Patents

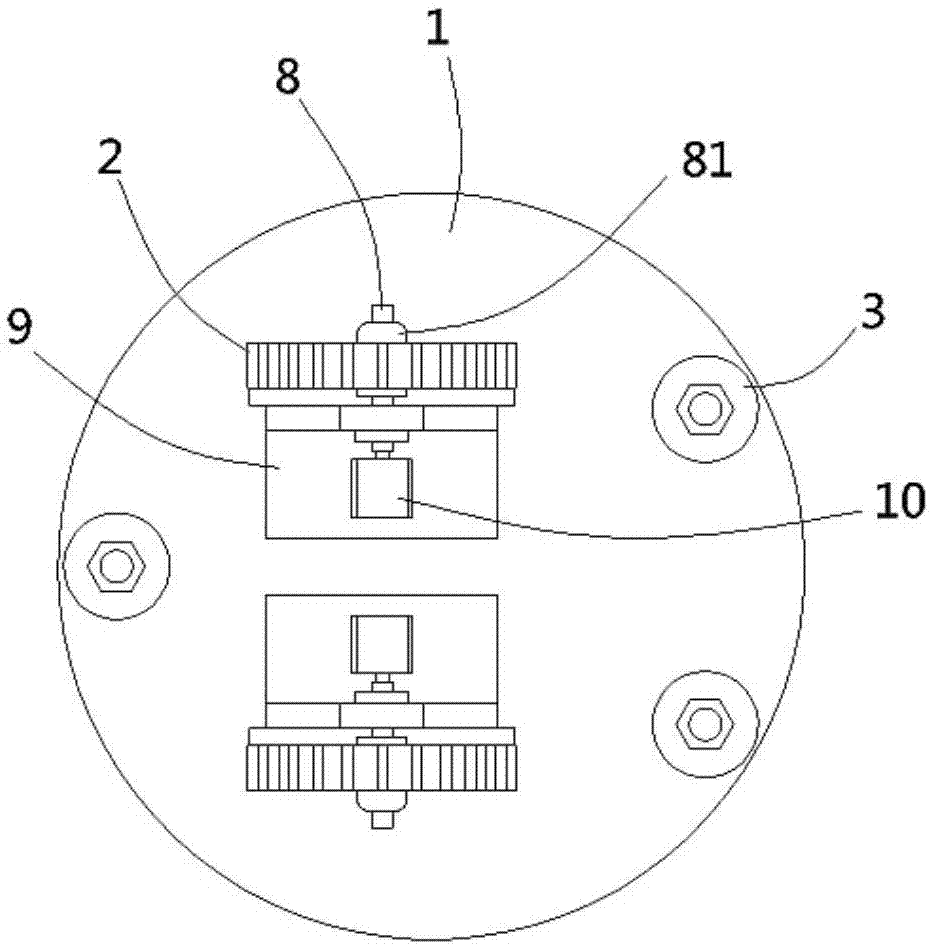

Literature

122results about How to "Reduce wear consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

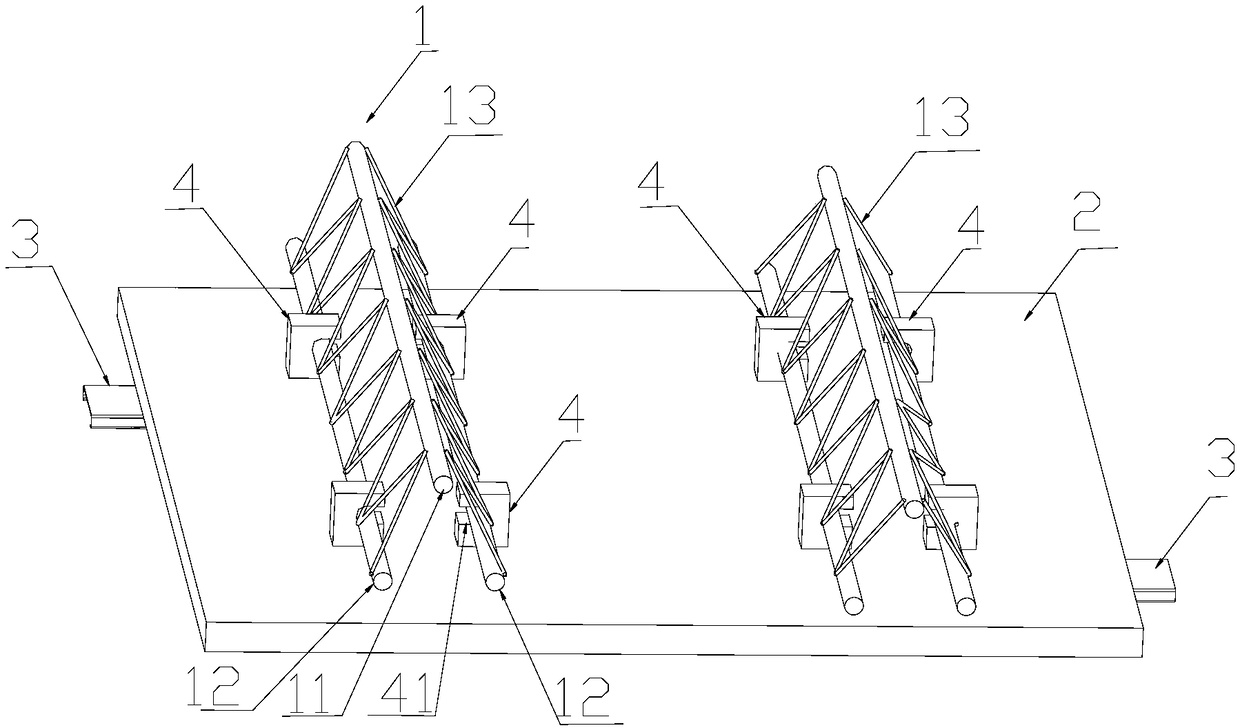

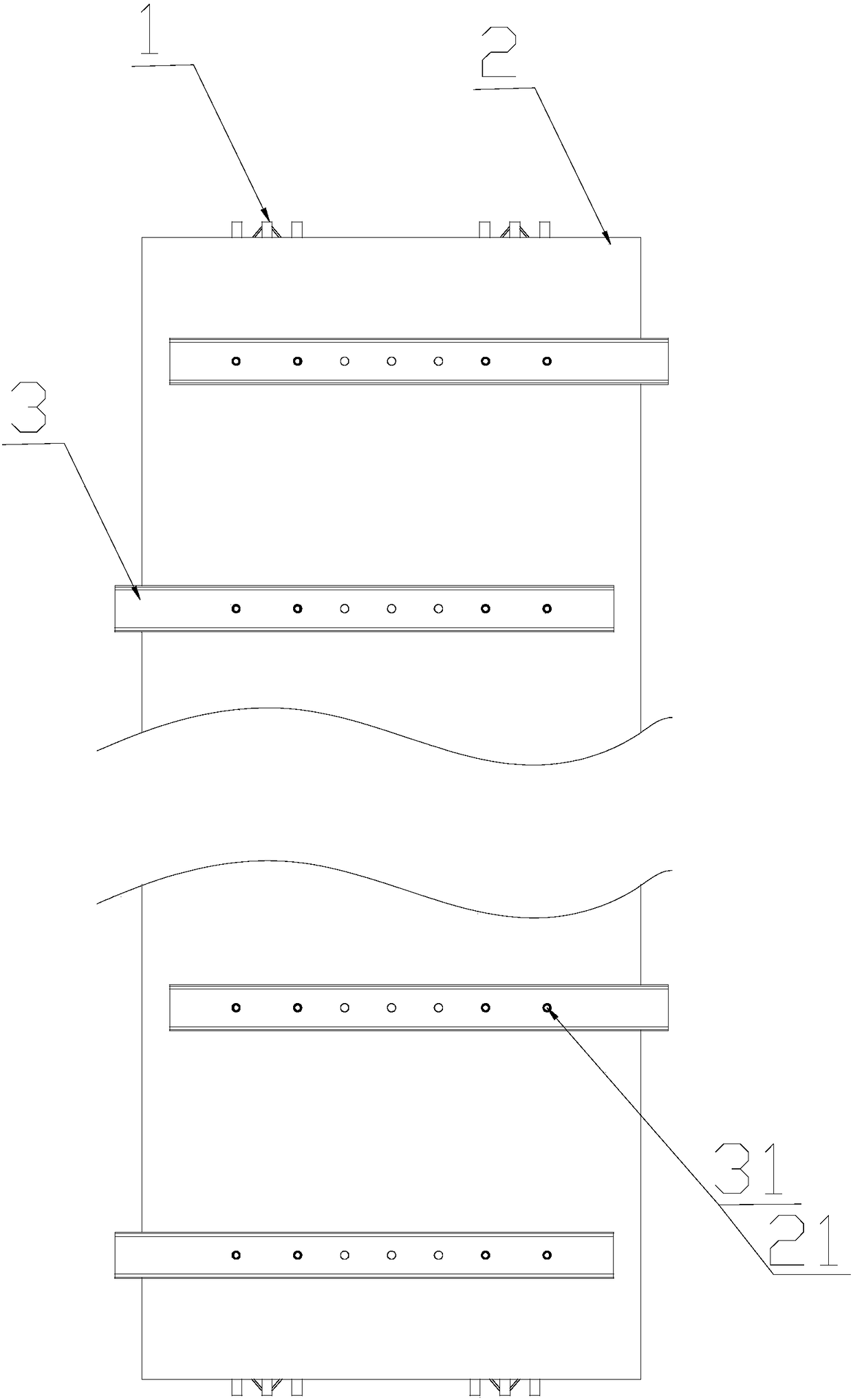

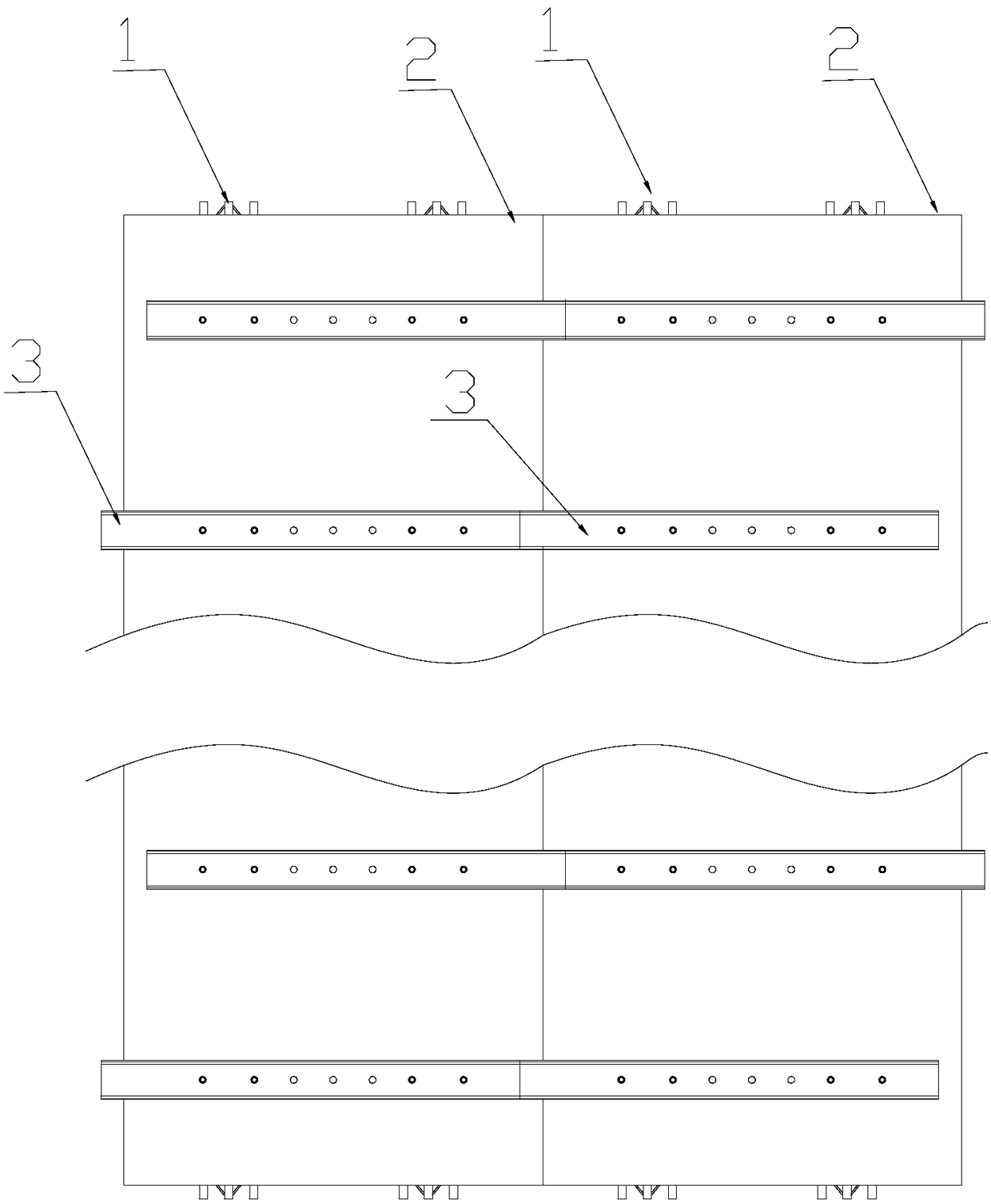

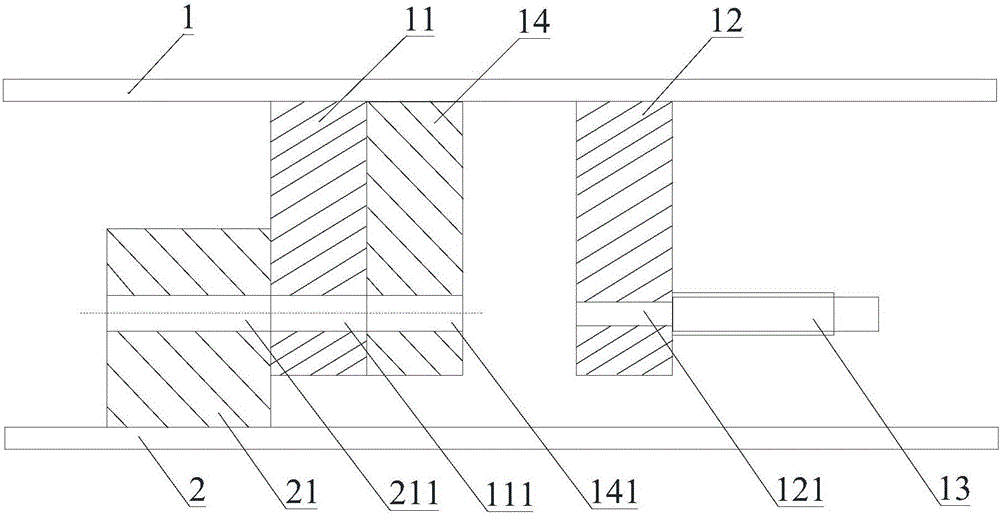

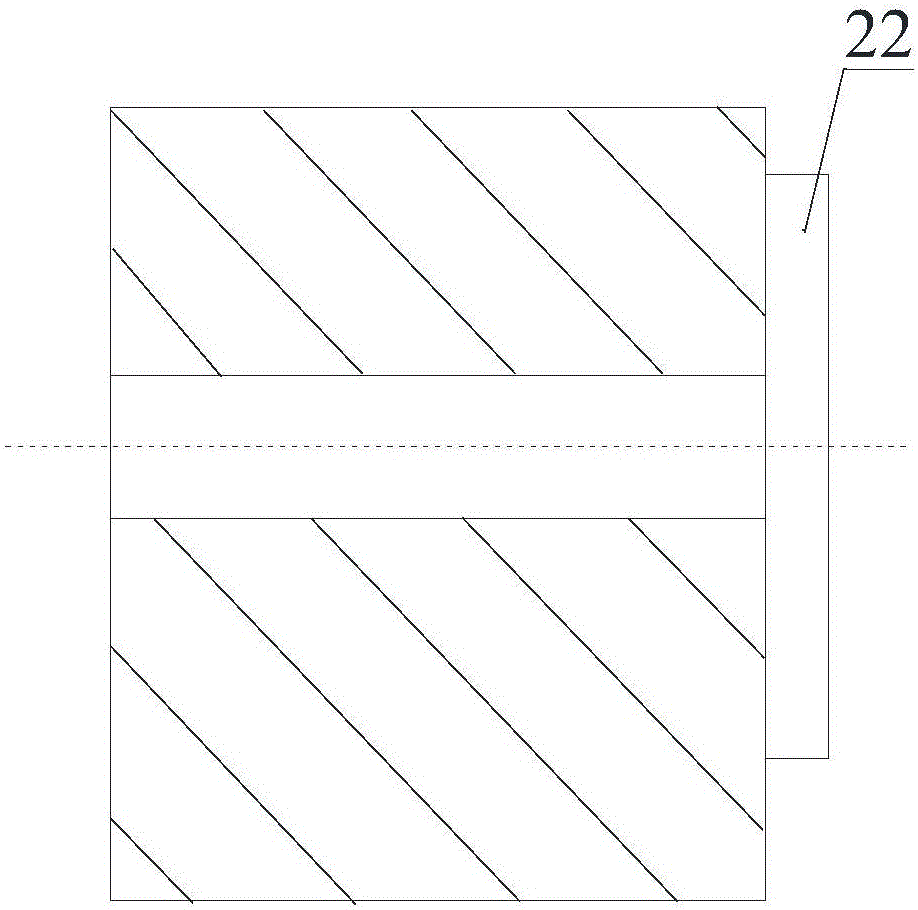

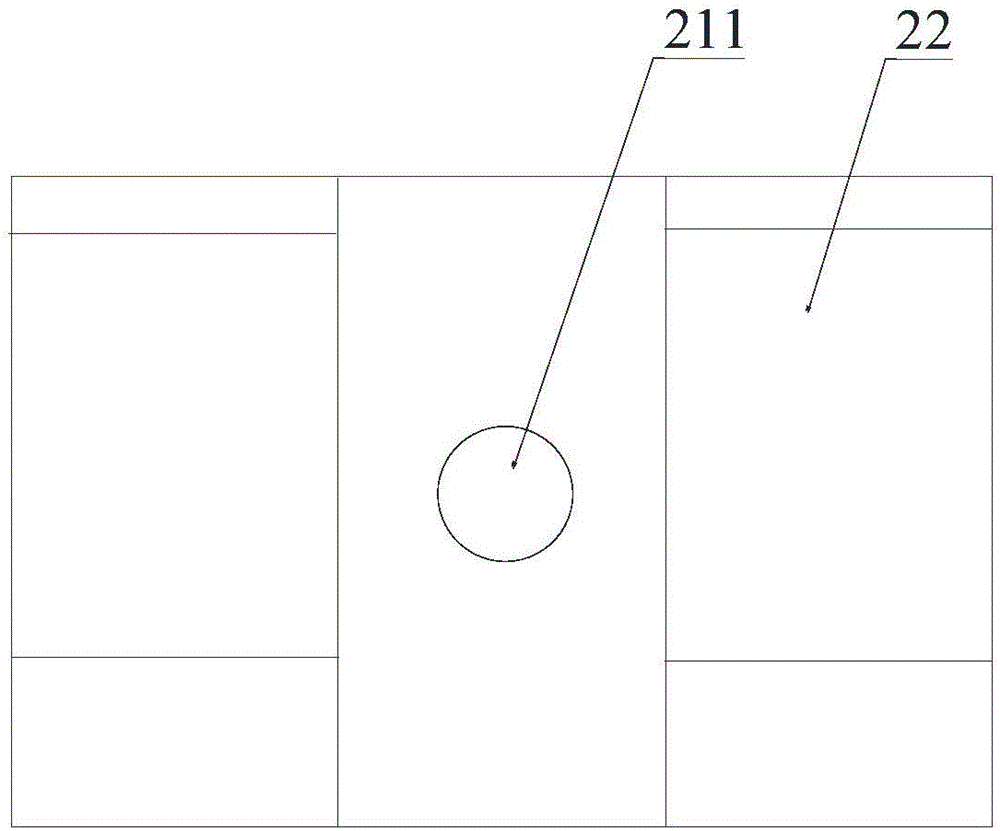

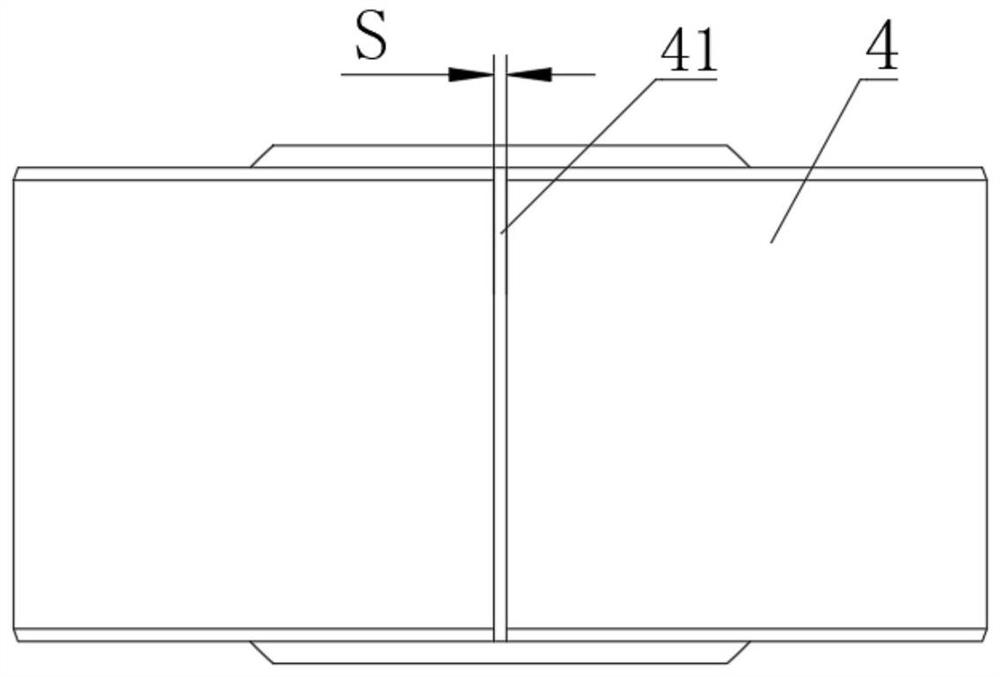

Assembled steel bar truss floor support plate

PendingCN108086555AReduce misalignmentStable and Efficient UtilizationFloorsBuilding reinforcementsSteel barBuilding material

The invention relates to the technical field of building materials, in particular to an assembled steel bar truss floor support plate which comprises a floor support plate body. One side of the floorsupport plate body is detachably connected with a steel bar truss, and supporting parts are arranged on the other side of the floor support plate body at intervals and extend out of the floor supportplate body. According to the floor support plate, the supporting parts are arranged on the lower side of the floor support plate and extend out of the left or the right of the floor support plate, extending portions of the supporting parts support adjacent floor support plates when the floor support plates are spliced, the floor support plates of two sides of a splicing seam are supported by the supporting parts, misplacement of the splicing seam is decreased and even disappeared, the supporting parts are disassembled when the floor support plate is disassembled, extra supporting part disassembling workload is not increased, and the reusable floor support plate and the reusable supporting parts are more stably and efficiently used.

Owner:ZHE JIANG ZHONGYI BUILDING MATERIALS TECH CO LTD

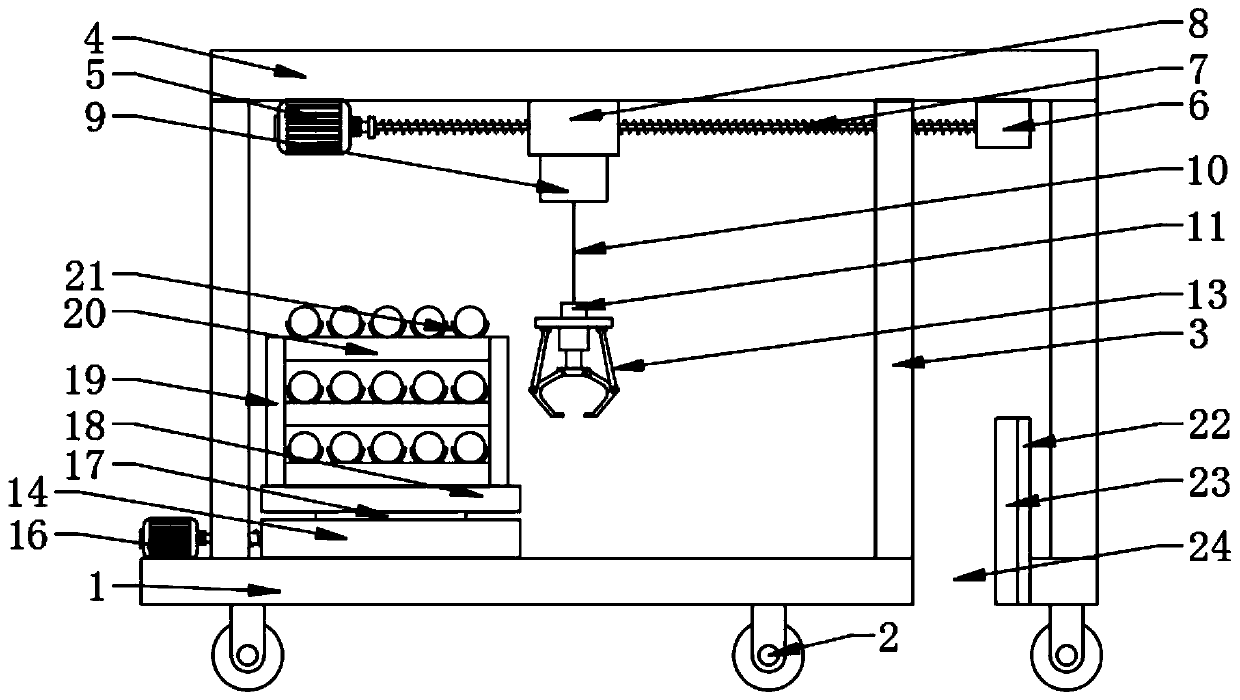

Pipeline embedding device for water conservancy projects

InactiveCN110937518AAchieve placementEasy to placePipe laying and repairBase supporting structuresElectric machineryHydraulic engineering

The invention discloses a pipeline embedding device for water conservancy projects, and relates to the technical field of pipeline embedding devices. A winch is fixedly installed at the bottom of a threaded seat, a support rod is fixedly connected between two groups of connecting steel blocks, the bottom ends of the two groups of connecting steel blocks are fixedly equipped with clamping devices,the left end of a second lead screw penetrates through a fixing seat to be fixedly connected to a second motor, an inner cavity of the fixing seat is provided with a guide seat connected to the outerwall of the second lead screw in a sleeving manner, an object containing plate is fixedly arranged between fixing frames, the top of the object containing plate is evenly and fixedly provided with limiting rings, two groups of guide plates are fixedly arranged on the right side of the top of a base, protection plates are fixedly assembled on the side walls between the two groups of guide plates, and a discharging channel is arranged between the two groups of protection plates. Automatic clamping and laying of pipelines are realized, pipeline protection can be realized, the needs of continuouspipeline placing and laying are met, and the pipeline laying efficiency is improved.

