Microwave-assisted rock breaking drill bit, electricity conductive drill rod and microwave-assisted rock breaking device

A microwave-assisted, drill bit technology, applied in the direction of drill bits, drill pipes, drill pipes, etc., to reduce the difficulty of rock breaking, reduce rock strength, and improve the effect of ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

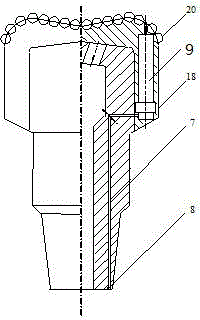

[0027] Embodiment 1, in conjunction with attached figure 1 , 2 , a microwave-assisted rock-breaking drill bit, comprising:

[0028] The drill insert 18 and the blades 19, cutting teeth 20, and joints distributed on the drill insert 18. Each blade 19 is embedded with an auxiliary rock-breaking microwave generator 9, the drill bit insert 19 is embedded with a cable 7, and an independent conductive coil 8 is embedded at the joint, and the cable 7 is connected between the conductive coil 8 and the auxiliary rock-breaking microwave generator 9 between.

[0029] The microwave-assisted rock-breaking drill bit based on the foregoing embodiments further includes:

[0030] The drill bit is a PDC drill bit.

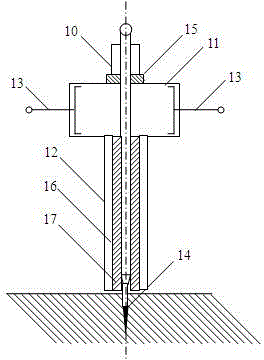

[0031] See attached image 3 , Bottomhole auxiliary rock-breaking microwave generation, 9 consists of a magnetron 10, a rectangular waveguide 11, a coaxial waveguide 12, a tuning mirror 13 and an electrode needle 14, wherein the coaxial waveguide 12 is composed of an external c...

Embodiment 2

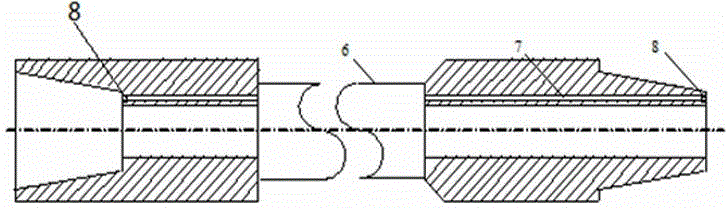

[0034] Embodiment 2, in conjunction with attached Figure 4 , a conductive drill pipe 6, comprising a drill pipe body and joints connected to both ends of the drill pipe body, wherein a cable 7 is embedded in the drill pipe body, and independent conductive coils 8 are respectively embedded in the two joints of the drill pipe.

Embodiment 3

[0035] Embodiment 3, a microwave-assisted rock-breaking device utilizing the above-mentioned microwave-assisted rock-breaking drill bit includes a drilling rig, a power supply system and a control system, wherein the control system includes a microwave generation controller, and the microwave-assisted rock-breaking drill bit is connected to the drilling machine, including through The mechanical connection established between the microwave-assisted rock-breaking drill bit and the drilling machine, and the line connection established through the cable of the microwave-assisted rock-breaking drill bit, the independent conductive coil, the power supply system and the microwave generation controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com