A hobless hard rock tunneling machine using microwave and liquid nitrogen jet to break rock

A technology of hard rock boring machine and microwave radiation, which is applied in mining equipment, tunnels, earthwork drilling, etc., can solve the problems of long construction period and high cost, and achieve the effect of reducing excavation cost, light weight and improving excavation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

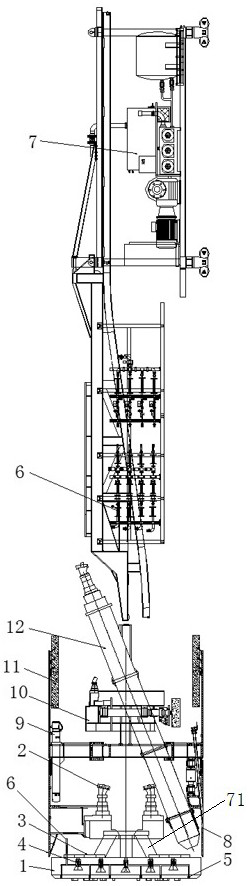

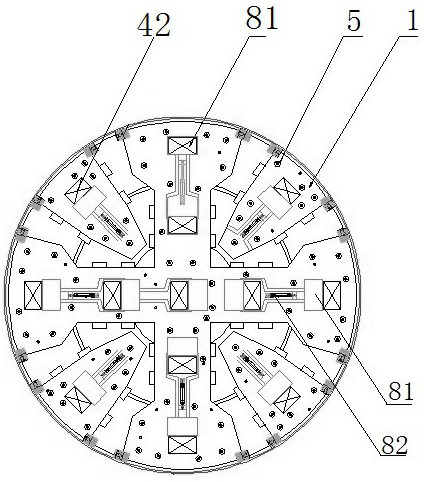

[0036] Example 1, a non-rolled hard rock excavator of microwave and liquid nitrogen jet, such as figure 1 As shown, including the shield 8, the shield 8 is provided with a high-span center drive system 2, and the high-span center drive system 2 is connected to the connecting frame 71 greater than one meter, and the non-hob cutting cutter 3, a high-span center drive system. 2 Plite the non-hob cutting wheel to rotate. The shield 8 is provided with a tubular assembly machine 10 and a screw conveyor 12, and the feed end of the screw conveyor 12 is located adjacent to the rear side of the unveiled knife cutter disk 1.

[0037] Since the non-roller tool disc 1 is driven by a high-span center drive system 2, the back of the non-horing blade can have sufficient assembly space, and the microwave transmitter 3 is set at the back of the unable knife disk 1. The microwave transmitter 3 is connected to a microwave radiation arm 4 leading to the front side of the non-hobbick 1. The microwave i...

Embodiment 2

[0045] Example 2, a non-rolled hard rock tractor using microwave and liquid nitrogen jet, such as Image 6 and Figure 7 As shown, the liquid nitrogen high pressure delivery tube includes a stainless steel tube and a stainless steel flexible telescopic tube, and the stainless steel pipe can effectively maintain the temperature of liquid nitrogen in liquid nitrogen high pressure conveying tubes, stainless steel flexible telescopic tubes are contraction phenomena for pipelines under ultra-low temperature, every separation It is certainly designed telescopic structure. The outer and stainless steel flexible telescopic tubes are provided with a polyurethane foaming insulation layer 68 to further ensure the temperature of liquid nitrogen in the liquid nitrogen high pressure delivery tube.

[0046] The other structure of the present embodiment is the same as in Example 1.

Embodiment 3

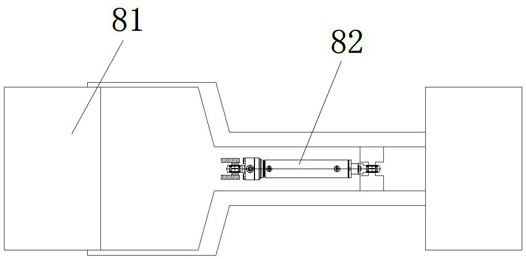

[0047] Example 3, a non-rolled hard rock mining machine using microwave and liquid nitrogen jet, such as Figure 8 As shown, the connecting port of the liquid nitrogen high pressure conveying tube is employed with autonomous research and dual hard sealing structures. Given the sealing material such as Dingqing Rubber, fluoroprote rubber, the high pressure and ultra-low temperature state, the viscosity and density of liquid nitrogen is small, the surface tension is also lower than water, ultra-low temperature, low viscosity, ultra-low surface tension The selection of liquid nitrogen in the high pressure delivery is large, so the dual hard sealing structure specifically designed.

[0048] The double hard seal structure includes an outer screw 63 that is welded to one end liquid nitrogen high pressure delivery tube 6, and the other end liquid nitrogen high pressure conveying tube 6 is provided with a stop step 64, and the liquid nitrogen high pressure conveying tube 6 is inserted with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com