Owner:宁夏中康建设集团有限公司

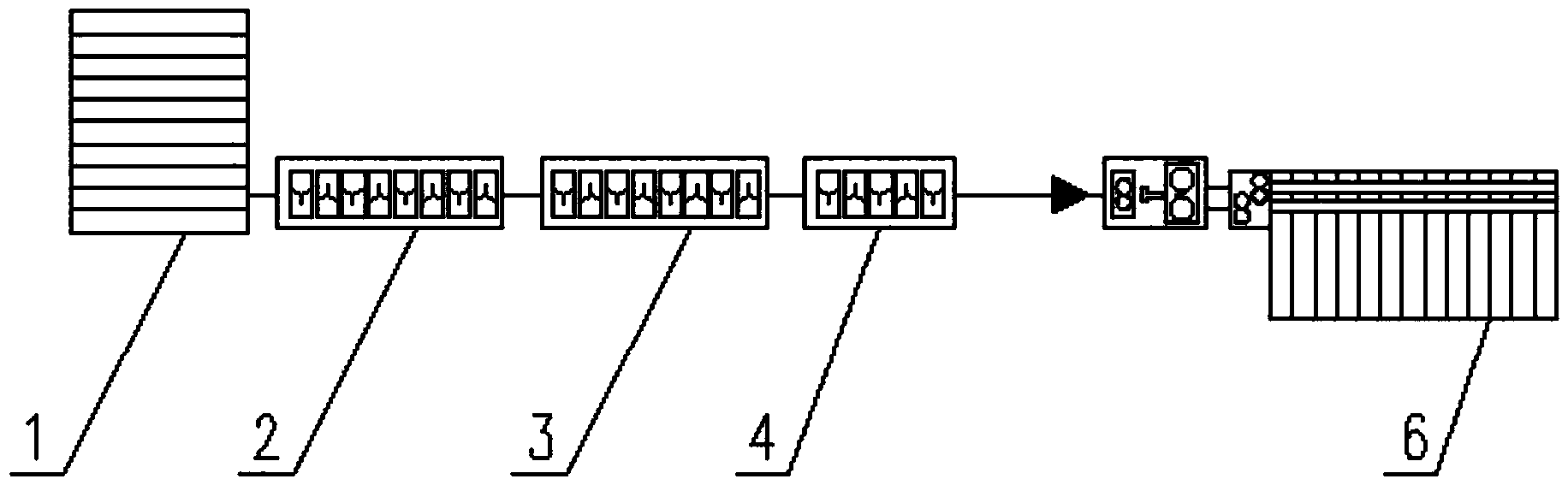

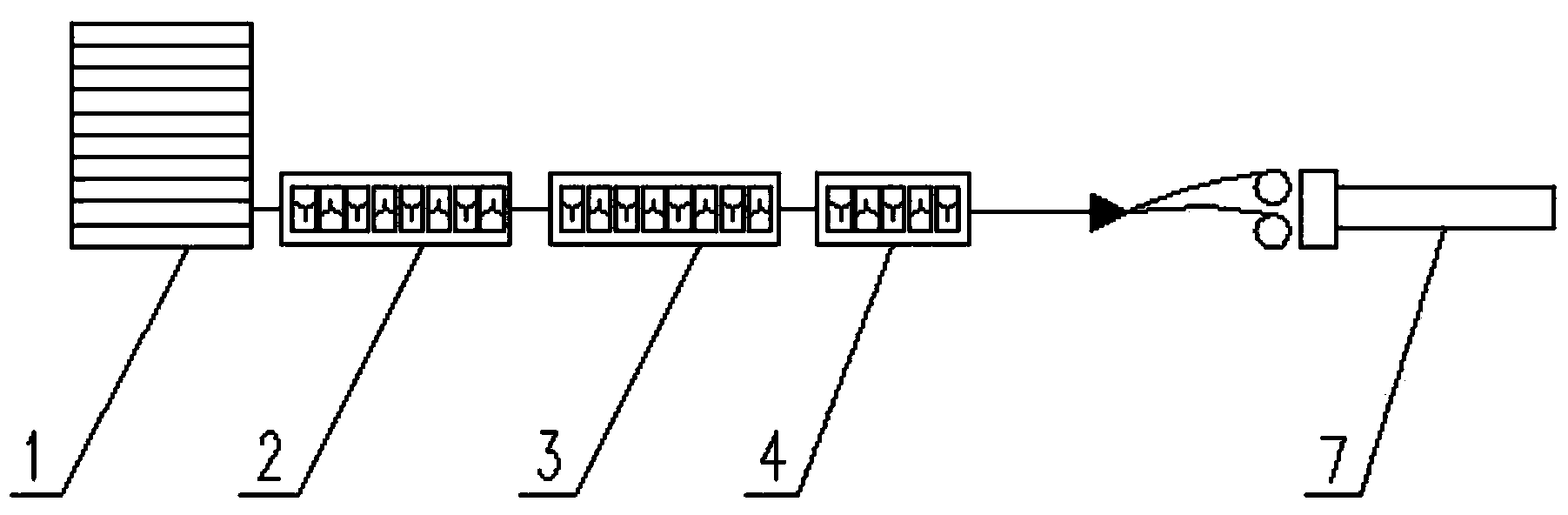

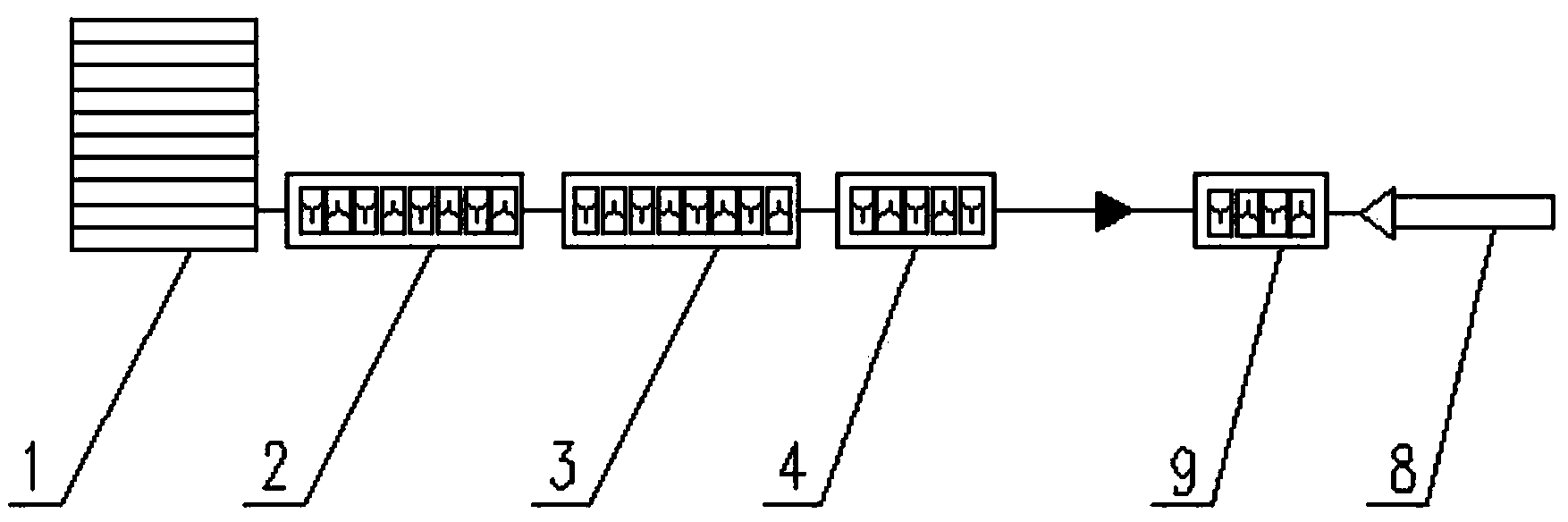

Compact wire and bar rolling production line

ActiveCN103706634AFlexible configurationIncrease flexibilityFlexible work arrangmentsMetal rolling arrangementsProduction lineEngineering

The invention relates to a compact wire and bar rolling production line which sequentially comprises a heating furnace, a rough rolling unit, an intermediate rolling unit, a finish rolling unit and a collecting system. The collecting system comprises at least one of a cooling bed, a coiling and collecting system and a wire collecting system. The rough rolling unit, the intermediate rolling unit and the finish rolling unit are respectively provided with a Y-type three-roll rolling mill and an inverted Y-type three-roll rolling mill, and the Y-type three-roll rolling mills and the inverted Y-type three-roll rolling mills are distributed in an alternating mode. A rolling machine set adopts the three-roll rolling mills of the same structural mode, the rolling machine set is universal, a wire and bar collecting system can be flexibly distributed, and flexibility of wire rolling is high. A high-speed steel feeding system is arranged so as to increase rolling speed of the rolling machine set and improve production efficiency, the brake sliding distance between high-speed rolled workpieces is shortened, the rolling length is further shortened, and investment is reduced. An arranged wire reducing sizing rolling unit further rolls and produces wires, and facilitates improvement of rolling quality of the wires and size precision of products.

Owner:CISDI ENG CO LTD

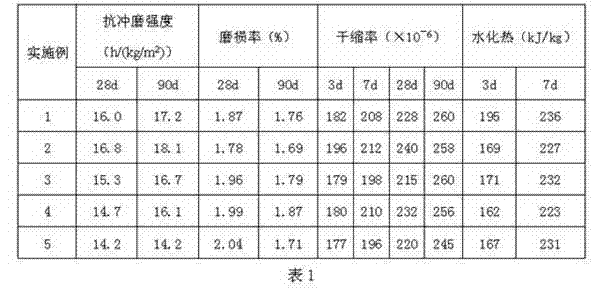

Abrasion resistant low-heat portland cement

ActiveCN102161583AReduce heat of hydrationImprove drying shrinkageSolid waste managementSuperplasticizerWater flow

The invention relates to abrasion resistant low-heat portland cement which is prepared from a low-heat portland cement clinker, an abrasion resistant mixed material and a proper amount of gypsum. The abrasion resistant low-heat portland cement comprises the following components by weight percent: 85-98% of the low-heat portland cement clinker, 2-10% of the abrasion resistant mixed material and 1-10% of the gypsum, wherein the abrasion resistant mixed material is mainly prepared from active micro-silicon powder, ultrafine low calcium coal ash and a proper amount of superplasticizer. The abrasion resistant low-heat portland cement provided by the invention has no crazing phenomenon, abrasion loss caused by the fact that concrete pushes or laminates substances is reduced, and the resistance to concrete damage generated by acting on sand inclusion and stone water flow is improved; and the abrasion resistant low-heatportland cement has the characteristics of low hydration heat, small dry shrinkage, good durability and excellent abrasion resistance, and the concrete is prepared just according to concrete design requirement so as to meet the abrasion resistant requirement on engineering parts with high concrete abrasion resistant requirement in the water and electricity fields such as diversion tunnels, spillway tunnels, dams, airfield runways and the like.

Owner:JIAHUA SPECIAL CEMENT

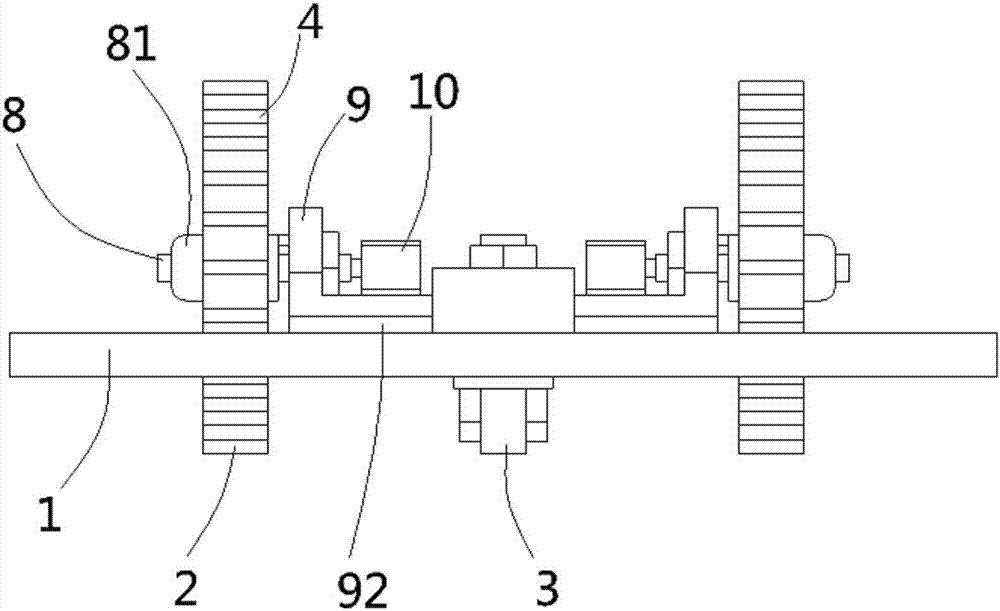

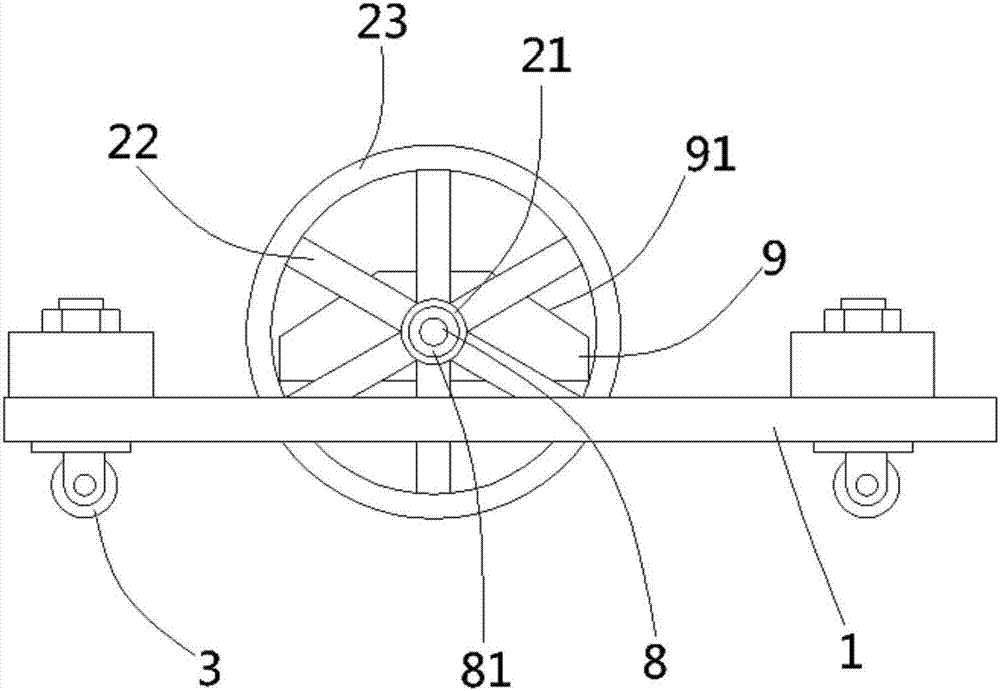

Robot chassis with switchable walking wheels

ActiveCN107264667AReduce coefficient of frictionReduce wear consumptionWheel attachmentsVehiclesRoad surfaceDrive motor

The invention discloses a robot chassis with switchable walking wheels. The robot chassis comprises a chassis body, and the walking wheels are arranged on the chassis body in an inserted mode. Each walking wheel comprises a hub part; six spokes are evenly formed on each hub part; anti-slide grooves are evenly formed in the outer walls of wheel rims; splicing blocks are inserted in the anti-slide grooves; and a connecting rod is formed on each splicing block. The splicing blocks on each wheel rim are divided into six sets corresponding to the spokes, each set of splicing blocks form a fan-shaped structure, the splicing blocks between every two adjacent sets of splicing blocks are overlapped with the connecting rods, three of the overlapped connecting rods extend into the spokes and are fixed to piston rods of shifting air cylinders, and the connecting rod of the splicing block in the middle of each set of splicing blocks is arranged in the wheel rim; a fulcrum shaft is fixed to the hub part in an inserted mode, one end of the fulcrum shaft is hinged to a support, a driving motor is fixed on the support, and a rotary shaft of the driving motor is fixedly connected with the fulcrum shaft. The robot chassis can achieve switching of the contact faces between the walking wheels and the ground so as to adapt to special situations of the road surface.

Owner:XUZHOU XINFA MACHINERY

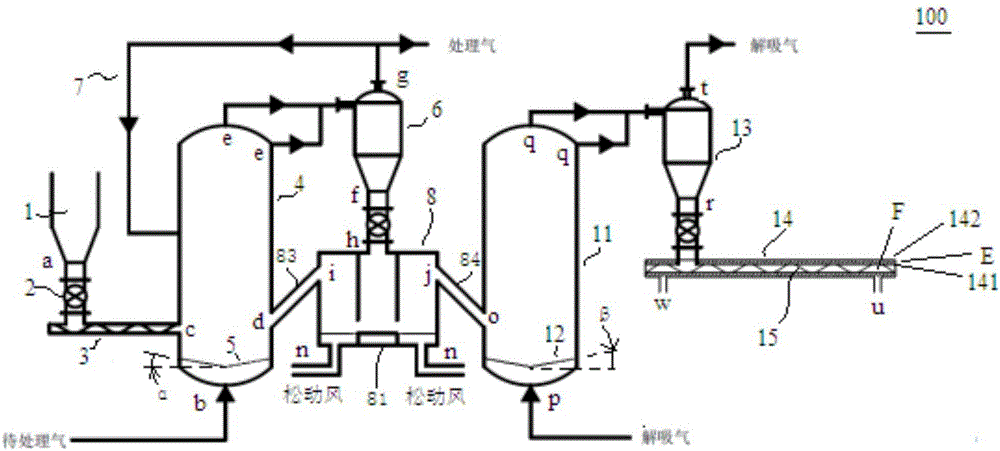

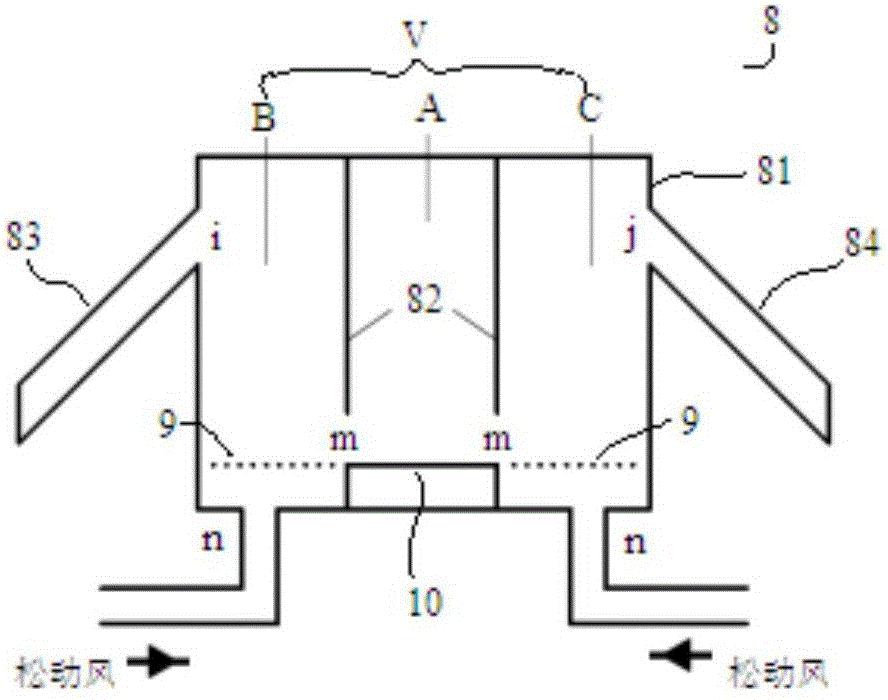

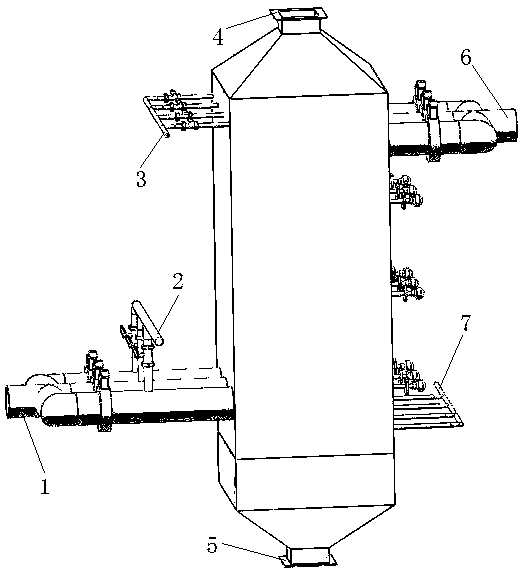

Fluidized bed gas adsorption-desorption system and treatment method thereof

ActiveCN105903314AHigh gas velocityReduce labor intensityDispersed particle separationGas solidFluidized bed

The invention discloses a fluidized bed gas adsorption-desorption system and a treatment method thereof. The system includes an adsorption fluidized bed, a regeneration fluidized bed, an adsorption side gas-solid separator, a desorption side gas-solid separator and a feed divider. The adsorption fluidized bed has an adsorbent inlet, a to-be-treated gas inlet, a first returned material inlet and a first mixture outlet. The adsorption side gas-solid separator is connected to the first mixture outlet. The regeneration fluidized bed has a second returned material inlet, a desorption gas inlet, and a second mixture outlet. The desorption side gas-solid separator is connected to the second mixture outlet. The feed divider has a feed inlet, an adsorption side divided material outlet and a desorption side divided material outlet, the feed inlet is connected to an adsorption side solid-discharge port of the adsorption side gas-solid separator, the adsorption side divided material outlet is connected to the first returned material inlet, and the desorption side divided material outlet is connected to the second returned material inlet. The system provided by the invention is easy to operate, the system treatment ability is enhanced, and the adsorption efficiency, adsorption economical efficiency and operation continuity are improved.

