Tunneling machine using laser for rock breaking

A roadheader and rock-breaking technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as hob wear and replacement frequency, abnormal damage of metal tools, and reduced efficiency of shield tunneling, so as to reduce excavation costs, The effect of improving rock breaking efficiency, saving tool cost and risk of tool change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

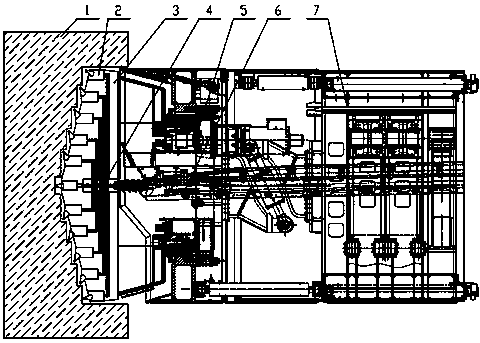

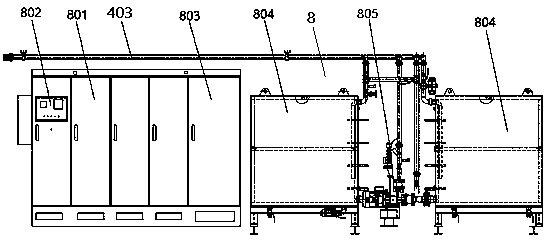

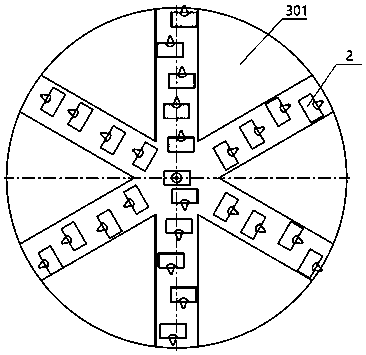

[0023] Embodiment 1: as Figure 1-5 Said a kind of roadheader that utilizes laser to break rocks includes a roadheader host and a water and electricity output system 8 that matches with the body of the roadheader host. A cutter head system 3 is provided at the front of the roadheader host. 3, several laser generators 2 are uniformly arranged on the cutterhead 301, and the laser generators are arranged on the cutterhead 301, so that the movement track of the laser generators 2 covers the entire excavation surface, and the laser generators 2 follow the rotation of the cutterhead. This enables full-face excavation. The emitting end of the laser generating device 2 has an inclination angle with the face rock 1 at the excavation site, and the laser rays emitted from the emitting end of the laser generating device 2 act on the face rock 1. There is an inclination angle between the launch end and the excavation surface, so the formed laser ray is non-perpendicular to the excavation ...

Embodiment 2

[0027] Embodiment 2: A tunneling machine that utilizes laser to break rock, the cutter head 301 is conical, and the inside of the cutter head 301 is provided with a porous passage that matches the water cooler 202 and the laser generating device box 203, and the porous passage of the cutter head 301 An electric slip ring 402 is provided at the general entrance, and the electric slip ring 402 is connected with a transmission and distribution pipe 403 through a hydraulic rotary joint 401 . Other structures and working principles are the same as in Embodiment 1.

Embodiment 3

[0028] Embodiment 3: A tunneling machine using laser to break rock, the best angle for the laser emitter 201 to incline radially outward along the center of the cutterhead 301 is between 15° and 25°. Other structures and working principles are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com