A hobless hard rock roadheader using laser and high-pressure wind jet to break rock

A hard rock roadheader and high-pressure air technology, which is applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve the problems of low energy utilization rate and poor slag discharge effect, and achieve the effects of light weight, cost saving and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

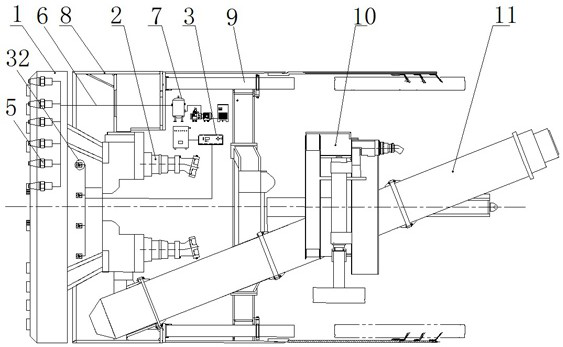

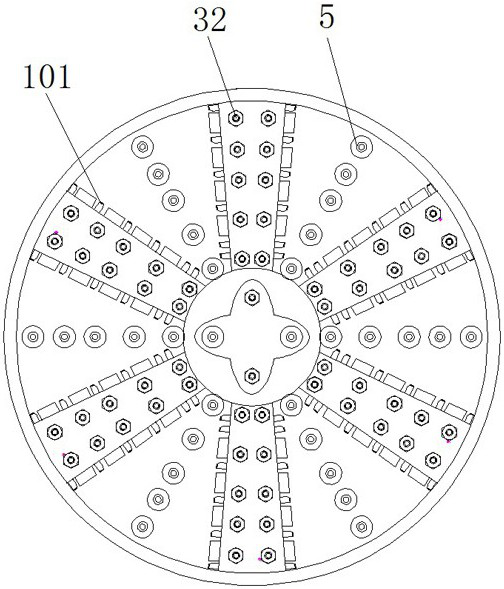

[0021] Embodiment 1, a kind of hard rock tunneling machine without hob that utilizes laser and high-pressure air jet to break rock, such as figure 1 As shown, the shield body 8 is included, and the shield body 8 is provided with a central main driving unit 2 connected to the hob-free cutterhead 1, and the central main driving unit 2 drives the non-hob cutterhead 1 to rotate in a circumferential direction. A segment assembly machine 10 and a screw conveyor 12 are arranged inside the shield body 8 , and the feeding end of the screw conveyor 12 is located at the rear side adjacent to the hobless cutter head 1 . Because there is no hob, not only the cost of the hob is saved up to several million, but also because there is no hob and other tools, the weight of the front panel of the roadheader is reduced by 2 / 3, so the main drive only needs to use 1 / 3 of the previous configuration. , which saves at least millions of dollars.

[0022] Since the hobless cutterhead 1 is driven by the...

Embodiment 2

[0026]Embodiment 2, a hobless hard rock tunneling machine using laser and high-pressure wind jet to break rock, the laser emitting end 32 of the laser transmitter 3 is directed perpendicular to the front tunneling surface, which can ensure the application efficiency of laser energy reach the highest.

[0027] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

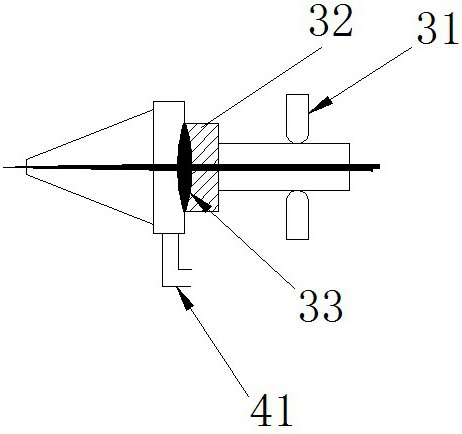

[0028] Embodiment 3, a kind of hard rock tunneling machine without hob that utilizes laser and high-pressure wind jet to break rock, such as image 3 As shown, the laser transmitter 3 is connected with an angle monitoring device 31 and an angle adjusting device, and the angle monitoring device 31 and the angle adjusting device are connected with the control center. The control center can monitor the direction of the laser emitting end 32 of the laser transmitter 3 in real time through the angle monitoring device 31, and correct the deviation by controlling the angle adjustment device after exceeding the error range, so as to achieve the highest rock-breaking efficiency and avoid burns to the equipment .

[0029] Other structures of this embodiment are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com