Owner:SHENWU TECH GRP CO LTD

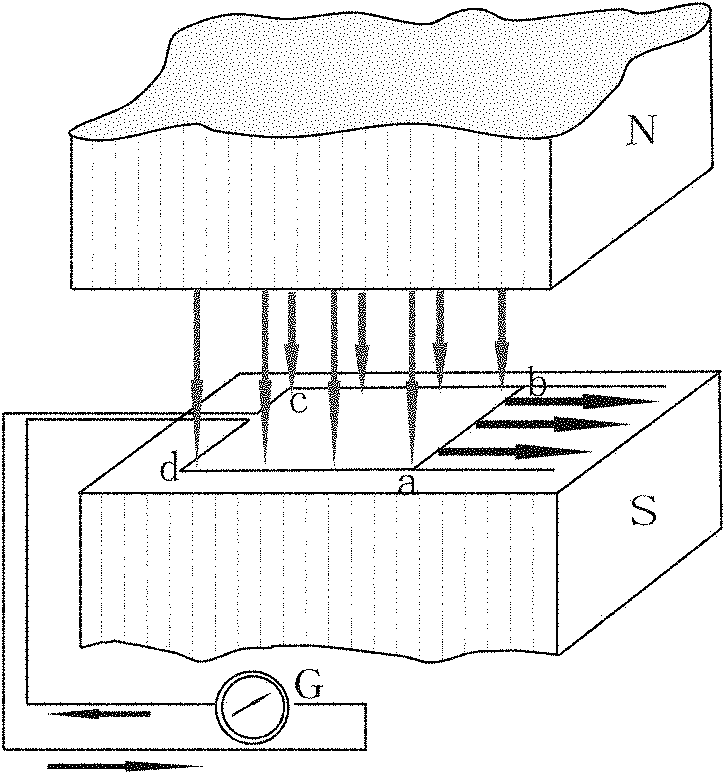

Highway downhill running inertia generating system

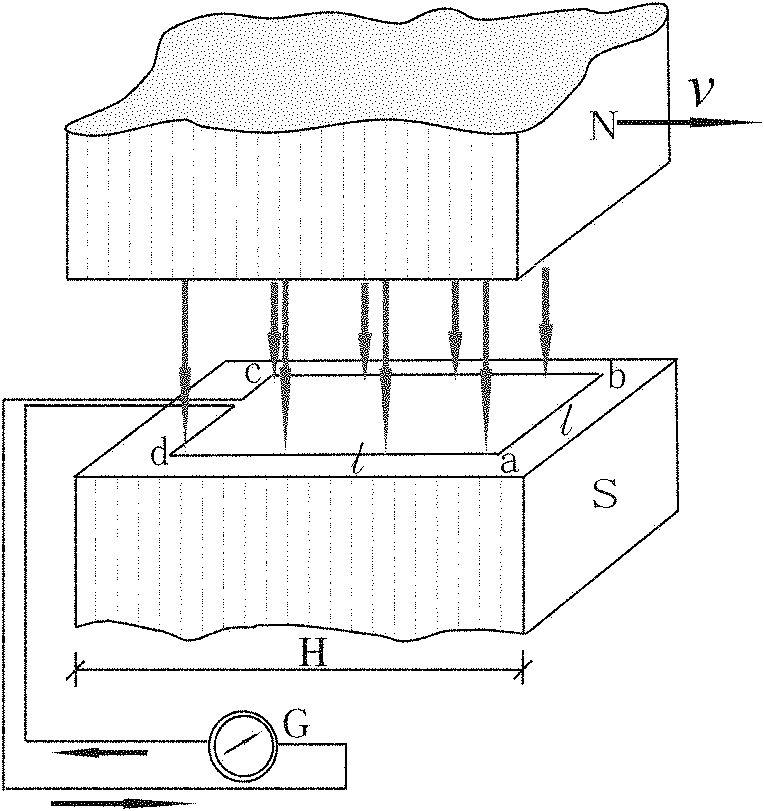

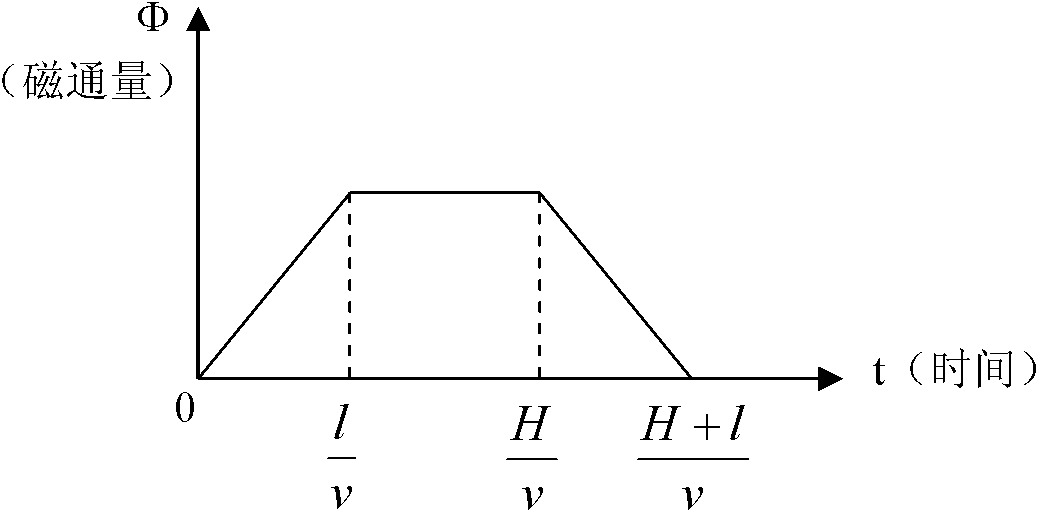

InactiveCN102022291AReduce wear consumptionIncrease resistanceMachines/enginesMotorsElectromechanicsDownhill running

The invention belongs to the technical fields of traffic engineering and electromechanics, in particular to a highway downhill running inertia generating system. The highway downhill running inertia generating system comprises a plurality of road surface embedded poles embedded at proper positions on a road surface of a highway downhill line, and vehicle-mounted poles corresponding to the road surface embedded poles, wherein road surface embedded closing coils are arranged on the road surface embedded poles; each road surface embedded closing coil is connected with a constant amplitude rectifying device; constant amplitude rectifying devices are connected in parallel to a direct current bus; and the direct current bus is connected with a storage battery, an inverter and electric equipment. The system can effectively utilize highway downhill running inertia and generates power due to change of the magnetic flux of the closing coils to supply power to power utilization places; and because the vehicle-mounted poles are stressed by an electromagnetic force, the downhill running resistance can be increased, and automobile brake wear consumption is reduced.

Owner:HUNAN INSTITUTE OF ENGINEERING

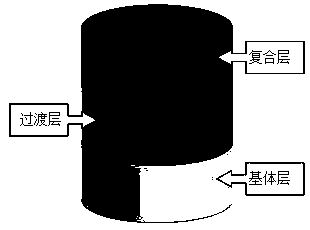

Tungsten carbide-steel based composite material and preparation method thereof

The invention relates to a tungsten carbide-steel based composite material capable of regulating and controlling particle microscopic interface growth through rare earth and a preparation method thereof. The tungsten carbide-steel based composite material comprises a composite layer, a transition layer and a base body layer. The preparation method comprises the steps that tungsten carbide-steel powder mixed powder with a rare earth element-coated surface is adopted to serve as a composite layer material, tungsten powder-steel powder mixed powder serves as transition layer material, steel powder serves as base body layer material, wherein the rare earth element is the mixture of one or more of Nd, Y and Ta, tungsten carbide particle-steel powder mixed powder with the rare earth element powder-coated surface layer, the tungsten powder-steel powder mixed powder and the steel powder are jointly pressed into a composite layer-transition layer-base body layer prefabricated body, and the prefabricated body is placed in a vacuum tube type sintering furnace to be sintered and formed.

Owner:KUNMING UNIV OF SCI & TECH

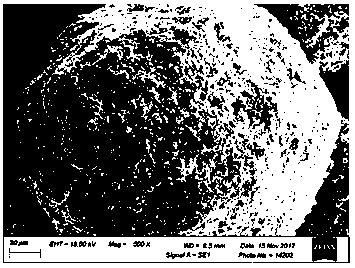

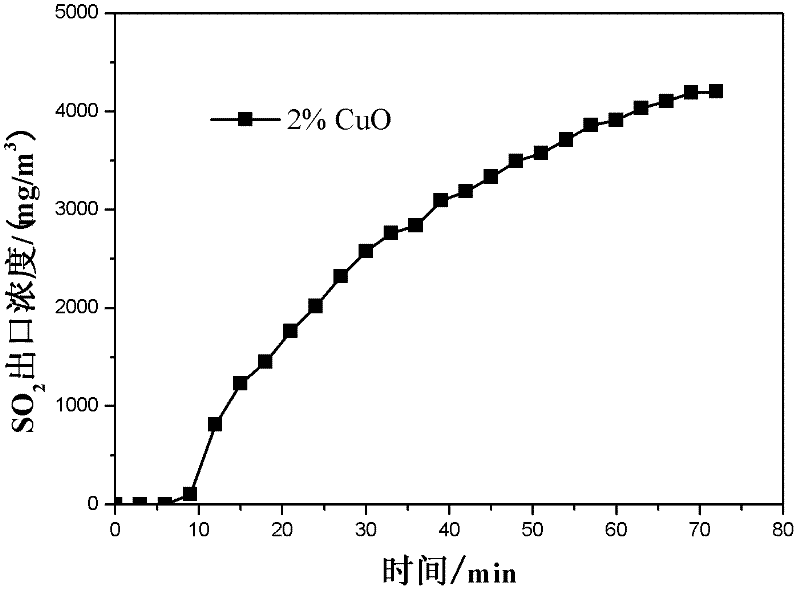

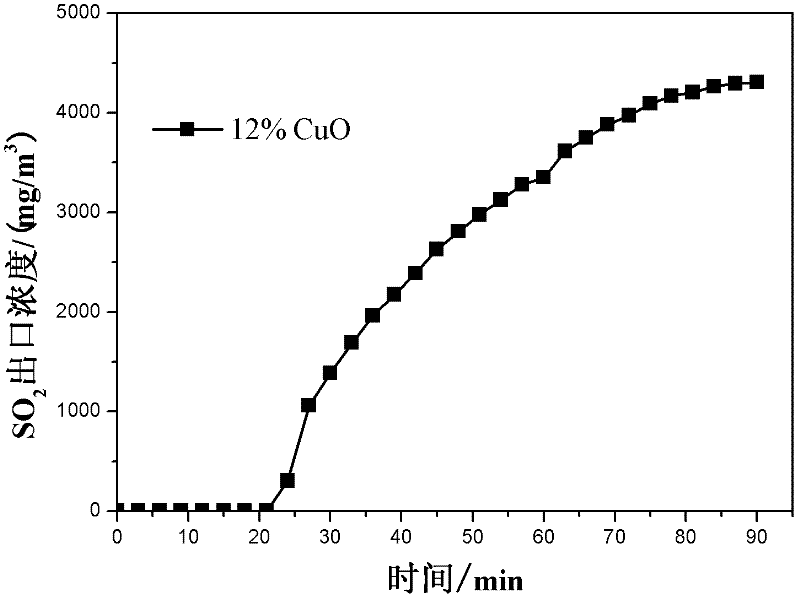

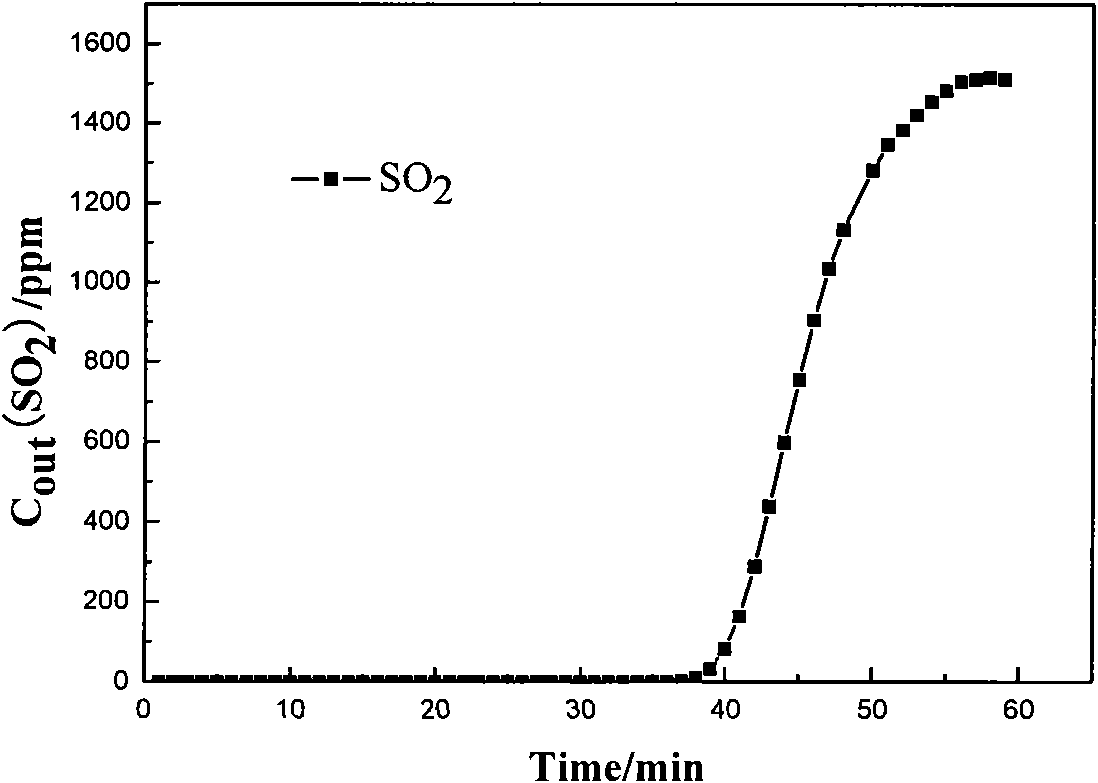

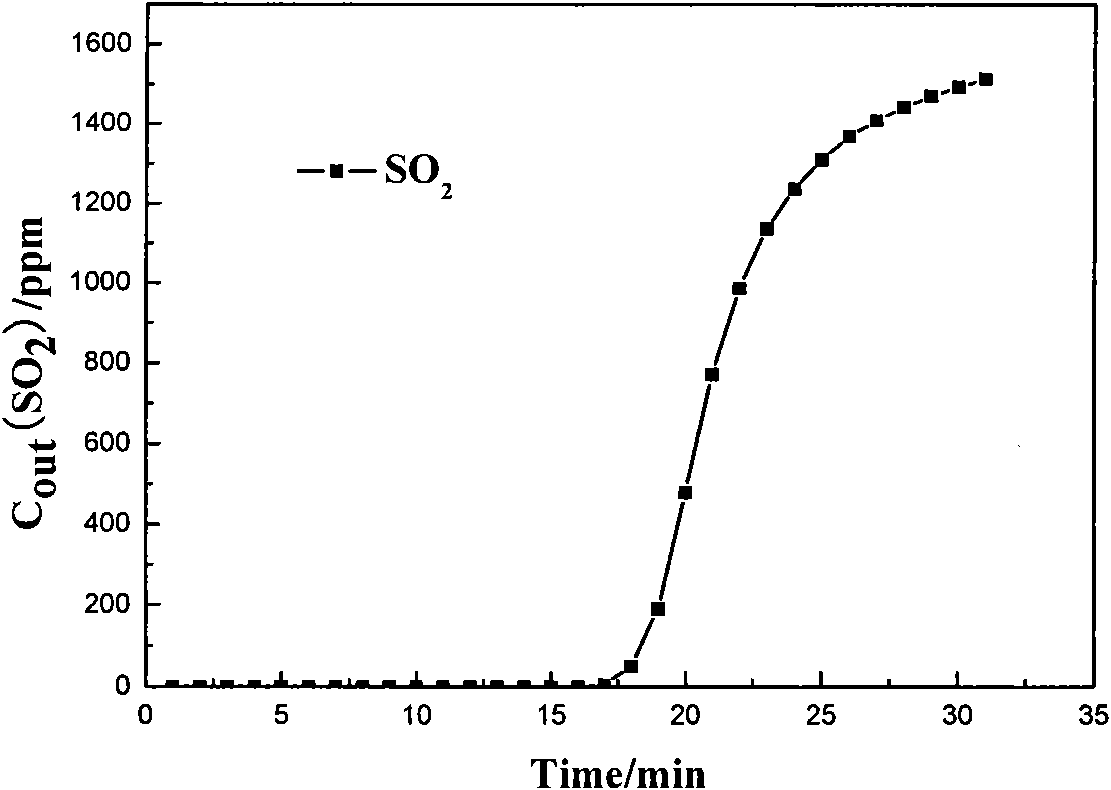

Copper oxide loaded attapulgite catalyst and preparation method and applications thereof

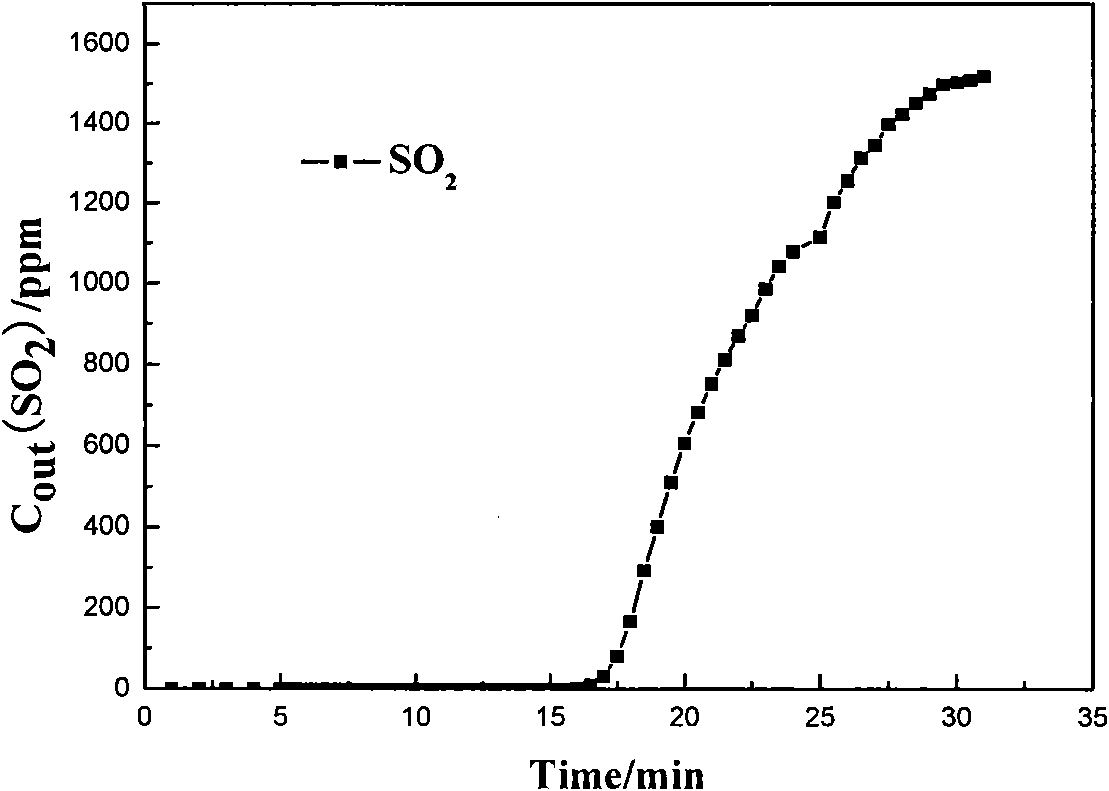

InactiveCN102500372AImprove desulfurization efficiencyWide variety of sourcesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurActive component

The invention discloses a copper oxide loaded attapulgite catalyst and a preparation method and applications thereof. The copper oxide loaded attapulgite catalyst is a composite which uses the calcined attapulgite as the catalyst carrier and is loaded with copper oxide; and the weight of copper oxide accounts for 2-20% of the weight of the catalyst carrier. The preparation method of the catalyst comprises the following steps: adopting the isovolumetric impregnation method to load a catalyst precursor on the surface of the catalyst carrier, drying and calcining to obtain the copper oxide loaded attapulgite catalyst, wherein the catalyst precursor is Cu(NO3)2. The catalyst disclosed by the invention is used to remove SO2 in the flue gas. The cheap and available attapulgite is used as the catalyst carrier, thus reducing the cost of the catalyst and the environmental load; and attapulgite has better formability and thermal stability, and the catalyst which is loaded with the copper active component has higher sulfur capacity.

Owner:HEFEI UNIV OF TECH

Mechanical arm metal surface restoration agent and preparation method thereof

InactiveCN106752639ALow self-friction coefficientImprove the lubrication effectDrying oil coatingsAnti-corrosive paintsFuranFiber

The invention provides a mechanical arm metal surface restoration agent and a preparation method thereof. The mechanical arm metal surface restoration agent comprises the following components in parts by mass: 5-8 parts of furan resins, 5-8 parts of alkyd resins, 3-9 parts of nano-silicon sol, 0.5-3 parts of 8-hydroxy-chinolin-sulfate, 4-10 parts of China wood oil, 2-3 parts of nanometer zinc borate, 1-3 parts of brucite fibers, 0-1.5 parts of p-toluenesulfonic acid, 1.5-3 parts of coupling agents, 2-4 parts of methoxypolyethylene glycols and 1-3 parts of polyvinyl acetate emulsion. The mechanical arm metal surface restoration agent is prepared by the steps of heating, stirring, performing ultrasonic treatment, mixing and the like. The prepared mechanical arm metal surface restoration agent is low in self-friction coefficient, high in lubricating property, uniform and dense in coating and high in binding force with the metal surface, has excellent wear resistance, acid and alkali resistance and corrosion resistance, performs coating protection on the metal surface and has a certain self-restoration function on wear, corrosion, scratch and the like produced on the metal surface. The working life of the mechanical arm is greatly prolonged, and the economic benefits are improved.

Owner:安徽臣诺机器人科技有限公司

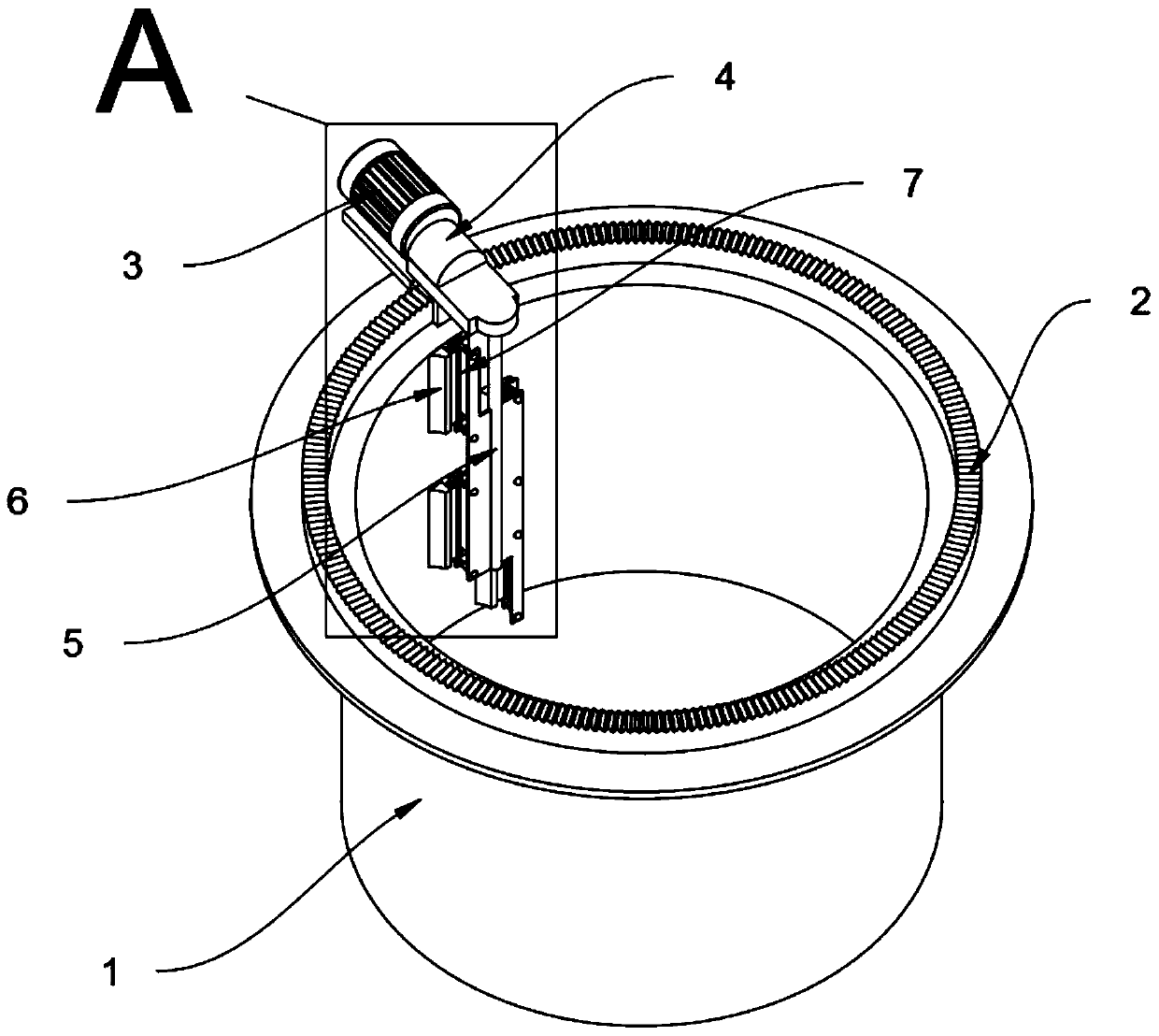

Wall scraping mechanism for sewage treatment tank

ActiveCN110772839AEasy to cleanSolve the problem of scrapingSedimentation separationInterference fitSludge

Relating to the technical field of wall scraping devices, the invention discloses a wall scraping mechanism for a sewage treatment tank, and solves the problems that the existing sludge scraper cannotscrape sludge and impurities on the tank wall and blades are easily ruined when encountering a hard obstacle. The wall scraping mechanism for a sewage treatment tank comprises scrapers, the scrapersare inserted into scraper holders in an interference fit manner, and the scraper holders are movably connected in a connecting sheet of a support rod body. The device employs the mode of clinging thearc-shaped scraper bodies and the scraper holders to the tank wall to scrape mud, and solves the problem that no device can scrape sludge and impurities on the tank wall at present, when the scraper bodies of the scraper holders in the device touch a hard obstacle and cannot move forwards, limiting blocks pull the scraper bodies to rise along the rotating shafts of fixed-axis rotating blocks, andafter crossing the obstacle, the scraper bodies reset again under the action of reset springs to perform sludge scraping treatment on the tank wall, thus protecting the scraper bodies from being ruined by the hard obstacle.

