A hobless hard rock tunneling machine using laser and liquid nitrogen jet to break rock

A technology of hard rock roadheader and laser emission, which is applied in the directions of cleaning methods, cleaning methods and appliances, chemical instruments and methods using gas flow, etc., can solve the problems of low energy utilization rate, poor slag discharge effect, etc. , The effect of reducing excavation costs and avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

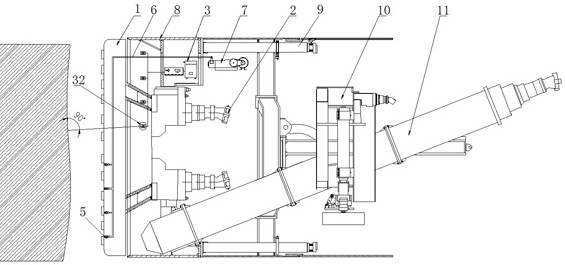

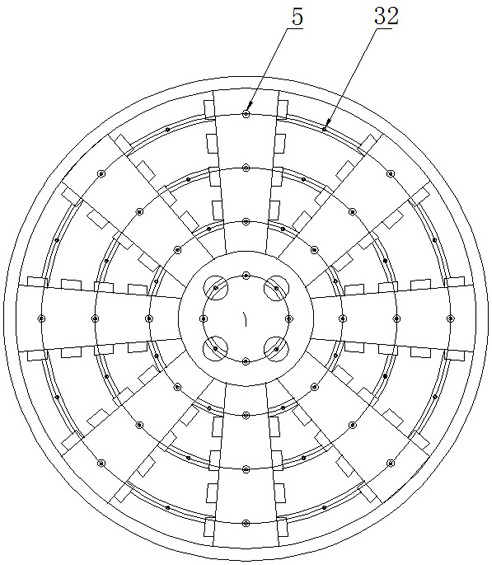

[0030] Embodiment 1, a kind of hob-free hard rock tunneling machine that utilizes laser and liquid nitrogen jet to break rock, such as figure 1 As shown, the shield body 8 is included, and the shield body 8 is provided with a central main driving unit 2 connected to the hob-free cutterhead 1, and the central main driving unit 2 drives the non-hob cutterhead 1 to rotate in a circumferential direction. A segment assembly machine 10 and a screw conveyor 12 are arranged inside the shield body 8 , and the feeding end of the screw conveyor 12 is located at the rear side adjacent to the hobless cutter head 1 .

[0031] Since the hobless cutterhead 1 is driven by the central main drive unit 2, there is enough space for assembly at the back of the hobless cutterhead, and a laser emitter 3 is arranged on the back of the hobless cutterhead 1. Laser is a new type of light source. Compared with ordinary light sources, it has the characteristics of high brightness, high orientation, and hig...

Embodiment 2

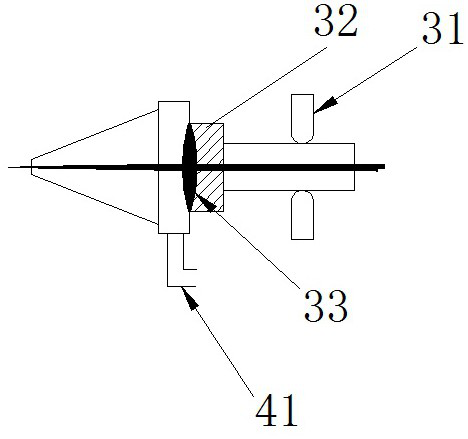

[0039] Embodiment 2, a hob-less hard rock tunneling machine using laser and liquid nitrogen jets to break rock, the laser emitting end 32 of the laser transmitter 3 is directed perpendicular to the front tunneling surface, which can ensure the application efficiency of laser energy reach the highest.

[0040] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0041] Embodiment 3, a kind of hob-free hard rock tunneling machine that utilizes laser and liquid nitrogen jet to break rock, such as image 3 As shown, the laser transmitter 3 is connected with an angle monitoring device 31 and an angle adjusting device, and the angle monitoring device 31 and the angle adjusting device are connected with the control center. The control center can monitor the pointing of the laser emitting end 32 of the laser emitter 3 in real time through the angle monitoring device 31 , and correct the deviation by controlling the angle adjustment device after exceeding the error range.

[0042] Other structures of this embodiment are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com