Radial horizontal drilling system using supercritical carbon dioxide and drilling method thereof

A technology of carbon dioxide and liquid carbon dioxide, applied in directional drilling, liquid/gas jet drilling, etc., can solve problems such as high requirements, high rock breaking threshold pressure, reservoir pollution, etc., to improve rock breaking efficiency and low index requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

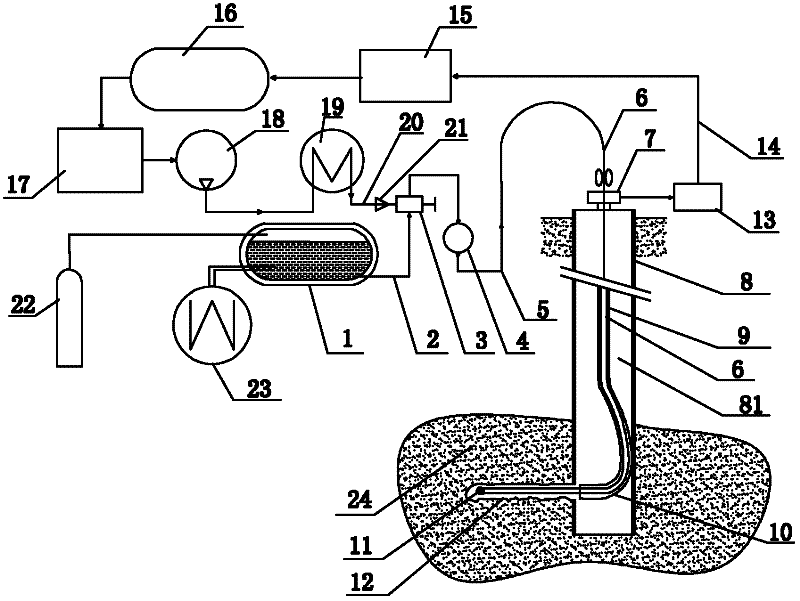

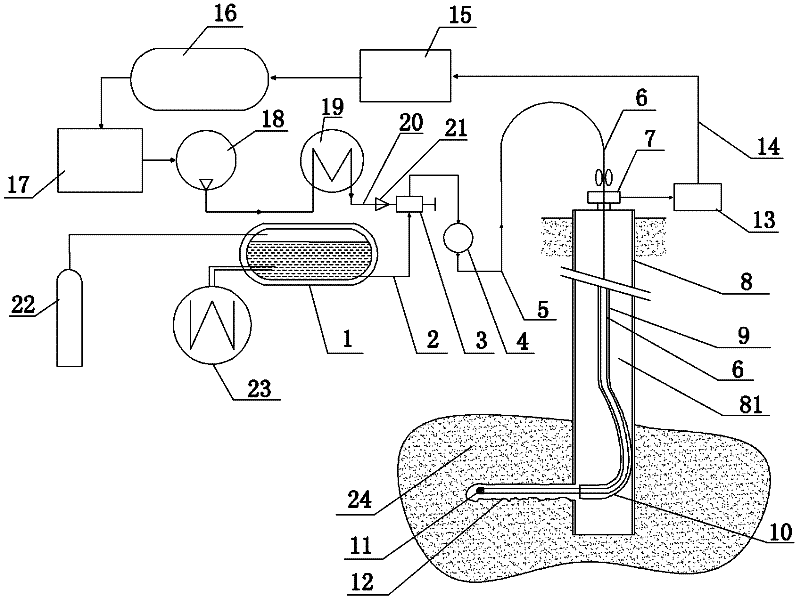

[0021] As shown in the drawings, the supercritical carbon dioxide radial horizontal well drilling system includes: a liquid carbon dioxide supply device arranged on the ground, the liquid carbon dioxide supply device includes a liquid carbon dioxide storage tank 1, and the carbon dioxide in the liquid carbon dioxide storage tank 1 The pressure is 2 to 4 MPa, the temperature is -20°C to 0°C, to ensure that the carbon dioxide is liquid, and the booster pump 4 is connected to the liquid carbon dioxide storage tank 1 through the high pressure pipeline 2, and the high pressure pipeline 2 is provided with a valve 3. The high-pressure pipeline 2 mentioned here refers to a pipeline with a pressure bearing capacity of 35 MPa or more; a drilling device arranged in the wellbore 8, the drilling device includes an oil pipe 9 and a diverter 10 installed at the bottom of the oil pipe 9, and also includes a set The flexible drill pipe 6 in the oil pipe 9 can be bent within a certain range, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com