Owner:力峰精密机械(广东)有限公司

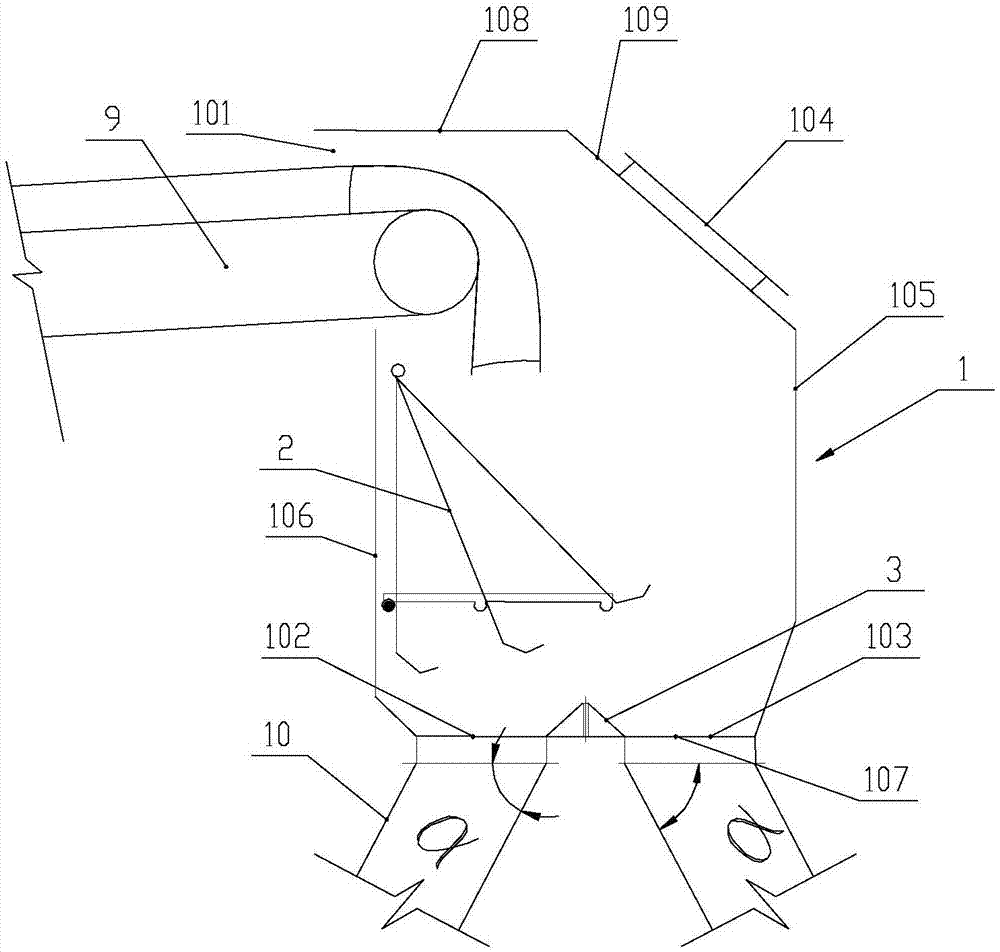

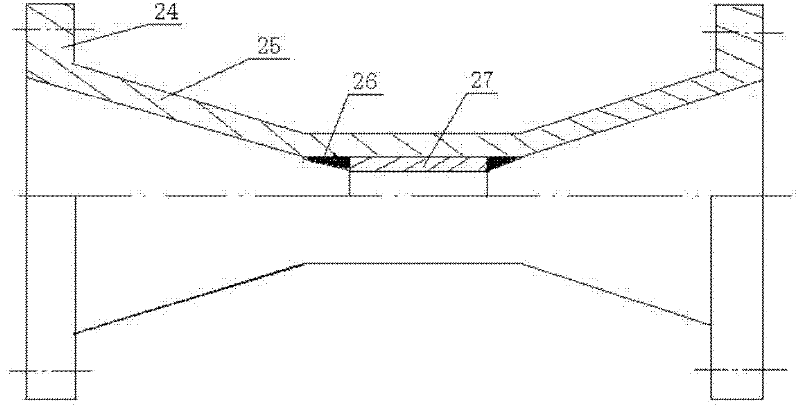

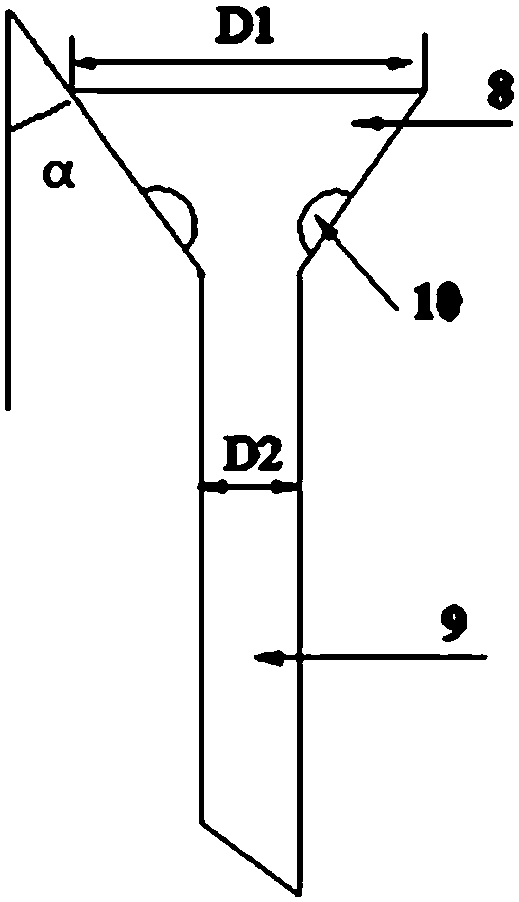

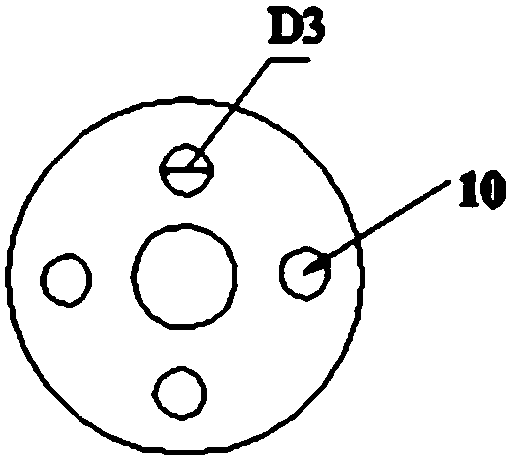

Funnel device with distributing and material guiding functions

PendingCN107010330AIncrease the cross-sectional areaLess investment in equipmentLarge containersConveyor partsEngineeringElectrical and Electronics engineering

The invention discloses a funnel device with the function of diverting and guiding materials, which comprises a funnel with an upper material inlet and two left and right symmetrical lower outlets, and a material guiding device located in the funnel for adjusting the flow direction of materials. In the funnel, there is a dividing plate between the two lower discharge ports; the material guide device is located below the feed port, one end of the material guide device is fixed in the funnel, and the material guide device can rotate around the fixed end to the The first station corresponding to the lower left outlet, the second station corresponding to the partition plate, and the third station corresponding to the lower right outlet. The funnel device uses the funnel and the material guide device to realize the combination of the three functions of diversion, material guide and storage and transportation, which increases the cross-sectional area of the material in the funnel, saves equipment investment, reduces the occupation of the factory building, and improves the space utilization rate of the factory building.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

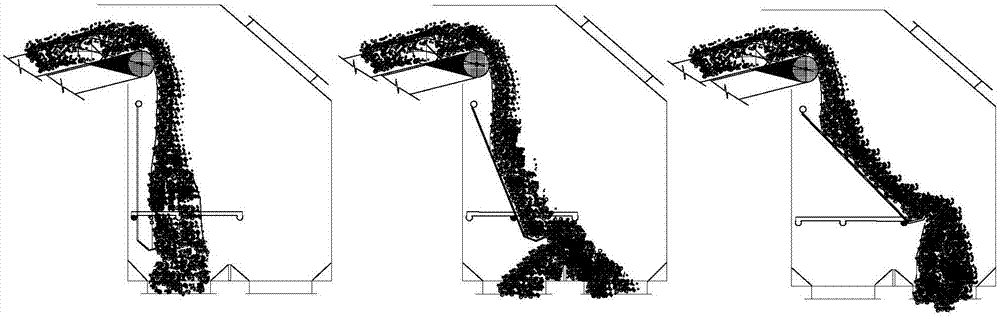

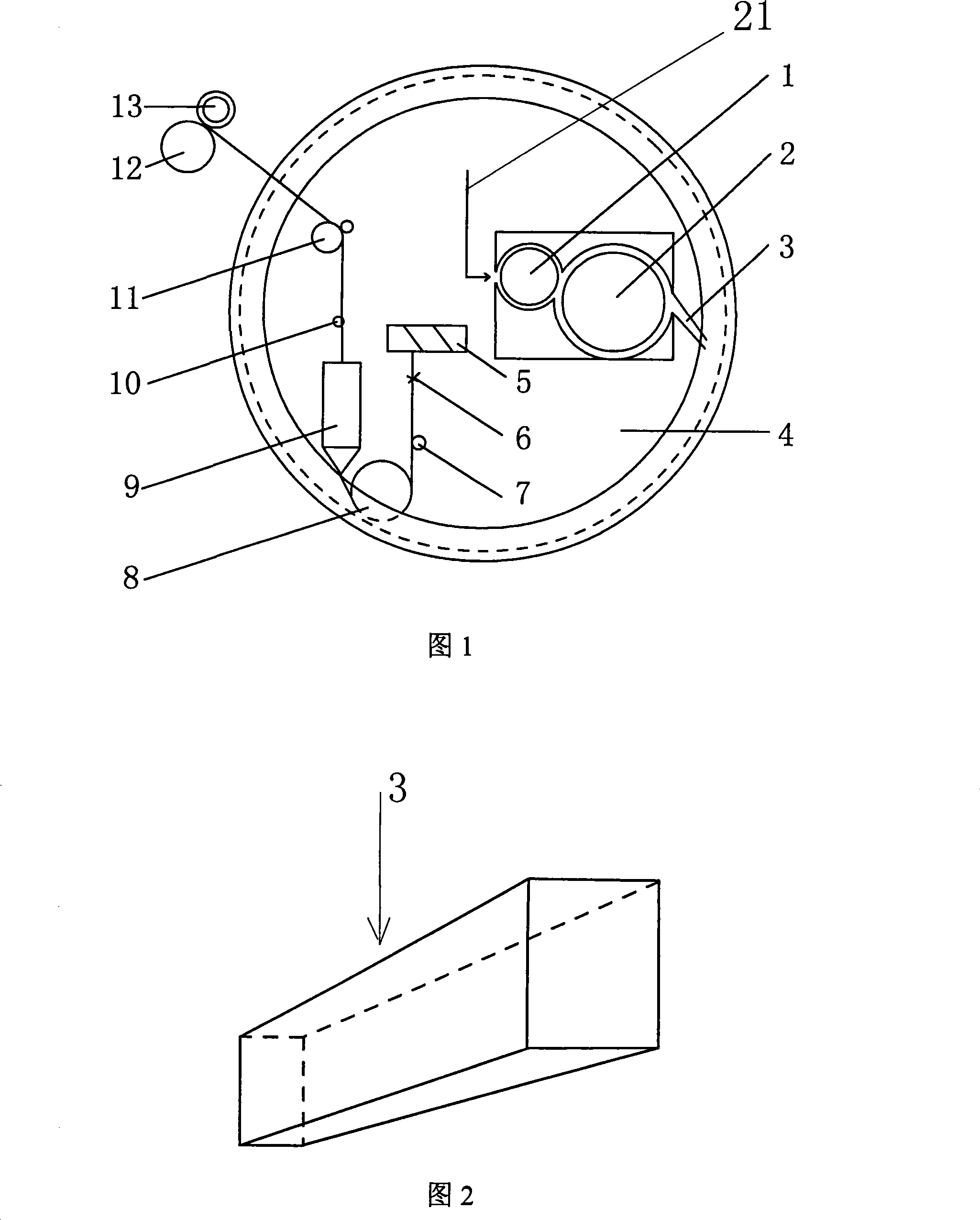

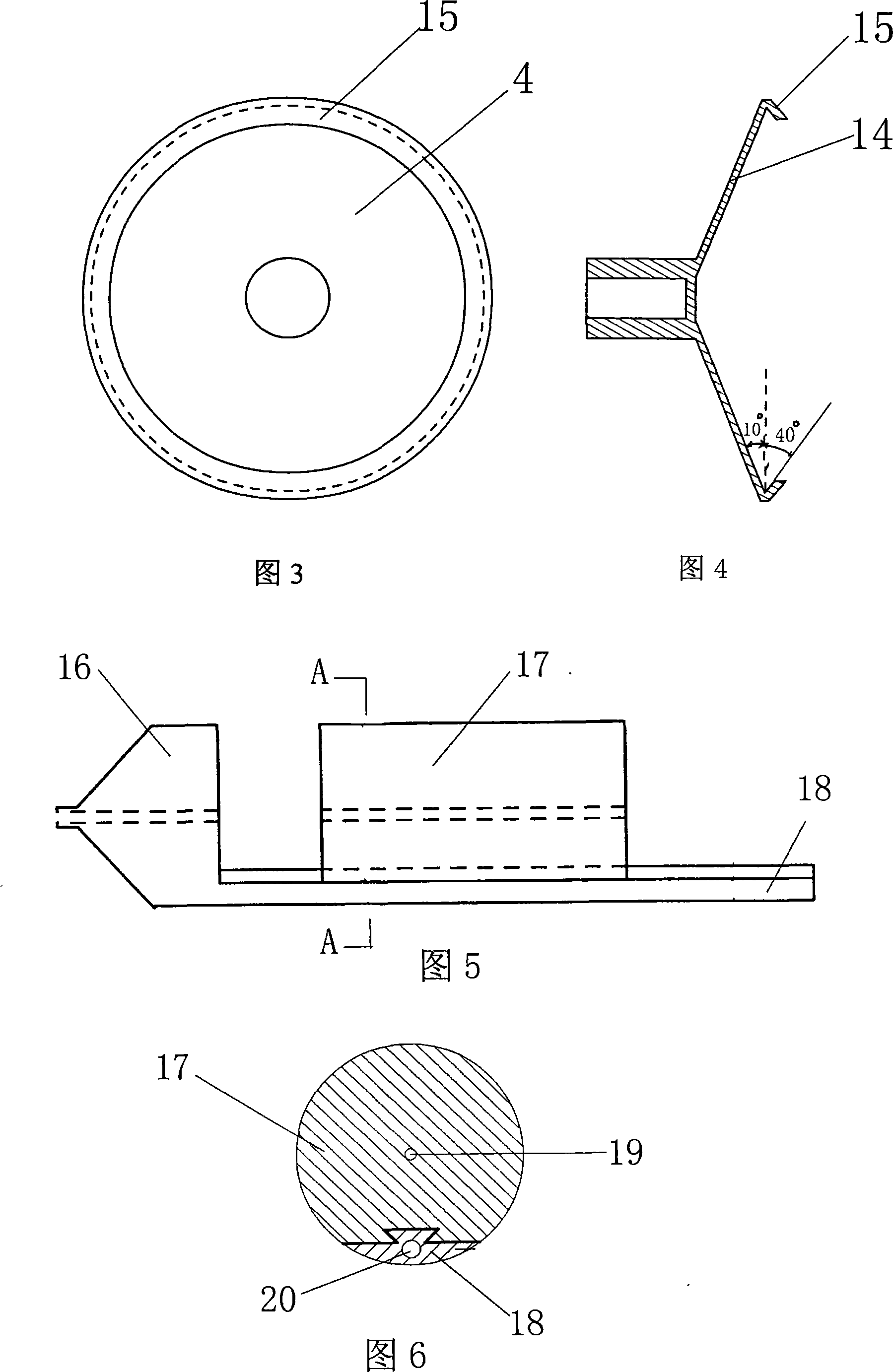

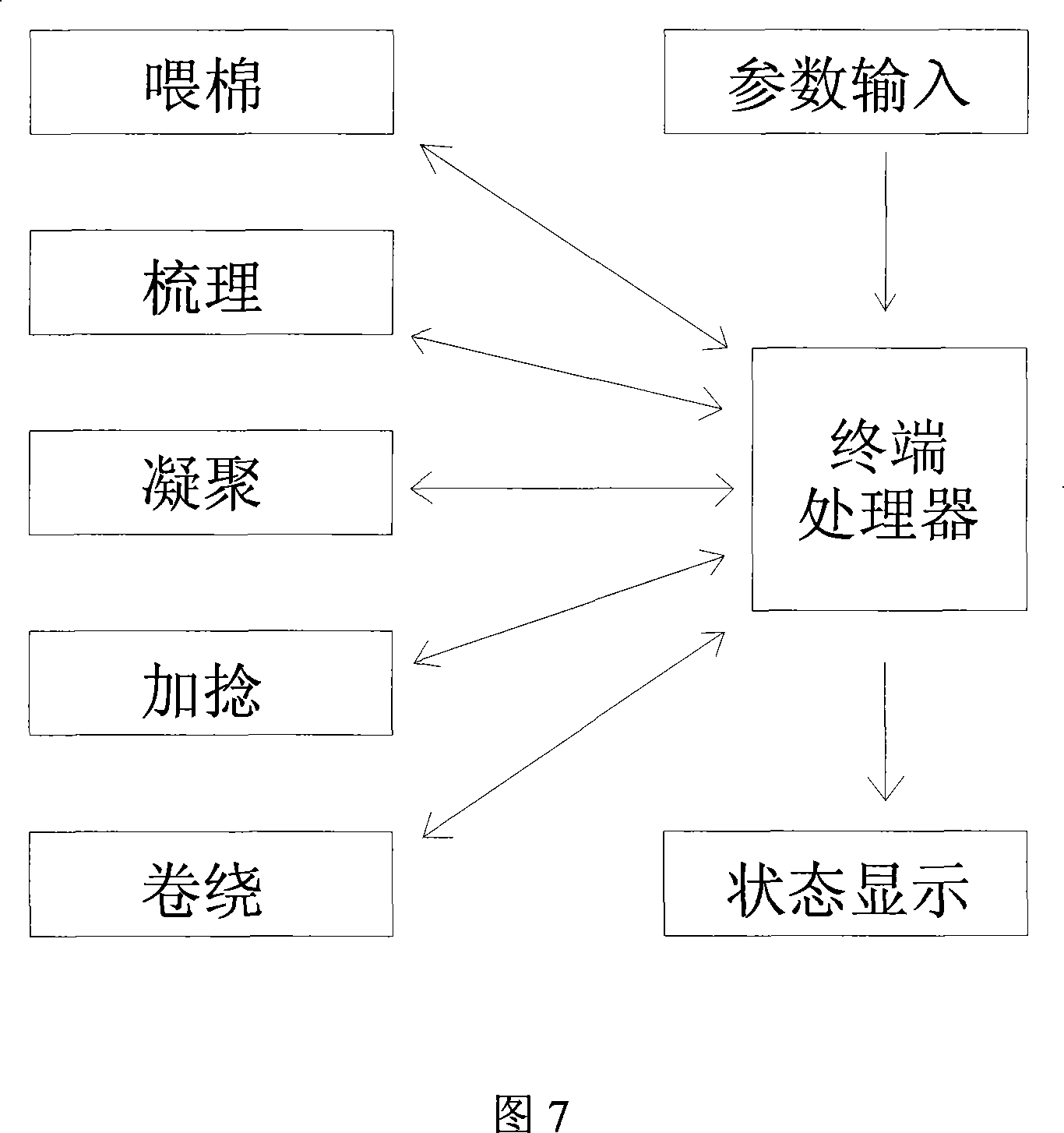

Vortex spinning machine

InactiveCN101158068AGive full play to twisting efficiencyReduce wear consumptionContinuous wound-up machinesOpen-end spinning machinesFiberYarn

The invention relates to a spinning machine, in particular to a swirling spinner. According to the technical proposal of the invention, a cotton feeder, a carding roller drafting mechanism, a gradual withdrawing fiber conveying mechanism, a closed fiber collecting device, a swirling stranding machine and a winding device are arranged in sequence along the direction of the movement of cotton slivers; a long wire frame, a tensile device, a wire guider and a pressing roller are arranged along the direction of the movement of long wires; cotton slivers led from a sliver can first go through the cotton feeder and the carding roller drafting mechanism and then enters the closed fiber collecting device through the gradual withdrawing fiber conveying mechanism for drafting, integrating and clustering to form fiber strip which is then sent to the swirling stranding machine along with the rotation of the closed fiber collecting device; and meanwhile, core wires led from the long wire frame are sent to the swirling stranding machine through the wire guider and the pressing roller after going through the tensile device. The swirling spinner spares easily worn spinning parts and employs air flow to act on fibers, which fully activates high efficiency of swirling stranding machine and thus improves spinning rate.

