Pulse cavitation multiple jet nozzle

A technology of multi-hole jet and nozzle, which is applied in injection device, injection device, drilling with liquid/gas jet, etc. It can solve the problems of large pressure loss, low efficiency of jet energy utilization, complex nozzle structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

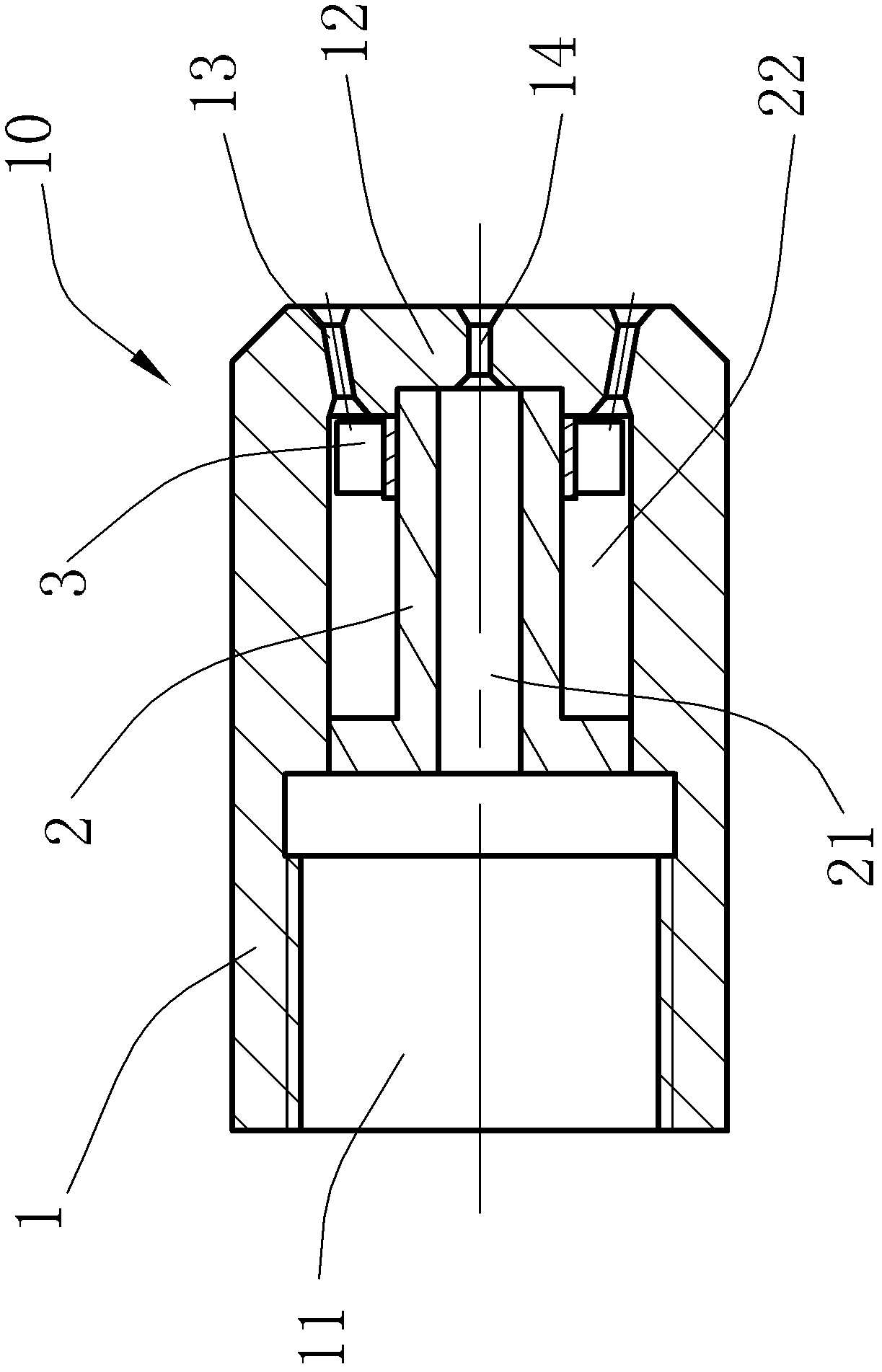

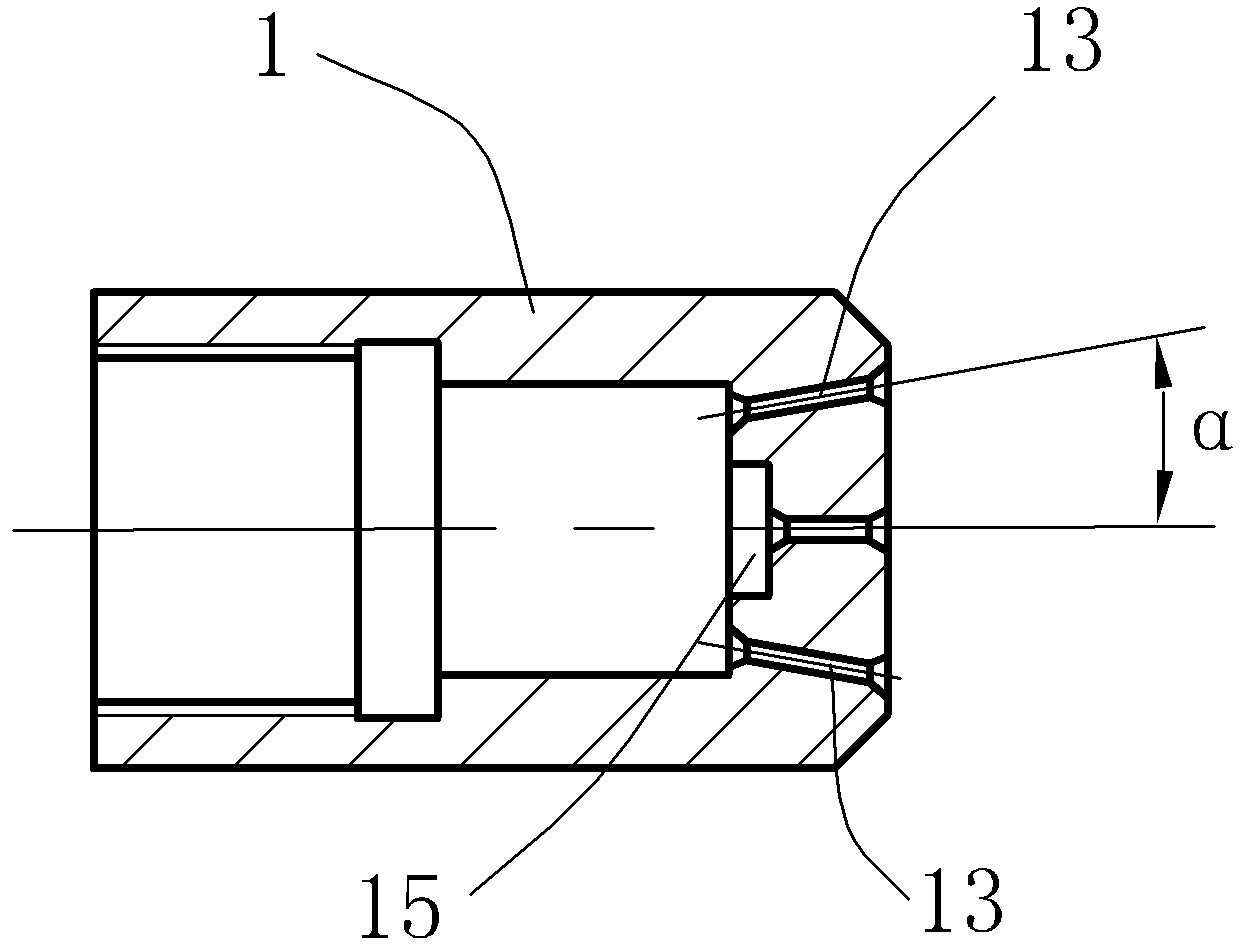

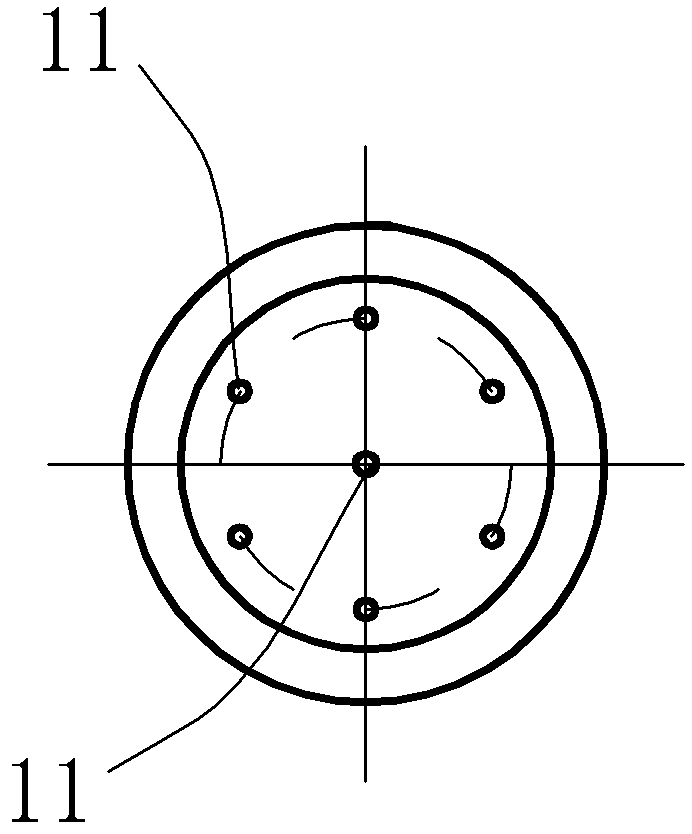

[0029] The pulse cavitation multi-hole jet nozzle proposed by the present invention comprises: a nozzle body, which forms a hollow cylindrical body with one end as an open end and the other end as a spray end, the open end is used to connect a fluid pipeline, and the spray end is provided with There are a plurality of injection ports; a central injection port is provided at the center of the injection end, and a plurality of side injection ports are arranged around the central injection port; a rotatable impeller is arranged in the nozzle body, and the A part of the fluid passes through the center of the impeller and the central injection port to form a continuous straight jet flow, and another part of the fluid impacts the blades of the impeller to make the impeller rotate, and the lateral injection port located on the outer periphery of the central injection port The flow field at the inlet produces regular disturbances, forming pulsed jets and cavitation bubbles to form cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com