Hydraulic auxiliary rock breaking mechanism with direction controllability and cutting method thereof

A hydraulic and rock-breaking technology, which is applied in the field of hydraulic-assisted rock-breaking mechanism and its cutting, can solve the problems of reducing mechanical impact rock-breaking capacity, efficiency, service life and reliability of equipment, low rock-breaking efficiency, and large amount of dust. , to achieve the effects of reducing the difficulty of rock breaking, improving crushing efficiency, and reducing water and abrasive consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in more detail below with reference to schematic diagrams, wherein preferred embodiments of the present invention are shown, and it should be understood that those skilled in the art can modify the present invention described herein while still achieving the advantageous effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

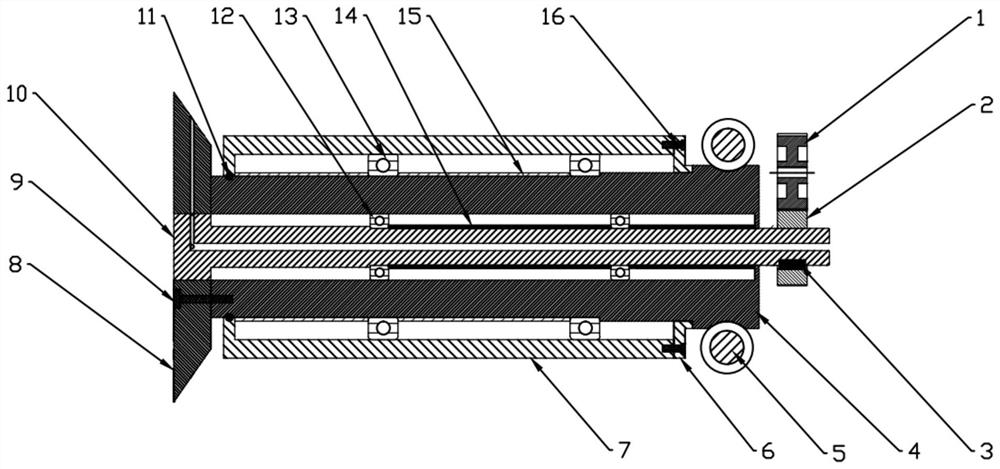

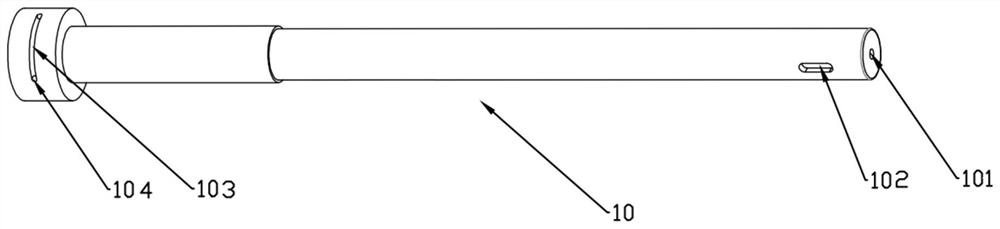

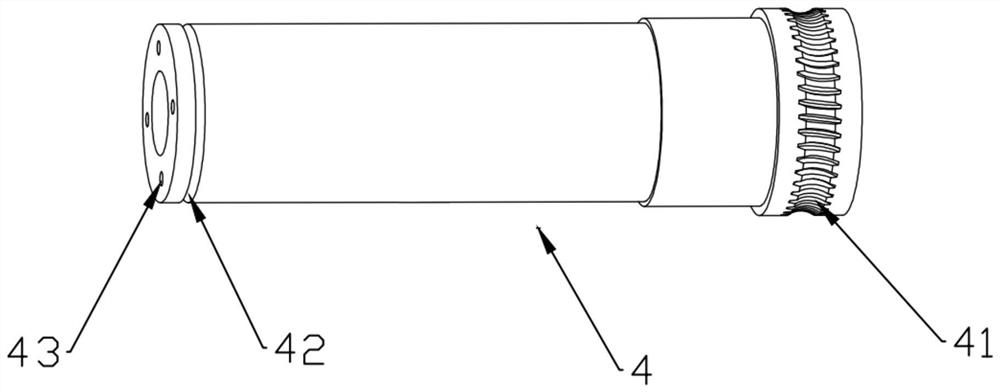

[0045] Such as figure 1As shown, a direction-controllable hydraulic auxiliary rock-breaking mechanism includes a cutting main shaft 4, and a sealing shaft 10 is installed in the cutting main shaft 4; one end of the cutting main shaft 4 is fixed with a hob by fastening screws Ⅰ 9 8. The high-speed abrasive jet generated by the external abrasive jet generator is sprayed into the sealed shaft 10 from the jet inlet of the sealed shaft 10, and the high-speed abrasive jet flows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com