Owner:JIANGNAN UNIV

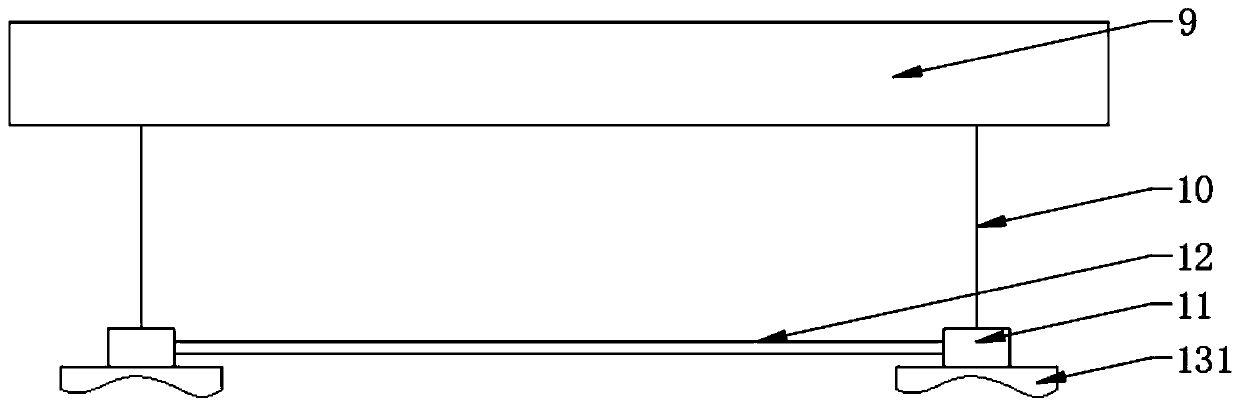

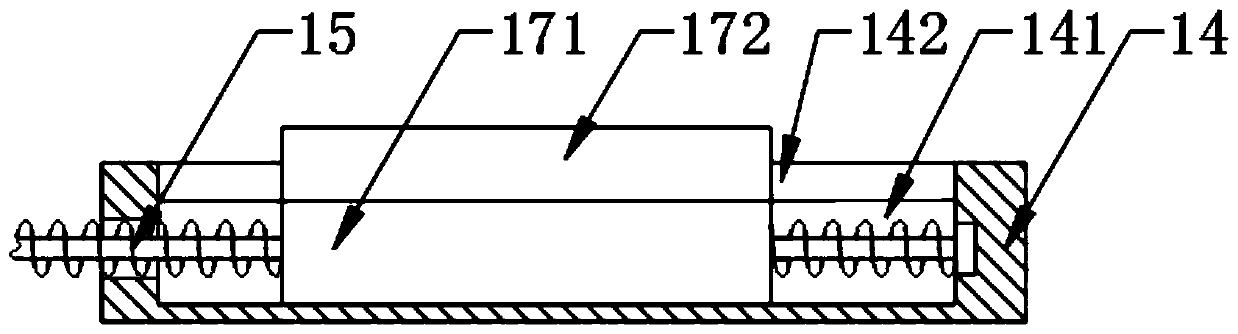

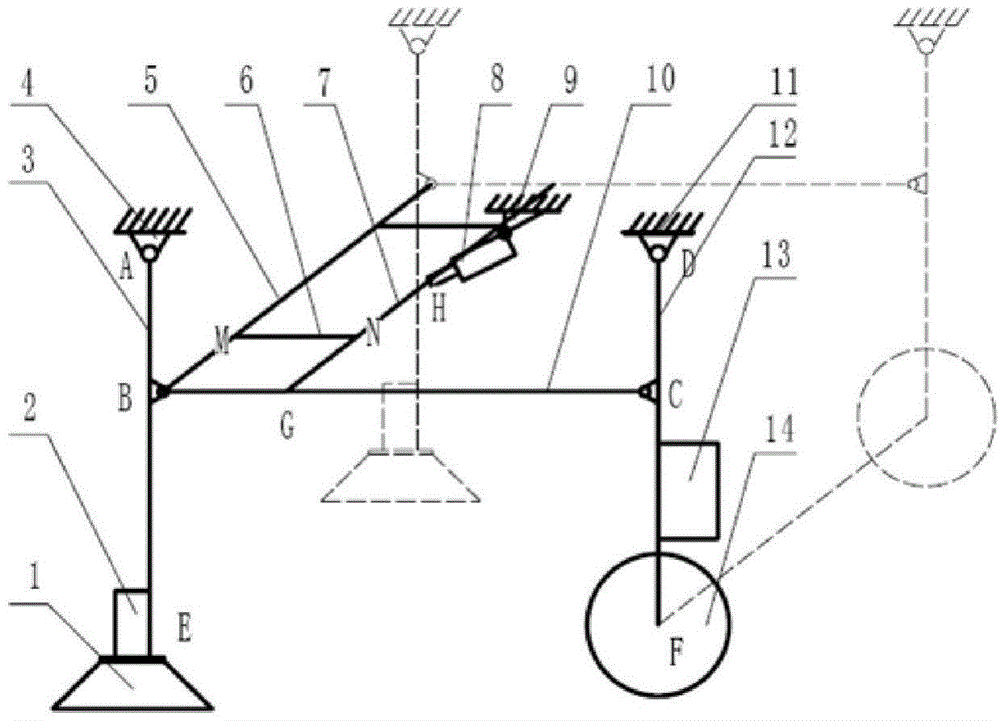

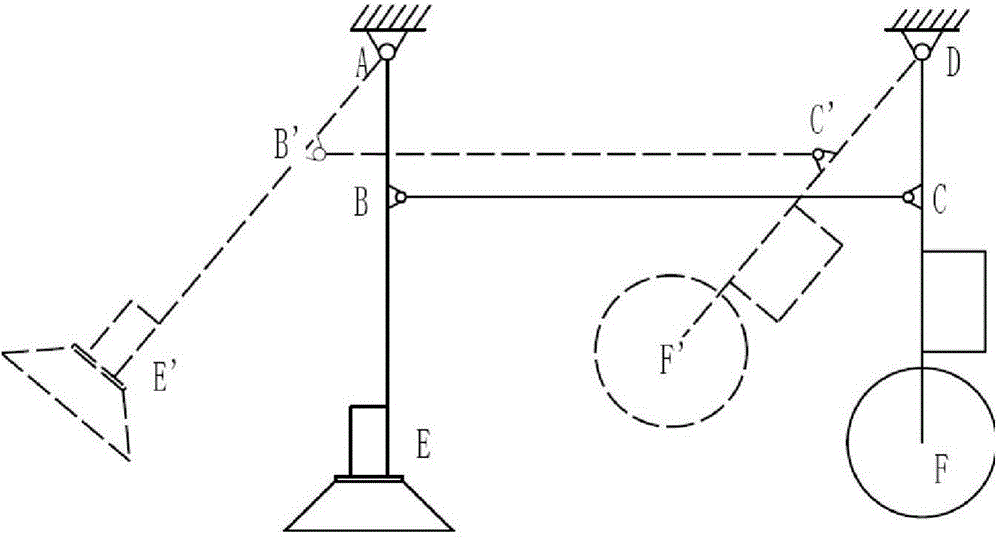

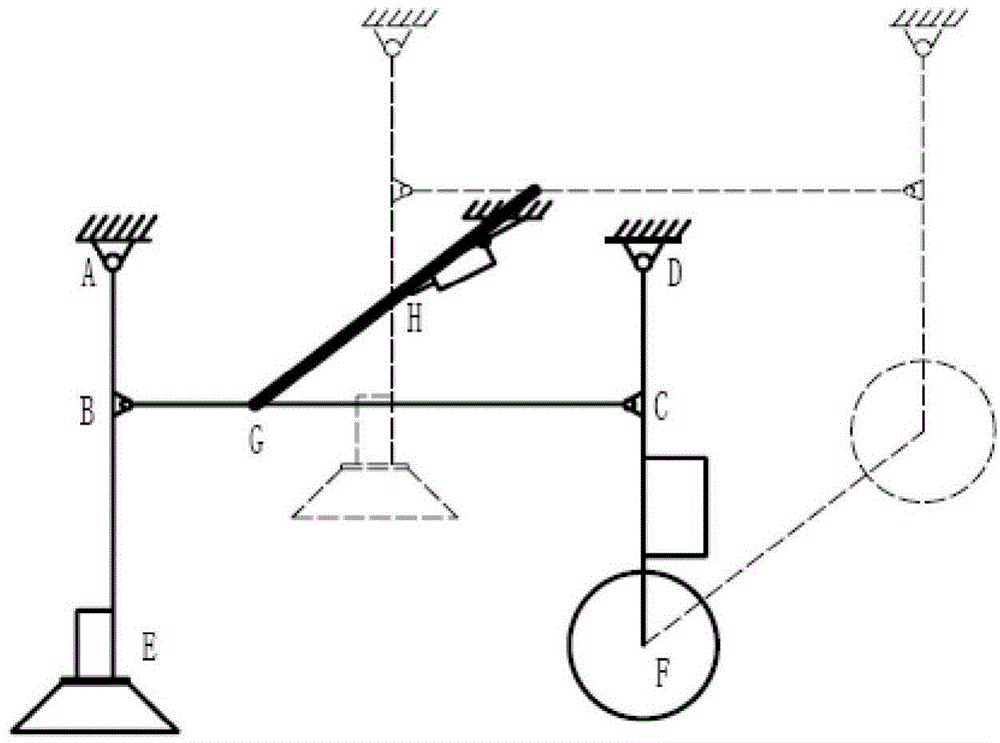

Linkage lifting mechanism for tray brushes and rolling brush of sweeper

The invention discloses a linkage lifting mechanism for tray brushes and a rolling brush of a sweeper. The lifting mechanism comprises a first quadrangular linkage mechanism, a second quadrangular linkage mechanism, a fixed support, an electric drive pusher (8), wherein the second quadrangular linkage mechanism is opposite to the first quadrangular linkage mechanism, and the fixed support is connected with the first quadrangular linkage mechanism and the second quadrangular linkage mechanism; the fixed support comprises a first cross beam (5) and a second cross beam (7) of the fixed support and a first fixed link or a second fixed link (6), wherein the first cross beam (5) and the second cross beam (7) are oppositely arranged and are respectively connected with the first quadrangular linkage mechanism and the second quadrangular linkage mechanism, and the first fixed link or the second fixed link (6) is connected with the first cross beam (5) and the second cross beam (7); one end of the electric drive pusher (8) is hinged with a sweeper frame (9), and the other end of the electric drive pusher (8) is hinged to the second cross beam (7) of the fixed support. According to the linkage lifting mechanism disclosed by the invention, misplacement can be prevented, and the sweeping effect is improved.

Owner:SOUTHEAST UNIV

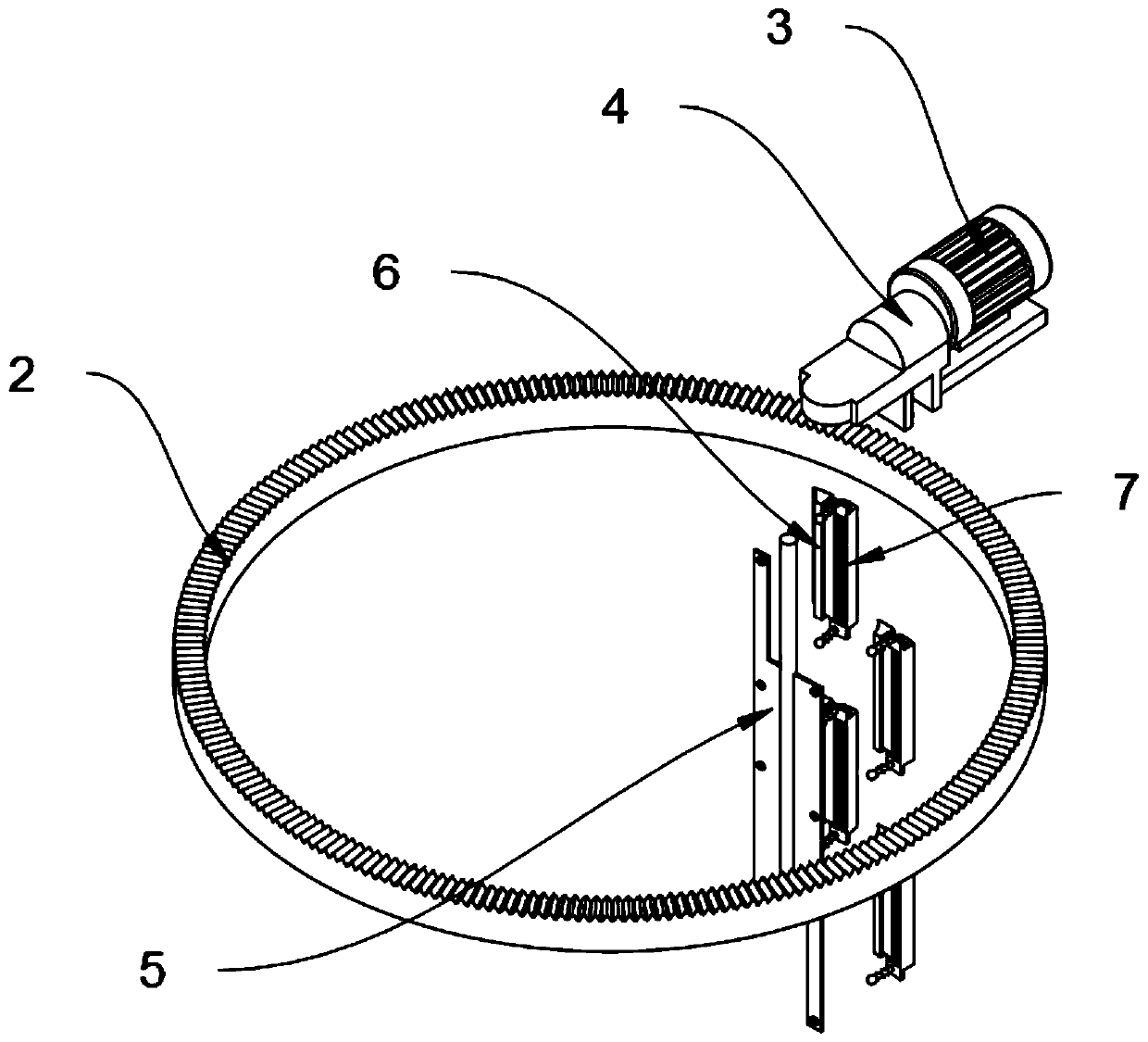

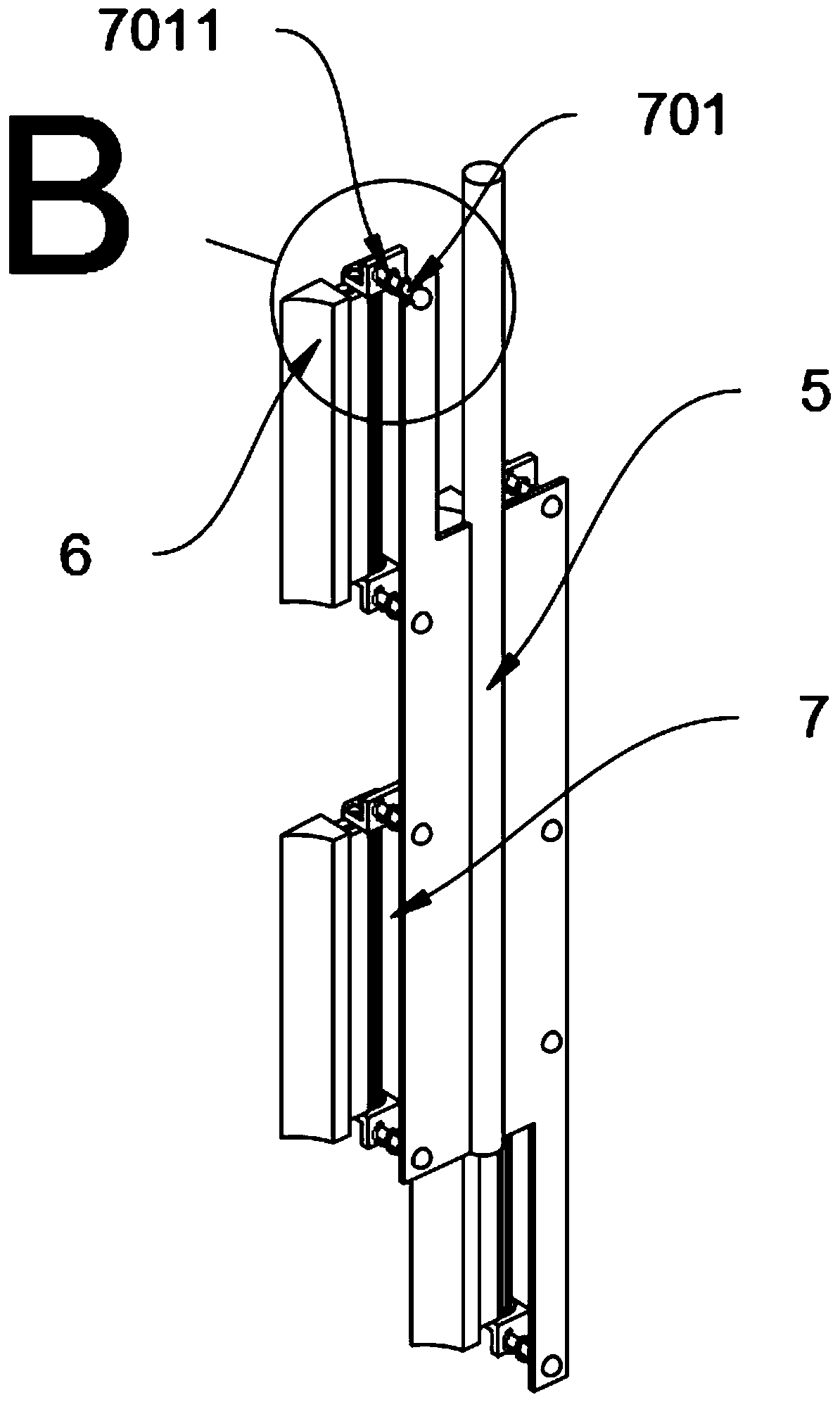

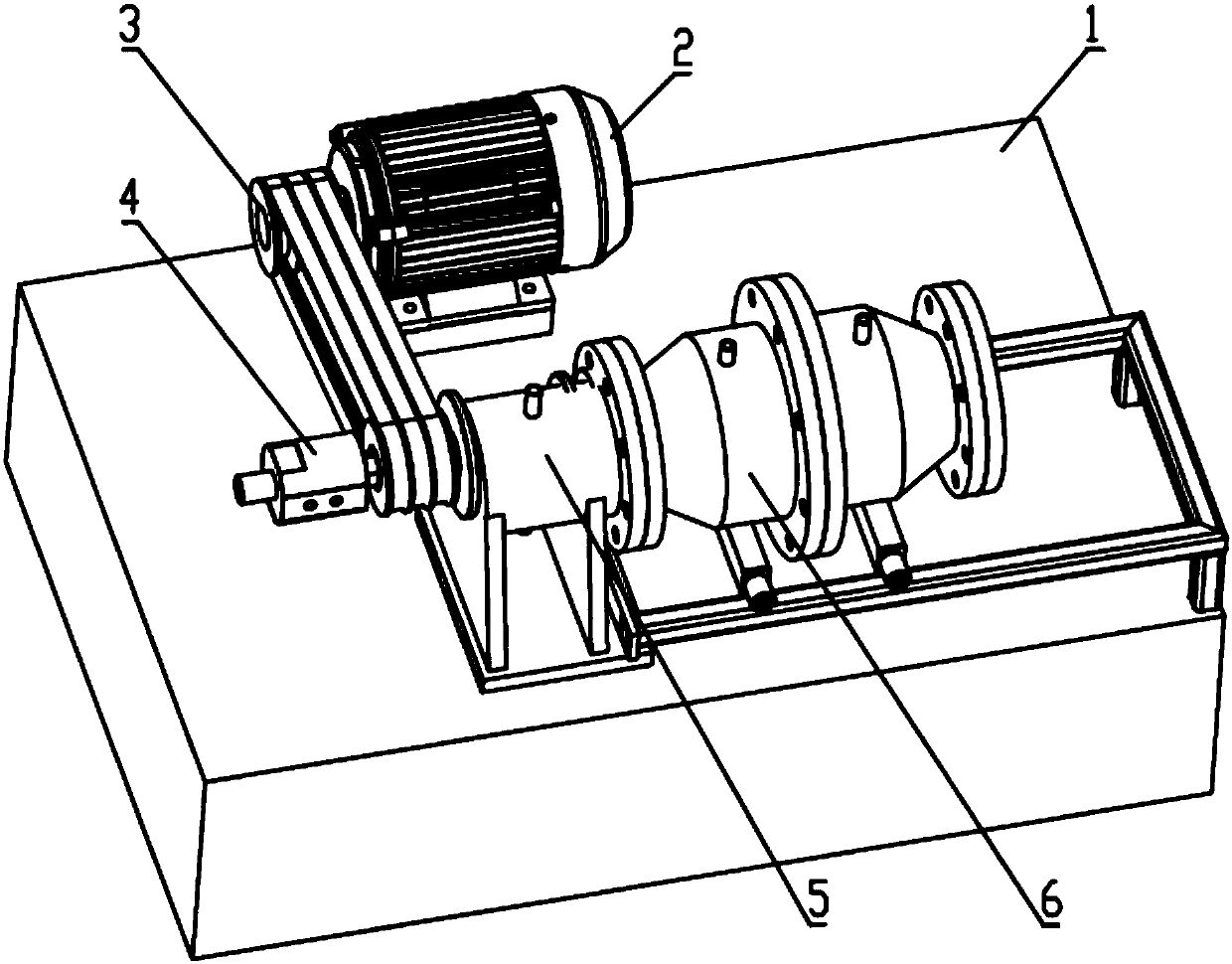

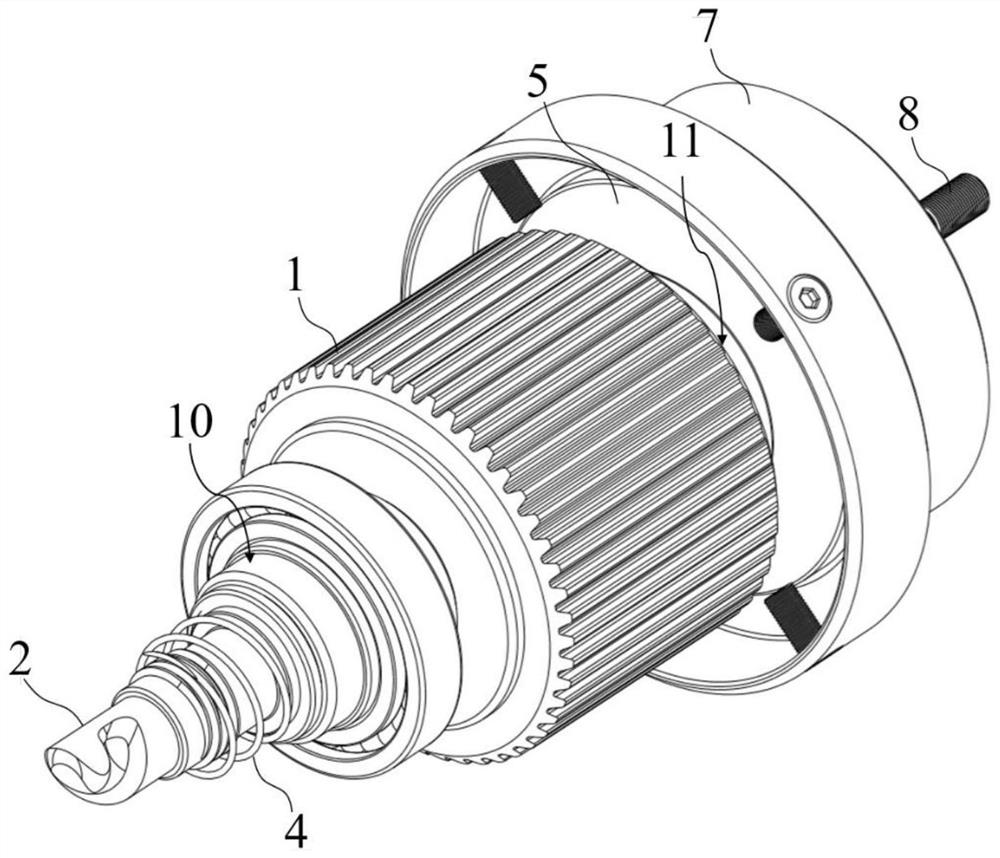

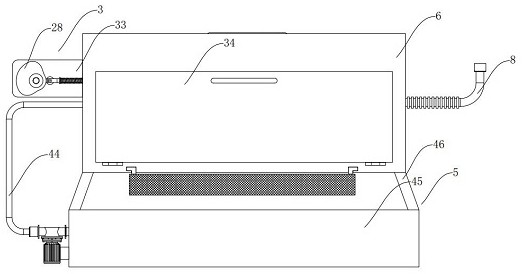

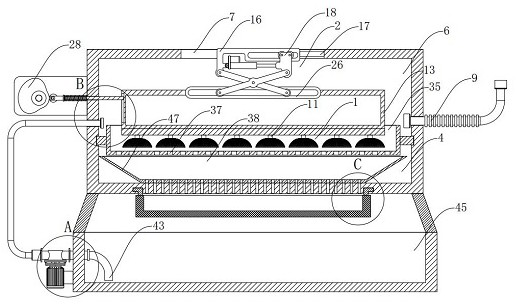

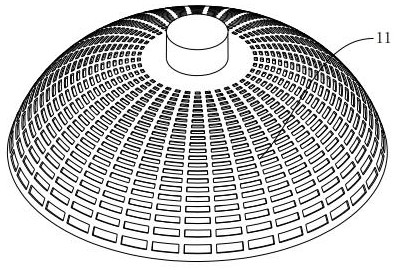

Rod pin type bifrustum-shaped sand mill device

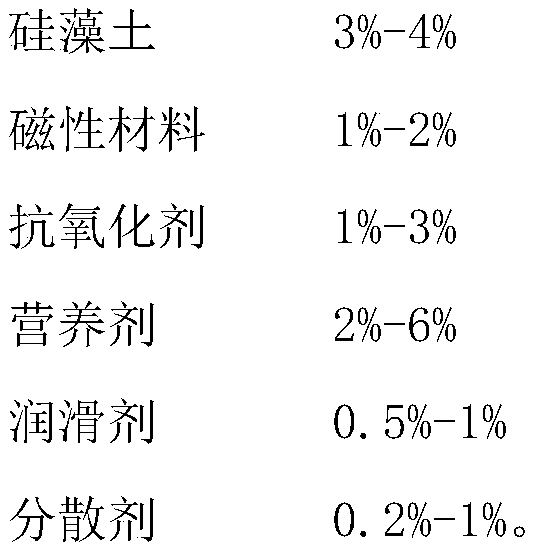

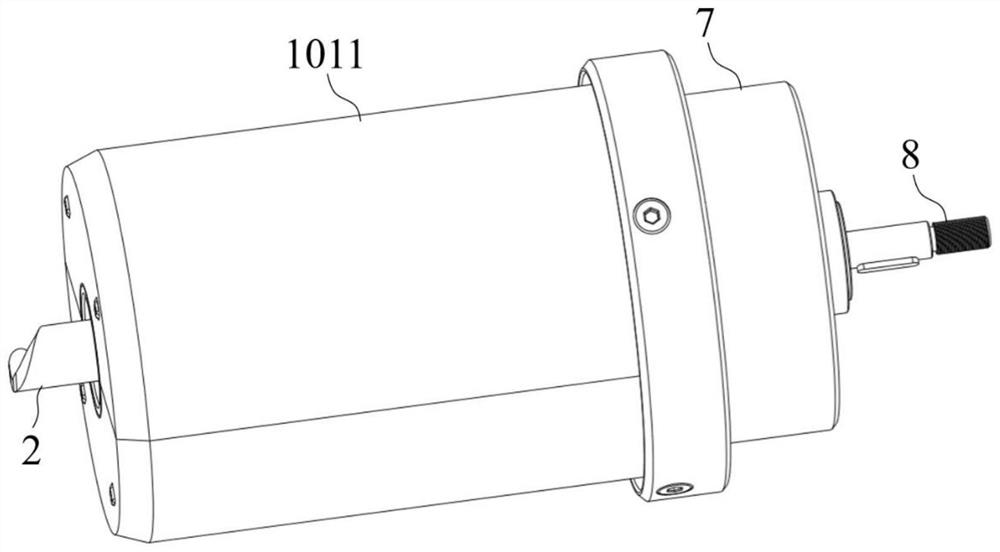

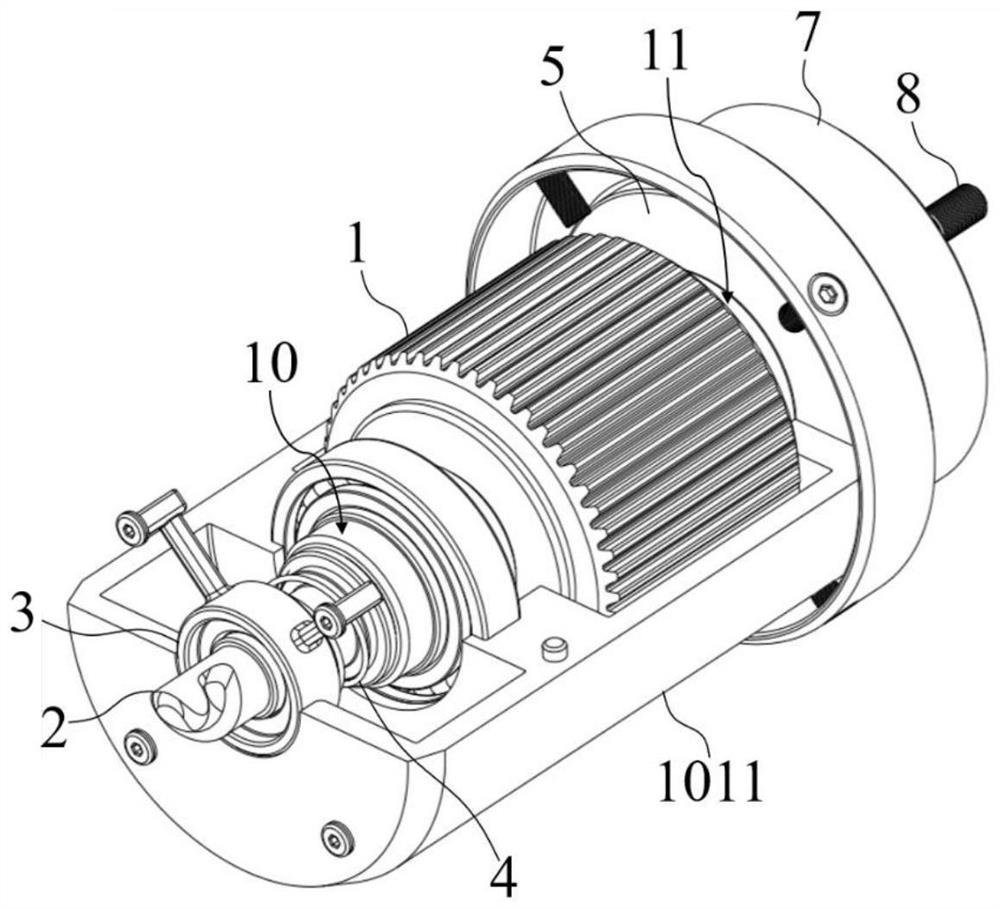

ActiveCN107626395ACompact structureReasonable structureGrain treatmentsSurface mountingElectric machinery

The invention relates to a rod pin type bifrustum-shaped sand mill device. The rod pin type bifrustum-shaped sand mill device comprises a rack, wherein a motor is arranged on the upper surface of therack; the output end of the motor is connected with a spindle component through a driving component; one end of the spindle component is supported by a bearing base component; a sand mill barrel bodycomponent is arranged at the outer end of the bearing base component through a sealing device; a stirrer connected with the spindle component is arranged inside the sand mill barrel body; rollers arearranged on two sides of the sand mill barrel body component; a guide rail bracket for the rollers to run is arranged on the upper surface of the rack. The rod pin type bifrustum-shaped sand mill device disclosed by the invention has the advantages of compact and reasonable structure and convenience in operation; a barrel body with a conical structure is adopted, and the inner part of the barrel body is matched with the pin rod type stirrer for grinding materials, so that good milling effect and high working efficiency are realized.

