A rock-breaking mechanism combined with pulse jet and mechanical impact

A mechanical impact, pulse jet technology, applied in the field of rock drilling or crushing, can solve the problems of tool wear, large consumption, large water consumption, etc., and achieve the effect of simple high-pressure water sealing, improving capacity and efficiency, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

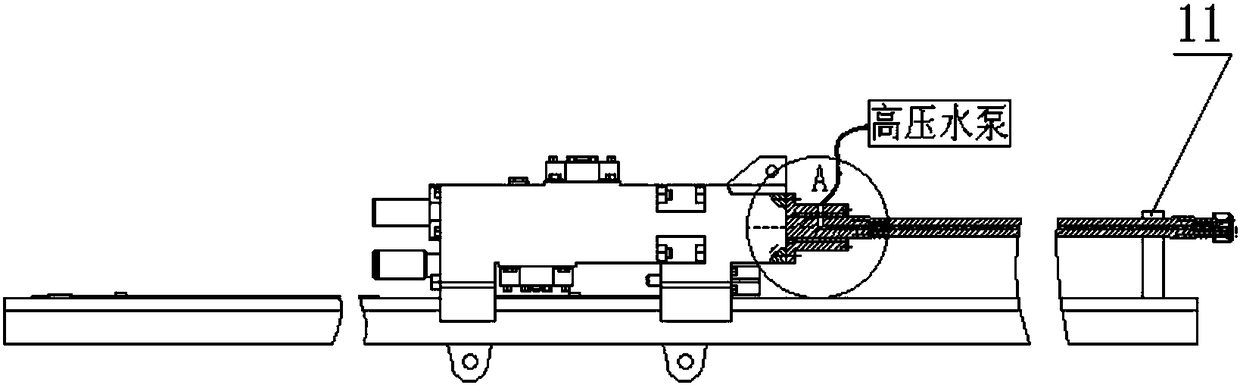

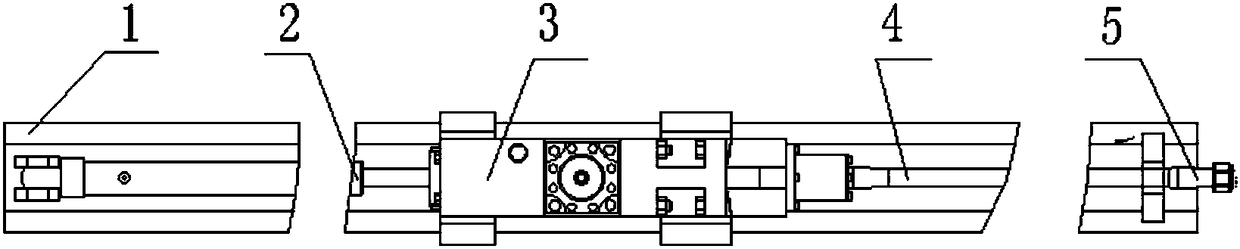

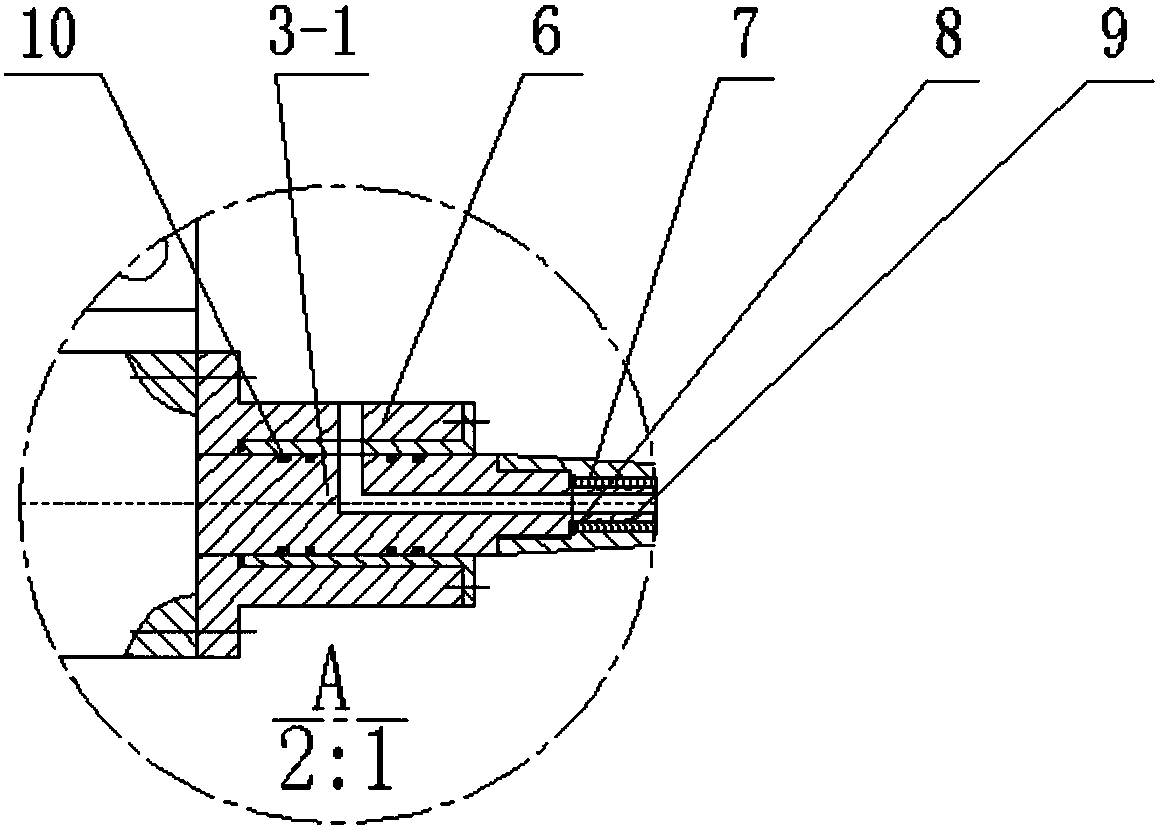

[0027]A pulse jet and mechanical impact combined rock breaking mechanism of the present invention mainly includes guide rail 1, propulsion cylinder 2, hydraulic impact power head 3, drill pipe 4, drill bit 5, dynamic seal combination sleeve 6, static seal transition sleeve 7, elastic Back-up ring 8, static seal ring 9, dynamic seal ring 10, drill pipe support seat 11. The cylinder body of the propulsion cylinder 2 is hinged with the guide rail 1, the piston rod of the propulsion cylinder 2 is hinged with the housing of the hydraulic impact power head 3, the housing of the hydraulic impact power head 3 is slidably installed on the guide rail 1, and one end of the drill rod 4 passes through the drill The rod is connected to the internal thread 4-2, the output shaft is connected to the external thread 3-1-3 and the hydraulic impact power head outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com