilling tool 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com