Laser-assisted tunnel boring machine and rock breaking method thereof

A tunnel boring machine, laser-assisted technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of poor adaptability to different rock surfaces, reduce driving efficiency, increase construction costs, etc., to improve rock breaking efficiency, reduce Construction cost, the effect of saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the technical solutions and accompanying drawings.

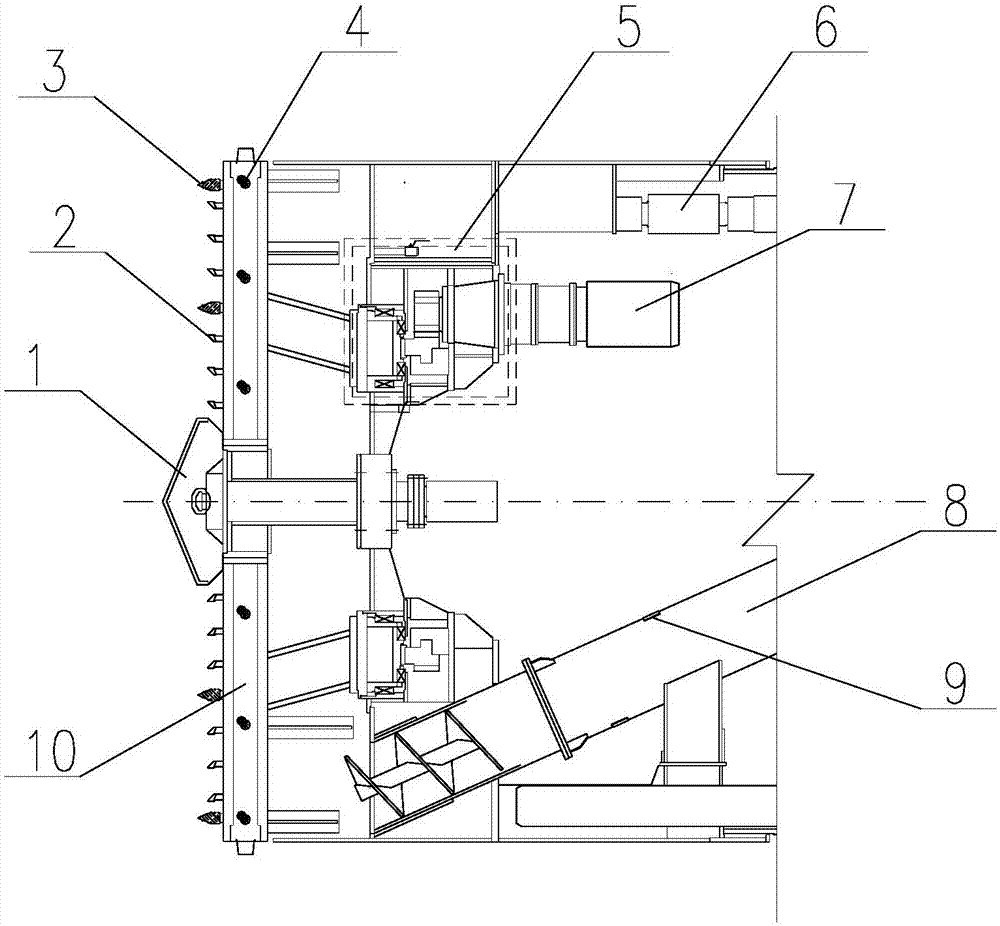

[0020] The traditional tunnel boring machine drives the cutterhead 10 to rotate through the driving device 7, and at the same time opens the propulsion cylinder of the tunnel boring machine to push the shield machine forward. With the advancement of the propulsion cylinder, the cutterhead continues to rotate and is sheared and squeezed. The broken stones are sent to the belt conveyor by the screw conveyor 8, and then transported to the outside by the belt conveyor.

