A leading-guided roadheader cutter head for extremely hard rock excavation

A guided, extremely hard technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve problems such as low efficiency, fast consumption of hobs, and difficult rock breaking, so as to reduce engineering investment, save costs, and reduce broken rocks. Effect of Rock Difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

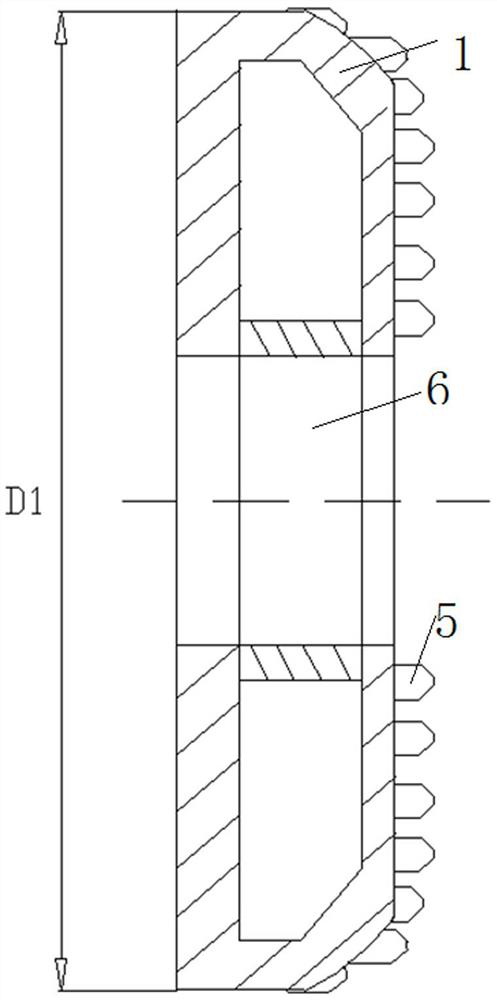

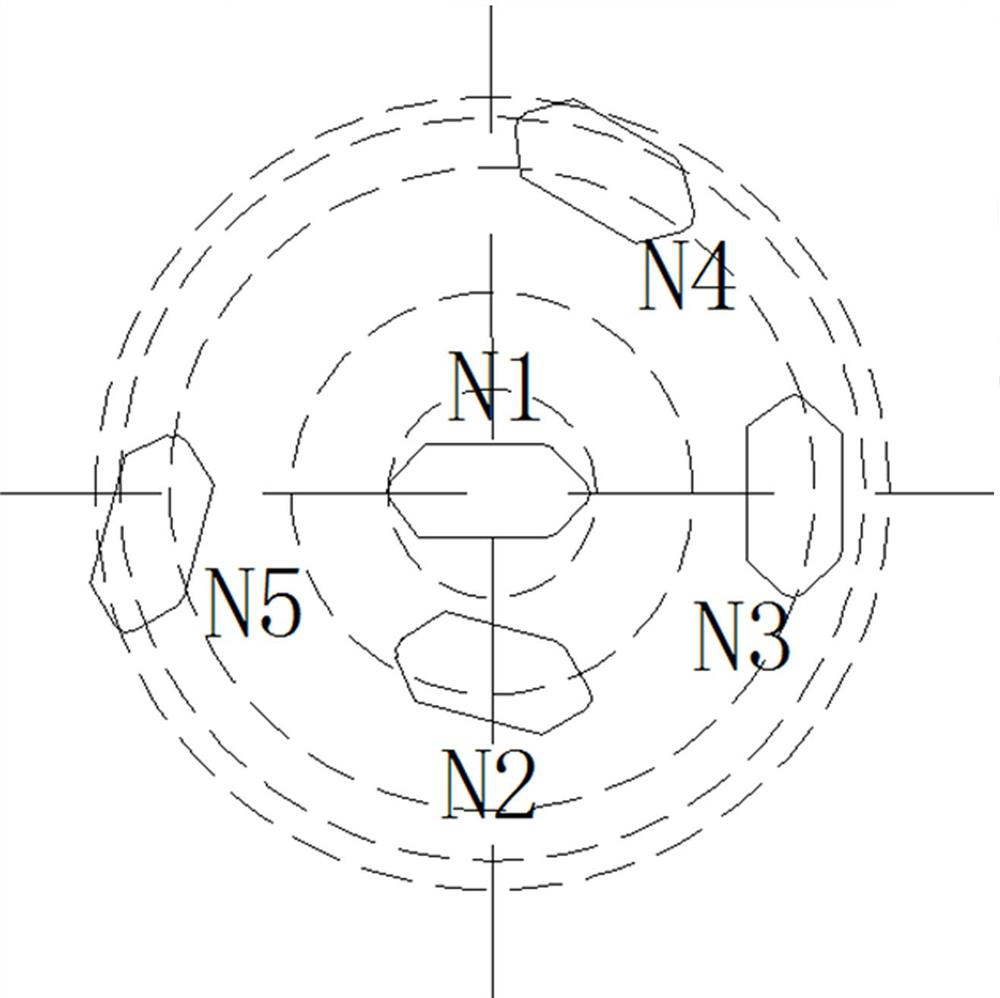

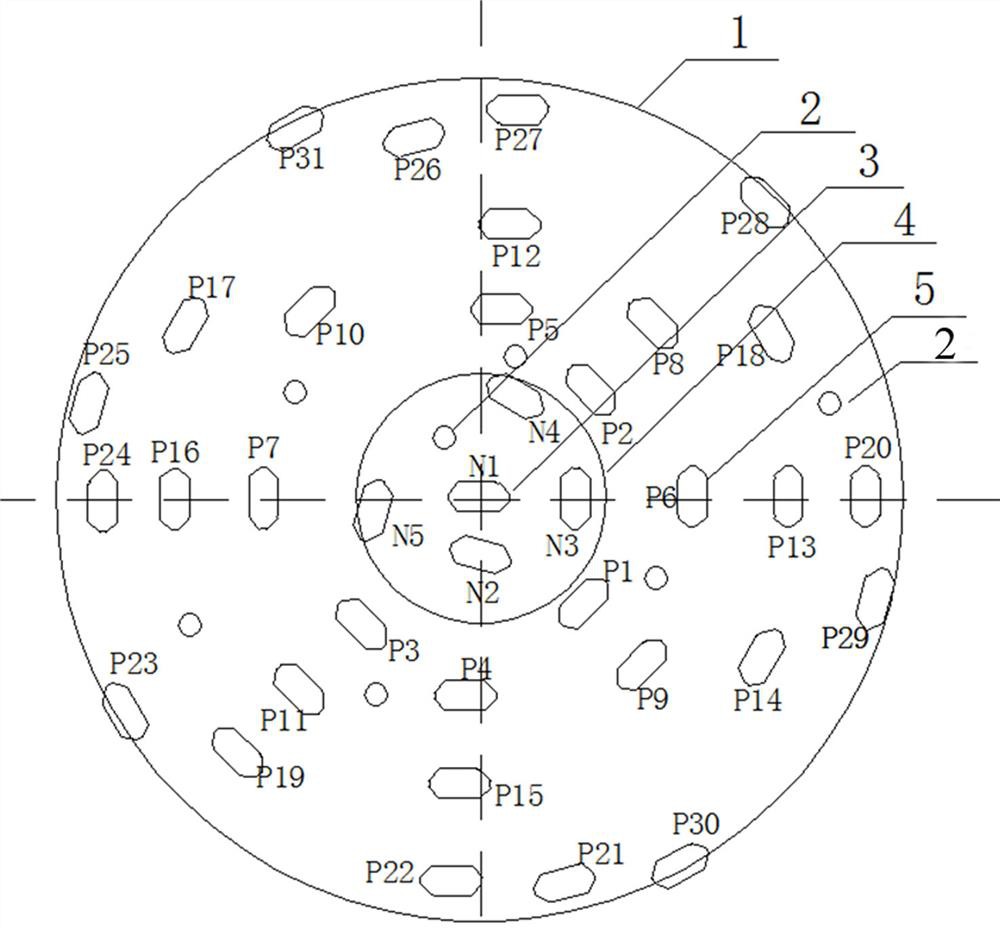

[0028] Such as Figure 1-4 As shown, a leading-guided roadheader cutterhead for excavation of extremely hard rock includes a conical small cutterhead 4 for breaking rock in advance and a small cutterhead for subsequent expansion and rock breaking arranged on the outside of the small cutterhead 4 . A large planar cutterhead 1 is provided with a plurality of first hobs 3 and second hobs 5 respectively on the small cutterhead 4 and the large cutterhead 1, and the blades of the first hobs 3 and second hobs 5 break rock The trajectory lines of the first hob 3 and the second hob 5 do not overlap, and the rock-breaking trajectory lines of the blades of the first hob 3 and the second hob 5 cover the entire rock face. Figure 5 shown.

[0029] The taper angle of the small cutter head 4 β ≤ arctan( f + µ ),in f Be the friction coefficient of small cutterhead 4 and hard rock contact, µ is the correction coefficient set according to the rock strength. The harder the rock strength, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com