Owner:WUXI HOPE LIGHT IND EQUIP TECH

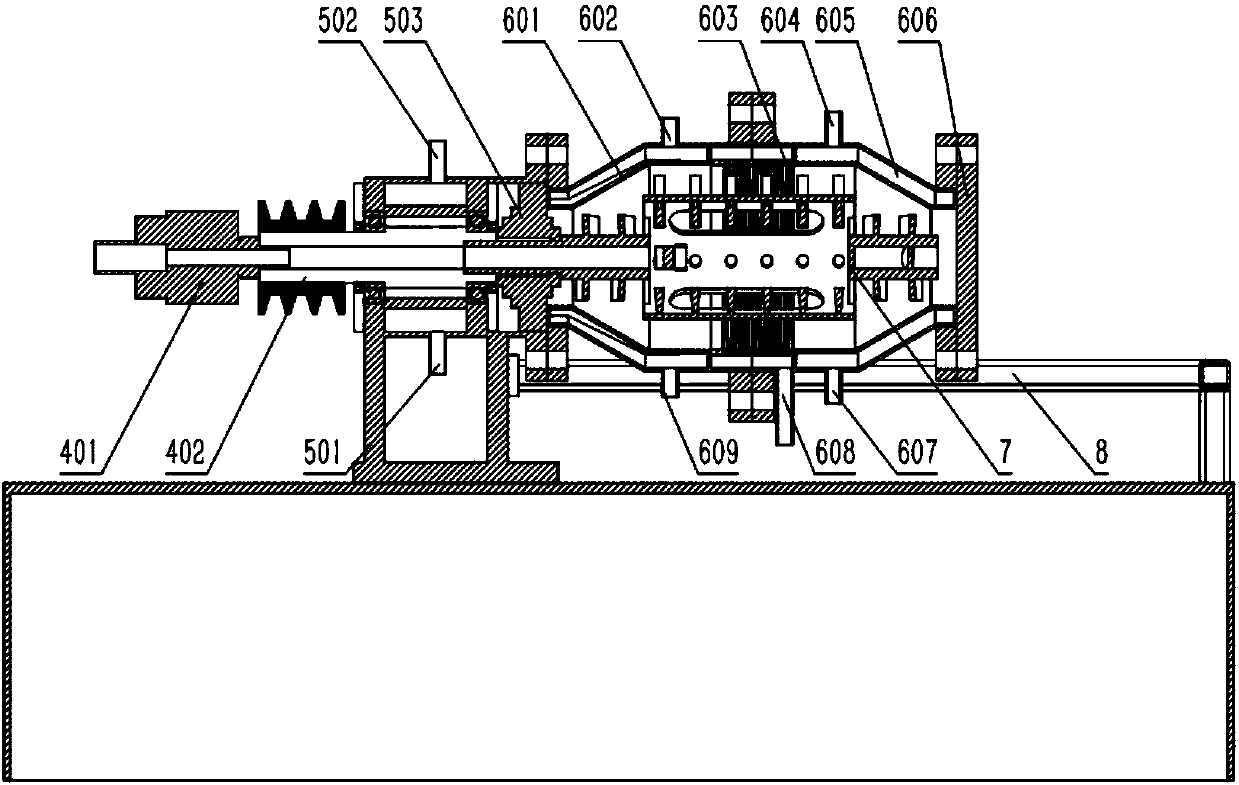

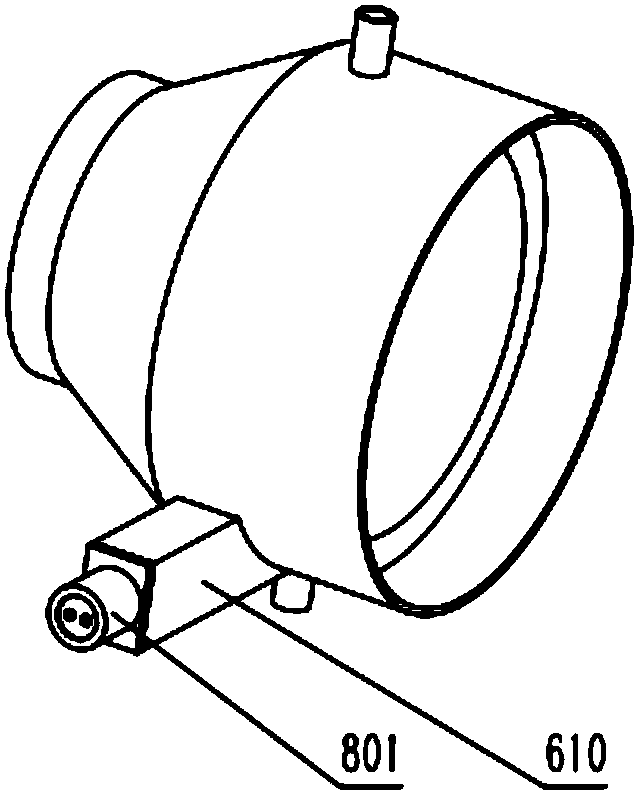

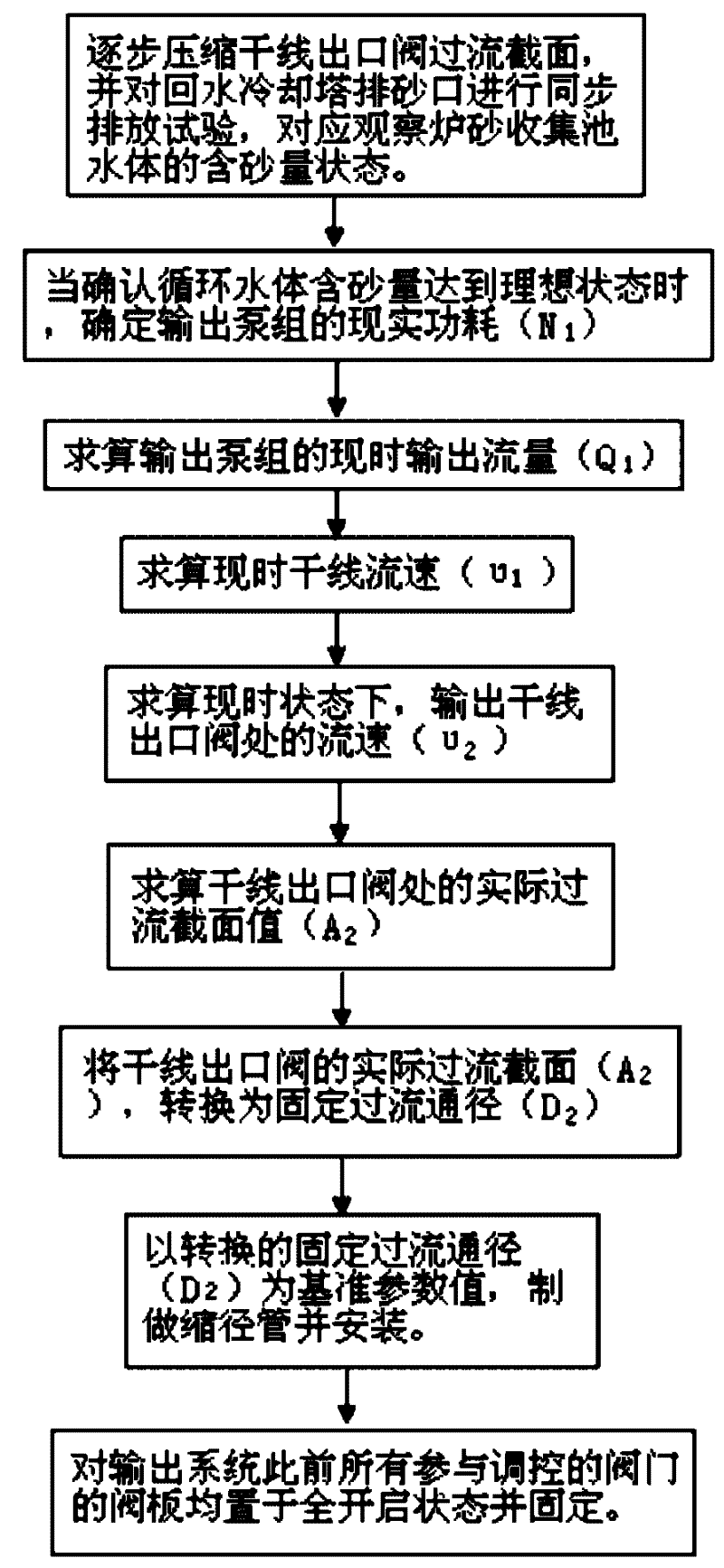

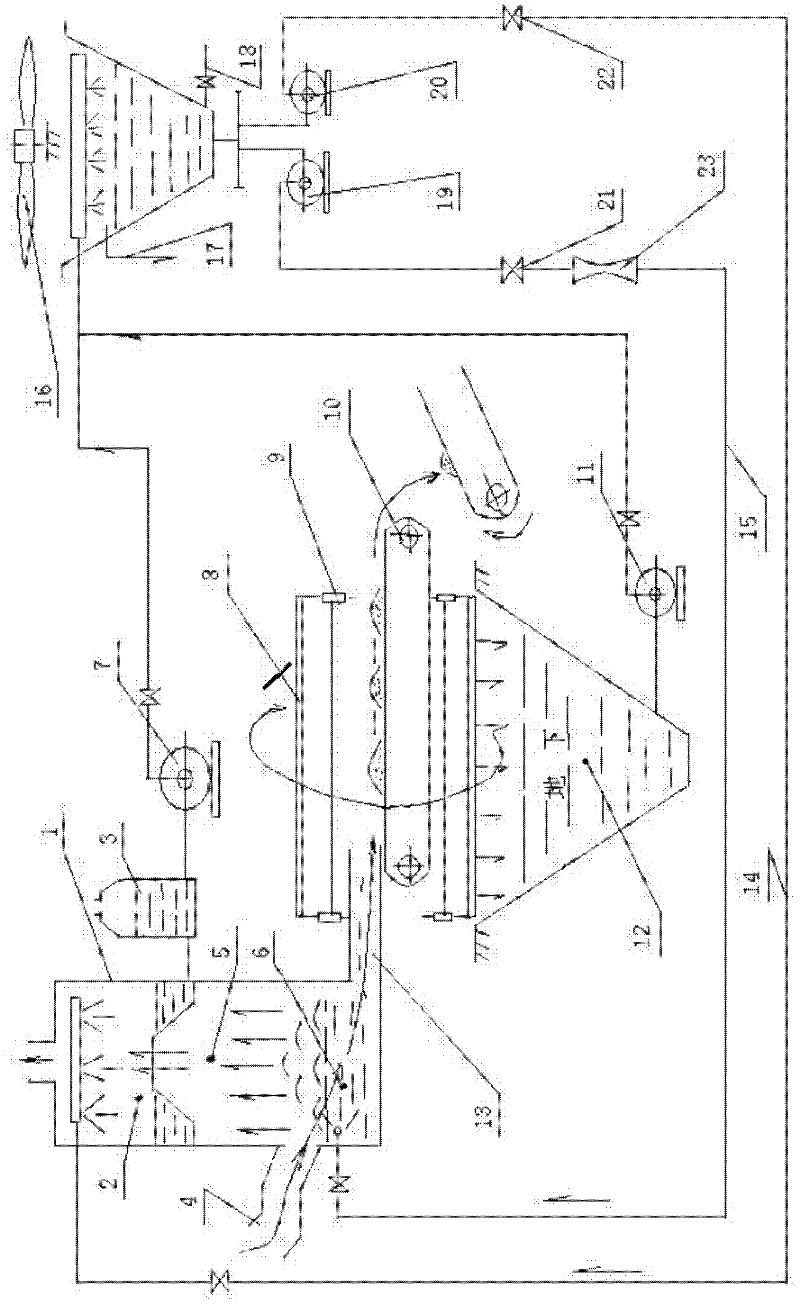

Method for controlling sand content of water body of blast furnace INBA circulating system and flow-limiting device thereof

InactiveCN102230037AEliminate cloggingReduce the cost of slaggingProcess efficiency improvementBlast furnace smeltingForming processes

The invention relates to the technical field of blast-furnace smelting and slag-forming process and discloses a method for controlling the sand content of a water body of a blast furnace INBA circulating system, which can control the shape and size of furnace sand particles by controlling the fluid dynamic energy in the granulating and slag-forming procedure. By the means of controlling the slag-forming water supply energy in the water supply link and the mode of controlling the shape and size of the formed slag from the beginnings of the slag-forming process to effectively capture the formed slag, the sand content of the water body of the INBA circulating system is controlled, so as to achieve the purpose of eliminating the blockage of furnace sand in the circulating system, preventing the wear damage of equipment and reducing the blast furnace slag-forming cost. The method works reliably, has obvious effects and is easy to promote and apply.

Owner:武汉钢铁有限公司

Pipe cutting device

The invention discloses a pipe cutting device. The pipe cutting device comprises an upper machining base and a lower machining base, wherein the lower machining base is provided with a cutting module with a first through hole, a first inner support pipe with magnetism, and a magnetic body for adjusting axial position of the first inner support pipe; the upper machining base is provided with a punch bonded with the cutting module and provided with a second through hole, and an elastic ejector rod for pushing a second inner support pipe; and during cutting, the first inner support pipe and the second inner support pipe are respectively positioned on two sides of a cutting port. During cutting by the pipe cutting device, as the inner support pipes are arranged in a pipe, and the two inner support pipes are respectively positioned on two sides of the cutting port, when the punch downwards moves to cut off the pipe, the deformation of the cutting port of the pipe is lower, and the yield of the pipe is improved; and when the punch is acted on the pipe, the pipe is cut off mainly through shearing force, so that the pipe material wear and loss can be reduced, and the pipe material utilization rate is increased.

Owner:易捷通电子有限公司

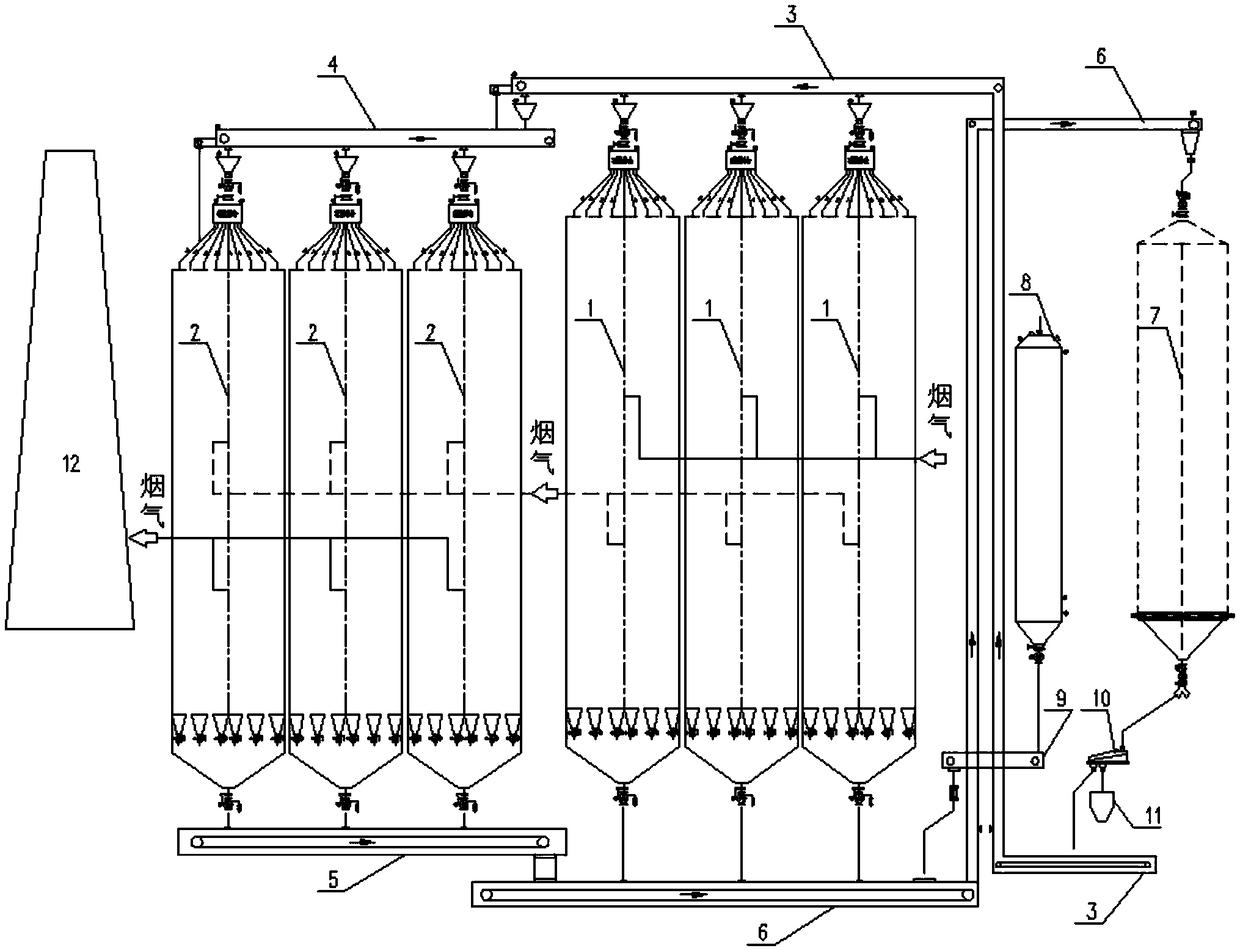

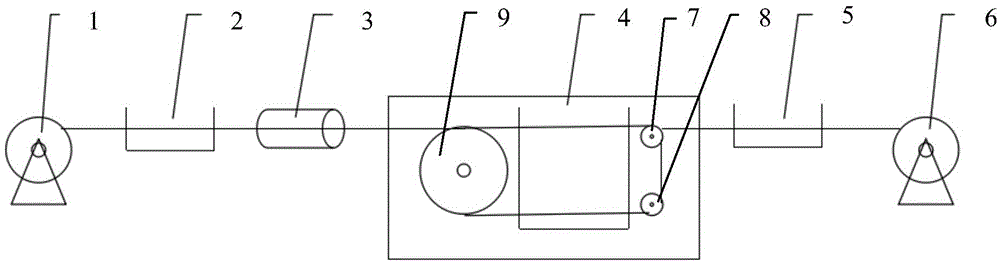

Desulfurization and denitrification active coke asynchronous circulation flue gas purification device and method

PendingCN109433012AReduce wear consumptionFull flue gas responseDispersed particle separationIndustrial wasteExhaust fumes

The invention belongs to the technical field of industrial waste gas treatment and in particular provides a desulfurization and denitrification active coke asynchronous circulation flue gas purification device and method. Active coke is fed into a desulfurization unit and a denitrification unit through conveyer belts respectively, the active coke after desulfurization and denitrification is directly fed into a regeneration device, and thus the active coke can be circulated and recycled. The active coke in the desulfurization and denitrification process is circulated relatively independently, so that desulfurization and denitrification active coke circulation velocities are different, the circulation velocity of active coke of a denitrification device can be reduced according to situations,namely, the circulation amounts of active coke fed into the denitrification unit and the desulfurization unit can be respectively and independently adjusted according to practical demands, and thus the abrasion loss of the active coke can be reduced; in addition, the desulfurization unit comprises a plurality of desulfurization cabins, the denitrification unit comprises a plurality of denitrification cabins, the plurality of cabins in different units can be connected in parallel or connected in series, and thus flue gases can be reacted more sufficiently.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