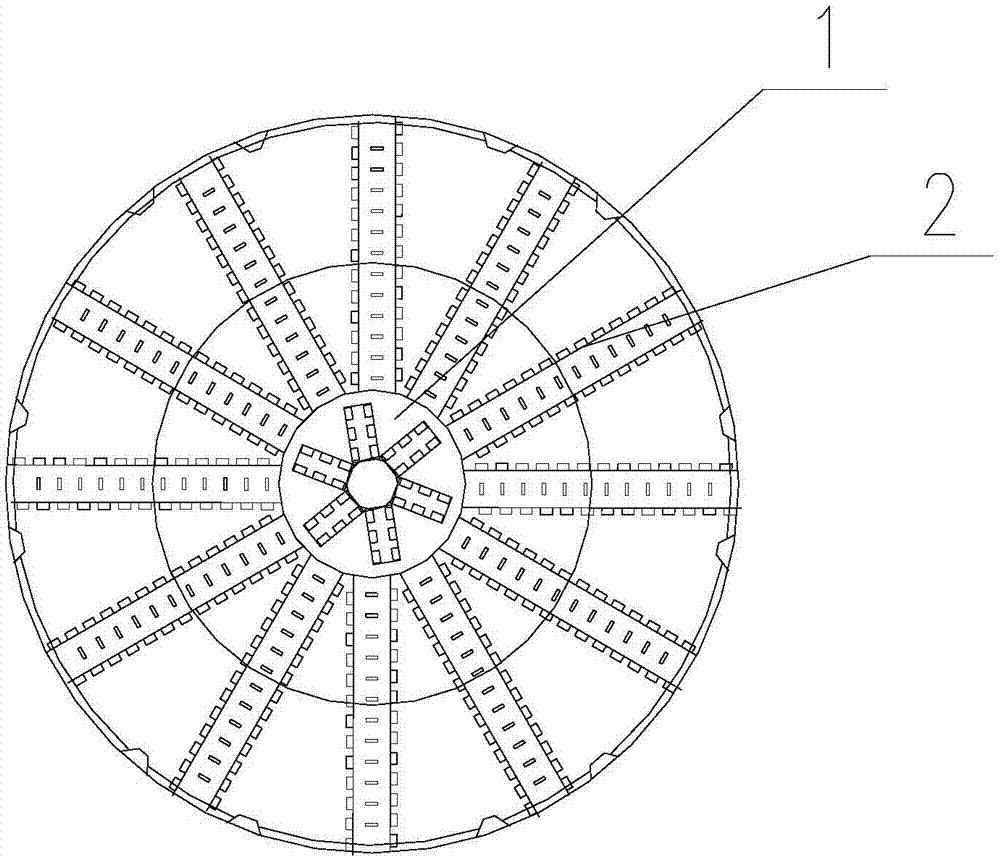

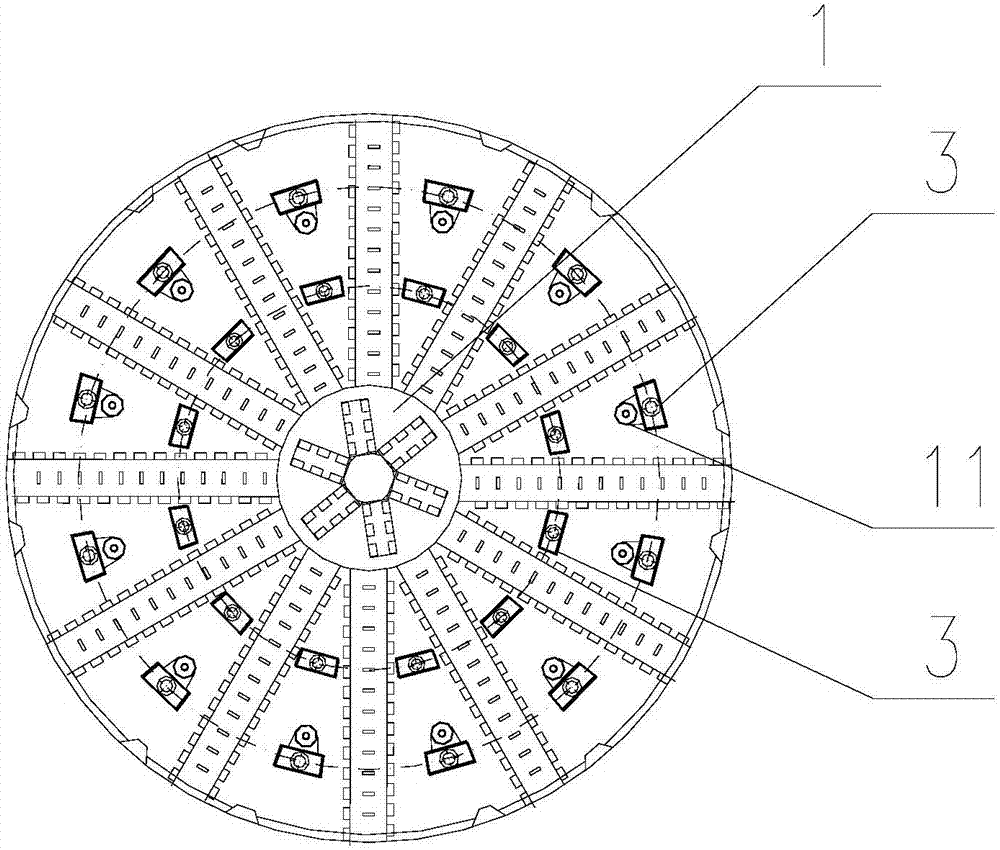

[0021] On the basis of the traditional roadheader, the laser 3 and the water spray system 11 are arranged on the cutter head 10 and the blade 2 is alternately distributed, wherein the laser adopts a fiber laser, and there are various types of work by setting different output powers to adapt to rocks of different strengths. , by setting the moni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com