TBM cutterhead aiming at complete hard rock

A cutter head and hard rock technology, applied in mining equipment, tunnels, earth-moving drilling, etc., can solve problems such as lack of adaptability, and achieve the effect of reducing the difficulty of rock breaking, reducing construction costs, and improving rock breaking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

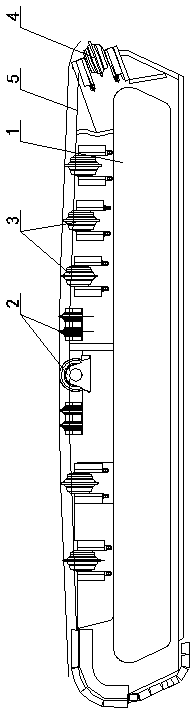

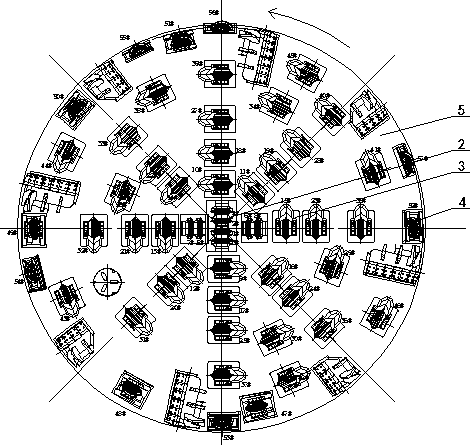

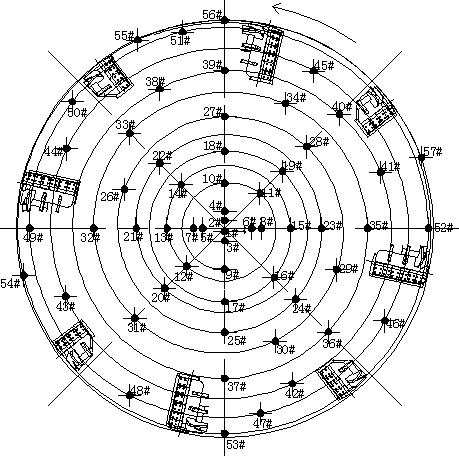

[0021] Embodiment 1: as figure 1 , 2 , 3 and 4, a kind of TBM cutterhead for complete hard rock includes a cutterhead body 1, a hob is arranged on the front panel 5 of the cutterhead body 1, and the hob is radially directed from the center to The edge is arranged, and the center is high and the edge is low in a stepped distribution with a certain distance between the knives.

[0022] from Figure 4 The relationship between the knife height curve 7 and the knife height comparison line 8 can be clearly seen in the figure.

[0023] To further describe, the front panel 5 of the cutter body 1 is in the shape of a truncated cone, and the hobs are spirally distributed on the front panel 5 of the cutter body 1 .

[0024] During the excavation process, the center cutter 2 breaks the rock in advance, and the hob near the center breaks the rock first, providing a free free surface on one side for the adjacent hob to break the rock. Each hob breaks the rock on the corresponding step. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com