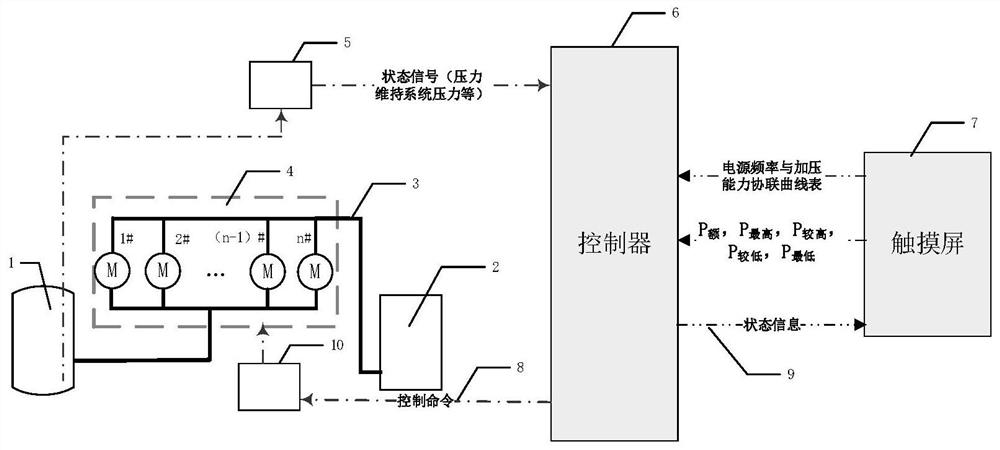

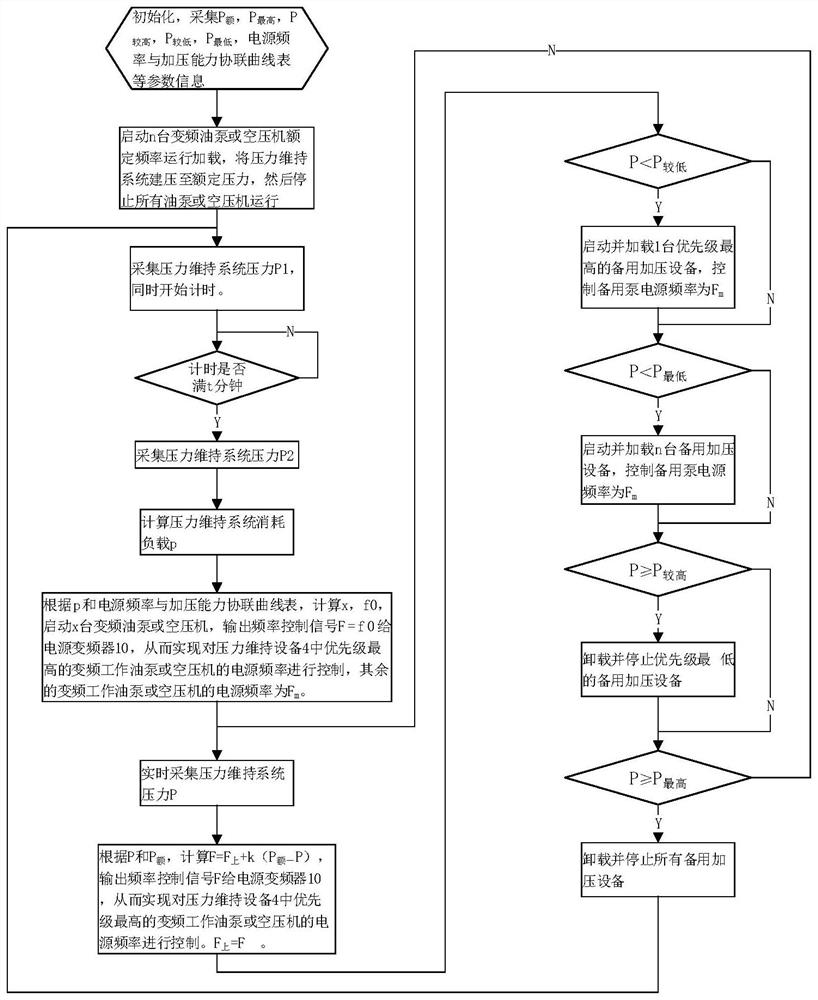

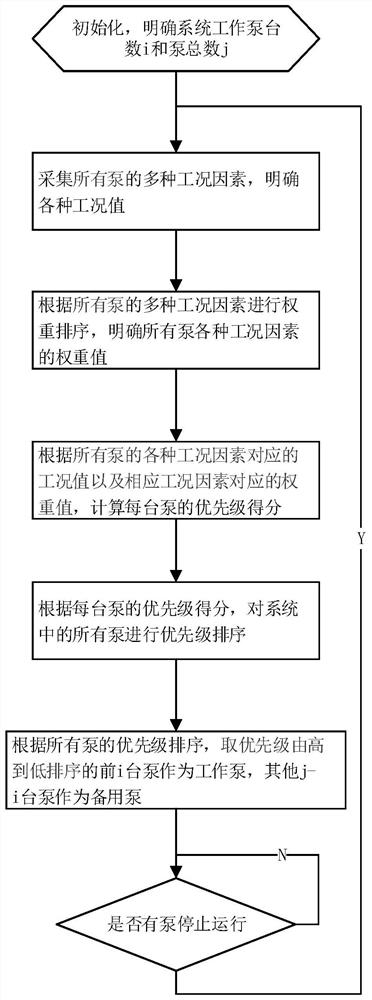

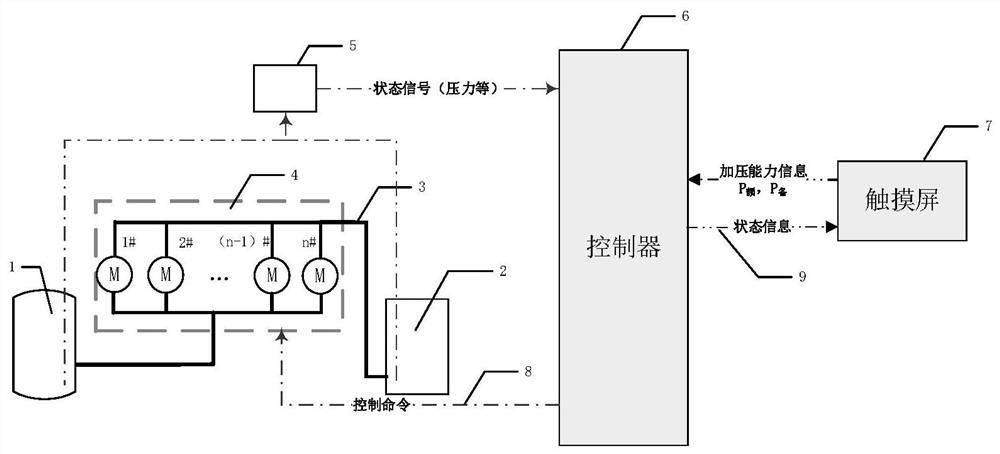

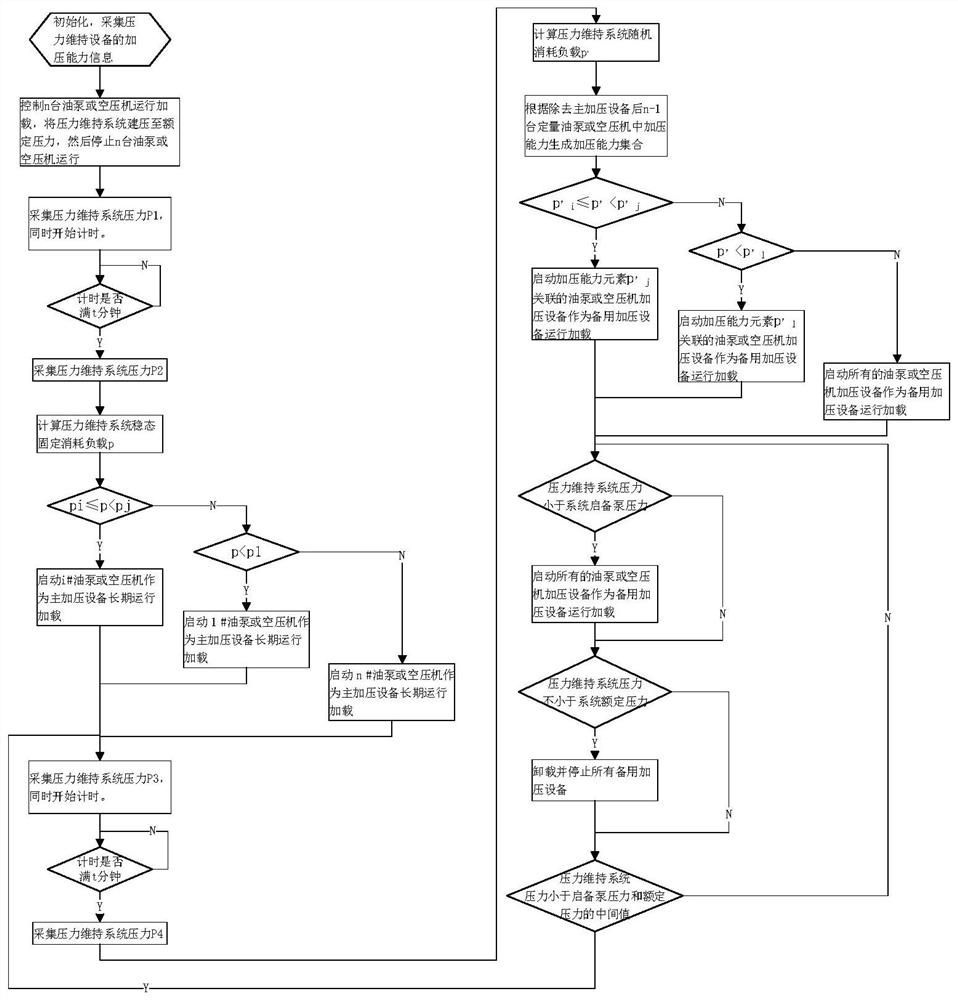

Pressure maintaining system adopting variable-frequency pressure maintaining equipment and self-adaptive control method

ActiveCN112783224AExtend your lifeReduce wear consumptionFluid pressure control using electric meansInteraction deviceMaintaining equipment

The invention discloses a pressure maintaining system adopting variable-frequency pressure maintaining equipment and a self-adaptive control method. The system comprises a pressure container, a non-pressure container and pressure maintaining equipment; and the pressure container is connected with the non-pressure container through pressure maintaining equipment. The pressure container is provided with a sensor. The sensor and the pressure maintaining equipment are both connected with a controller, and the controller is connected with a man-machine interaction device. The invention aims to solve problems that the consumption load is not matched with the output power of the pressure maintaining equipment, the pressure maintaining equipment is frequently started, stopped or loaded and unloaded, the abrasion consumption of equipment original parts is aggravated, the service life of the pressure maintaining equipment is influenced, energy loss is caused, and the system energy efficiency and economy are influenced.

Owner:CHINA YANGTZE POWER

Self-adaptive control method of pressure maintaining system

ActiveCN112731982AWide adaptabilityAvoid loading and unloadingFluid pressure control using electric meansControl systemSystem pressure

The invention relates to a self-adaptive control method of a pressure maintaining system, the related control system comprises a plurality of fixed-frequency oil pumps or air compressors with different models and specifications as pressure maintaining equipment, the system also comprises a pressure container and a non-pressure container, and the pressure container is connected with the non-pressure container through the pressure maintaining equipment. The pressure container is provided with a first sensor, and the non-pressure container is provided with a second sensor. The first sensor, the second sensor and the pressure maintaining device are connected with the controller, and the controller is connected with a man-machine interaction device. According to the invention, the problem that the random consumption load with a long change period of the pressure maintaining system is not matched with the output power of the pressure maintaining equipment, that is, the pressure maintaining equipment is frequently started, stopped or loaded and unloaded due to the fact that the speed of random consumption reduction with a long change period of the system pressure is not matched with the pressurizing capacity of the pressure maintaining equipment, then abrasion consumption of original parts of equipment is increased, the service life of pressure maintaining equipment is affected, energy loss is caused, and system energy efficiency and economy are affected can be solved.

Owner:CHINA YANGTZE POWER

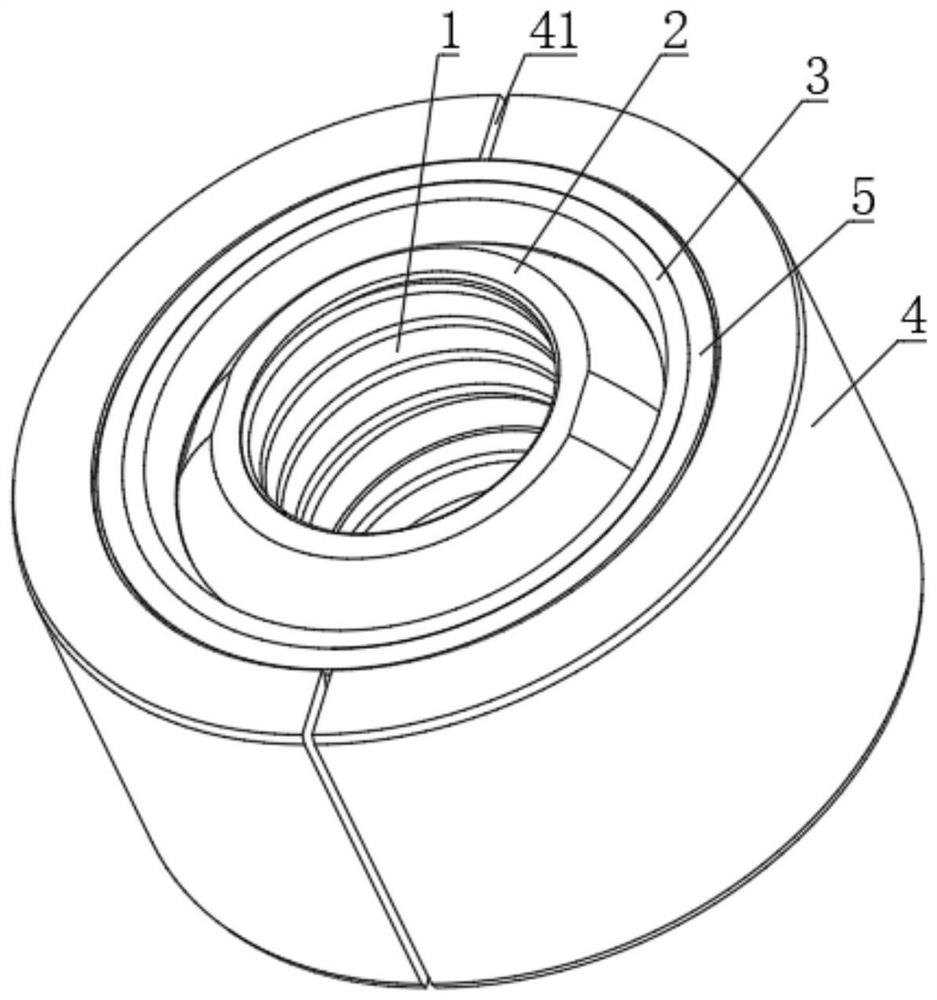

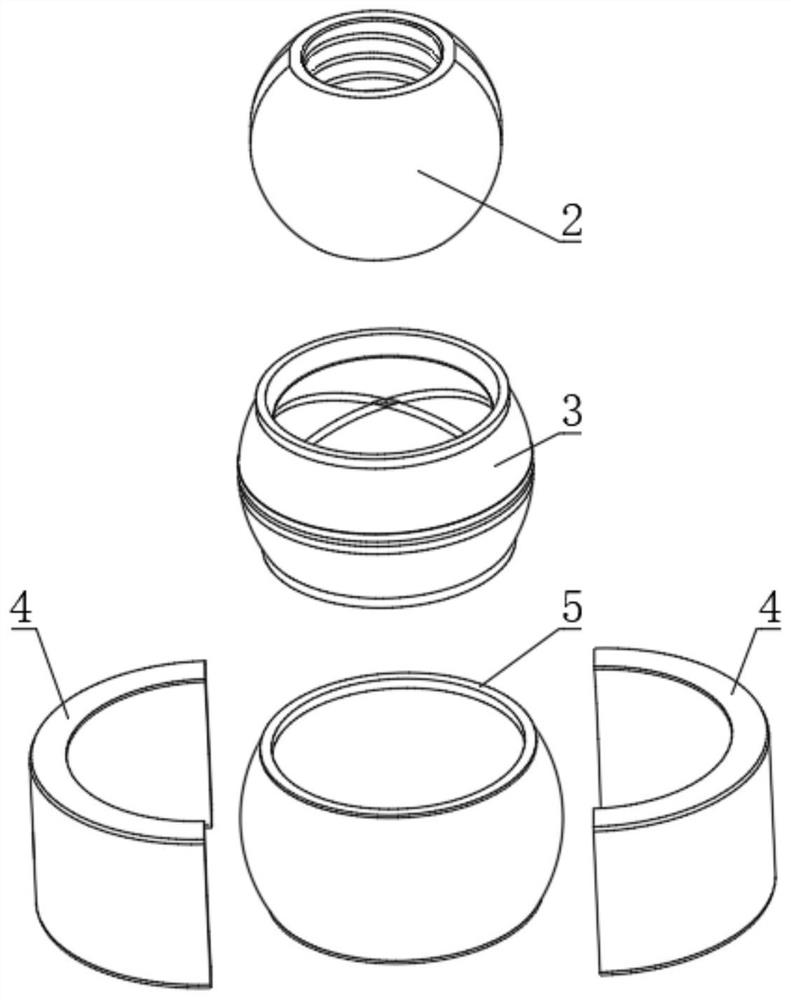

Rigidity-adjustable ball joint and thrust rod assembly

PendingCN112879417AExtended service lifePrevent extrusionPivotal connectionsPivoted suspension armsSuspension (vehicle)Ball joint

The invention discloses a rigidity-adjustable ball joint and thrust rod assembly, and belongs to the technical field of automobile suspension systems. The assembly comprises a thrust rod bracket, a pin shaft, a thrust rod, a ball body, a bearing outer ring and rigidity adjusting sleeves, wherein the ball body is in sliding universal connection with the bearing outer ring; the bearing outer ring is connected with the rigidity adjusting sleeves through an elastic layer; adjusting gaps are formed by the corresponding end faces of the rigidity adjusting sleeves on the two sides; the thrust rod and the rigidity adjusting sleeves are fixedly mounted; and the pin shaft is inserted into a mounting shaft hole and is connected with the thrust rod bracket. Free universal rotation of the thrust rod assembly is achieved through a ball joint, torsion stress of the elastic layer is released, and the elastic layer is only subjected to pressure load; the elastic layer achieves the buffering function of the thrust rod assembly, and the impact load in the force transmission process of the thrust rod is reduced; and the rigidity adjusting sleeves are provided with the adjusting gap, so that rigidity adjustment of the thrust rod assembly is achieved, the reliability of the thrust rod assembly is improved, the service life is prolonged, meanwhile, flexible connection of a suspension system and an axle assembly is achieved, and the comfort of a whole vehicle is improved.

Owner:SINO TRUK JINAN POWER

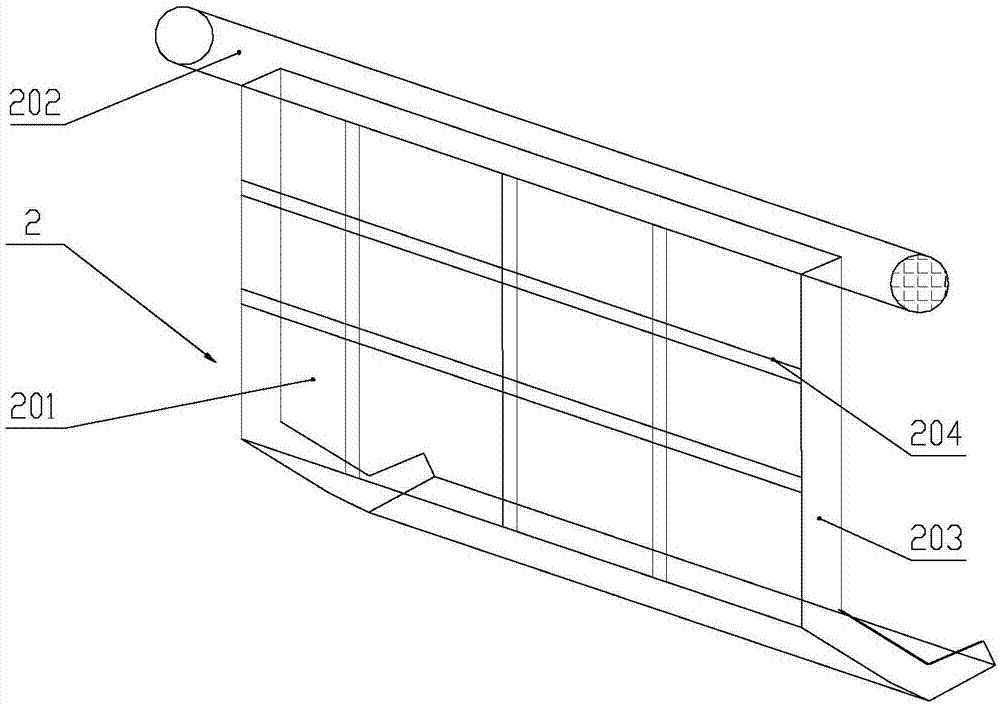

Plating tank, diamond fretsaw manufacturing device and manufacturing method thereof

The invention discloses a plating tank used for diamond fretsaw manufacturing. The plating tank comprises a wire guide roller fixing frame, a tank body, a first wire guide roller, a second wire guide roller and a third wire guide roller, wherein the first wire guide roller, the second wire guide roller and the third wire guide roller are all rotatably arranged on the wire guide roller fixing frame and are arranged in an aligned mode, the diameter of the first wire guide roller and the diameter of the second wire guide roller are smaller than that of the third wire guide roller, the first wire guide roller and the second wire guide roller are arranged in an up-and-down mode, the axis of the first wire guide roller and the axis of the second wire guide roller are located on a same perpendicular line, the tank body used for conducting plating is arranged between the third wire guide roller and the first wire guide roller and the second wire guide roller, the top of the third wire guide roller is flush with that of the first wire guide roller, and the bottom of the third wire guide roller is flush with that of the second wire guide roller. The invention further discloses a diamond fretsaw manufacturing device adopting the plating tank and a diamond fretsaw manufacturing method.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

Modified attapulgite flue gas desulfurization agent and preparation and application thereof

InactiveCN102029141AImprove adsorption capacityHigh selectivityOther chemical processesDispersed particle separationClay mineralsFlue gas

The invention discloses a modified attapulgite flue gas desulfurization agent and preparation and application thereof. The flue gas desulfurization agent is attapulgite activated by thermal treatment. A preparation method comprises the following steps: extruding attapulgite clay with double rollers; drying and crushing to obtain powder the particle size of which is 200 meshes; adding distilled water into the powder, and stirring to obtain suspension; centrifuging and drying to obtain an attapulgite sample; crushing, then screening the attapulgite sample and adding the obtained product in a fixed bed reactor; performing thermal treatment in nitrogen atmosphere to obtain the desulfurization agent with sulfur capacity of 252-2,331 mg of SO2 / 100 g; adding the desulfurization agent in the fixed bed reactor, wherein the reaction temperature is controlled between 50 and 200 DEG C; and introducing normal-pressure flue gas, wherein the air speed is 4,128.3 h<-1>. In the invention, the attapulgite used is clay ore, which swells in water and is easy to form when dried; and after proper thermal treatment, the shape is kept unchanged; moreover, the attapulgite has relatively high mechanical strength and can relatively remarkably reduce the abrasion loss.

