Vibration and pressure well drilling tool

A technology for drilling tools and driving rods, applied in vibration drilling, etc., can solve the problems of increased drilling tool structure complexity, increased drilling fluid damping and top torque negative feedback, accelerated PDC bit damage and failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following is a specific embodiment of a vibratory pressurized drilling tool of the present invention, which is used to explain but not limit the present invention; the place where the drilling fluid enters is defined as "upper" and the place where the drilling fluid exits is "down".

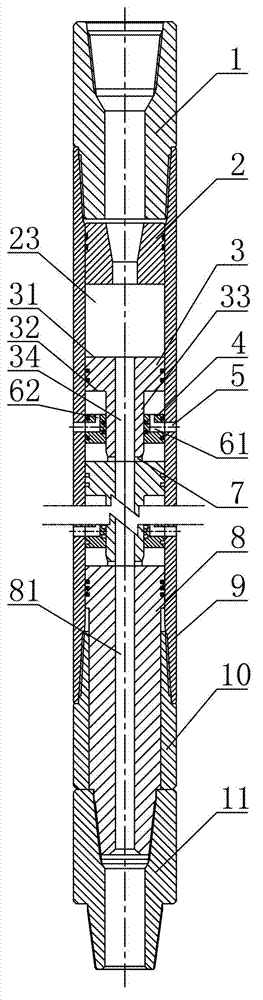

[0014] As shown in the accompanying drawings, a vibratory pressurized drilling tool includes a sleeve 9, an upper joint 1 is installed on the upper end of the sleeve 9, and a nozzle 2 is installed at the lower end of the upper joint 1 inside the sleeve 9, and the nozzle 2 has a hollow The nozzle channel, wherein the inlet of the nozzle channel is larger than its outlet, is divided into an upper conical section and a lower cylindrical end; the lower end of the sleeve 9 is threaded with a driving nipple 10, the sleeve 9 and the driving nipple 10 A driving rod 8 is slidably installed, and the polygonal outline fits between the driving rod 8 and the inner wall of the driving nipple 10, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com