Owner:HEFEI UNIV OF TECH

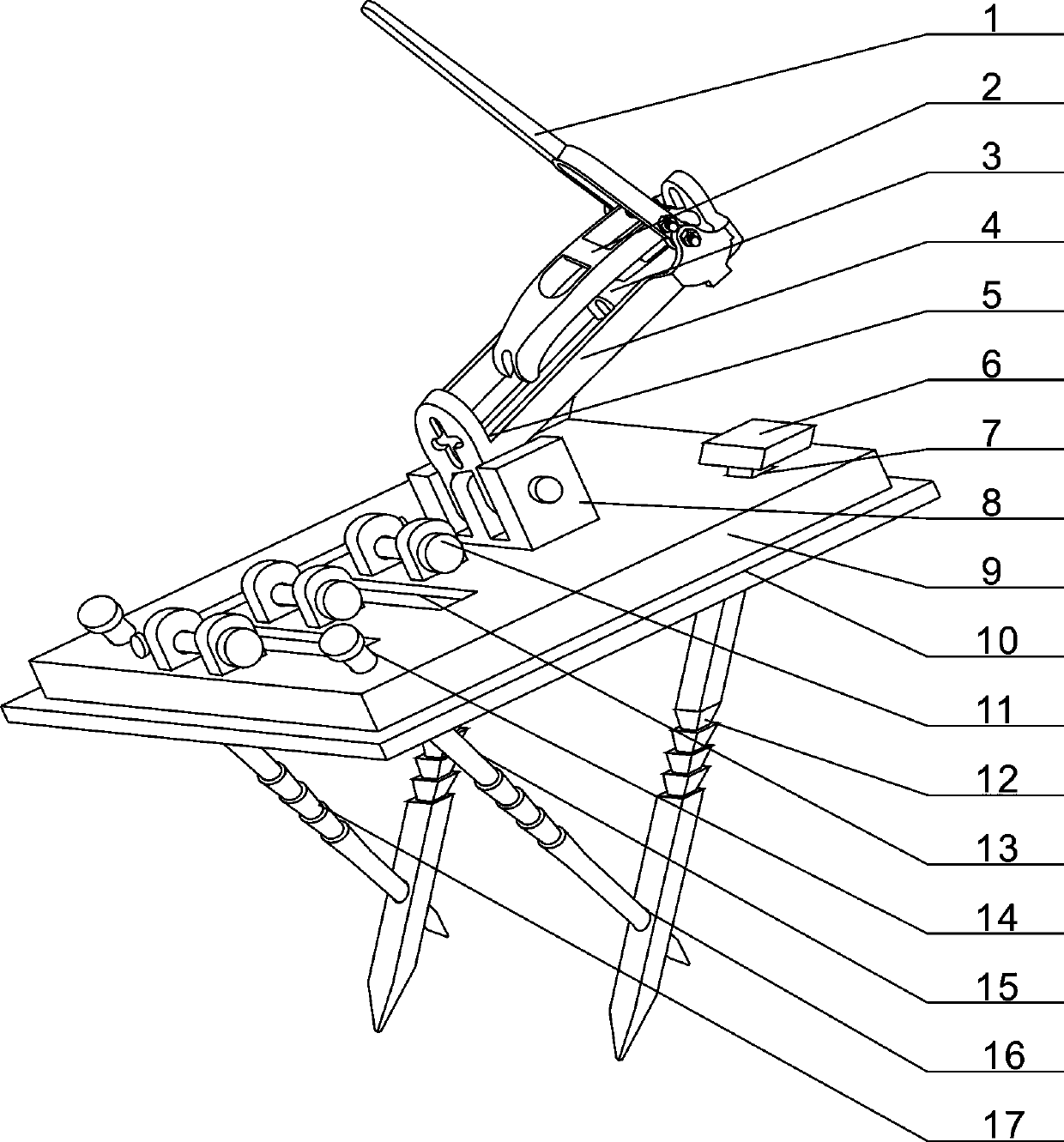

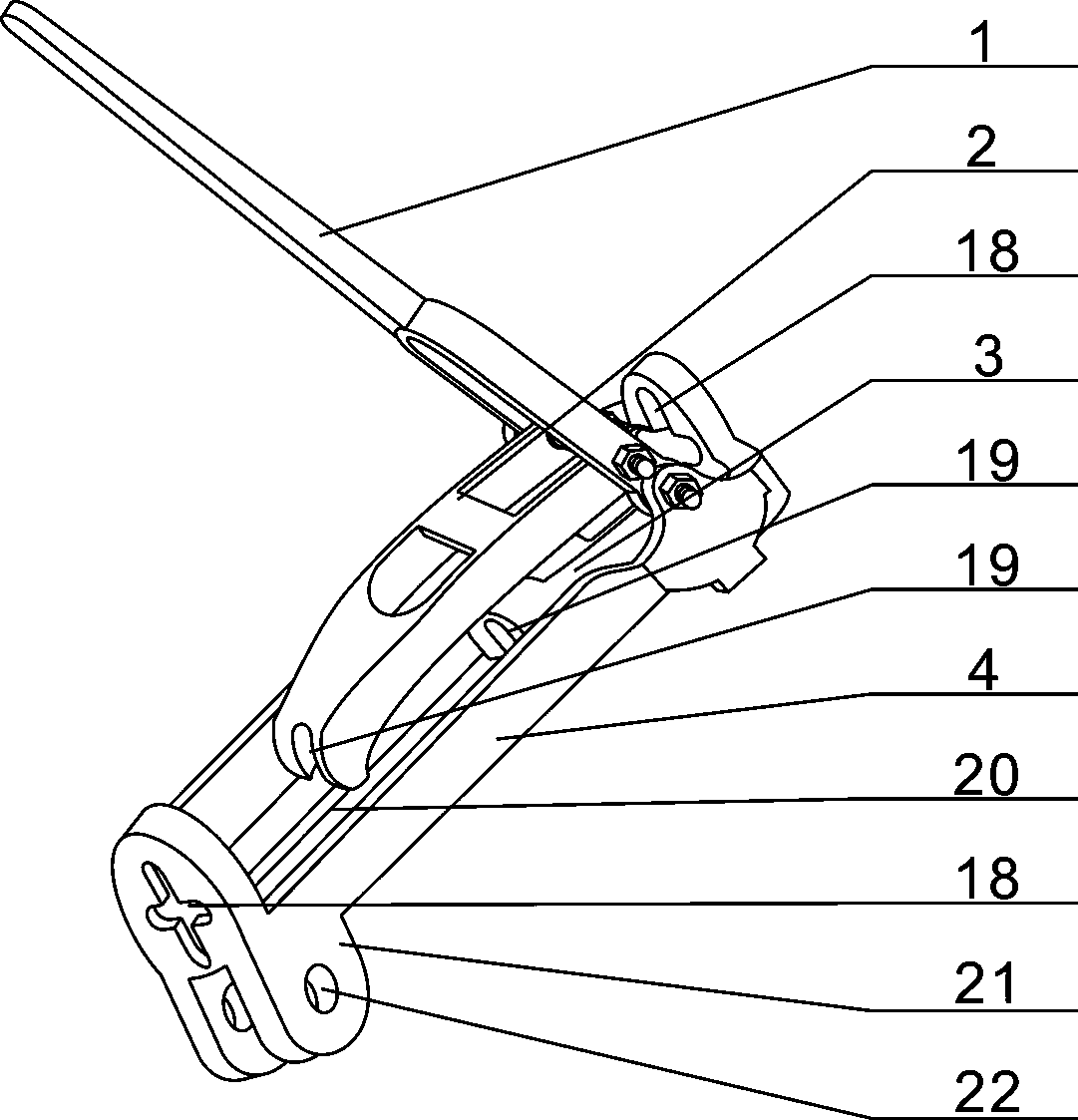

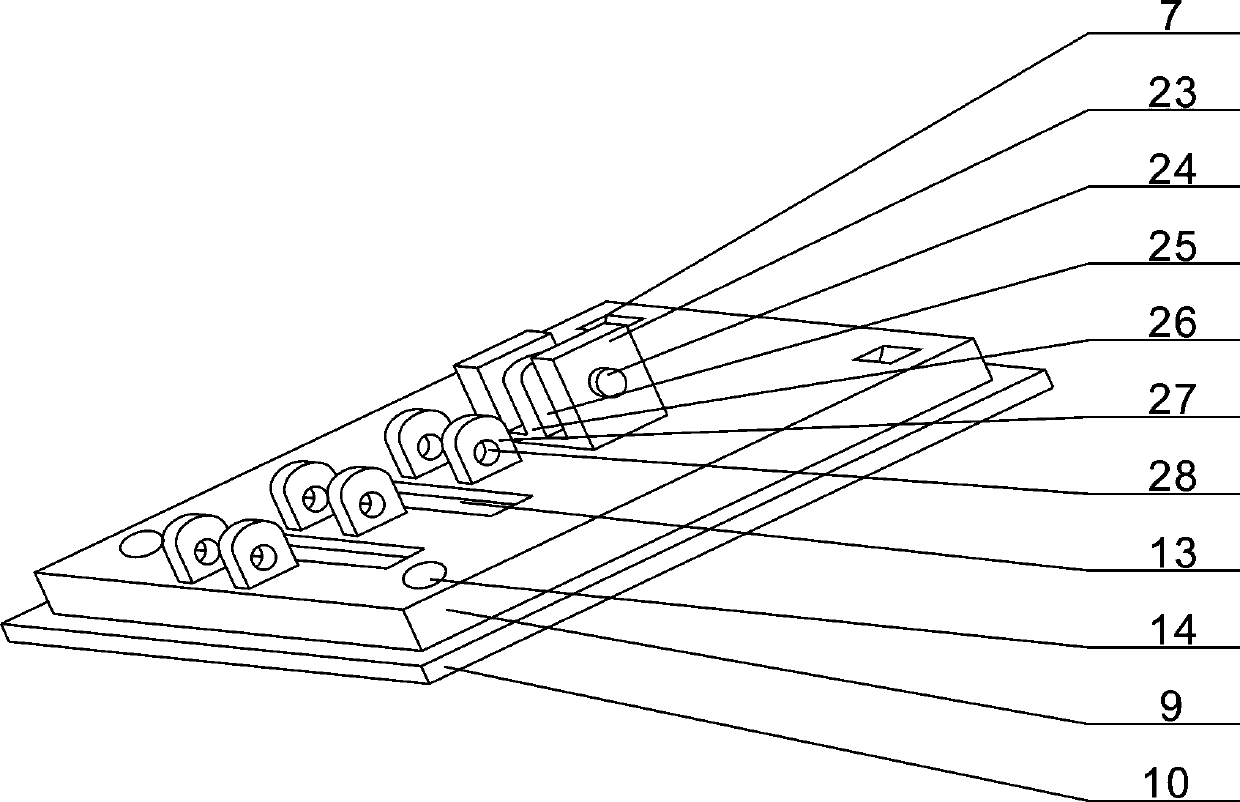

Traction, fixing and self-locking device capable of realizing multi-level protection and application thereof

InactiveCN110594359ARealize traction tension operationReduce wear consumptionDerricks/mastsRopes and cables for vehicles/pulleySelf lockingEngineering

The invention discloses a traction, fixing and self-locking device capable of realizing multi-level protection and application thereof, and relates to a traction device. The front end of a tractor ishinged and movably connected with a fixing bottom plate through a hinge connecting piece; a plurality of iron chain clamping pieces are orderly arranged on the lower side of the hinge connecting pieceon the upper surface of the fixing bottom plate at intervals; a groove is formed in the portion, between every two iron chain clamping pieces, of the fixing bottom plate; circular guide holes which are inclined upwards are formed on both sides of the lower part of the upper surface of the fixing bottom plate correspondingly; and columnar inserting rods are inserted into the circular guide holes.Through the traction, fixing and self-locking device, the traction tensioning operation of the guy rope iron chains can be realized, after the guy rope iron chain is pulled and tensioned, multiple sections of the guy rope iron chain can be fixed and clamped without the tractor continuously limiting and blocking the iron chain, the effect of multi-time protection is realized, and the wear consumption of the tractor is greatly reduced.

Owner:PANJIN SENDAXIN PETROLEUM TECH

Active coke flue gas purification device and cooling method

PendingCN109045994AReduce the temperatureIncrease unloading speedGas treatmentDispersed particle separationFlue gasProcess engineering

The invention relates to an active coke flue gas purification device and a cooling method. The device comprise a flue gas purification bin, wherein a feeding port is formed in the upper end of the flue gas purification bin, a discharge port is formed in the lower end, a gas inlet flue is arranged at the lower part of one side, a gas outlet flue is arranged at the upper part of the other side, anda plurality of cooling walls are arranged in the flue gas purification bin and divide the flue gas purification bin into a plurality of flue gas purification chambers; the plurality of flue gas purification chambers are all communicated with the feeding port, the discharge port, the gas inlet flue and the gas outlet flue. According to the purification device, when temperature rise of a certain flue gas purification chamber is abnormal, only flue gas circulation of the flue gas purification chamber can be cut off, cut-off of flue gas flow of the whole device is avoided, and the utilization rateof the device and the purification efficiency of the flue gas are increased.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

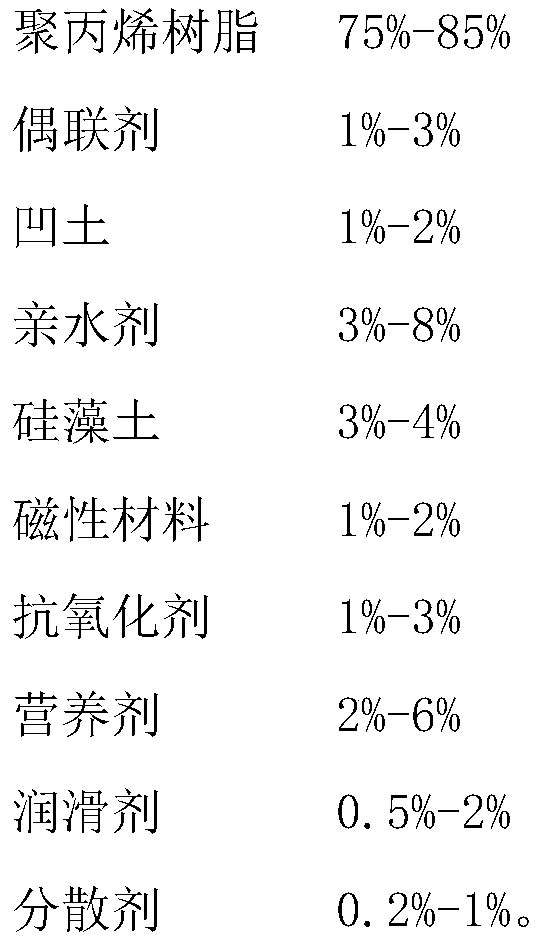

Fluidized bed biological filler, preparation method thereof and flowing composite active microbe biological bed

InactiveCN111233133AImprove impact resistanceImprove wear resistanceSustainable biological treatmentBiological water/sewage treatmentBiotechnologyFluidized bed

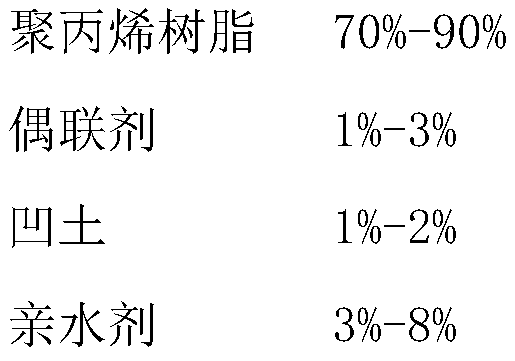

The invention discloses a fluidized bed biological filler. The filler is composed of the following components in percentage by weight: 75%-85% of polypropylene resin, 1%-3% of a coupling agent, 1%-2%of attapulgite, 3%-8% of a hydrophilic agent, 3-4% of diatomite, 1%-2% of magnetic materials, 1%-3% of antioxidants, 2%-6% of nutritional agents, 0.5%-2% of lubricating agents and 0.2%-1% of dispersing agents and has good biological adhesiveness. The invention further discloses a preparation method of the fluidized bed biological filler and a flowing composite active microbe biological bed adopting the fluidized bed biological filler.

Owner:浙江永续环境工程有限公司

Bidirectional transmission conversion device and transmission method thereof

ActiveCN111911556AClutch structure is simpleReduce cost consumptionPropulsion partsMotorised scootersClutchMechanical drive

The invention discloses a bidirectional transmission conversion device and a transmission method thereof, and belongs to the field of mechanical transmission. The device comprises an actuator for providing driving force, output ends being arranged at two ends of the actuator, and the actuator being capable of rotating forwards and backwards; the device also comprises two output shafts in transmission connection with the output ends of the actuator correspondingly; and two clutch transmission pieces arranged at the two ends of the actuator and in transmission connection with the corresponding output shafts through thread pairs respectively; and under the action of forward and reverse rotation of the actuator, the output shafts move relative to the corresponding clutch transmission pieces inaxis directions of the output shafts. The purpose of two-way transmission conversion can be achieved through the simple clutch transmission structure, and compared with the prior art, the device is small in abrasion consumption, not prone to breaking down and low in manufacturing cost and maintenance cost in a using process.

Owner:软丰科技(江苏)有限公司淮安分公司

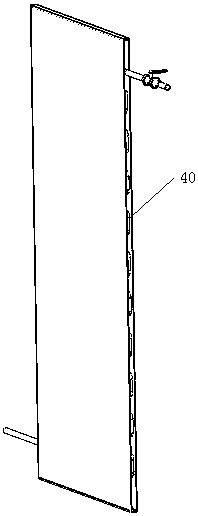

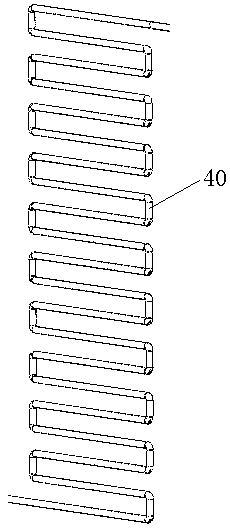

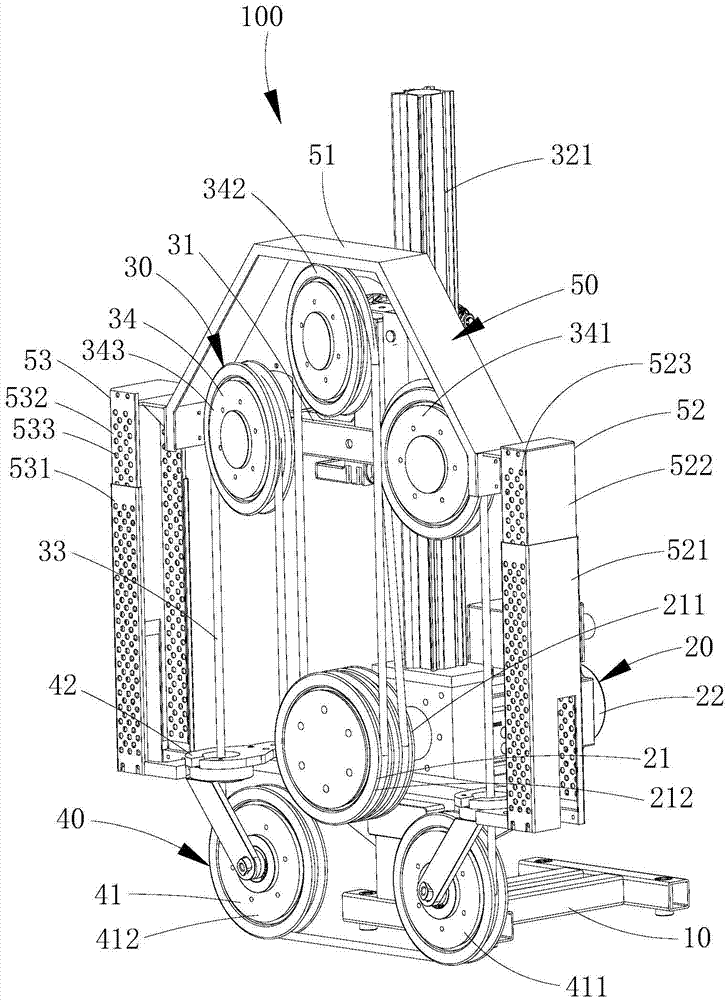

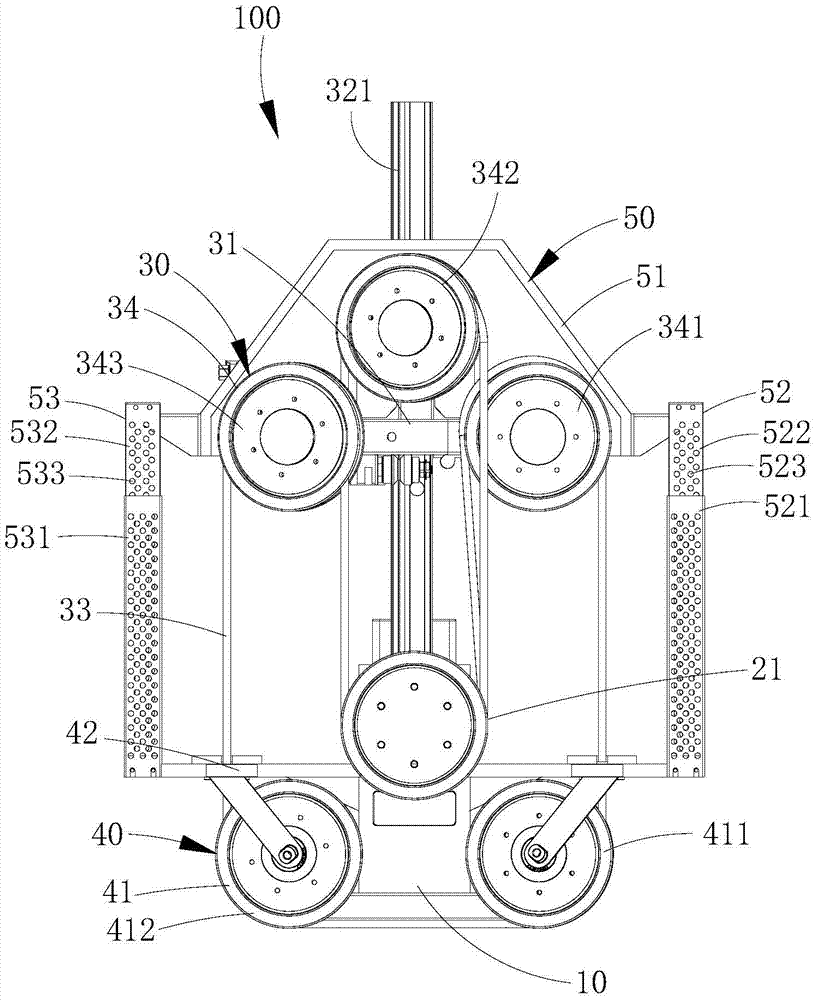

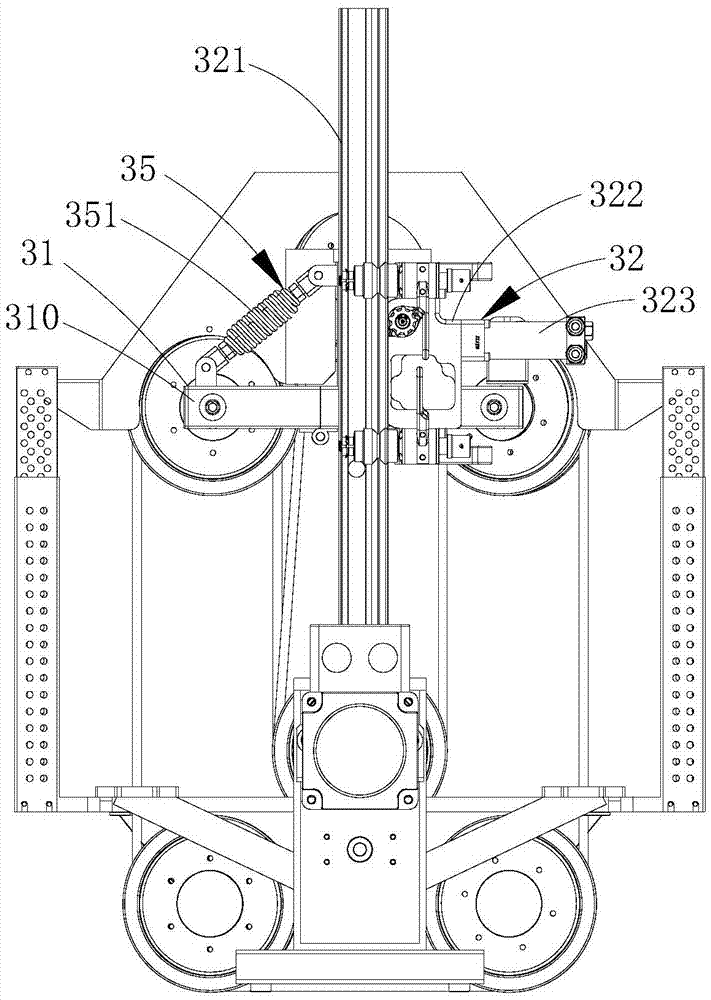

Wire saw

ActiveCN106956369APrevent crushingReduce the chance of damageWorking accessoriesStone-like material working toolsDrive wheelWire saw

A wire saw (100) comprises an installation seat (10), a driving assembly (20), a travelling cutting unloading assembly (30) and a wire collecting assembly (40). The travelling cutting unloading assembly (30) comprises a travelling support (31), a lifting mechanism (32), a diamond string bead wire (33), at least one driven wheel (34) and an unloading mechanism (35), the travelling support comprises a rotary arm (310) and a first supporting arm (311) rotatably connected with the rotary arm (310), and the unloading mechanism comprises a restoring piece (351); and one end of the restoring piece (351) is connected to the travelling support (31), and the other end of the restoring piece (351) is connected to rotary arm (310). When external force acts on the driven wheels (34), the restoring piece (351) is driven by the rotary arm (310) to rotate from an initial area to a rotary area to remove acting force on the driven wheels (34) through the unloading restoring piece (351), the rotary arm (310) is returned to the initial area through the unloading restoring piece (351), and in this way, the problem that components of the wire saw (100) are damaged due to falling off of a cutted object is solved.

Owner:陈立文

Local vibration type gas micro-explosion separating and screening device for gravel

InactiveCN114798429AAchieve water saving effectEasy to useSievingScreeningClassical mechanicsMechanical engineering

The invention discloses a local vibration type gas micro-explosion separating and screening device for gravel. The local vibration type gas micro-explosion separating and screening device comprises a gas micro-explosion type vibration assembly, an adaptive lifting mechanism, a reciprocating vibration mechanism, a screening and material taking mechanism, a water circulation mechanism, a main operation shell, a top through groove and a water conveying leather hose. The invention belongs to the field of gravel screening, and particularly relates to a local vibration type gas micro-explosion separating and screening device for gravel. In order to solve the contradictory characteristic that vibration is used for screening gravel and cannot be directly used for screening (preventing the gravel from splashing and dust attached to the surface of the gravel from flying), a gas micro-explosion type vibration assembly controlled by an adaptive lifting mechanism and a reciprocating vibration mechanism is arranged; and under the condition that traditional pressurizing equipment is not used, the speed and the effect of screening out impurities such as sand grains and soil on the surface of the gravel are greatly improved.

Owner:徐州新路智能科技有限公司

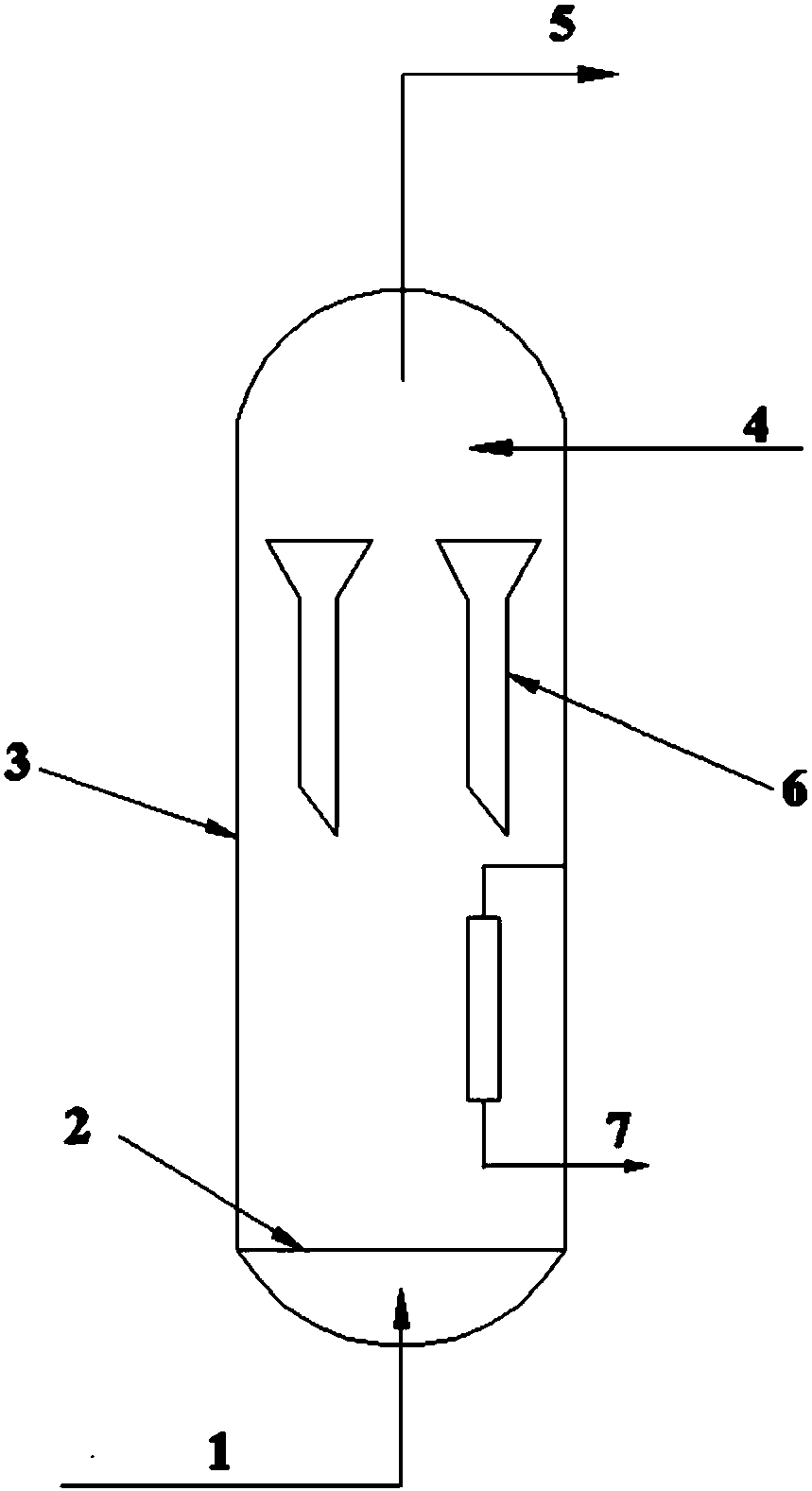

Slurry bed reactor and Fischer-Tropsch synthesis method

PendingCN110385089AImprove performanceReduce wear consumptionLiquid hydrocarbon mixture productionChemical/physical processesLiquid productSynthesis methods

The invention relates to the field of hydrocarbon synthesis and specifically provides a slurry bed reactor and a Fischer-Tropsch synthesis method. The reactor comprises a reactor inlet section, a gasdistributor, a reaction section and a gas-liquid-solid separation section arranged from bottom to top; a solid-liquid separator communicating with a liquid product outlet of the reactor is arranged below the middle inside the reaction section; a plurality of degassing, liquid collecting and diversion parts are arranged above the middle inside the reaction section; and each of the degassing, liquidcollecting and diversion parts comprises a funnel-shaped open section and a diversion pipe section communicating from top to bottom. Compared with the prior art, the reactor provided by the inventionis capable of obviously improving the performances of a catalyst when being applied to a gas-liquid-solid three-phase reaction, and the wear and consumption of the catalyst are obviously reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com